Manufacturer of

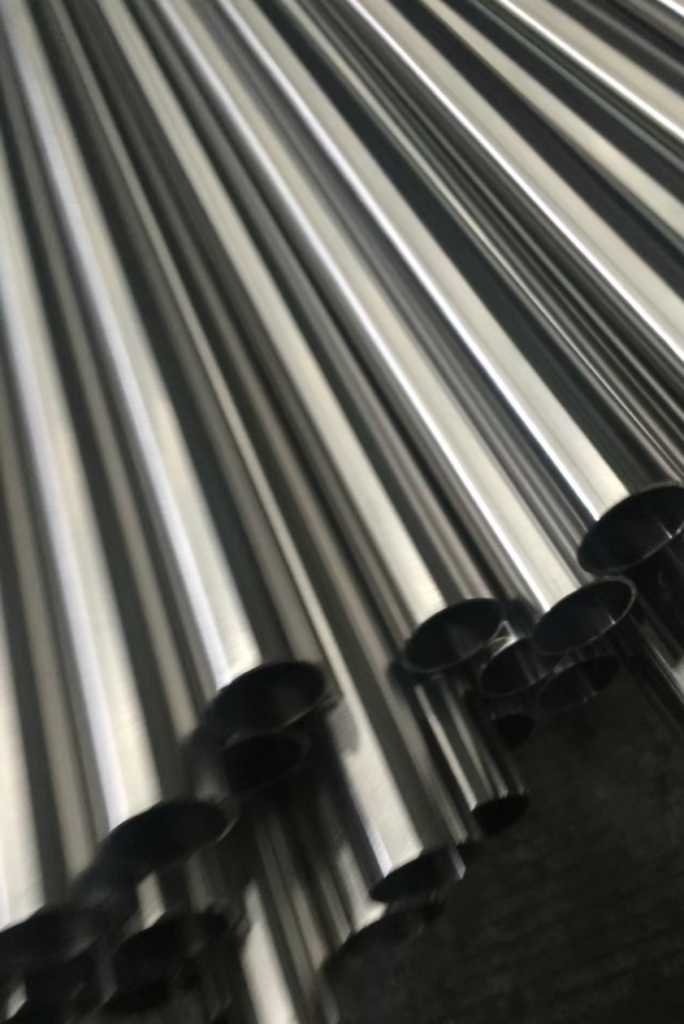

Steel Pipes, Coils, Fittings, and Flanges

High-Quality Materials, Precision Manufacturing

Offering nickel-based alloys, austenitic, duplex, urea-grade, and super stainless steel.

About Us

Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd. specializes in producing high-performance stainless steel pipes, coils, fittings, flanges, etc. With advanced equipment and strict quality control, we deliver reliable solutions for various industries.

- Diverse Material Range

- Advanced Production Lines

- Custom Solutions

- Strict Quality Control

- Global Expertise

- Sustainability Focus

2018

Our Products

We offer a wide range of steel products, including pipes, coils, fittings, and flanges, crafted from premium materials like nickel-based alloys, austenitic steel, duplex steel, urea-grade, and super stainless steel. Designed to meet the highest standards, our products ensure exceptional performance in demanding industrial applications.

why you should choose us

With years of expertise, advanced technology, and a commitment to excellence, we deliver high-performance stainless steel solutions tailored to meet your industrial needs.

Building the Future with

Precision and Strength

What Our Clients Say

Our commitment to quality and precision is reflected in the trust and satisfaction of our clients. Here’s what they have to say about working with us.

Our Blog

Get in touch

Contact Us

- WhatsApp: +86 15057563345

- Email: [email protected]

- Address: Lantian Industrial Zone, Longwan District, Wenzhou City, Zhejiang Province, China