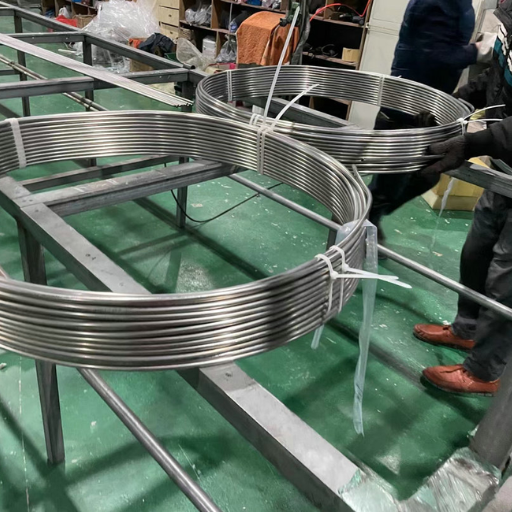

The coils of stainless steel tubing serve a vital role in many industries, from chemical processing and food manufacturing to marine uses. Due to their dependability and effectiveness, 304 and 316 stainless steel are two of the most popular grades. However, understanding the unique distinctions between these materials is critical for effective selection. This article aims to broadly compare 304 and 316 stainless steel tubing coils, emphasizing their chemical composition, corrosion resistance, strength, and overall performance in differing conditions. By the conclusion, you will know which grade best aligns with your operational requirements.

What are the Key Differences Between 304 and 316 Stainless Steel?

The primary distinction between the two grades of stainless steel, 304 and 316, is the material’s makeup and the level of corrosion resistance. Both grades comprise iron, nickel, and chromium, but 316 stainless steel has an additional 2-3% of molybdenum. This inclusion adds to 316’s resistance against corrosion, especially with chlorides and challenging environments like saltwater.

Compared, 304 stainless steel is cheaper and ideal for use where severe corrosive resistance is unnecessary. 316 is more suitable for marine, chemical processing, and high-salinity environments because it is much more effective at enduring pitting and crevice corrosion.

What is the chemical composition of 304 and 316 stainless steel?

The chemical makeup of each type of stainless steel is 304 and 316 differs only slightly, which explains each type’s different features and uses. The more critical constituents of 304 stainless steel include chromium in the proportion 18-20%, nickel in the proportion 8-10.5%, and carbon in the proportion up to 0.08%. For 316 stainless steel, the composition is approximately the same, but the chromium value is 16-18%, nickel is 10-14%, and molybdenum is 2-3%. The added molybdenum makes 316 more corrosion-resistant, especially with heavy chloride salt exposure. Although both grades consist mainly of iron, these particular differences in the elements change their specific traits and uses.

How do the mechanical properties of 304 and 316 stainless steel compare?

Both types of stainless steel have high strength and durability values, but there are subtle differences. Both grades are within the same tensile strength range, with 304 typically rising to 515-750 MPa and 316 slightly lower at 485-750 MPa. Yield strength, however, displays a slight difference, with 304 more often having the greater yield strength of 205 MPa compared to 316’s average of 170 MPa.

Elongation at break is a key mechanical metric that depicts a material’s ability to stretch before fracturing. Both grades demonstrate reasonable elongation properties, typically exceeding 40 percent. Nevertheless, this may differ depending on the processing and heat treatment applied.

Hardness is another consideration; 304 and 316 have similar Brinell hardness values, averaging 200 HB. However, 316 is preferred in areas requiring high toughness due to its better resistance to deformation, such as harsh marine or chemical environments.

The difference in mechanical performance of these two grades is minor for most general applications. However, 316’s added molybdenum translates to superior pitting and crevice corrosion resistance, essential for specific industries like chemical processing or marine engineering.

What are the corrosion resistance capabilities of 304 vs. 316 stainless steel?

Stainless steel’s resistance to corrosion comes mainly from its chromium, which protects the base material from oxidation by forming a passive oxide layer on the surface. Surrounded by mildly corrosive environments, Grade 304 stainless steel, which contains roughly 18-20% chromium and 8-10.5% nickel, is always preferred because of its superb corrosion resistance. However, it can still experience pitting and crevice corrosion in chloride-laden conditions, such as saltwater or de-icing salts.

Because of the added element, grade 316 stainless steel, which contains 2-3% molybdenum, has better corrosion resistance than grade 304. 316 is often considered the better alternative for marine construction, as it endures pitting and crevice corrosion in remarkably acidic and chloride-filled environments. Laboratory tests also tell us that grade 316 outperforms grade 304 in critical pitting temperature (CPT) tests, further proving 316’s strength in salty conditions.

While both stainless steels demonstrate strong corrosion resistance, the choice of 304 or 316 will ultimately depend on the application’s surroundings and performance expectations.

When should you use 304 stainless steel tubing coil?

A 304 stainless steel tubing coil is best where corrosion resistance is needed, but the operating environment is not aggressive and does not expose the coil to chlorides. It typically works for food and beverage processing and other industrial activities where corrosion is not a significant factor. Moreover, 304 stainless steel is the most economical option for applications where elevated temperatures are not prevalent, and the mechanical requirements are within specification limits.

What are the typical applications for 304 stainless steel tubing?

Due to its affordable pricing and remarkable corrosion resistance and durability, 304 stainless steel tubing has become popular across various sectors. Within the food and beverage industry, 304 stainless steel is used to produce sanitary process equipment, piping, and storage tanks because its surface is non-reactive. In chemical processing plants, 304 tubing is frequently used in mild chemical transfer lines because it can handle non-aggressive solutions.

In addition, the beauty and strength of the material make it widely used in the construction industry, especially in architecture, for things like handrails, frames, and other forms of embellishments. 304 is an alloy that also assists other sectors like automotive and aerospace in supplying tubing for exhausts, fuel lines, and hydraulic systems, which need moderate strength with corrosion resistance. Furthermore, stainless steel is used to manufacture medical appliances such as surgical and diagnostic tools because of its biocompatibility and simple sterilization response. This demonstrates that versatile and dependable traits showcase the importance of the alloy in other major industries.

How does the cost of 304 stainless steel compare to 316?

The differences in their chemical compositions explain why 304 stainless steel is generally cheaper than 316 stainless steel. 316 stainless steel has a higher percentage of nickel and contains molybdenum, significantly improving its ability to resist corrosion, especially in environments rich in chlorides. However, these additional elements increase the production cost. On average, 316 stainless steel is about 20-30% more expensive than 304, but that often depends on the market and supplier. The price difference means that 304 becomes a more economical option when exceptional resistance to harsh chemicals or marine environments is not critical. For buyers, the 304 versus 316 debate usually resolves around performance needs and budget constraints.

What are the advantages of using 304 stainless steel in specific environments?

The incredible affordability and corrosion resistance mixture make 304 stainless steel an excellent option for many applications. The chromium-nickel blend of this stainless steel prevents oxidation and slows down corrosion even in moderately acidic and moist environments. One of the most critical applications of 304 stainless steel is in the food and beverage industry, where hygiene is vital in manufacturing industrial dishwashers and other food processing tools.

Moreover, 304 stainless steel’s outstanding strength and ductility make it easier to fabricate and weld than other metals. Because of its adaptability can be used in various applications, such as architectural frameworks or piping systems, which require continuous structural modification. In addition, 304 is often used for less aggressive outdoor applications or indoors where the contact with chlorides and saline-prone conditions is low because it protects against moderate corrosion degradation under standard conditions for a long time without too much care and maintenance.

When should you use the 316 stainless steel tubing coil?

316 stainless steel tubing coil is the optimal candidate for uses that demand superior corrosion resistance, especially in environments containing high amounts of chlorides, saline water, or harsh chemicals. It is well-suited to bulky marine, chemical processing plants, and industries with a predominance of acidic or corrosive operating conditions. Moreover, its further resistance to pitting and crevice corrosion makes this steel ideal for use in demanding environments where ruggedness is necessary.

What industries benefit most from 316 stainless steel tubing?

316 stainless steel tubing is one of the most widely used steel products in places where strength and corrosion resistance are a must. In the marine industry, for example, it is used for ballast tanks, seawater piping, and structural supports because of its ability to endure extreme exposure to salt and moisture. In the same way, the chemical processing industry utilizes 316 stainless steel tubing for transporting and storing highly pure chemicals, including some corrosive substances, because its chemical attack resistance reduces the risk of contamination, making processes safer.

The pharmaceutical and biotechnology industries are important users as the tubing’s non-reactive surface ensures compliance with rigorous sanitary boundaries. At the same time, system integrity is maintained under pressures and temperatures during hot steam sterilization. Moreover, in the food and beverage sector, 316 stainless steel tubing is essential for processes like dairy and beer brewing, which involve acidic or saline products and where cleanliness and resistance to corrosion are critical.

Lastly, the oil and gas industry uses 316 stainless steel tubing in offshore platforms, piping systems, and refineries, where it is subjected to harsh environmental conditions such as exposure to chlorides and sour gas environments. These industries exemplify the vast need for 316 stainless steel tubing, which offers outstanding operational capability in extreme conditions.

How does 316 stainless steel perform in corrosive environments?

Due to the unique chemical composition of 316 stainless steel, which contains chromium, nickel, and an increased molybdenum content, its performance in corrosive environments is unparalleled. These elements positively contribute to the metal’s corrosion resistance, especially pitting and crevice corrosion in chlorides. This is especially useful in marine applications, where the material is exposed to seawater.

Research suggests that 316 stainless steel parts endure subgrade chloride concentrations of up to ~1000 parts per million without significant damage. The material’s critical pitting temperature (CPT) is generally hotter than other stainless steel, usually at 50 to 60°C, depending on the alloy and environmental conditions. This is a warm threshold for ensuring reliable performance in saline conditions.

Moreover, 316 stainless steel shows strong resistance to sulfuric acid, phosphoric acid, and acetic acid in low and moderative quantities, broadening its usefulness in Industry. Its ability to withstand localized corrosion is attributed to the formation of a stable, self-repairing passive oxide layer on the surface of the metal. This allows it to operate dependably in harsh conditions, such as chemical processing plants, offshore platforms, and desalination plants. Such attributes explain why 316 stainless steel is still an industry leader in the corrosion battle.

What are the long-term benefits of using 316 stainless steel tubing?

Due to the material’s properties and wide range of applications, using 316 stainless steel tubing offers several advantages in the long term. To begin with, its resistance to pitting and cleave corrosion is unparalleled, especially in chloride-rich settings. This ensures durability and low maintenance for offsets supporting structures, even under severely corrosive environments. Such corrosion resistance strengthens the lifespan of critical systems and minimizes the need for replacements and maintenance.

Moreover, 316 stainless steel tubing has outstanding mechanical properties, including high tensile and yield strength, which enables it to retain its screen structural integrity under extreme pressure and temperature changes. This is especially beneficial for highly demanding applications in the petrochemical, marine, and pharmaceutical processing industries.

From an economic perspective, the initial price of 316 stainless steel tubing might be higher than that of other tubing. However, its long life, coupled with the reduced repairs and maintenance needed over time, lowers lifetime costs. In addition, the 316 stainless steel material’s compliance with rigorous industry standards and regulations makes it easier to use in sensitive areas, such as the food production industry or medical equipment manufacturing, which require cleanliness and sterility.

Lastly, the recyclability of 316 stainless steel is an environmental advantage, substantiating its use and integrating it with eco-friendly practices while minimizing overall material wastage. All these benefits make 316 stainless steel tubing a durable investment for those industries that seek dependability, effectiveness, and optimal performance in their operations.

What are the Manufacturing Processes for Stainless Steel Tubing Coils?

The manufacturing processes for stainless steel tubing coils involve several key steps to ensure precision, quality, and durability:

- Melting and Casting: Raw materials, including iron, chromium, nickel, and molybdenum, are melted in a furnace and cast into solid slabs or billets.

- Hot Rolling: Depending on the required tubing dimensions, the slabs or billets are heated and rolled into thinner sheets or rods.

- Cold Drawing: To achieve precise measurements and smooth surfaces, the material undergoes cold drawing, reducing the tube diameter and enhancing its strength.

- Welding (if applicable): Flat sheets are formed into a tube shape for welded tubing and joined along the seam using high-frequency or TIG (tungsten inert gas) welding for a clean, secure bond.

- Annealing: The tubing is heat-treated to restore ductility and remove internal stresses, ensuring optimal performance under various conditions.

- Surface Finishing: Tubing surfaces are polished or passivated to improve corrosion resistance and meet specific industry standards.

- Inspection and Testing: Tubing coils are subjected to rigorous quality control measures, including dimensional checks, pressure testing, and surface analysis, to confirm they meet industry specifications.

These steps collectively produce high-quality stainless steel tubing coils suitable for applications across diverse industries.

What is the process of creating seamless stainless steel tubing?

Several precise steps are involved in creating seamless stainless steel tubing. First, a cylindrical solid billet is heated to high temperatures until it can be worked on. Next, the heated billet is pierced using a mandrel or extruded to form a hollow tube. Rolling and stretching are performed on the hollow tube until the desired dimensions and wall thickness are achieved. The tube is then annealed to augment its mechanical properties and surface quality. This is followed by either pickling or polishing, depending on the intended finish. Lastly, the product undergoes quality ultrasonics testing and dimension checking to meet industry standards.

How are welded stainless steel tubing coils produced?

Welded stainless steel tubing coils are made from meticulously balanced stainless steel strips chosen to meet the specifications. These strips are cleaned to eliminate contaminants and provide a uniform weld. Stainless steel tubing coils are produced through a tightly controlled process to guarantee operational performance, structural integrity, and precise fabrication. The strips are cleaned and then fed through rollers to achieve the targeted coil width and thickness before being transformed into a tube at specified forming rolls.

After the strips are shaped in a bowl into a tubular form, they are joined edge to edge using ways like welding with Tungsten Inert Gas (TIG) or welding with High-Frequency Induction (HFI). In welding, the heat generated has to be very closely controlled to reduce the zone of heat impacts while keeping the wrought qualities of the stainless steel. The stainless steel tubing, for example, is first welded, then annealed, which is the welding post-processing procedure that relieves stress and restores ductility. For coils, the tubes are further coiled into long continuous Aforms, which maximize space during storage and transport.

Pickling or surface treatments can be done during or after the welding of the tubes to enhance their corrosion resistance or to make them more visually appealing. Also, the tubing undergoes rigorous non-destructive testing, such as eddy current and hydrostatic testing, to ensure no defects and that it complies with industrial norms. Together with modern techniques, these steps ensure seamless stainless steel welding tubing coils can be relied on.

What factors affect the quality of stainless steel tubing production?

The processes of selecting the raw materials and producing stainless steel tubing will determine the quality assurance the steel needs. Chemical making or popular composition is one of the most critical factors. First, stainless steel’s components are a mixture of metals known for their ability to withstand moisture attacks. Many other metals contain chromium, nickel, molybdenum, and several other alloying elements.

Not to mention, all other parts of a fabrication process must be followed, including all welding methods. In TIG (Tungsten Inert gas) and laser welding, cleansing or contamination must be guarded to ensure the absence of all possible inaccuracies and precise structural consistency. Proper heat treatment improves the grain structure uniformity, internal stresses, and ductility. In addition, surface finish treatments such as pickling and passivation will greatly enhance oxidation and scaling resistance. All other parts of a fabrication process must be followed, including all welding methods. Such Request for Quotation (RFQ) will include, but should not be limited to, pickling blasting passivation and O-ringing. All other proposals for leakage control about specification documented work will be disregarded due to a labor rate under unmatched business standards.

Cutting-edge testing techniques by sail induce arbitrary radiographic or ultrasonic testing. Guaranteeing the cleanness of the parts produced is as important. Surface finishing operations ought to comply with the TA policies of land. Results of estimates obtained reveal that manufacturers not following them stick to the plans of delivering units out of business standards set under unmatched business standards, suggesting unethical practices.

Effective procedures such as quality checks, automation, and integration of modern technologies like AI for spotting errors play a significant role. All these contribute to manufacturing high-performing stainless steel tubing tailored for various uses, from medical equipment to aerospace.

How to Choose Between 304 and 316 Stainless Steel Tubing Coil?

When choosing between 304 and 316 stainless steel tubing coil, the decision primarily depends on the environmental conditions and application requirements:

- 304 Stainless Steel: Ideal for general-purpose use, it offers excellent corrosion resistance, strength, and affordability. It performs well in environments without significant exposure to harsh chemicals or salts.

- 316 Stainless Steel: The better choice for applications exposed to corrosive environments, such as marine settings or chemical industries, due to the inclusion of molybdenum, which enhances resistance to pitting and crevice corrosion.

304 is typically sufficient for cost-sensitive applications where corrosion risk is minimal. However, 316 is recommended for superior resistance in aggressive environments despite the higher upfront cost. Always consider the specific application conditions when making your selection.

What factors should influence your choice of stainless steel grade?

Selecting an appropriate stainless steel grade requires paying attention to several vital aspects. First, I check the atmosphere or environment the material will be habiting in to see whether there is moisture, chlorides, or even extremely high or low temperature since they influence the corrosion resistance requirements of the material. Secondly, I look at the mechanical properties that need to be fulfilled, such as the tensile strength or hardness of the material. Thirdly, I analyze the material’s costs to acquire without throwing the budget out the window while still achieving the required objectives. Lastly, I must check whether any regulatory or application-specific standard needs to be followed. Weighing all these factors helps to arrive at the most appropriate grade for the intended application.

How do environmental conditions affect the choice of stainless steel?

In selecting an appropriate grade of stainless steel, I consider non-environmental and environmental factors. I focus on readily machinable 316L for corrosive environments because of its relatively good machinability and corrosion resistance for stainless steel. Coastal and marine environments, for example, need special consideration for high corrosion resistance, so higher levels of molybdenum are a must. Then, there are atmospheric pollutants, plus exposure to weather extremes like moisture and temperature, which must also be evaluated. The environment’s demands must also be met with the material properties I am constructing.

What are the best practices for selecting the right stainless steel tubing supplier?

When choosing a stainless steel tubing supplier, specific details matter—for example, checking the supplier’s certifications like ISO 9001 and their adherence to quality control policies. What I also consider is the category they specialize in as well as product variety. Do they have the right grades and sizes applicable to my work? How good is their customer service? Can they provide enough material traceability? These issues are also critical. Other factors I look at are the logistics, delivery times, and project deadlines. I can efficiently build lasting supplier partnerships with all these factors while ensuring quality and reliable stainless steel pieces.

Reference Sources

-

Ryerson

- 304 vs 316 Stainless Steel: What’s the Difference?

This source explains the general-purpose suitability 304 and the superior corrosion resistance 316 for harsher environments.

- 304 vs 316 Stainless Steel: What’s the Difference?

-

Eagle Stainless

- 304 vs 316 Stainless Steel – What’s the Difference?

Highlights the presence of molybdenum in 316, which is absent in 304, and discusses their welding and forming properties.

- 304 vs 316 Stainless Steel – What’s the Difference?

-

Thyssenkrupp Materials

- Difference Between Stainless Steel 316 and 304

Focuses on the chemical composition differences, particularly the molybdenum content in 316, and its impact on corrosion resistance.

- Difference Between Stainless Steel 316 and 304

Frequently Asked Questions

Q: What is the main difference between stainless steel 304 and 316?

A: The primary difference between stainless steel 304 and 316 is that 316 contains molybdenum, which enhances its corrosion resistance, especially against chlorides, making it suitable for marine environments.

Q: How does the corrosion resistance of ss 304 compare to ss 316?

A: While both ss 304 and ss 316 have good corrosion resistance, ss 316 offers better protection against corrosion and oxidation, particularly in harsh environments with chloride exposure.

Q: Are stainless steel tube coils from 304 or 316 more widely used in industrial applications?

A: Stainless steel tube coils made from ss 304 are more widely used in general applications due to their cost-effectiveness. In contrast, ss 316 is preferred for applications involving exposure to corrosive substances.

Q: What are the typical applications for stainless steel 316 coil tubing?

A: Stainless steel 316 coil tubing is typically used in chemical processing, marine applications, and any environment where high corrosion resistance is required.

Q: Can I contact you for custom stainless steel tube coils?

A: Don’t hesitate to contact us for custom stainless steel tube coils tailored to your needs and requirements.

Q: What are the benefits of using stainless steel coiled tubing?

A: The benefits of using stainless steel coiled tubing include flexibility, resistance to corrosion, ease of installation, and reduced material waste due to its continuous length.

Q: How do I choose between 304 stainless steel and 316 stainless steel coil tubing?

A: Choosing between 304 and 316 stainless steel coil tubing depends on the environment and application; if exposure to chlorides is expected, ss 316 is recommended, while ss 304 is suitable for less corrosive environments.

Q: What is the significance of the grade of stainless steel in tubing applications?

A: The grade of stainless steel determines the alloy composition, affecting properties like strength, corrosion resistance, and suitability for specific applications. Therefore, it is crucial to select the right tubing.

Q: What is the standard thickness range for 1-inch stainless steel coil tubing?

A: Depending on the application and pressure requirements, the standard thickness range for 1-inch stainless steel coil tubing is 0.035 to 0.065 inches.

Q: How can I find a reliable ss coil pipe supplier in India?

A: You can find a reliable ss coil pipe supplier in India by researching reputable companies, checking customer reviews, and verifying their certifications in providing high-quality stainless steel products.