To create sustainable plumbing infrastructures, the appropriate fitting selection is integral in maintaining proper function, efficiency, and reliability, especially in piping and plumbing systems. Out of all the available options, female pipe fittings are essential when it comes to sealing and connecting pipes for reliable network systems in residential and industrial frameworks. So, what are female pipe fittings, and how are they differentiated from the rest of the fittings? This guide will give you the definition of female pipe fittings and their main advantages and uses while covering other important considerations for your plumbing decisions. Be it for DIY projects, professional plumbing tasks, or just a casual intrigue, this article aims to provide useful knowledge and actionable insights to all readers.

What is a female pipe fitting, and how does it work?

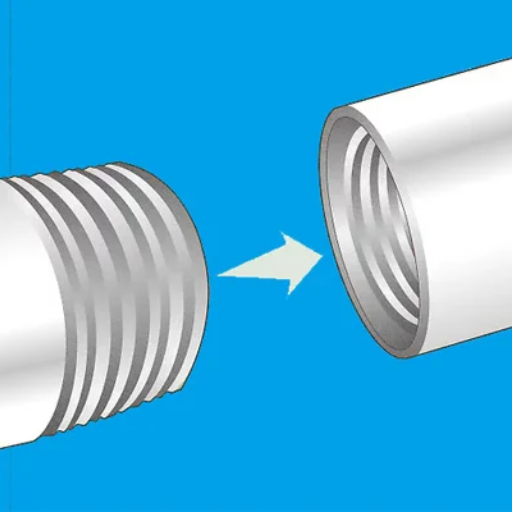

A female pipe fitting is a plumbing fitting designed to accept the male end of a pipe or fitting. The female pipe fitting also has threads in the interior that permit it to be connected securely to a pipe or fitting with external threads. These fittings are widely utilized to unite, extend, or change the direction of pipe systems in the domestic, industrial, and municipal plumbing systems. Their simple design permits them to be used for basic alignment and connection of pipe, which allows the passage of liquids and gases with minimal resistance.

Defining the female pipe: Key Characteristics

A female pipe fitting is a notable addition to plumbing engineering systems due to its engaging applications and remarkably durable fixtures. They are made out of materials including brass, PVC, copper, or stainless steel because they work with various settings, such as high-pressure or high-temperature regions. For instance, brass female pipes are widely appreciated for their corrosion resistance, making them ideal for both residential and industrial settings. Likewise, PVC fittings are inexpensive and light, which makes them ideal for non-strengthening systems.

The most striking feature that comes with these types of female pipes is their ability to be threaded internally, making it possible for them to amalgamate tightly with male threaded pipes or fittings. This type of structure minimizes leakage and efficacy issues arising from variation in conditions. Industry reports suggest that there is an increased inclination towards infrastructure development along with the use of female pipe fittings, projected to grow with a surge in demand estimated to increase at a CAGR of about 5-6% in the next decade. The fittings serve the significant purpose of effortless fluid transfer through the water supply systems, HVAC systems, and chemical processing pipelines.

Moreover, improvements in technology concerning materials like the creation of eco-friendly and high-strength polymers have increased the effectiveness and lifespan of female pipe fittings. This advancement enables use in both contemporary and traditional plumbing systems. In general, these components are fundamental to the construction of piping systems that are safe, dependable, and efficient globally.

How female threads differ from male threads

The application and function of female and male threads differ from one another. The female thread is internal as it is cut onto the inner side of a fitting. This creates a hollow cylindrical groove. Male threads are external as they are cut on the outer side of the pipe, forming a screw-like protrusion. The threaded cylinders are called female and male threads. The complementary design helps male and female threads to plug together, locking firmly and sealing within the piping systems.

Another example of differences that can be noticed is the measurements of both external and internal threads (sizes) and tolerances. Female threads perfectly match with the screw specifications of male threads, and guarantee precision. One of the most well-known ones, like ISO or ANSI, also states that the angle of thread, pitch, and depth must be uniform between these components. Take, for instance, the National Pipe Thread or NPT standards, which state the taper of the male thread must be equal to the internal thread engagement with a female fitting to provide an airtight compression seal and non-leaky joint.

Their uses also vary slightly from industry to industry. Female threads are usually preferable for fittings needing to. Their nature gives a smoother finish and look. Male threads are better for coupling into other valves, elbows, or other threaded components for bronze castings. The combination of both male and female screws form the basis of multi-purpose plumbing, mechanical and industrial systems all over the world. The apparent gaps have their most important use in achieving integrated and efficient connection methods in many different situations.

Common uses of female pipe fittings in plumbing systems

Female pipe fittings are essential in modern plumbing to ensure connections are tight and dependable. They are often used in households, businesses, and industries for purposes such as joining water supply lines, managing wastewater, and connecting irrigation systems. Female pipe fittings are particularly efficient in preventing leaks because of their internal threads that bond with male threaded pieces.

One of the most common applications of female pipe fittings is in water distribution systems. For example, they are routinely used to attach pipes to appliances such as sinks, toilets, and water heaters to maintain a constant water flow. Furthermore, female fittings are manufactured in various materials such as PVC, stainless steel, and brass, which makes them usable for different pressures and temperatures, as well as the fluids being transported. Statistics indicate that the demand for PVC fittings in plumbing systems is continuing to rise due to their lightweight and corrosion resistance, with estimates showing a steady 2-3% annual increase in the U.S. plumbing market.

Moreover, female fittings are crucial for the gas piping subsystem, especially for connecting pipes safely in HVAC units and gas-powered appliances. Their adaptability both in high-pressure settings and in delicate systems which need precision and reliability underscore their usefulness. With the right choice of materials and proper installation practices, female pipe fittings serve plumbing systems with efficiency and durability.

Types of threaded pipe fittings: Which one should you use?

The kind of threaded pipe fitting you should use will depend on your application and its requirements. Below are the most common types, along with their uses:

- Couplings:Best used for the joining of two pipes of the same diameter, coupling guarantees secure and leak-proof joint.

- Elbows: Used to change the direction of flow, usually operating at 45 or 90-degree angles.

- Tees: Used to allow for the branching of a pipe into two outlets. Best used for creating multiple flow paths.

- Adapters: Change pipes from one size or type to another which enables the fitting of the components of different systems.

- Caps and Plugs: Used to seal the end of a pipe to inhibit flow.

Take into consideration the pipe material, system pressure, and level of strain to select an appropriate fitting. Plumbing system compatibility must always be verified for reliability and safety.

Exploring different types of pipe fittings

Elbow Fittings

Pipe fitting elbows are very important for pivoting the flow of a pipe at a certain angle, usually set at 45 degrees or 90 degrees. It is used in plumbing, industrial systems, and even to solve spatial problems without damaging fluid flow. They come in a variety of materials like PVC, copper, brass, and stainless steel. For example, copper elbows are used in residential water systems because they do not corrode easily and have great durability. Industry reports also mention that elbow sizes between 1/2 inch and 2 inches are the most frequently used in a wide range of applications, from small houses to larger industrial plumbing systems.

Tee Fittings

With a tee fitting, the single flow in a pipe can either split into two or merge into one, forming a letter “T”. Tee fittings are widely used in systems requiring efficient distribution or collection of fluids. They come in equal or reducing configurations, meaning the same size will be kept or different sizes will be connected. For instance, PVC tee fittings are extensively used in irrigation systems because they are very strong under different pressures. Research data suggests that using high-quality tee fittings along with other system components can cut leakage incidents by 20%, which shows the importance of material and design selection.

Couplings

Couplings are designed to join two pipes with the same diameter, either permanently or at a joint that can be later disassembled. Flexible or rigid, they are useful in almost any dismantlement or maintenance operation by replacing damaged parts in pipes. Usually made of rubber and stainless steel, flexible couplings are ideal for systems experiencing vibration or movement, adding more strength to the piping works. An analysis of market trends shows that PVC and CPVC couplings have become popular in domestic houses due to affordability and ease of installation.

Union Fittings

Provided pipes need to be disconnected often without damaging them, Union fittings are appropriate, unlike Couplings, which are more complex. The need for careful maintenance conducted often makes them a crucial fitting in the pipeline of choice. Union fittings are important for their three part union—a nut, a female end, and a male end—each of which screw tightly yet mantain the ability to come apart. Stainless steel unions are used in the oil and gas industry due to their power and ability to resist high-pressure surroundings with as high as 3,000 psi pressure ratings.

Choosing the appropriate fitting to match the requirements of your system optimizes operational efficiency, reduces risks, and increases longevity. Following industry developments in manufacturing and material science will be helpful in selecting fittings that meet high safety and performance standards.

Choosing between NPT and other thread types

Every option comes with its own set of advantages and disadvantages. Understanding them is critical while selecting the best type of thread for any particular system. National Pipe Taper (NPT) threads are one of the most used threads in the US today since they are helpful in making pressure-tight seals on pipes and fittings. NPT threads have a tapered configuration that aids in forming a strong seal as threads tighten during fitting. This type of thread, however, does require the addition of thread sealants such as Teflon tape or pipe joint compound to prevent leaks.

Unlike NPT thread types, parallel type threads such as the BSPP (British Standard Pipe Parallel) maintain a straight-thread design. It relies on external means of sealing such as O-ring or a gasket. They are, however, popular among European countries and others because of the tighter tolerances and better sealing capabilities. Studies show that systems utilizing parallel threads alongside elastomer seals are more reliable for applications with vibrations or thermal expansion.

An additional important area is suitability. Compatibility of NPT threads with other standards, such as BSPT or metric threads, is not possible without a proper fitting. This is due to the 60 degree angle and taper of NPT threads. Like the European system, regions also have set conventions and maintenance cycles which need to be aligned with the system’s working pressure and temperature. For overly severe conditions, some technicians stick to SAE threads because those are best suited for hydraulic sealing.

The comprehensive thread system knowledge you possess will help optimize the decision to be the safest and most suitable for the application. Regular reference to specifications and standards, such as ASME B1.20.1 for NPT and ISO 228 for parallel threads, helps guarantee system safety while ensuring broad operating range compatibility.

How to properly connect a pipe using female pipe fittings

To connect a pipe using female pipe fittings, done in certain steps are taken:

- Prepare the Pipes: Ensure that the threaded male pipe and the female fitting are cleaned and free of any dirt. This guarantees a leak-proof, airtight connection.

- Apply Thread Sealant: Attach plumber’s tape (Teflon tape) unto the male threads in a clockwise manner. Warding off leaks is further enhanced by this step.

- Align the Pieces: Adjust the female fitting to rest on top of the male fitting pipe; do not rotate it yet so that you do not cross misalignment threads.

- Hand-Tighten: Initiating stirring the female fitting softer with her hands, and then fitting her on top of the stepped male threads.

- Tighten with a Wrench: Fix or secure it in an adjustable wrench, and when doing so, ensure boundaries are placed on borders of over-tightening since it is fatal to the threads.

- Inspect for Leaks: If there are any, repair them by looking through the pipe and if there are any gaps in plugs deem them faulty and with some applying extra tension close tighter making messing somewhat necessary.

Adhering to the suggestions given will ensure a safe and strong connection with female pipe fittings.

Step-by-step guide to connecting two pipes

-

- Measure the Pipe Diameters: Start with the proper measuring of the pipes’ diameters which ensures that there won’t be any compatibility issues. Most pipes are labeled with their dimensions, however, it’s good practice to verify this data due to it being crucial to avoid incorrect fittings.

- Select the Appropriate Fitting Type: Select the fitting based on copper, PVC, and other materials you are dealing with, as well as putting them into use. Some of the most common choices are slip joints for PVC pipes, compression fittings and solder fittings for plumbing uses, and threaded fittings for metal pipes.

- Prepare the Pipe Ends: As with any form of geometry, proper alignment within a set of pre-defined boundaries requires cutting the pipe ends as clean as possible. Thus, a pipe cutter or other kinds of saw that give a precise cut must be used. Following the saw operation, one should sand the border or any rough surface added by the cut.

- Apply Sealing Material as Needed:

-

-

- For threaded connections, use pipe thread seal compound or thread seal tape (sometimes called Teflon tape) to maintain a leakproof seal.

-

For non-threaded connections, a PVC or similar join may require the use of solvent-based adhesives. Follow the manual’s guidelines for use precisely.

-

- Align and Join the Pipes:

-

-

- Join the pipes by pushing or twisting them according to the kind of fitting used..

- Here, I see mention of a wide range of activity. IT does mention align bones of a vertebrae collage which can then wrap up using cap joints. Also verify of blockages alongside checking along for lesions Minimizing leak paths..

-

- Secure the Connection:

-

-

- Access joins are crucial. Apply slather, forcing up and down, then slowly withdraw, easing fixation parameters

- Test the setup I see fit, my tight covers, and add a few drops of liquid.

-

- Pressure Test the Connection:

-

-

- Covering up pierced holes completely is ideal. It saves from undergoing pressure testers. A test as simple as this can be used to pretend vividly planar tools.

-

Following all the steps ensures that the joint between the two pipes is reliable and dependable which will allow the system to work effectively. Whether working on small plumbing repairs at the house or dealing with bigger projects, specificity and focus on every little detail is important.

Common mistakes to avoid when using threaded fittings

Extreme care and attention to detail are essential in order to avoid leaks and damage when working with threaded fittings. These are some of the most significant complications, along with some pointers on how to mitigate them:

- Over-tightening the fittings

Applying too tight of a seal is one of the most common mistakes encountered. Over-tightening will put too much stress and result in weakening the threads leading to stripped or cracked fitting. Soft materials like PVC or brass are particularly susceptible to this. Most fittings need hand-tightening plus an additional minor turn with a wrench to form a good seal.

- Using the wrong sealing material

Using incorrect placement of sealing components sealing putty instead of tape, and other dangerous materials, such as thread seal tape, is more prone to failure. Ensure that their compatibility is at hand as it relates to the threaded fitting and for what fluid the sealer is specified. An illustration is gas systems, which tend to require a special type of thread sealant gun for high-pressure compatibility.

- Cross-threading the connection

Misalignment when soldering passes leads to incorrect installation and the component not spinning as easily as intended leading to the relative opposite. This is a highly irresponsible mistake that can lead to permanent destruction of the fitting and the joint. Make it a rule to conduct clean threads and mix up the adapter followed by lightly fastening it to check initial position.

- Reusing damaged or worn threads

Using fittings that have suffered deformities like stripping or cross-threading, as they will weaken the connection, is not advisable. The usage of any combination of mechanical threads will eventually lead to some form of wear and tear. Use marks and wear level should be checked, and the accessories should be changed as suited.

- Lack of cleaning and preparation

Foreign matter like dirt and grease can adversely affect forming a seal. Constructing and cleaning work entails cleaning the fitting and inspecting threads prior to assembling them which is critical.

- Failure to follow material-specific guidelines

Plastics and metals would have different torque and sealing functions, thus the need to comply with specific instructions. Not complying would either lead to overtightening or the screws losing the hold resulting in repair works on the fitting joints. Refer to the manufacturer’s instructions for recommendations and best practices.

Avoiding these critical lapses will protect your connection from leaks and maintain its integrity over time, while simultaneously increasing the longevity of your fittings and reducing upkeep costs. Consistently monitoring each connection during installation, in conjunction with an incremental workflow, guarantees optimal results.

What are the advantages of brass pipe fittings?

The right selection of piping and plumbing fittings is essential for the efficiency and longevity of any system. Out of many materials, both DIYers and professionals seem to settle for brass pipe fittings. Have you ever wondered why brass fittings are so recommended and popular? This article will discuss the most important benefits of brass pipe fittings while emphasizing their unparalleled strength, versatility, and reliability in numerous situations. Whether your interest is about how easy they are to install, or resistance to corrosion and extreme temperatures, this guide will equip you with the insights needed to make the right choices on your next undertakings.

Understanding the benefits of brass pipe in plumbing

Due to their outstanding performance and longevity, brass pipe fittings are a go-to for many plumbing systems. One of the standout benefits of brass is its high resistance to corrosion. Unlike other materials, brass does not rust easily, even when exposed to water for prolonged periods of time. This property reduces the need for frequent installations and maintenance, therefore ensuring longevity in plumbing systems.

Brass fittings are also versatile within many industries; they can be employed for hot and cold water systems. This is due to their capability of withstanding extreme temperatures. For example, the melting point of brass is approximately 1,600°F (870°C), making it suitable for industrial and commercial plumbing systems that are high-pressure and high-temperature environments.

Brass fittings are also straightforward to install, offering another advantage. They are strong yet malleable, meaning they can be intricately crafted during threading, providing more intricate designs than harder metals such as steel. This flexibility streamlines installation and helps save time and labor costs.

As a recyclable material, brass is also environmentally friendly. It is not only an option for those looking for reliability and performance, but also for sustainable practices aimed at reducing waste when incorporating non-durable materials.

All of these features delineate why brass pipe fittings are considered reliable for plumbers, contractors, and engineers, offering an optimized blend of longevity and adaptability for various plumbing needs.

Comparing brass with other materials used in pipe fittings

Brass has many comparative advantages over other materials, such as PVC, stainless steel, and copper,r in terms of pipe fittings, considering different factors like durability, cost efficiency, eco-friendliness, and multifunctional use.

Durability and Longevity

The corrosion resistance and durability of brass pipe fittings is impeccable. Unlike PVC which deteriorates with constant UV and heat exposure, brass does not get unstable or unusable in harsh environments. Stainless steel also provides good resistance to corrosion, but is more susceptible to stress fractures in high-pressure systems. On the other hand, brass is better as it is less prone to stress fractures. Moreover, brass fittings often last for decades, making them a true long-term investment.

Cost Comparison

Compared to materials such as PVC, which comes from irreplaceable petrochemical resources and is difficult to recycle, brass fittings are much more environmentally friendly. Made from copper and zinc, brass is completely recyclable without any degradation of its properties, which is ideal considering the increasing availability of construction and other materials that are eco-friendly. Although stainless steel does undergo recycling, its production is far more energy consuming, ultimately giving it a larger environmental impact than brass.

Environmental Implications

Brass fittings are substantially more sustainable than some other materials, such as PVC, which is derived from non-renewable petrochemicals and is hard to recycle. Brass, composed of copper and zinc, is fully recyclable without losing its material properties, aligning well with growing demands for eco-friendly building materials. Stainless steel is also recyclable, but its energy-intensive production process can have a higher environmental footprint compared to brass.

Versatility and Applications

An advantage brass boasts is its unique versatility. Brass fittings have broad compatibility with different piping systems, and they can be used in residential plumbing or industrial systems. Copper is useful because of its antimicrobial attributes; however, it does not perform well in extreme temperatures or high-pressure situations. Moreover, PVC is mostly suitable for residential or low-temperature water systems. On the other hand, brass is capable of withstanding hot and cold water, as well as enduring high-stress situations.

Thermal Conductivity

For hot water installations, brass’s mid-range thermal conductivity is more favorable than PVC, which weakens under heat. Brass is also versatile in welded forms, which increases efficiency in assembly. While copper has the best heat conductivity, too much heat transfer can be detrimental to some applications, lowering overall efficiency. PVC is often limited to residential low-pressure water systems but works well in low-stress environments. Stainless steel, while less conductive, may struggle to bend like brass in extreme temperatures.

When looking into the different scenarios where the fittings will be used, including withstand factors such as durability, cost, and versatility, brass stands out as the superior choice offering reliability without an irresponsible environmental footprint.

Troubleshooting common issues with female pipe threads

Common Issues and Solutions for Female Pipe Threads

- Leakage

-

-

- Cause: A compromised seal or threads that are damaged.

- Solution: Apply Thread sealant tape or pipe joint compound to fill the gaps and maintain a tight seal. Check the threads for damage and replace fittings if required.

-

- Cross-threading

-

-

- Cause: Lack of alignment when fixing parts.

- Solution: Thoroughly check to ensure that male and female threads are aligned before tightening. Do not overtighten as it may cause further issues

-

- Corrosion

-

-

- Cause: Moisture or unfit materials.

- Solution: Use materials that resist corrosion like stainless steel or brass in areas of potential rust. Conduct routine checks and maintenance for fittings.

-

- Thread Damage

-

-

- Cause: Inaccurate tools or too much torque.

- Solution: Protect connections from over-tightening by first-hand tightening, and use tools minimally to preserve usable threads.

-

When you deal with these problems in an anticipatory way, you shall protect yourself against any risk regarding the durability and performance of the female pipe thread joints.

How to handle damaged female threads

If threads are not correctly managed, it can pose hazards like leakage and system failure of the system due to unreliable connections. Step one would be to evaluate the level of damage inflicted on the thread. In case the stripping isn’t too deep, attempts can be made with a thread repair tool, thread chaser, or similar instruments that aid in restoring functionality. Such devices remove a portion of the thread, enabling sufficient accommodation without the need for alteration.

But for more extensive areas of damage or cuts, employing a threaded insert like a Helicoil can provide sturdier connections as well. Such inserts establish threads with adequate functionality and strength within the damaged area that effectively become superior to the preexisting set of threads. For example, common stainless steel threaded inserts endure substantial torque and stress fractures, making them useful in vital systems like engine blocks or pipe assemblies.

In case the infliction of damage turns out to be worse than expected or structural vulnerabilities are accompanied, safer options would be enduring long-lasting problems, way of replacing the damaged parts entirely. The use of anti-seize and lubricants would also aid in mitigating further and corrosive damage by lessening friction on the threads during fastening. Following these methods guarantees fortified, tight bolt connections and complete elimination of leakage.

Ensuring a secure fit in pipe connections

For leak prevention, structural support, and overall performance of the system, a dependable and secure fit in pipe connections is paramount. The following are important in achieving this goal:

- Material Compatibility

Choosing the right piping and fittings requires the correct material selection. Stainless steel and copper are a good choice because they resist corrosion and are durable. However, they must be compatible with the fluid that will pass through them to ensure no chemical reaction will occur to destroy the bond over time.

- Thread Type and Size

For a secure connection, the proper fit of threaded parts with NPT and BSP cut is crucial. Some variations of a thread’s measurement can cause a weak seal that leaks under pressure.

- Pipe-sealing Compounds and Tapes

Careful craftsmanship while using sealant tapes on threaded pipes leads to tighter seals due to proper adjustment of pressure and improved friction. The application of pipe sealing compounds and PTFE tapes enhance the connection strength by over 25 percent.

- Torque Application

The requirements of torque are critical. Snugging too much leads to stripped threads and cracked fittings, while too little opens the possibility for leaks. A torque specification chart for parts used can provide useful insight.

- Testing for Leaks

Each assembly must undergo pressure checking of pipe junctions and connections, especially for truly cylindrical structures which are built to endure high pressure. Air tests and water tests are quick ways to highlight areas that require adjustments.

Select installation methods and precut measures like the use of corrosion resistant materials and proper torque application help achieve a firm fit in pipe joints. All these measures ultimately enhance system durability while minimizing upkeep.

Reference Sources

- Creating New Metaphors for Women Engineering Students Through Qualitative Methods1:

- Key Findings: This study explored the experiences of female engineering students in living-learning programs (LLPs) using metaphorical analysis. It identified five interpretive metaphors: LLP as a Starting Point, LLP as a Neighborhood, Engineering Classes as Challenges, Different as Normal, and Female Engineers as a Support System. The research highlighted the importance of positive metaphors in describing women’s experiences in engineering, contrasting with traditional deficit models like the “leaky pipeline.”

- Methodology: Conducted 13 semi-structured interviews with female engineering students, analyzed using systematic metaphorical analysis under a constructivist theoretical framework.

- Investigation of Customer Knowledge Management (CKM) Dimensions: A Survey Research2:

- Key Findings: Focused on CKM in polymeric pipe and fitting manufacturers in Isfahan, this study revealed weak integration among CKM dimensions (Content, Competence, Collaboration, and Composition). It emphasized the need for systematic customer satisfaction and complaint recording systems to enhance CKM practices.

- Methodology: Survey-based research involving 22 manufacturers, using a questionnaire with a 76% response rate. Data were analyzed to assess CKM dimensions and their application in the industry.

- Standard Values of Maximum Tongue Pressure Using a Disposable Measurement Device3:

- Key Findings: Although not directly related to pipe fittings, this study established baseline tongue pressure values for adults, noting age-related declines. It serves as an example of precise measurement and data collection in engineering and health sciences.

- Methodology: Measured tongue pressure in 853 Japanese adults using a disposable oral probe, with data collected and averaged over three trials per participant.

Frequently Asked Questions (FAQs)

Q: What are female pipe fittings, and how are they used in piping and plumbing?

A: Female pipe fittings are components used to connect sections of pipe or tube in piping and plumbing systems. They have female threads, which means they can accept male pipe threads to form a secure connection. These fittings are essential for directing and controlling the flow of liquids or gases.

Q: What is the difference between a female pipe fitting and a male pipe fitting?

A: The primary difference is in the threading. Female pipe fittings have internal threads and are designed to receive male pipe threads. Male pipe fittings, on the other hand, have external threads and fit into female fittings. Both types of fittings are used to connect pipes together.

Q: How do I choose the right type of female pipe fitting for my project?

A: To choose the right type of fitting, consider the material (such as galvanized pipe fittings or cast pipe), the pipe size, and the specific application. You’ll also need to ensure compatibility with the pipe’s material and size, such as using an inch female fitting for a specific diameter pipe.

Q: What are some common types of female pipe fittings?

A: Common types include pipe adapters, pipe unions, pipe couplings, and pipe tees. Each type serves a unique purpose, such as connecting different pipe sizes or allowing for directional changes in a pipe run.

Q: How are female NPT threads different from other thread types?

A: NPT (National Pipe Taper) threads are a standard for threading pipe fittings in North America. Female NPT threads are tapered, which helps create a tight seal when used with male NPT threads. This is different from straight threads, which do not taper and may require additional sealing methods.

Q: Can female pipe fittings be used with both plastic and metal pipes?

A: Yes, female pipe fittings can be used with both plastic and metal pipes, such as steel pipe or iron pipe. However, it is important to ensure that the materials are compatible to prevent corrosion or damage and to use the appropriate type of connector, such as a pipe fitting coupler or push to connect fittings.

Q: What is a pipe union,n, and how does it differ from a coupling?

A: A pipe union is a type of fitting that allows for easy disconnection and reconnection of pipes, which is helpful for maintenance. Unlike a coupling, which permanently connects two pipes, a union can be easily unscrewed, making it ideal for systems that require regular maintenance or modifications.

Q: Why is it important to know the pipe size when selecting a female pipe fitting?

A: Knowing the pipe size is crucial because fittings are designed to fit specific diameters. Using the incorrect size can lead to leaks or system failure. It’s important to match the fitting size with the size of the pipe or tube for a secure connection.

Q: What role do grooved pipe fittings play in piping systems?

A: Grooved pipe fittings are used to connect pipes without threading or welding. They feature grooves that align with a coupling, allowing for quick assembly and disassembly. This type of fitting is often used in larger systems where speed and flexibility are important.

Q: How does a pipe adapter work in a plumbing system?

A: A pipe adapter is used to connect pipes of different sizes or types, such as transitioning from a steel pipe to a plastic pipe. It can have either male or female ends and may include features like female x male connections or adapter NPT configurations to accommodate various setups.