In a myriad of processes, heat exchangers perform an essential yet understated role and are critical for the thermal transfer within a system, machinery cooling, or temperature maintenance. Noteworthy, the performance and lifespan of a heat exchanger are highly dependent on one factor: material selection. Choosing the appropriate grade of steel will not only affect maintenance and durability, but also operational efficiency, heat exchanger corrosion resistance, and cost-effective management. Focusing on the best steel types for heat exchangers, this guide will explain the reasoning behind material selection. Provided that you are an engineer, project manager, or any professional in the field, this article will enable you to understand the concepts required for making optimal decisions regarding system performance and reliability.

What types of steel are commonly used in heat exchangers?

- Stainless Steel

Stainless steel is one of the best choices for heat exchangers considering the grade’s 304 and 316 superb resistance to corrosion and high temperature. The moisture or the chemical environment does not affect its working as it can withstand a variety of conditions.

- Carbon Steel

This is the best option in terms of strength and pricing. Carbon steel is used in heat exchangers working under less corrosive environments dealing with low moisture and chemical exposure.

- Duplex Stainless Steel

This has all the features of both stainless steel and carbon steel, making it super strong with increased resistance to stress corrosion cracking. Those areas that are highly prone to corrosion and require high-pressure applications are ideal for the use of this complex steel.

These materials are chosen according to the defined parameters of the application such as the operating conditions, required efficiency, and cost.

Carbon steel vs. stainless steel: comparing heat exchanger materials

In choosing heat exchanger materials, the choice between carbon steel and stainless steel usually involves an assessment of cost, reliability, and performance within certain operating parameters. A deeper analysis follows.

- Corrosion Resistance

In the presence of moisture, salt and other corrosive materials, stainless steel outperforms carbon steel. For example, stainless steel grades like 316L answer chloride corrosion on ship fittings and parts used in chemical processing. On the contrary, carbon steel with its protective coatings or linings can be degraded in corrosive environments, but maintainability is increased because of these protective coatings over time.

- Thermal Conductivity

Compared to other grades of stainless steel, carbon steel has better thermal conductivity. This could be useful in systems where transfer of heat is crucial. However, in applications where resistance to fouling is more essential, stainless steel is better due to its smooth surface which prevents deposition of particulates.

- Strength and Durability

Carbon steel undoubtedly has exceptional tensile strength and load-bearing capacity, but the carbon steel’s rivalry with stainless steel shows durablility due to it’s oxidation and thermal fatigue resistance. A good example of this is duplex stainless steels which offer a unique blend of strength and resistance to stress corrosion cracking which makes them suitable for high pressure applications.

- Cost

Seeing from a more practical angle, carbon steel is more economical compared to stainless steel. This makes carbon steel the go-to for more austere projects. Nevertheless, the stainless steel’s first expense outweighs the carbon steel’s ever-growing expense in corrosive environments. While stainless steel may be pricier at first due, its longevity and lesser maintenance requirements make it more economical over time.

- Industry-Specific Applications

-

-

- An example would be the use of Carbon Steel in oil refineries and power plants since these places have high pressures and temperatures, yet the surroundings are not too corrosive.

-

Stainless Steel is widely used in the food processing industry and in the pharmaceutical and chemical industries due to the need for high durability, corrosion resistance, and the ability to withstand hygienic cleaning.

-

Latest studies point out that with the presence of chloride, stainless steel heat exchangers are more beneficial since they can up to 50% increase lifespan and reduce operational expense. At the same time, carbon steel is still a good choice for strutural strength for non corrosive high pressure systems because of its economic value.

In essence, the decison of choosing either stainless steel or carbon steel should be made after thorough reserach of the conditions in which the system will be used such as the environment, heat required, and system cost for fuel efficient performance.

Alloy steels and their role in heat transfer applications

The mechanical and thermal properties of alloy steels greatly enhance the efficiency of heat transfer systems, hence their significance. The addition of alloying elements such as chromium, molybdenum, nickel, and silicon improves the strength, resistance to corrosion, and thermal conductivity. This makes these steels appropriate for high-performance domains, such as enhanced oxidation resistance at elevated temperatures, improved creep strength, and pitting protection in corrosive environments provided by molybdenum.

Alloy steels are critical in the construction of heat exchangers due to having the unique capability to transfer heat efficiently, while simultaneously enduring severe pressures, temperatures and thermal cycling. Certain grades of some alloys are estimated to possess thermal conductivities between 35 and 45 W/m·K. This ensures energy transfer occurs. Furthermore, due to their unrivaled impact toughness, nickel-based alloy steels are preferred in cryogenic environments because of their low-temperature brittleness.

From processing chemicals to power plants, all industries use alloy steels due to their versatility to thermally and environmentally sustain modern industrial systems. Their dependability accentuates their value in achieving an enduring and efficient heat transfer system across sectors. In heat-intensive industries, there is an advancement in performance and sustainability by optimizing the alloy composition tailored to specific applications using custom alloy steels.

Specialty metals for high-temperature heat exchanger environments

The most demanding applications of heat exchangers require them to work in ultra-high temperatures, and this increases the need for thermal stress resistance, while also protecting against corrosion and oxidation to ensure mechanical integrity is not compromised. It is important that thermal metals respond positively to such conditions. For example, aerospace and power generation industries prefer to use Inconel alloys due to their outstanding resistance against oxidation and creep, as well as their high nickel content and ability to withstand temperatures above 1,000°F. Also, More stainless steel grades are being like 310S or 253MA, because of their economic value in relation to heat resistance.

There are also titanium alloys, which represent saltwater-resistant materials with lethal strength-to-weight ratios. Research shows titanium’s corrosion rates are dramatically lowered compared to carbon steels, which increases its reliability in chloride-rich systems. With these materials, the advanced technology in high-temperature heat exchangers can be made more durable than ever, resulting in improved system consistency and reduced long-term maintenance costs, which meet evolving needs in industrial sustainability.

How does stainless steel perform as a heat exchanger material?

For a heat exchanger, stainless steel is an effective material due to its exceptional strength, corrosion resistance, and thermal conductivity. Its performance in high-temperature environments or places with moisture and chemicals is superb. Reducing maintenance needs due to durability puts stainless steel as a dependable choice for numerous industrial applications. Furthermore, the resistance to stainless steel scaling enhances long-term efficiency.

Benefits of stainless steel heat exchangers for corrosion resistance

Stainless steel heat exchangers are considered of the highest quality due to their resistance to corrosion. This is especially true in settings where they are exposed to saltwater, acids, or industrial chemicals. This passive resistance to stainless steel degradation is due to the layer of chromium oxide. Because of this feature, stainless alloy grades 304 and 316 are preferred in marine and chemical processing applications.

Stainless steel heat exchangers are also cost-efficient in the long term as they incur lower spending on replacements. Data suggests that the lifespan of stainless steel heat exchangers when maintained properly is over twenty years. This is significantly greater than carbon steel alternatives, which succumb to rust and corrosion, along with plenty of other issues during use. This issue is magnified with carbon steel’s lack of resistance to pitting and crevice corrosion. Expanded durability is achieved without the increased risk due to exposure to chlorides.

Moreover, stainless steel’s exceptional ability to withstand high stress and temperature further increases its use in power generation, oil refining, and even desalination. These features boost efficiency while minimizing downtime and improving safety. This makes stainless steel heat exchangers an intelligent investment for businesses that want to resist corrosion and reduce long-term costs.

Different grades of stainless steel for heat exchanger tubes

Grades of stainless steel differ from one another with regard to corrosion resistance, mechanical attributes, and overall characteristics, so optimal selection for an industrial application relies on knowing the grade and its properties. Below are some commonly used stainless steel grades best suited for crafting tubes of heat exchanges:

- 304 Stainless Steel: One of the most used grades everywhere, from food processing industries to water applications, because it is cheap and has very good corrosion resistance. Best used within moderate temperature ranges.

- 316 Stainless Steel: Used extensively in marine environments, chemicals, and pharmaceuticals due to its superbly high corestion resistance against harsh acids, 316 stainless steel is enhanced with molybdenum which makes it even stronger.

- Duplex Stainless Steels (2205): Best suited for harsh situations like offshore platforms and seawater exposed heat exchangers due to its explantory resistance to stress corrosion cracking while having superb austenitic and ferritic attributes.

- 321 Stainless Steel: This grade has Titanium, which enhances its resistance to high temperatures, making it suitable for heat exchangers working in high-temperature environments.

- 904L Stainless Steel: 904L is widely used in processing industries that have highly corrosive materials due to its remarkable resistance to sulfuric and phosphoric acids.

- Super Austenitic Grades (e.g., 254 SMO): These steels are used in critical applications such as desalination plants, as they withstand pitting and crevice corrosion better than any other material in high chloride environments.

The different grades from mild to extreme allow industries to choose materials based on their requirements like corrosion resistance, temperature resilience or mechanical durability. For example, duplex stainless steels exhibit greater yield strength than 304 and 316 grades which lessens the wall thickness for some heat exchangers and increases cost efficiency.

Choosing the correct grade of stainless steel for an application involves understanding the operating environment, which includes chemical exposure, temperature range, and mechanical stress. By aligning the demands of the materials with these criteria, industries can maximize the lifespan and efficiency of the stainless steel components, greatly improving the performance of their heat exchangers.

Thermal conductivity considerations when choosing stainless steel

In my application involving stainless steels, I pay attention to thermal conductivity requirements. Compared to other metals like aluminum or copper, stainless steel has lower thermal conductivity. However, austenitic and ferritic grades provide adequate thermal performance with exceptional wrought corrosion resistance, strength, and toughness. I focus on these properties to maximize the efficiency of heat transfer while maintaining structural integrity and shielding the metal from corrosive conditions.

What factors should I consider when selecting steel for a heat exchanger?

Ideas first on steel choices for heat exchangers give us an insight into the strategy required for maximizing efficiency. This piece of equipment needs careful attention. Addressing issues like industrial performance, performance estimation, and even the delay of the device makes thermal conductivity very important.

- Thermal Conductivity

The thermal conductivity value associated with the steel will dictate the efficiency with which the heat exchanger does its work. Stainless steels of austenitic and ferritic types provide reasonable levels of thermal conductivity and aid in ferro alloy, while other fields will benefit more from having abrasives, including copper and aluminum, based on their level of heat exchanger performance needs. For the case of industrial heat screws, a compromise between conductivity and other properties use of these devices is realistic.

- Corrosion Resistance

Moisture, different forms of chemicals, and high salinity are some of the things that can result in the material undergoing corrosion maintenance challenges can be caused inside a heat exchanger. Grade 304 and 316 stainless steels are best placed pardon a fist is corrosion resistance.. For issues with extremely chemically aggressive environments of high pH, duplex stainless steel is better due to what these forms provide.

- Temperature Resistance

Depending on the application, the working temperatures can greatly vary from very cold temperatures to cryogenic conditions. The best placed to work with high temperature regions, strong with the need for operating under extreme cooling, is austenitic stainless steels of the type 310 or even high boron ferritic steel, because of reliability challenges during secondary bond forming.

- Mechanical Strength

Heat exchangers are commonly exposed to high levels of mechanical strain due to pressure differences and fluid flow within the system. In applications where outstanding mechanical properties, as well as resistance to fatigue cracking, are required, duplex stainless steels or low-alloy steels are some of the best options.

- Weldability and Fabrication

The assembling and manufacturing of heat exchangers involves a lot of welding and forming. The production of austenitic stainless steels can be done at high speed without jeopardizing, while ensuring elegant quality finishes. Moreover, formability and machinability might be critical for components that are complex and are thin walled.

- Cost and Availability

Also, the project budget and availability of certain steel grades is of consideration. For demanding applications, duplex or super duplex steels are high performing but carry a higher cost than conventional grades such as 304 or 316 steels. Determine the cost-benefit ratio to ensure that value without percieved performance is sacrificed in selecting the best economical option.

- Regulations and Standards

Other applicable rules and guidelines also need to be considered. Heat exchangers, and especially those used in the food processing, pharmaceuticals, or chemical industries, are required to follow applicable industry standards. For example, some stainless steel grades are FDA-listed or certified to ASME or ASTM standards, which makes them eligible for specific deemed safe and compliant uses.

Evaluating these aspects enables the designers and engineers to make a fully informed decision on the steel grade selection so that the heat exchanger can function efficiently, safely, and reliably throughout its life.

Balancing thermal efficiency, durability, and cost-effectiveness

Progress of materials and design techniques is highly influential, especially needed to achieve an optimal balance between thermal efficiency, lifespan, and cost. One striking improvement includes the use of high-performance alloys like titanium or nickel-based composites due to their exceptional resistance to corrosion and extremes. For marine applications, titanium is required along with its attributes, such as being less than 0.01 inches in corrosion per year in seawater.

Moreover, heat exchanger designs are refined using CFD simulations. These CFD simulations allow engineers to identify,enhance, and minimize energy losses by optimizing fluid flow patterns. This significantly increases thermal transfer rates. Data of the industry highlights aimsset by modern CDF -driven designs : an improvement of 20% in the efficiency of heat transfer, as per comparison to conventional designs.

Additive manufacturing, also known as 3D printing, is one of the advancements of manufacturing that can achieve cost-effectiveness. The precise fabrication of complex geometries made possible through this approach reduces material wastage and time taken to produce it. According to research, highly customized designs can achieve a 30% decrease in production costs from additive manufacturing.

Using new materials, simulations, and manufacturing technologies optimizes the entire heat exchanger industry, allowing it to address the increased need for reliable and cost-effective solutions across various sectors.

Environment assessment: choosing steel for corrosive conditions

To maximize the durability of steel in a corrosive environment, knowing the corrosive factors is paramount. These factors are temperature, humidity, chemical exposure, and pressure. Due to its oxidation resistance, stainless steel is often utilized because of its chromium content, which provides a protective oxide layer.

Stainless steel types 304 and 316 are commonly used for moderate corrosive environments and conditions. For example, type 316 consists of molybdenum which helps in chloride resistance usually found in maritime shipping or industrial work. Data indicates that 316 stainless steel is able to sustain concentrations of chloride at 1000 ppm while 304 grade can withstand nearly between 200 ppm.

If faced with the extremity of highly aggressive conditions, coated carbon steels and duplex stainless steels perform better. Duplex stainless steel is the blending of austenitic and ferritic steel. This blending improves pitting and crevice corrosion resistance, results in astonishing tensile strength. Research suggests that some duplex grades like 2205 are able to withstand 50-100% more destructive pressure than standard austenitic grades.

Furthermore, the strategies performed for monitoring and maintenance also enhance the steel’s longevity in said conditions. Inspections, protective coverings, and cathodic protection systems prevent degradation over time, guaranteeing safety and sustainability in vital areas like chemical processing, offshore platforms, and wastewater treatment facilities.

Which steel offers the best corrosion resistance for heat exchangers?

For heat exchangers that need maximum corrosion resistance, duplex stainless steel is the most effective. Due to high levels of chromium and molybdenum, duplex stainless steel has remarkable resistance to pitting, crevice corrosion, and stress corrosion cracking. Because of this, it is highly useful in tough conditions like seawater and aggressive chemical solutions.

Duplex stainless steel and its excellent corrosion resistance properties

Used in simplex form, duplex stainless steels are effective due to their high strength and resistance to corrosion in industrial applications. These types of steels have a specific structure that contains a mixture of austenite and ferrite phases, giving them resistance to corrosion. According to industrial regulations/recommendations, duplex stainless steels commonly have 22% to 26% chromium and molybdenum from 3% to 6%, further protecting these types of steels from pitting and crevice corrosion in places saturated with chloride.

Duplex stainless steels have great corrosion resistance when exposed to an aggressive chloride environment such as seawater. Performance tests reveal that the PREN (Pitting Resistance Equivalent Number) value for most of the grades is greater than 35, which indicates outstanding durability under challenging environments. Moreover, the resistance to stress corrosion cracking makes duplex stainless steels reliable for use in heat exchangers in industries dealing with sulfuric and hydrochloric acid.

A notable advantage of duplex stainless steels is that they possess better mechanical properties, and thus have higher tensile strength than austenitic stainless steels like 304 or 316 considerably by twofold. This indicates a decreased usage of materials required for construction and maintenance, thus reducing expenses. Moreover, withstanding harsh corrosion highlights their versatility and effectiveness across the chemical processing, marine, and power generation industries.

Titanium and nickel alloys for extremely corrosive environments

The unique alloy grades ti 2, ti 5, hastelloy c-265, monel 400 and inconel 625 boast unrivaled protection from corrosive environments. Careful applications of these alloys spanning from nuclear reactors to chemical process systems underline their outstanding corrosion resistance grades. Desalination plants, offshore constructions, and marine applications utilize their resistance against seawater and chloride stress corrosion. Titanium alloys like Gr 2 and Gr 5 are essential for these functions due to their reliability even in extreme temperatures and chemical conditions.

Chemical processing industries, and even certain military uses rely on swift use of sulfuric, hydrochloric, and nitric acids. The highly oxidizing or acidic environment does not affect nickel based alloys including hastalloy c 276, monel 400 or inconel 625. The unrivaled acid resistance of hastalloy c 276 enables more efficient and safe operations. Active, weary corrosion and persistent pitting are problems of paramount concern, and alloys cast provide powerful tools for whisper rust prevention.

A key factor in the success of these alloys is their inherent ability to form protective oxide layers. These alloys enhance device structural safety while sustaining their intrinsic traits like mechanical resistance to deformation and temperature variation. Creep suppression at increased temperatures renders these alloys invaluable for heat exchangers, turbo, and combustion assemblies.

Research from industrial applications reveals a major decline in yearly maintenance expenses with the use of titanium and nickel alloys in highly corrosive environments. These alloys’ durability and strength offer a cost-efficient and eco-friendly alternative for some of the most demanding industries.

Preventing corrosion in shell and tube heat exchanger designs

The prevention of corrosion in shell and tube heat exchangers is best achieved by integrating their material selection with optimally structured design and effective maintenance procedures. The use of titanium, nickel alloys, or duplex stainless steels with great corrosive resistance is a critical step. These materials suffer minimal chemical erosion from aggressive fluids due to high temperatures. For example, titanium has a strong resistance to seawater and chlorides; making it highly preferred in marine and offshore industries.

Other considerations include encouraging smooth fluid flow to decrease highly energetic localized turbulence and stagnation that increase pitting and crevice corrosion. Baffle spacing with tube rote optimization can increase negative flow enhancement thus improving performance. Furthermore, active advanced maintenance such as regular inspection and cleaning assist in preventing corrosion and fouling buildup. Non-destructive testing (NDT) is one of the new technologies that help in early detection of wear and tear, thus enabling timely repairs and maintenance before damage escalates.

New developments in heat exchanger components’ endurance, such as coatings and surface treatments, have taken a step forward. You can now use advanced polymer coatings and anti-corrosion linings as protective barriers that improve equipment lifespan. Research shows that industries employing these methods have reported operational downtime and maintenance cost savings by up to 30%. Businesses that combine innovative techniques with strong maintenance routines can trust the longevity and power of their heat exchanger systems.

What are the best materials for industry-specific heat exchangers?

Each industrial application will have specific operational requirements like temperature, pressure, and the interacting fluids, which dictate the best materials for industry-specific heat exchangers. Here are some commonly selected materials:

- Stainless Steel: Used in applications with high corrosion concerns like food processing, chemicals, and pharmaceuticals.

- Titanium: Used in seawater and corrosive chemical environments flare protection and offshore oil rigs because of its superior seawater and chemical resistance.

- Copper Alloys: Used in HVAC systems and power plants due to their great heat conductivity.

- Aluminum: Ideal in the construction of automobiles and aerospace vehicles for its lightweight and efficiency, also used in automotive and aerospace heat exchangers.

- Carbon Steel: Used in the oil and gas industry, in moderately corrosive conditions, due to their durability and affordable price.

Choosing the right material ensures effective operations, eliminates waste, maximizes productivity, and enhances cost savings in an industrial context.

Optimal steel choices for oil and gas heat exchanger applications

Selecting steel for use in oil and gas heat exchangers requires taking into consideration the ability to resist corrosion, withstand temperature, as well as mechanical strength. Some of the best steel options are:

- Stainless Steel (e.g., 304 and 316 grades): As far as alloys go, stainless steel’s most notable attribute is its high resistance to corrosion, even in harsh environments that pose aggressive salts, acidic compounds, or other corrosive agents. Specifically, grade 316 is further improved by the inclusion of molybdenum, which makes it ideal for extreme chemical exposures and conditions of high salinity such as offshore platforms.

- Duplex Stainless Steel: Strain-controlled cracking, pitting, and general corrosion pose a unique challenge for different kinds of steels. Duplex stainless steel offers extremely high resistance against those and more while remaining one of the most durable alloys. If you are looking for an alloy for a high-pressure system with elevated amounts of chloride that stands up to stress corrosion cracking and pitting, look no further than duplex stainless steel.

- Carbon Steel with Protective Coatings: Protecting against corrosion in harsh environments requires expenditure; however, carbon steel’s durability and cost make it appealing. For applications involving moderate pressures and temperatures, protecting carbon steel using alloys resistant to corrosion, extending cladding, lining, or coating proves beneficial for strength and longevity.

- Nickel Alloys (e.g., Alloy 625, Alloy 825): These materials maintain high resistance to corrosion even in the presence of H2S, CO2, and elevated temperatures, making them ideal for projects that demand utmost reliability under the sour gas condition.

- Low-Alloy Steel: Low-alloy steels are designed for applications with high strength requirements. strength and can function in places with high temperatures. Compounds with chrome and molybdenum (e.g, 1.25 Cr and 2.25 Cr grades) and other alloys are able to withstand the intense conditions of oil and gas processing.

Factors such as pressure, temperature, and even corrosive agent exposure inform which type of steel is used. With operational context in the oil and gas industry, using advanced material selection increases safety, enhances operational efficiency, and cuts costs.

Heat exchanger materials for chemical processing environments

During chemical processing, heat exchangers have great importance even when they function under very high temperatures and aggressive chemicals, or fluctuating pressure. It is extremely critical to choose the right material for heat exchangers, as this will determine their efficiency, longevity, and safety.

- Stainless Steel

Stainless steel is commonly used in heat exchangers because of its great resistance to corrosion and high thermal conductivity. Capable of enduring both acidic and chloride-rich environments, grades 304 and 316L are particularly favored. As per industrial standards, stainless steel is functional within -250°F to 1500°F, which is suitable for many processes in the chemical industry.

- Titanium

With an estimated lifespan of 10 to 20 years under severe conditions, Titanium is highly resistant to corrosive chemicals, especially for chloride and seawater exposure. This property, along with its lightweight, makes it a reliable and efficient choice despite its higher initial price.

- Nickel Alloys (e.g., Hastelloy)

Alloyed with nickel, Hastelloy is specifically engineered for harsh conditions involving strong acids such as hydrochloric and sulfuric acid. They are highly resistant to pitting, crevice corrosion, and stress-cracking corrosion. A good example is Hastelloy C-276 as it is stable up to 1900 °F, making it suitable for demanding chemical processes.

- Copper Alloys

The alloys of copper, including brass and bronze, are greatly used due to their high thermal conductivity and antimicrobial properties. They are employed in activities where there is a necessity for great heat transfer and efficiency. However, they are not appropriate in operations involving the use of acidic chemicals because of the chances of corrosion.

- Graphite and Ceramic Materials

For the purposes of withstanding a harsh chemical reaction, non-metallic materials like graphite and ceramics are gaining prominence. The materials can be exposed to the most aggressive alkalis and acids while withstanding extremely high temperatures without losing their reliability.

While choosing a material for a heat exchanger, the composition of the fluid, pressure, temperature, and lifecycle costs should be considered. Newer technologies aimed at improved energy efficiency, reduced upkeep, and enhanced longevity support optimization in chemical processes and expand design choices available for cheaper-to-maintain processes.

HVAC and boiler systems: material selection for efficiency and longevity

The performance and reliability of HVAC equipment, as well as boiler systems, rely heavily on the materials used for their parts. For instance, stainless steel is a good selection because of its unmatched resistance to corrosion, toughness, and ability to withstand extreme temperatures. In condensing boilers, stainless steel is specifically preferred for heat exchangers and in copper systems since it withstands degradation over time due to acidic condensate.

Copper is a commonly used metal due to the value placed on its ability to ensure rapid heat transfer. It is frequently used in HVAC coils and boiler piping for its efficiency in heat exchange processes. However, systems with copper may necessitate increased maintenance when used in scaling or corrosive environments.

Research indicates that more and more alloys of aluminum are being utilized as exchangers in HVAC units. Their low weight, coupled with strong thermal conductivity make them the best option true modern energy conserving systems. However, aluminum may require protective coatings for resisting corrosion in high humidity areas.

Stos sough emerging materials like PEX (cross-linked polyethylene) for porpose of HVAC and boiler systems prone ductility and durability in tubing while reducing labor costs. PEX proves most useful in radiant heating systems becuase of its scaling and freezing resistance.

Choosing the right materials for temperature, pressure, and fluid composition can improve the performance and lifespan of HVAC and boiler systems. Using efficient materials lowers energy requirements, thereby maintaining long-term sustainable operations.

How do different steels affect heat transfer efficiency?

Different types of steel have distinct thermal conductivities and therefore carry out heat transfer with different levels of efficiency. For instance, carbon steel’s thermal conductivity is moderate, which allows it to be used for a system that requires consistent heat transfer, but not extreme heat transfer. Contrarily, stainless steel, while having better resistance to corrosion, also has a lower thermal conductivity than carbon steel, which may lead to some applications having less efficiency in heat transfer. Specialized alloy steels with optimized properties help strike a better balance between conductivity, strength, and durability. The optimum steel depends on the system’s operation and environmental temperature, and other conditions like weather.

Thermal conductivity comparison between steel heat exchanger materials

Depending on the composition, various materials used for making steel heat exchangers have differing thermal conductivities which is important in understanding them so that system performance can be maximized. An example of this is the fact that carbon steel possesses a thermal conductivity value in the range of 43 to 58 W/mK at roughly room temperature. This makes it widely used in applications that demand effective heat transfer while keeping costs low.

Unlike carbon steel, stainless steel has electric conductors with stronger alloys like chromium and nickel which reduces its thermal conductivity to about 15 W/mK. Although this lowers the efficiency of heat transfer, the other properties of stainless steel such as its resistance to corrosion and durability are superior which allows this material to perform better in harsher or more corrosive environments.

Alloy steels comprise thermal conductors that have been specially engineered to offer a blend of thermal and tensile strength along with high-temperature creep resistance. Depending on the alloys, the thermal conductivity of these materials can be customized to lie anywhere from 20 to 50 W/mK broadening industrial application options.

Industries are able to customize the designs of their heat exchangers, whether for precise durability thresholdes, extensive lifetimes, or harsh environmental durability to specific uses by tailoring material works based on the properties outlined. Outlining precise material specifications per each case results in improved performance alongside lowered expenses.

Impact of material thickness on heat transfer in exchanger tubes

The Efficiency of heat transfer is affected by the thickness of the walls in a heat exchanger tube. The reduced thermal resistance of thin-walled tubes generally increases the speed of heat exchange in these tubes. However, having thin materials may greatly compromise structural strength, particularly in high-pressure or corrosive environments. Thus, a balance is key for safe and effective operation.

It has been noted that increasing the thickness of the tube wall results in lower efficiency of heat transfer. This is due to the thicker walls impeding thermal conductivity. For instance, in mechanical applications, stainless steel tubes perform better when the wall thickness is 0.5 mm compared to 1.5 mm due to higher heat transfer rates, despite having lesser mechanical strength. The same is true for copper tubes , which have outstanding performance in thermal conductivity, but have to work within the set limits of thickness to avoid changes in shape beyond acceptable limits.

For other Industries that face harsh conditions like high temperatures or aggressive chemicals, the material and the thickness used have to be aligned with operational demands to maintain durability while ensuring good thermal performance. With the advancement in computing modeling for thermodynamic analysis, more precise predictions for the behaviors of heat transfer are possible. This enables better selection of dimensions for the walls of the tubes designed for specific industrial applications.

Finned heat exchangers: material considerations for efficient heat transfer

Selecting materials impacts the thermal efficiency and durability of finned heat exchangers in different applications. Important parameters are thermal conductivity, resistance to corrosion, strength, and cost. In instances where thermal conductivity is of primary importance, metals such as aluminum and copper are preferentially used. Copper, for example, is a good heat conductor and has a thermal conductivity of about 400 W/m·K, while aluminum is somewhat less conductive at 235 W/m·K. However, it is more economical and lighter.

For more corrosive environments, greater corrosion resistance may be obtained with stainless steel or nickel alloys which ensures dependability over longer periods of operation. The chromium components of stainless steel make it resistant to abrasive and elevated temperatures, deeming it fit for chemical processing and power generation industries. Besides, titanium continues to be used in harsh environments, especially in marine applications where saltwater corrosion resistance is vital.

Recent studies emphasize the need of ensuring accuracy in material–fin pairing for optimizing the performance of a heat exchanger. In microchannel heat exchangers, for example, the application of advanced aluminum alloys, coupled with innovative manufacturing techniques, results in up to 30% efficiency improvements. These achievements underscore the advancements in material science that continue to improve the effectiveness and environmental friendliness of finned heat exchangers in industrial and commercial settings.

Reference Sources

- Failure Analysis of Boiler Tubes:

- This study focuses on the failure mechanisms in boiler tubes, including overheating, creep, stress corrosion, and oxidation. It highlights the importance of material selection and maintenance to prevent failures.

- Shell-and-Double-Concentric-Tube Heat Exchanger:

- A novel design using perforated helical baffles was analyzed. The study found that this design improves heat transfer by 26.7% and reduces pressure drop by 38.4% compared to traditional designs, making it a more efficient choice.

Frequently Asked Questions (FAQs)

Q: What is the best material for heat exchangers?

A: The best material for heat exchangers depends on the specific application, but stainless steel, particularly austenitic grades like 304 and 316, is often considered optimal due to its excellent corrosion resistance and good thermal conductivity. For high-temperature applications, nickel alloys like Inconel may be preferred, while copper and aluminum are excellent choices when weight and thermal efficiency are priorities. Carbon steel tubes are cost-effective for non-corrosive environments. Material selection should balance thermal performance, corrosion resistance, mechanical properties, and cost considerations for the specific operating conditions.

Q: Which material for heat exchanger applications offers the best corrosion resistance?

A: Stainless steel grade 316/316L provides superior corrosion resistance for heat exchangers, particularly in aggressive environments containing chlorides or acids. This highly corrosion-resistant alloy contains molybdenum, which enhances its resistance to pitting and crevice corrosion. For extremely corrosive conditions, specialized materials like titanium, Hastelloy, or Inconel may be necessary. Using the wrong material can lead to premature equipment failure, so corrosion resistance should be a primary consideration when designing heat exchangers for chemical processing, marine environments, or applications with corrosive fluids.

Q: What is the most cost-effective material for industrial heat exchangers?

A: Carbon steel is typically the most cost-effective material for heat exchangers in non-corrosive environments with moderate temperatures and pressures. It offers good thermal conductivity and mechanical strength at a lower price point than specialty alloys. For applications with mild corrosion concerns, copper or aluminum may provide a good balance between performance and cost. While stainless steel costs more initially, its durability can offer better long-term value in corrosive environments. The cost-effectiveness ultimately depends on balancing initial investment against maintenance requirements, expected service life, and the potential consequences of failure.

Q: How do different types of heat exchangers influence material selection?

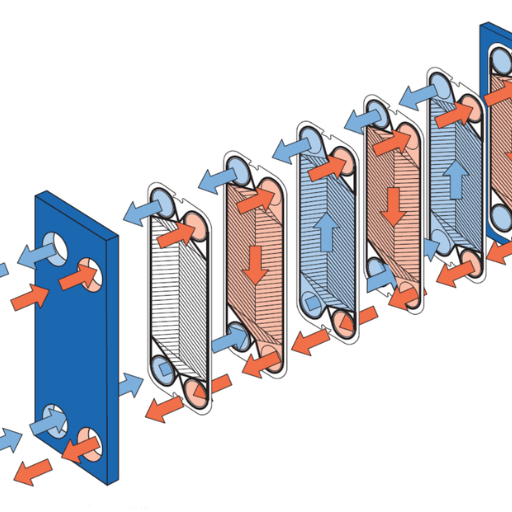

A: Different types of heat exchangers require specific material considerations. Shell and tube exchangers often use carbon steel shells with copper, stainless steel, or titanium tubes, depending on corrosivity. Plate heat exchangers typically employ stainless steel, titanium or high-nickel alloys due to their thin construction requiring corrosion resistance. Air-cooled exchangers may use aluminum for fins while maintaining steel tubes. Spiral heat exchangers often use specialized stainless steels for handling challenging fluids. The material selection for heat exchanger components must account for the unique mechanical stresses, temperature gradients, and potential for fouling specific to each exchanger design while ensuring high efficiency and product quality.

Q: What is the best material for heat exchanger applications in food processing?

A: For food processing heat exchangers, 316L stainless steel is generally considered the best material due to its excellent corrosion resistance, sanitary properties, and ability to withstand cleaning chemicals. This grade is non-porous, doesn’t affect taste or color, and meets strict regulatory requirements for food contact. The low carbon content in 316L minimizes the risk of sensitization during welding. For specialized applications, titanium may be used when extreme corrosion resistance is needed, while copper is sometimes suitable for heat exchangers not in direct food contact. Material selection must prioritize food safety, cleanability, and compliance with FDA, USDA, and 3-A Sanitary Standards.

Q: What materials are commonly used for automotive heat exchangers?

A: For automotive heat exchangers like radiators, heater cores, and intercoolers, aluminum is most commonly used due to its excellent thermal conductivity, light weight, and reasonable cost. Copper/brass combinations were traditional choices and still offer superior heat transfer, though they’re heavier and more expensive. In modern vehicles, specialized aluminum alloys with corrosion inhibitors are preferred for their contribution to fuel efficiency. For exhaust gas recirculation (EGR) coolers and other high-temperature applications, stainless steel is typically employed. Material selection for automotive heat exchangers must balance thermal performance, durability, weight considerations, manufacturability, and cost constraints while withstanding vibration and thermal cycling.

Q: What material is suitable for heat exchangers in cryogenic applications?

A: For cryogenic heat exchangers operating at extremely low temperatures (typically below -150°C), austenitic stainless steels (304L, 316L) are most suitable due to their excellent low-temperature ductility and toughness. Aluminum alloys (5000 and 6000 series) are also commonly used for heat exchangers in cryogenic applications like LNG processing due to their excellent thermal conductivity and increased strength at low temperatures. Copper and copper alloys may be used for specialized cryogenic applications. Materials for cryogenic service must maintain ductility without becoming brittle at extremely low temperatures, resist thermal cycling fatigue, and have good thermal conductivity while meeting stringent safety requirements for handling liquefied gases.

Q: How important is thermal conductivity when selecting materials for heat exchangers?

A: Thermal conductivity is a critical factor in material selection for heat exchangers as it directly impacts heat transfer efficiency. Materials with good thermal conductivity, like copper (385 W/m·K) and aluminum (205 W/m·K), can achieve high efficiency with thinner walls and compact designs, while stainless steel (15-45 W/m·K) requires greater surface area or thickness. However, material selection must balance thermal performance against other factors, including corrosion resistance, mechanical properties, and cost. In many industrial applications, corrosion resistance often takes precedence over thermal conductivity, as using the right material that resists the service environment ensures longer equipment life despite potentially lower thermal efficiency.

Q: What materials are best for heat exchangers in air conditioning systems?

A: For air conditioning systems, copper is traditionally considered the best material for heat exchangers due to its excellent thermal conductivity, corrosion resistance, and antimicrobial properties. Aluminum is increasingly used for its lighter weight, lower cost, and good thermal performance, particularly in residential systems. Modern systems often feature copper tubes with aluminum fins (Cu/Al) as a cost-effective compromise. For corrosive environments, copper-nickel alloys or coated aluminum may be used. Material selection must balance thermal efficiency, manufacturability, weight, and cost constraints while considering the specific refrigerants used, as newer, environmentally friendly refrigerants may have different material compatibility requirements.