Stainless steel has become an essential material in almost every industry due to its excellent mechanical properties and its ability to resist corrosion perfectly. Among the numerous applications, the manufacture of stainless steel pipes and seamless tubing has been particularly prominent, with the healthcare, drug, and other manufacturing industries frequently using these pipes and tubes. This in-depth guide reveals the amazing and intricate universe of stainless steel, drawing a line between steel pipes and seamless tubes, highlighting their particular features, and giving you practical advice to make your decision better.

Introduction to Steel and Stainless Steel

⚙️ What is Steel?

Steel, which is an alloy predominantly composed of iron and carbon, is one of the strongest and most commonly used metals. The carbon contained in the iron is the primary reason for the varying strength of steel. Moreover, different metals, such as manganese, chromium, or nickel, are usually incorporated into an alloy based on its intended use and the quality of the alloy. The presence of these elements is beneficial in enhancing certain characteristics like resisting rust, toughness, or ductility, depending on the steel type.

💡 Key Characteristics of Steel:

- Universal Impact: Used in buildings, pipelines, roads, cars, and airplanes

- Easy Formability: Can be easily shaped for various applications

- Cost-Effective: Inexpensive material of choice across industries

- Versatile Alloying: Can be customized with different elements for specific properties

✨ Properties of Stainless Steel

Stainless steel is a material that is constantly well regarded due to its excellent properties, and this is the reason why it is so common in all kinds of industries. One such property that gets a lot of focus is that it cannot get rusted, mainly because the chromium in it generates a very thin layer that is impervious to water and air, and this layer is also resistant to oxidation. The property of stainless steel not getting rusty or stained makes it appropriate for locations where there is a chance of exposure to moisture or chemicals, hence, it is used in the kitchen, medical devices, and heavy industries.

🛡️ Corrosion Resistance

Chromium forms a protective layer that resists water, air, and chemicals

💪 High Strength

Excellent tensile strength for high stress and extreme weather conditions

🔥 Heat Resistance

Can withstand high temperatures without losing structural integrity

♻️ Additional Benefits:

- Versatility: Can be cut, welded, and bent without losing properties

- Recyclability: Can be re-used without diminution of core characteristics

- Low Maintenance: User-friendly operations with minimal upkeep

- Aesthetic Appeal: Trendy and elegant appearance

⚖️ Differences Between Steel and Stainless Steel

Steel and stainless steel are two distinct types of metals that differ from each other in several aspects such as composition, physical and chemical properties, and applications. For example, steel is an iron-carbon alloy where the constituents are in such a ratio that the resulting metal is not only very strong but also very cheap. This has convinced builders, car manufacturers, and industries to use it. On the other hand, the main disadvantage of steel is that it will corrode in a relatively short duration if it is left outdoors without any protective covering since it does not have rust resistance.

Understanding Steel Pipes and Tubes

🔧 Steel Pipes Types

Steel pipes come in quite numerous types, each one meant for a specific industry or commercial use. The main types are seamless steel pipes, welded steel pipes, and galvanized steel pipes.

1. Seamless Steel Pipes

Very strong due to no welding or joint and the ability to bear enormous pressure. These pipes have made their way to oil and gas applications, boiler systems, and certain other sensitive areas.

2. Welded Steel Pipes

Made by rolling steel into circles and sealing the joints through welding. They offer a low-cost alternative to other types, and they are perfect for situations where the pressure is not more than medium, such as in water distribution and infrastructure projects.

3. Galvanized Steel Pipes

Zinc-coated to improve corrosion resistance. These pipes are mostly placed underground in construction sites, and water is their main product during transportation.

🎯 Selection Criteria: Choosing among the steel pipe types requires considering durability, corrosion resistance, pressure requirements, and cost in order to get the best match for the application.

⭐ Seamless Pipes: What Are They?

Seamless pipes are the kind of steel pipes that have constant and uniform structure for the complete length as they have been totally produced without seams or welds. Their manufacturing process is mainly the piercing of a solid steel round bar to get a hollow cylinder that is then stretched and shaped according to the desired standards.

🔍 Key Attributes of Seamless Pipes:

| High Strength | No weak points from welding |

| Durability | Long-lasting in demanding conditions |

| Pressure Resistance | Ideal for high-pressure applications |

| Leak Prevention | No welded joints minimize leakage risk |

| Applications | Oil & gas, power generation, automotive, construction |

⚡ Welded vs. Seamless Steel Pipes

Welded and seamless steel pipe selection goes hand in hand with the specific application requirements. Understanding their differences is crucial for making informed decisions.

Welded Pipes

✅ Advantages:

- Lower manufacturing cost

- More readily available

- Customizable dimensions

- Suitable for low-medium pressure

⚠️ Disadvantages:

- Seam can corrode

- Structural weakness at weld

- Vulnerable under high pressure

Best For:

Plumbing, structural support, mechanical tubing

Seamless Pipes

✅ Advantages:

- Excellent strength

- Superior durability

- Withstands extreme conditions

- Homogeneous structure

- Minimal leak/failure risk

⚠️ Disadvantages:

- Higher manufacturing cost

- More expensive initial investment

Best For:

Oil & gas, power generation, chemical processing

💡 Decision Guide: The final decision will be based on the intended application. When a project requires the utmost reliability in the case of high pressure or high temperature, seamless pipes are usually the better option. In contrast, welded steel pipes present a practical and efficient solution for cost-conscious projects that operate under moderate conditions.

Manufacturing Process of Stainless Steel Pipes

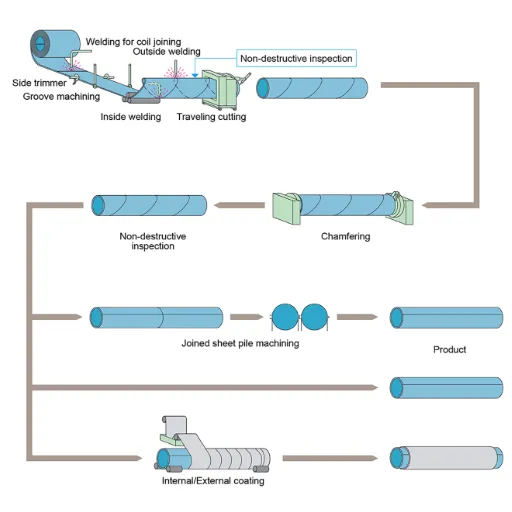

🏭 Manufacturing Process Overview

The process of manufacturing stainless steel pipes is an array of clearly visible and highly accurate steps that proceed one after the other in order to ensure the product’s durability, quality, and resistance to corrosion. To start with, the metals that produce stainless steel, that is, chromium, nickel, and molybdenum, are blended together by melting in an electric arc furnace.

Manufacturing Process Steps

Raw Material Melting

Seamless: piercing/extrusion; Welded: rolling and welding

Solid Shape Formation

Molten steel formed into billets or slabs

Pipe Formation

Quality Control

Non-destructive testing and surface treatments

🔬 Seamless vs. Welded Manufacturing:

Seamless Pipe Process:

The billet is subjected to a piercing operation which creates a hollow tube, then stretched and formed through either extrusion or rolling methods.

Welded Pipe Process:

Steel sheets or plates are arranged in cylindrical form and edges fused together using electric resistance welding (ERW) or laser welding.

🌱 Modern Manufacturing Trends:

High-end technologies and apparatus, along with revolutionary data insights, indicate an upward movement in demand for environment-friendly and cost-effective methods. Many manufacturers are utilizing:

- Precision forming techniques

- Automated welding processes

- Energy-efficient methodologies

- Waste reduction strategies

🔍 Manufacturing Quality Control

Quality control in manufacturing is the most important factor that ensures that the product is up to standard and meets the customer’s needs. It is the manufacturers’ use of the latest technological advancements—automation in the inspection process, and predictive analytics—that makes them more able to spot defects, waste less, and generally increase their efficiency.

⚙️ Quality Control Methods:

| Method | Purpose | Application |

|---|---|---|

| Ultrasonic Testing | Detect internal flaws | Structural integrity verification |

| Radiographic Examination | X-ray inspection | Weld and material quality |

| Hydrostatic Testing | Pressure resistance check | Leak detection |

| Six Sigma | Process improvement | Defect reduction |

| Statistical Process Control | Monitor production | Real-time quality tracking |

| AI & Machine Learning | Predictive analytics | Error detection, maintenance scheduling |

🔬 Surface Treatments: After testing, treatments like pickling and passivation aimed at improving resistance against environmental influence are applied to the surface of the pipes. The entire procedure displays technological accuracy, adherence to industry standards, and sustainability—conveying both conventional know-how and present-day progress.

Advantages of Stainless Steel in Piping Systems

Corrosion Resistance

The high chromium content which creates a passive oxide layer is the main reason why stainless steel is linked to its exceptional corrosion resistance. This feature is a great advantage for the petroch-мical, the pharmaceutical, and the water treatment industries, as it enables them to keep their structures intact even in harsh environments with chemicals, moisture, or very high or low temperatures.

Durability and Longevity

Latest information shows that stainless steel is among the strongest materials for longevity. It is resistant to rust, can work in high-pressure situations, and withstands very high and very low temperatures. The life expectancy of stainless steel pipe networks is predicted to be over 50 years with minimal care, thus being economical and eco-friendly at the same time.

Cost-Effectiveness

The reason for the cost-effectiveness in the long run lies in the longevity and the fact that they require little maintenance. The replacement of piping systems in industries with stainless steel results in the repair and replacement costs being lower. The property of stainless steel to resist corrosion leads to a reduction in the frequency of maintenance, which in turn, saves time and money. The total of these benefits amounts to significant financial savings over the years.

Key Applications of Stainless Steel Pipes and Tubes

⛽ Applications in Oil and Gas Industry

The oil and gas sector heavily relies on stainless steel tubes and pipes owing to their ability to withstand the most extreme environmental conditions. Recent statistics show that the global demand for stainless steel has increased significantly for the production of pipelines, refining systems, and offshore platforms.

🔥 Key Benefits for Oil & Gas:

High Temperature Tolerance

Withstands extreme heat in refining processes

Pressure Resistance

Handles high-pressure conditions safely

Chemical Resistance

Resists hydrogen sulfide and other aggressive chemicals

Leak Prevention

Reduces operational risks and ensures safe transfer

🔬 Advanced Materials: Modern advanced grades like duplex and super duplex alloys offer great strength and resistance to corrosion, matching the industry’s increasing demand for cost-effective but strong solutions. Their recyclability makes them crucial material in modern energy infrastructure.

🏗️ Use in Construction and Infrastructure

Stainless steel is a fantastic material for the construction and infrastructure sector because it possesses great technical qualities like durability, resistance to corrosion, and aesthetics. Its use can be seen in the areas of structural elements, cladding, roofing, and even as part of the reinforcement system where life and strength are the main considerations.

🌆 Construction Applications:

| Structural Elements | Columns, beams, and load-bearing components |

| Cladding & Roofing | External and internal architectural finishes |

| Reinforcement Systems | Rebar and structural strengthening |

| Urban & Industrial | Bridges, tunnels, and infrastructure projects |

♻️ Sustainability Benefits:

According to the Latest reports architects and engineers have inclination to stainless steel in green constructions that is 100% recyclable and eco-friendly building practices. It requires very little maintenance and its durability in extreme weather conditions is another plus point. Urbanization trends will be one of the main factors in creating resilient and future cities by promoting the use of stainless steel in infrastructure development.

🏥 Medical and Food Industry Applications

Because of the excellent hygienic qualities and the fact that it lasts forever and withstands rust, stainless steel is widely applied in the medical and food industries. Recent data indicates that stainless steel is extensively utilized for surgical instruments, implants, and hospital equipment owing to its property of maintaining sterility and preventing bacteria from growing.

🏥 Medical Applications

- Surgical instruments

- Medical implants

- Hospital equipment

- Sterilization equipment

- Diagnostic tools

Why? Provides sterile conditions and prevents bacterial growth

🍽️ Food Industry Applications

- Processing equipment

- Storage tanks

- Commercial sinks

- Conveyor systems

- Food preparation surfaces

Why? Ensures food safety and complies with stringent sanitary standards

🔬 Non-Reactive Property: Stainless steel does not react with food and beverages, thus allowing the original flavor and quality to be retained, which is why it is the preferred material for a wide variety of critical applications in these industries.

Frequently Asked Questions (FAQ)

❓ What are the benefits of seamless stainless steel pipe when compared to welded pipe?

Seamless stainless steel pipes often exhibit superior combined strength and toughness characteristics, as they do not feature weld beads, which are points of vulnerability during stress and corrosion. The application of seamless stainless steel pipe instead of welded pipes is justified by its greater wall thickness and pressure resistance for oil and gas pipelines as well as power generation facilities.

Key Advantages:

- Smoother surface finish

- Reduced chances of defects at weld seams

- Better performance in critical applications and exhaust systems

- Improvement in high-temperature and corrosive environments

- Longer service life

❓ How does the manufacturing process for seamless stainless steel pipes influence the quality?

The production of seamless pipes starts with a steel billet that is pierced and stretched to produce a hollow shell which substantially determines the accuracy of dimensions, wall thickness and surface finish. Therefore, the seamless stainless steel tubes produced in this way would have a tighter tolerance and a more uniform pipe wall thickness, thus making it suitable for high-pressure applications and ensuring the reliability of the piping system.

💡 Quality Impact: Not having a weld seam eliminates the risk of defects associated with fusion or welding, improving corrosion resistance and mechanical properties. The process and alloy steel selection, including duplex stainless options, dictate strength and durability for the harshest conditions.

❓ Why is seamless stainless steel tubing chosen for oil and gas industry pipelines?

Seamless stainless steel tubing is the most widely used material for oil and gas pipelines owing to its exceptional corrosion resistance and excellent mechanical properties even in extreme temperature conditions. The absence of a weld seam translates to very low chances of stress concentrators and leak points occurring, which is a requirement for safety in oil and gas pipelines and high-pressure applications.

| Accurate Control | Wall thickness, tolerance, and nominal pipe sizes controlled precisely |

| Material Options | Duplex stainless grades and alloy steel for strength and chloride resistance |

| Long-Term Value | Long life and low maintenance in critical applications with high downtime costs |

❓ What role does wall thickness and tolerance play in selecting a steel seamless pipe?

Wall thickness and tolerance are the key factors in the selection of a seamless steel pipe; they are responsible for the strength, pressure rating, and overall safety of the system. A very tight tolerance and a uniform wall thickness of the pipe contribute to the performance being very stable in high-pressure applications and at the same time, the risk of localized failure is reduced.

Critical Considerations:

- Accurate control needed for power plants, oil & gas, and critical applications

- Ensures design codes compliance

- Guarantees fittings and flanges compatibility

- Heavy-duty walls increase strength and resistance to mechanical damage

- Influences weight and cost balance

- Engineers must consider nominal pipe size and alloy steel grades

❓ Can seamless stainless steel piping systems be used for exhaust systems and high-temperature applications?

Indeed, seamless stainless steel pipes are the best choice for exhaust systems and other high-temperature applications because of their high strength and corrosion resistance even at elevated temperatures. The seamless pipe manufacturing process guarantees that the pipes have the highest quality structural integrity and are free of the drawbacks that might arise at the weld seams due to the thermal cycling customary with exhaust systems.

Material Selection

Heat-resistant stainless steels with appropriate wall thicknesses

Surface Benefits

Smooth internal surface improves flow characteristics and reduces fouling

Design Factors

Consider tolerance, surface finish, and thermal expansion

❓ How do cost and lifecycle considerations compare between seamless stainless pipes and welded pipe solutions?

Seamless stainless pipes were more expensive at the beginning compared to welded pipes because of sophisticated manufacturing techniques and the use of prime materials. Nonetheless, in the case of heavy-duty applications, the lifetime of the pipes usually turns out to be more favorable for the seamless ones. The bigger price for the first time can be balanced by the maintenance costs being lower, no or few failures due to welding-related problems that can be found, and the longer service life even in cases of corrosion or high pressure.

| Cost Factor | Seamless Pipes | Welded Pipes |

|---|---|---|

| Initial Investment | ⚠️ Higher | ✅ Lower |

| Maintenance Costs | ✅ Lower | ⚠️ Higher |

| Service Life | ✅ Longer (50+ years) | ⚠️ Shorter |

| Failure Rate | ✅ Fewer failures | ⚠️ More weld-related defects |

| Total Cost of Ownership | ✅ Lower (long-term) | ⚠️ Higher (long-term) |

💼 Investment Decision: In critical applications where downtime can result in enormous costs—like oil and gas pipelines, power plants, or installation of major piping systems—the total cost of ownership often makes the use of seamless stainless steel tubing the economically sound choice. Pipe wall thickness, system fittings compatibility, and the benefits of stainless steel seamless parts should all be considered by engineers in making a comprehensive decision. More often than not, the premium paid for seamless stainless steel pipe is justified by its strength, durability, and long-term risk which are all comparatively lower.

Reference Sources

📄 Crack Failure Analysis of Stainless Steel Seamless Pipe

This study discusses the failure behavior of stainless steel seamless pipes, providing insights into their performance and durability.

📄 Seamless Steel Tubes and Pipes for Boilers

This paper explores the manufacturing and research aspects of various steel tubes and pipes, including stainless steel seamless pipes.

📄 Stainless-Steel Piping

This article examines the properties and applications of stainless steel piping systems, including their resistance to corrosion and external factors.

🎯 Key Takeaways

Stainless steel seamless pipes are the ultimate solution for the most demanding industrial applications. Oil and gas, construction, medical, and food processing industries are the main ones where the pipes are used due to their great strength, corrosion resistance, and long-lasting life. Although the initial price is on the higher side, the long-term advantages, including reduced maintenance, less frequent failures, and increased service life, often make seamless stainless steel pipes a profitable investment for major infrastructure projects.