One of the main advantages of stainless steel lies in its lasting durability and non-corrosive nature along with several application possibilities including, primarily, the construction sector and cookware production. Despite its existence for so many years, the one feature or quality that still goes unnoticed is that of heat transference or the thermal conduction efficiency. Does it conduct electricity in the same manner as aluminums and copper, or is it more or less than such metals? And since nobody would ask, one may still wonder: what’s the point of that in a heat exchanger, a device or for that matter a simple cooker?

All these questions will be approached in this essay through an examination of the thermal conductivity of stainless steel and how it stands in relation to some other frequently used metals. You will be more informed about what effects thermal properties have on the performance of materials and their application at the finish.

Introduction to Thermal Conductivities

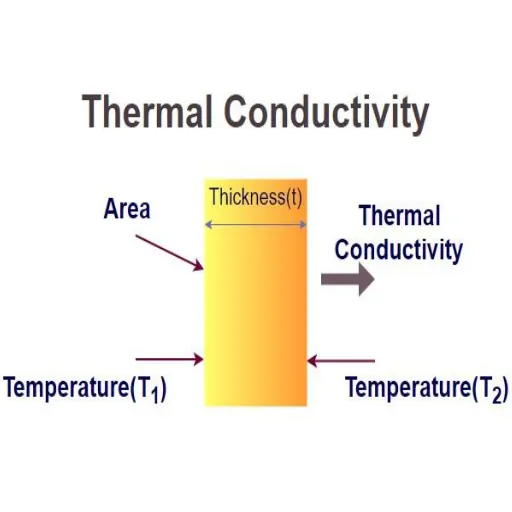

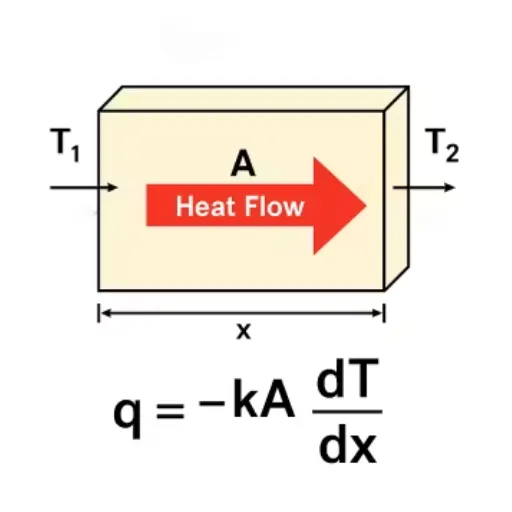

The Concept of Thermal Conductivity

It is also known as how much the material is able to transfer the warmth or heat. It is a measure of the heat flow through the material which is expressed in W/m·K. High thermal conductive materials in some cases are copper and aluminum metals for example, while border insulation low conductive include materials such as wood and plastic.

🔥 Key Thermal Property

Thermal conductivity of stainless steel is not high; rather it is measured to be 16.3 W/m·K at 300 K temperature. However, this can be observed that the other metals do not conduct heat like aluminum and copper, therefore it cannot also manufacture crockery. There can be many instances where one would prefer crockery which is heat resistant and one such material can be found in stainless steel.

With reference to the current information available, thermal conductivity is one of the most significant factors in engineering and design which affects the selection of materials for specific applications. A case in point is stainless steel which has less thermal conductivity than other metals such as copper but is much more resilient in terms of corrosion and wear. Such a compromise on material properties is what makes stainless steel popular in products such as cookware, heat exchangers, and industrial equipment where high thermal efficiency as well as the longevity of the material are equally relevant.

The knowledge of thermal conductivity of a substance makes it possible for engineers to engage in performance and energy conservation improvements, seeking to offer the best solution for the particular situation.

Role in the Selection of the Construction Materials

When it comes to picking potential materials, for example, for exercising engineering or industrial work, thermal conductivity, corrosion resistance, or even mechanical prowess of the material in question may be of great importance. For example, there are various applications from where stainless steel is extensively used due to its capacity to resist severe weather without losing its structural stability for an extended period of time.

🌍 Sustainability Trend: It has been observed that sectors like construction and manufacturing in particular are now more inclined toward promoting use of material design and manufacturing practices that are not only competent but also eco-friendly. This is in line with other objectives pursued around the world in a bid to minimize emissions and increase energy saving measures.

In this way, they can leverage material-specific properties and advanced computing skills among others to confirm that what is turned down for manufacturing will satisfy technical needs as well as dilute the cost while also being sustainable.

Understanding the Mechanisms of Heat Transfer

An understanding of what heat transfer means is a primary requirement among engineers and scientists. In practice, it involves the transference of thermal energy between different bodies or media. Heat is transferred in three main ways: namely, conduction, convection, and radiation.

⚡ Conduction

Heat is transferred inside a solid chain by the movement of atoms across a diffusion boundary. This process relies on the gradients of temperature within a body. Metals are very good at transferring heat because of the free electrons present which helps to transport heat energy.

🌊 Convection

Convection utilizes the movements of fluids that generate heat. This can occur naturally or through externally imposed actions known as pumping or fans. Convection is often used in industrial cooling applications.

☀️ Radiation

Radiation occurs by creating radiant energy and transferring heat from one body to another without any need for a medium. Objects at a high temperature, such as the Sun, radiate heat which is capable of heating other bodies present at a distance.

As the latest data concerning industries indicates, there is a growing concern over innovation strategies incorporating these techniques for thermal system improvement. As an illustration, due to recent breakthroughs in computational fluid dynamics such as CFD, engineer’s understanding has improved owing to air convection and air-ventilation systems, whereas novel materials like aerogels enhance thermal insulation due to advanced control over heat conduction. These applications of energy efficiency not only help construct but also isolate the system in an ecological way, allowing the current issues affecting both domestic and commercial energy sectors to be adequately resolved.

Thermal Conductivity of Stainless Steel

Unrivaled Heat Characteristics of Stainless Steel

Stainless steel dangerously remains unchallenged all the time due to its opportunities provided by its heat characteristics. Firstly, there exists low thermal conductivity as compared to non ferrous components like, aluminium or copper alloys. This feature makes stainless steel perfect for cookware, industrial kilns or boilers and heat exchangers as it does not conduct heat out easily.

Key Heat Characteristics:

- Low Thermal Conductivity: Compared to aluminum or copper alloys, making it ideal for controlled heat applications

- High Temperature Resistance: Can be used even in conditions where very low or very high temperatures are required

- Structural Stability: Retains its inherent shape without changing under temperature variations

- Corrosion Resistance: Combination of thermal properties and resistance to aggressive environments

- Versatile Applications: Perfect for chemical plants and food industries

Factors Influencing Heat Transfer

Heat transfer in materials such as stainless steel takes place based on some factors. One of these factors is the composition of the materials themselves. Conversely, the thermal conductivity of metals such as copper, and aluminum is high owing to their molecular make up whereas the reduced thermal conductivity of stainless steel is due to alloying elements such as chromium and nickel.

Analyzed recent data shows that there are material engineering improvements that are attempting to lessen these disadvantages. For instance, contributing factors, such as enhanced thermal conductivity through specialized alloys and surface improvement techniques, are being worked on and aimed at boosting thermal conductivity of stainless steel mainly for those industries where heat has to be properly managed, for instance, electronics and renewable industries. Hence, these aspects help in the selection of the proper material to use for a certain application, while also promoting the improvement of existing thermal products.

Different Classes of Stainless Steels and Their Behavior to Conduction

There are different types of stainless steels in the market that differ in chemical composition which overlaps with some grade and which influences the thermal conductivity of the steel. Some common stainless steel grades are the 300 series like 304 or 316 stainless steel chiefly found. It is important to note that in terms of corrosion resistance, those types of stainless steel are very resistant but thermal conductance is much less that of the metals such as Aluminum and/or Copper.

Over the years, stainless steels are being developed with modified alloy compositions so as to enhance their physical properties. In simple terms, there are distinct stainless steels in these industries and for specific applications, variations of existing stainless steels have been introduced all which help in achieving an optimal balance in terms of heat management and durability.

Comparing the Thermal Conductivity of Different Metals

Aluminum’s Capacity to Conduct Heat

Aluminum crowns with the highest aluminum’s capacity as an important in the design of mass with temperature due to its high ability to conduct the heat. The thermal conductivity of aluminum high reach is around 205 W/mK at room temperature with many other metal surpassing aluminum. Such degree of conductivity is expressly evident in electronic, automotive industries, architectural work and many others where stress is stridal in evacuating constricting heat.

♻️ Sustainability Advantage: Additionally, observations on aluminum parts shows its recyclable and many times available for use makes it a very attractive option for heat management.

Thermal Conductivity: The Effect of Copper

It is a well-known fact that copper has great thermal conduction since its thermal conductivity is approximately 385 W/(m·K) at ambient conditions. This makes it one of the best thermal conductors among all metals. That is why copper is extensively used in applications where there is a need for efficient heat dissipation like: electrical cables, heat exchangers, cooling systems, etc.

Heat transfer in copper is easier than in aluminum due to it having better energy transfer properties but it is also more expensive and heavier. However with recent improvements in manufacture and alloys, the use of copper has been much improved as the performance of copper has been increased even without any cost increase. Besides, the utility of copper has not gone down and will not because copper is very engineered thus always worth reusing.

Thermal Conductivity of Carbon Steel

Amongst the most commonly used materials across industries is Carbon Steel. It is light, strong, and tough but most importantly cheap which makes it a universal choice in many applications. However, the thermal conductivity of the carbon steel is far less than in copper or aluminum. In particular, the thermal conductivity of stainless steel ranges from 45 to 60 W/ (m – K) depending on the steel grades and composition.

Even in cases where superior thermal conductivity is required, conductors of carbon steels have fewer fans, as most applications, rather than thermal performance, involve other concerns such as mechanicals and this is where carbon steel finds its place. Structures, plant solutions and pipes always require steel most of the time. Due to recent developments in new alloys and coatings; carbon steels’ thermal performance has increased leading to more areas of application for steel without losing basic qualities like cost and strength.

Effective Thermal Conductivity in Industrial Applications

Advantages of Stainless Steel in Heat Exchangers

Stainless steel is advantageous in many ways that qualify it as a perfect material for use in heat exchangers utilized in industrial operations. For a start, it is highly resistant to corrosion, which makes it last longer even when put on moisture, chemical or heat charged conditions. This translates to decreased maintenance costs and increased useful lives of the equipment.

Key Advantages in Heat Exchangers:

- Corrosion Resistance: Lasts longer even in moisture, chemical or heat charged conditions

- Cost-Effective Maintenance: Decreased maintenance costs and increased equipment lifespan

- Efficient Heat Transfer: High capability to conduct heat facilitates energy efficiency in large systems

- Mechanical Strength: Strength and inertia from expansion when temperature changes occur

- Versatile Design: Easy to machine with different grades available for various industries

- Recyclability: Environmentally friendly and supports green initiatives

Further stainless steel stands out for its high capability to conduct heat as compared with other corrosion resistant properties, which facilitates heats transfers and heat exchangers at large systems energy efficiency. In addition, it is other mechanical qualities like stainless steel’s strength and inertia from expansion when temperature changes occur that ensure it will withstand such conditions without bending any parts or breaking.

Also, this type of material is very applicable due to being east to machine and has different grades to choose from to meet the needs of the chemical, power, food and other industries. Because the world is going green, stainless steel can be recycled and because of that it is ‘pro-environment’. Due to new creations in the field of science, it is the versatility and durability of stainless steel that invites the use of such material in various heat exchanger constructions.

High Temperature Environments Usage

Stainless steel is one of the most sought-after materials in high temperature applications because it is resistant to the effects of heat, as well as strong and impervious to oxidation. It is designed to withstand the effects of high temperature and does not flake or scale, hence, it is popularly used in the aerospace industry, power plants, or even petrochemical industries. Some other uses of this material are furnace parts, heat exchangers, and gas turbines.

🔥 High-Performance Grades

According to currently available statistics, it is emphasized that some of the high-performance alloy grades such as the 310 and 316 have been designed in such a way as to survive operating cases beyond 1,000°F (538°C), which is a very high temperature level without significant damage to the metal.

These characteristics possess a good balance which assures success of the material under adverse conditions over the feasible time intervals, hence operational and maintenance predictable costs are low with quite good efficiency rates. More so, it is particularly appealing due to its ability to be fabricated in forms that meet the particular high temperature demands, hence it has been established as the material to use in such situations.

Materials with Low Thermal Conductivity

Materials which possess a very low ability to undertake heat are regarded as poor thermal conductors. These are essential for some applications, mostly in insulation. Ceramic, plastic and certain glasses are among examples of materials that have good insulation. Here by ceramics, it is meant mostly dense refractories resistant to very high temperatures like matrices on micrometers, ovens and other equipment. Polymers have a lot of advantages, for they are light and inexpensive, but these are mostly insulators and items of consumer goods; these materials are sensitive to reheating and they decompose at low temperature.

Low Thermal Conductivity Materials:

- Ceramics: Withstand very high temperatures, used in ovens and industrial equipment

- Polymers/Plastics: Lightweight and cost-effective for consumer devices and insulation

- Glass: Medium thermal properties with excellent clarity and chemical resistance

- Aerogels: Advanced materials with exceptional insulation properties

- Carbon Fibers: Enhanced toughness with minimized heat conduction

The recent data suggest that promotion of successful functionality of low thermal conductivity engineering materials can be done with the assistance of carbon fibres and silica aerogels among other additives. Such tailoring of materials serves a plurality of purposes, such as maximizing their toughness, radical minimization of heat conducted, and most importantly, enhancing their performance. Therefore, it is imperative to comprehend the features of low thermal conductivity constituents and ways of improving them in the context of different sophisticated uses.

Frequently Asked Questions (FAQ)

How does electrical conductivity relate to stainless steel’s thermal conductivity?

The field of conductive heat transfer is where application of the Wiedemann-Franz Law is very common. The existence of this law however is not as much useful when one deals with austenitic stainless steel because of the admixture it exhibits and low free-electron presence in this case. Contrastingly, it is rather impossible to argue that the electrical conductivity of aluminium alloys is lower, unlike the case of different purity grade steels from copper. Further, the thermal conductivity of stainless steel, is only very small as opposed to the highest thermal conductivity value of copper which has values around 600 watt per meter per degree Kelvin. The capacity to have a low heat thermal conductivity in such designs very much appeals to those parts that require impeded heat flow, for instance, energy saving storage chambers, than insulation provisions in joints. In the attempt to achieve both adequate electrical and heat conduction properties, remember that even in terms of electricity, there is moderate conduction in SS (stainless steel) compared to aluminum or copper.

What is the thermal conductivity of metals and where does stainless steel fall?

The thermal conductivity of metals covers a broad range, from the cases where the thermal conductivity of a metal such as silver or copper is at its pick, to the cases where it is reduced to steel. Stainless steel is an example of a common structural metal with particularly low thermal conductivity and is generally well below the thermal conductivity of aluminum which is about 200 W/mK.

There are however some stainless steels that have thermal conductivities at room temperatures as low as 15-25 W/mK when appropriate steels can go up, but are absolutely dwarfed by copper. The advantage of the low thermal conductivity of stainless steel is that it can be used for constructions where heat transfer effects should be minimized, and the required thermal property can be obtained by choosing appropriate types of stainless steels and/or composites thereof.

What can I expect for heat dissipation characteristics in stainless steel as compared to aluminum?

Metals such as aluminum have a higher thermal conductivity compared to stainless steel. It also explains the preference for aluminum when quicker heat removal is wanted. In regard to thermal conductivities, aluminum is close to 200 W/m·K and most stainless steel alloys are contained within tens of W/m·K. Thereby, aluminum stands to multiply the thermal conductivities by roughly ten.

In the application of the thermal conductivity of stainless steel, it is suitable when heat is released in a controlled manner or for the purpose of containing heat where necessary because its thermal conductivity is lower. In addition, besides the durability, corrosion resistance properties of the material superiority steel is among the metals with lowest thermal conductivities however provides better mechanical strength than aluminum. Thus, for example, where thermal conductivity is increased for heat exchanger or some other parts, it is recommended to use aluminum or copper instead of using stainless steel.

What are various applications that use steel of low thermal conductivity other than corrosion resistance?

Unlike in conventional metallic applications, for instance; in structures composed of a thermal break which is either a vacuum jacket, architectural panels, structure or others, low thermal conductivity of stainless steel is advantageous as it assists in isolating the structure thermally, enhancing corrosion resistance and mechanical performance. Heat loss or heating of components that should be protected can be prevented by the use of low thermal conductivity materials in the following areas: components for thermal energy storages and the vitamin pipes.

Therefore, some bio application and food-preparation equipment have stainless steel components detailing which balance the hygiene, the corrosion resistance and heat transfer capability of the equipment. For structures that are equipped with façades and structural steel exposed to architecture, one option is to reduce the stainless or to avail of a thermal break as opposed to CLT as cut through steel arguing that this would cause conduction and condensation. Different grades of stainless steel can be utilized to achieve the desired mechanical and thermal performance under specific conditions.

What are the potential means that engineers may use to improve thermal management of stainless steel components?

The thermal performance of stainless-steel structures can be improved by the engineering choices made in the design, such as those that increase the cross-sectional heat path area, by the inclusion of highly conductive (copper and/or aluminum) inserts, and thermally conductive enhancing surfaces or coatings. Two sets of materials of different thermal conductivities ion, stainless steel and some other material of much higher conductivity, are placed in the same structure, in order to benefit all the properties of each material.

This enhancement is also possible in heat treatment and stainless steel alloy selections, since the thermal conductivity of stainless steel varies and some austenitic stainless steel grades are usually more thermally insulative while ferritic and martensitic are less so, which means that using other grades of stainless steels can improve the characteristics. In cases where thermal conductivity is an issue, the addition of thermal vias and/or the use of conductive fasteners, and the inclusion of structural can assist in heat spreading. Every time components are being enhanced, think about the thermal diffusivity and the overall thermal conductivity of the thermoplastic along with its mechanical properties.

Will the poor thermal conductivity of stainless steel place any limits on the technology uses of thermal storage and heat exchangers?

The use of stainless steel in making high-efficiency heat exchangers is limited by its low thermal conductivity. Nevertheless, it is mainly used earlier as it can withstand high temperatures, hostile environments, and guarantees a long service life. Stainless steel structures are very common in the manufacturing of heat exchangers in thermal storage systems while efforts are made in using those with higher conductivity or augmented inner positions.

Thus, melding together various thermal conductive properties allows attainment of greater strength and better thermal conductivity after fabrication. In cases of high demand for thermal conductivity, integrating copper or aluminum into stainless steel is deployed as a possible design solution. Since, of all the metals, stainless steel has one of the lowest thermal conductivity, it prepares the industry for sophisticated solutions in engineering processes that will avoid or allow bottlenecks of heat to flow and an interest in the factor of resistance offered at the points of contacts. In many industrial applications, the difficulties in thermal measures and aggressive environmental substances or casing strength of stainless steel species are appreciated using the appropriate ironic weakness.

Reference Sources

- Local Thermal Conductivity Mapping of Selective Laser Melted 316L Stainless Steel

This study investigates the thermal conductivity of 316L stainless steel produced through selective laser melting, focusing on variations due to processing. Read the study here - Thermal Contact Resistances in a Thermal Conductivity Test System

This research examines thermal contact conductance between stainless steel pieces using a guarded hot plate thermal conductivity test system. Access the research here - Update of Thermal Conductivity and Electrical Resistivity of Electrolytic Iron, Tungsten, and Stainless Steel

This report provides updated data on the thermal conductivity and electrical resistivity of stainless steel, electrolytic iron, and tungsten across various temperature ranges. View the report here

🎯 Key Conclusions

The concept of thermal conductivity of stainless steel is very important and should be well understood by engineers, designers, and manufacturers produced of different commodities. To an extent the thermal conductivity of the stainless steel is lesser for this metal than for those of copper and aluminum (16.3 W/mK compared to 385 W/mK or 205 W/mK), however this turns out to be an answer for applications that need to have reduced heat flow, resist corrosion and at the same time remain stable in structure. The heat exchanger industry, working at elevated equipment, and low thermal resistance cookware to preservation structural applications and patrons alike is impossible without stainless steel with its recreational temperature porous relations, mechanical denotations and waistline. Knowledge of the various grades, the heat diffusion processes, and how the different properties compare provides the professional, the means to make appropriate decisions about when best to inc;lude which materials in their projects to r;educe reoperation and at the same time ensure that the project brings returns.