Stainless steel enjoys a reputation for being strong, corrosion-resistant, and good-looking. However, you might be wondering if anodizing can even elevate these attributes to another level. This ingenious method improves the strength, working life, and look of the stainless steel, with applications straddling both industrial and consumer areas.

Are you a manufacturer, designer, or even just on the curious side when it comes to cutting-edge metal finishing? Then knowing how anodizing works and what benefits it offers is key to unlocking its potential. In this article, we’ll take a look at the science behind anodizing stainless steel, its practical applications, and some of the impressive advantages it offers.

The Anodizing Process

Anodizing is an electrochemical process used to thicken the natural oxide layer formed on the surface of metals to increase durability and corrosion resistance. Regarding stainless steel, it is, perhaps, the most common method of corrosion enhancement: the metal piece is dipped in an electrolyte bath and voltage is applied, resulting in the formation of a hard oxide layer that can be further colored or treated aesthetically.

What is Anodizing?

Anodizing is a really popular method of electrolysis that helps to improve the metal surface: corrosion resistance or durability, or aesthetics. The anodizing process involves dipping the metal into an electrolyte solution and passing an electric current through the material, causing the surface to oxidize and the formation of a protective oxide film.

This oxide layer is harder than the base metal and can be colored to attain the desired finish. Apart from these, anodized coatings are non-toxic and environmentally friendly, paving the way to the kind of sustainable design and manufacturing industries demand today.

Electrochemical Process Explained

To initiate anodizing, the metal, normally aluminum, is dipped into an electrolyte that can be sulfuric acid. The process involves several key components:

- The metal acts as the anode (positive electrode)

- A cathode (negative electrode) made of stainless steel is placed in the solution

- When current runs, oxygen ions are released from the electrolyte

- These ions react with the metal surface to create a stable oxide layer

Steps in Anodizing Stainless Steel

- Surface Preparation: The stainless steel surface must first be thoroughly cleaned of dirt, grease, or any impurities that could affect anodizing. This step could include degreasing, acid cleaning, or mechanical polishing to provide a smooth and uniform base.

- Electrolytic Bath Setup: The steel is placed in an electrolytic bath that generally contains sulfuric acid or other electrolytes that help the creation of the oxide layer. The composition of the bath can vary depending on the specific anodizing application.

- Anodizing: Current is passed through the acidified bath with the stainless steel acting as an anode. This causes a controlled oxidation to occur, whereby a durable and porous oxide layer is formed on the surface of the metal.

- Coloring (Optional): If additional aesthetic treatment is desired, dyes or pigments are introduced into the pores of the oxide layer, some of which will stain the oxide surface, giving the anodized surface a wide variety of colors while retaining its original qualities.

- Sealing: To improve wear and corrosion resistance, the surface is sealed. This is done either by immersing the anodized steel in boiling water or by using steam or other sealing solutions to close the pores of the oxide layer.

- Final Testing and Quality Control: After anodizing, the final product is subjected to stringent testing to meet specific requirements for consistency in thickness, uniformity, and functionality.

Benefits of Anodizing Stainless Steel

The anodization of stainless steel provides many benefits that enhance both functionality and aesthetics. One of the primary advantages is enhanced corrosion resistance while ensuring long-term durability against harsh environmental conditions.

Corrosion Resistance and Longevity

Corrosion resistance and the lifespan of materials are key considerations influencing a material’s failure and performance in tough situations. Materials like aluminum hugely benefit from processes such as anodizing, which forms a protective oxide layer against corrosion while keeping the material structurally sound over time.

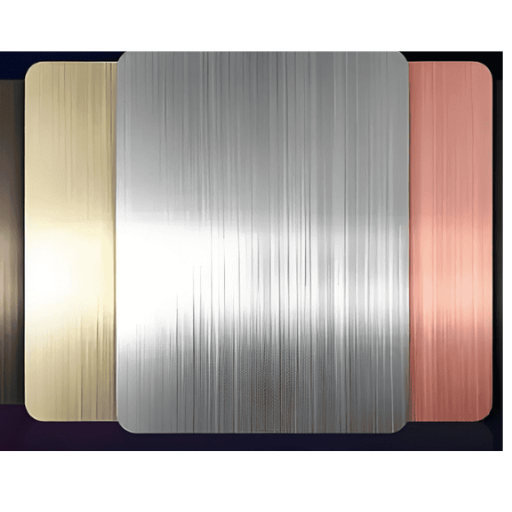

Aesthetic Improvements

The surface treatment process not only imparts strength to materials but also improves their visual appeal. Material scientists can now design surfaces with an almost infinite array of finishes, textures, and colors that satisfy both functional and aesthetic requirements. These modifications cater to industries such as interior design and consumer electronics, where customer preference is based largely on aesthetic appreciation.

Enhanced Surface Hardness

Enhanced surface hardness is achieved through various processes that make the outer portion hard with durable capability to resist abrasion. Modern processes include heat treatments, applying chemical coatings, or alloying surfaces by industrial methods to impart resistance against abrasion, corrosion, and mechanical stress.

Challenges in Anodizing Stainless Steel

Anodizing stainless steel presents unique challenges due to the characteristics of the steel and the engineering complexities of the process. Unlike aluminum, stainless steel does not present the suitable porous oxide layer required for the classical anodizing process, making the formation of a stable uniform coating very difficult.

Key Challenges Include:

- High chromium content that renders traditional anodizing nearly impossible

- Resistance to usual electrochemical reactions

- Need for precise controls and high energy consumption

- Difficulty in obtaining consistent finishes without undermining material integrity

Compatibility with Different Alloys

Anodizing processes are limited in their compatibility mainly depending on the chemical makeup of the alloy and the application for which the material is intended. While aluminum alloys perform well with various electrolyte solutions, other metals face certain challenges:

| Metal Type | Anodizing Compatibility | Common Challenges | Alternative Solutions |

|---|---|---|---|

| Aluminum | Excellent | Minimal challenges | Standard anodizing process |

| Stainless Steel | Limited | Poor oxide layer formation | Passivation, powder coating |

| Titanium | Good | Requires specialized techniques | Modified anodizing processes |

| Magnesium | Moderate | Surface finish quality issues | Hybrid processes |

Costs and Economic Considerations

The costs and economic viability of anodizing processes involve several variable factors:

- Material preparation expenses

- Chemical treatment costs

- Energy consumption (often the biggest expense)

- Waste treatment requirements

- Equipment and facility maintenance

Environmental Impact of Anodizing

Recognized for environmental friendliness among coating or plating methods, anodizing has several eco-friendly characteristics:

- Devoid of harmful heavy metals

- Main byproducts (like aluminum hydroxide) can be recycled or neutralized

- Non-toxic coating suitable for food preparation surfaces

- Relatively low energy consumption compared to other surface treatments

- Enables longer product service life, reducing material waste

Comparisons: Anodized Aluminum vs Stainless Steel

| Characteristic | Anodized Aluminum | Stainless Steel |

|---|---|---|

| Weight | Lightweight – excellent for aerospace and automotive | Heavier but provides substantial feel and strength |

| Corrosion Resistance | Excellent with anodized coating, but coating can wear | Inherent corrosion resistance, especially grades 304 and 316 |

| Strength | Moderate strength, suitable for most applications | Superior mechanical strength for heavy-duty applications |

| Aesthetics | Wide range of colors and textures available | Classic elegant appearance, limited color options |

| Thermal Conductivity | Excellent heat conductor | Poor thermal conductivity |

| Cost | More economical initial investment | Generally more expensive but durable |

Future Trends in Anodized Metals

With the rise of technology and environmental consciousness, the anodizing of metals is opening up for innovation:

- AI Integration: Machine learning for real-time monitoring and precision control

- Green Methods: Bio-electrolytes and closed-loop systems for environmental compliance

- High-Tech Applications: Use in aerospace, electric vehicles, and renewable energy

- 3D Printing Integration: Exploring anodized metals for additive manufacturing

- Nanotechnology: Nanostructured surfaces with specialized properties

Advancements in Anodizing Technology

Enhanced Corrosion Resistance

Modern anodizing focuses on superior corrosion resistance through advanced hydrothermal sealing techniques that significantly increase the lifespan of anodized surfaces.

Improved Dyeing Techniques

Contemporary dyeing methods offer wider color ranges with vibrant hues and consistent application, using high-performance organic and inorganic metallic dyes for enhanced UV resistance.

Micro-Arc Oxidation (MAO)

Also called Micro-Plasma Anodizing, this modern process applies very high voltage levels to deposit ultra-hard ceramic coatings onto aluminum and magnesium alloys, improving wear resistance and thermal stability.

Low-Temperature Anodizing

These approaches reduce energy consumption while forming denser oxide layers, particularly beneficial when hardness and abrasion resistance are priorities.

Nanostructured Coatings

Nanotechnology integration generates specialized surface properties including:

- Anti-reflective coatings

- Self-cleaning surfaces

- Antibacterial functions

- Enhanced wear resistance

References

-

ScienceDirect – Anodization of Medical Grade Stainless Steel for Improved Corrosion Resistance: This study focuses on developing electrochemical etching protocols for anodizing 316L stainless steel, targeting biomedical applications.

-

ACS Publications – Anodized Nanostructured 316L Stainless Steel Enhances Osteoblast Viability: Discusses how anodized stainless steel improves osteoblast functions and prevents bacterial growth, highlighting its biomedical applications.

-

MDPI – Electrodepositing Ag on Anodized Stainless Steel for Enhanced Properties: Explores the anodizing process of stainless steel and its effects on current density and material properties, with applications in advanced coatings.

Frequently Asked Questions (FAQ)

Can you anodize stainless steel?

Stainless steel cannot be anodized like aluminum. The anodizing process is quite specific to metals such as aluminum and titanium, which form a highly porous oxide layer when subjected to an electrochemical process. While stainless steel is corrosion-resistant to some extent, it cannot respond to anodizing in the same manner as aluminum.

What is the anodizing process on stainless steel?

An anodizing process on stainless steel is usually not considered due to the nature of stainless steel as it does not conform well to anodizing. Instead, other methods such as passivation or powder coating are more common to further protect stainless steel parts from corrosion. These processes work to improve stainless steel surface quality and durability.

Can stainless steel parts be anodized?

No, stainless steel parts cannot be anodized in the way aluminum parts can. Anodizing is an electrochemical process that results in an oxide layer on the metal surface, which does not apply to the stainless steel composition. Stainless steel, instead, is coated to provide additional corrosion protection.

How does anodized stainless steel compare to stainless steel?

Anodized stainless steel is an unfrequent expression since stainless steel cannot be anodized. In essence, a powder coating or black oxide finish applied to the stainless steel would confer many of the protective and aesthetic qualities of anodizing products, improving corrosion protection and wear resistance of the steel surface.

What are the benefits of anodizing titanium?

Anodizing titanium provides several benefits such as the enhancement of corrosion resistance, increased wear resistance, and the capability to generate an array of color selections via the anodizing process. Since the anodized finish is highly porous, it can offer excellent adhesion properties for coatings and dyes, thereby making this finish particularly suited to medical equipment and aerospace applications.

What is hard anodized aluminum?

Hard anodized aluminum is a term given to a relatively thicker, more robust anodized layer formed by a specific anodizing process. This form of anodization results in a very corrosion-resistant surface suitable for most applications requiring high-rate wear resistance, e.g., cookware, industrial components.

What is the difference between anodized aluminum and anodized stainless steel?

Anodized aluminum is prepared through an electrochemical process wherein a protective oxide layer is created on the aluminum surface, making it highly resistant to corrosion and allowing for color options. Unlike aluminum, stainless steel cannot be anodized; hence, it depends on other processes such as passivation or powder coating for surface treatment.

What are some treatments to increase corrosion resistance on stainless steel?

Some surface treatments that increase corrosion resistance of stainless steel include passivation, which removes the oxide layer and forms a more protective chromium oxide layer. Other treatments include surface coatings, which could be powdered coatings or black oxide, to put a layer of corrosion protection on top of the stainless steel surface.

What are anodized aluminum properties?

The properties that describe anodized aluminum are corrosion resistance, good surface hardness, and the ability to hold colors and dyes. Due to the anodized finish, it also becomes non-conductive, which makes it suitable for different applications, including electrical components and architectural finishes.