Stainless steel is one of the most versatile and important materials in present-day industries with its use ranging from construction to medical equipment and beyond. Its incredible resistance against corrosion and dulling, coupled with aesthetic appeal, makes stainless steel an integral part of multiple applications.

However, not all types of stainless steel are the same. Different grades serve different purposes with varied properties that make them suitable for specific applications. This comprehensive guide will help you understand the fascinating world of stainless steel grades—their classifications, characteristics, and ideal applications.

Overview of Stainless Steels

Stainless steels are essentially corrosion-resistant alloys, with the major elements being iron, chromium, and other elements such as nickel or molybdenum. The principal attribute that determines a stainless steel’s ability to resist rust and stain is a minimum percentage of 10.5% chromium, which promotes the formation of an invisible protective oxide layer on its surface.

Most common type with excellent corrosion resistance and formability. Used in kitchenware and building applications.

Good corrosion resistance, magnetic properties. Ideal for automotive and industrial applications.

High strength and hardness. Perfect for tools, knives, and cutting instruments.

Combines austenitic and ferritic properties. Excellent for chemical and marine environments.

Definition and Importance of Stainless Steel

Stainless steel is an alloy primarily comprised of iron with chromium content greater than or equal to 10.5% by mass. The presence of chromium imparts exceptional corrosion resistance through the formation of a chromium oxide layer on the surface that remains impermeable and self-healing when damaged.

Key Benefits of Stainless Steel:

- Corrosion Resistance: Superior protection against rust and oxidation

- Durability: Long service life in demanding environments

- Hygiene: Non-porous surface ideal for medical and food applications

- Sustainability: 100% recyclable without property loss

- Versatility: Wide range of grades for specific applications

- Aesthetics: Attractive finish for architectural applications

Key Characteristics of Stainless Steel Alloys

Corrosion Resistance

Stainless steel alloys achieve superior corrosion resistance primarily through chromium content. The chromium forms a passive oxide film on the material’s surface, creating a protective shield that regenerates even when compromised. This property is enhanced by higher chromium levels and the addition of elements like molybdenum or nitrogen.

Strength and Durability

The mechanical properties of stainless steel include high tensile strength and excellent durability, allowing them to withstand significant stress, temperature variations, and prolonged usage. Austenitic grades combine strength with ductility, while martensitic steels offer exceptional hardness for wear-resistant applications.

Thermal and Oxidation Resistance

Specialized grades like 310 or 309 excel in high-temperature applications such as furnace components, heat exchangers, and industrial ovens. Thermal conductivity and expansion coefficients vary among alloys, requiring careful evaluation for specific applications.

Recyclability and Sustainability

Stainless steel alloys are 100% recyclable without any degradation in properties, supporting global sustainability goals. This characteristic reduces raw material mining requirements and minimizes waste in both industrial and consumer sectors.

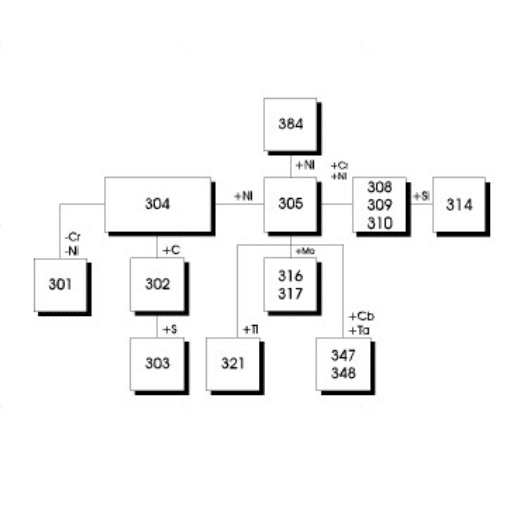

Classification of Stainless Steel Types

The largest category, featuring high chromium and nickel content for excellent corrosion resistance and formability. Grades 304, 316 dominate food processing, chemical, and pharmaceutical industries due to their versatility and hygienic properties.

Key Properties:

- Non-magnetic in annealed condition

- Excellent formability and weldability

- High corrosion resistance

- Good cryogenic properties

Contains chromium with minimal nickel, offering cost-effectiveness and moderate corrosion resistance. Grades 430, 409 are popular in automotive exhaust systems and architectural applications.

Key Properties:

- Magnetic properties

- Good thermal conductivity

- Stress corrosion cracking resistance

- Lower cost than austenitic grades

High carbon content provides exceptional hardness and strength after heat treatment. Grade 420 sees increasing use in surgical applications following healthcare technology trends.

Key Properties:

- High hardness and strength

- Heat treatable

- Moderate corrosion resistance

- Magnetic

Balanced microstructure combining austenite and ferrite phases for superior strength and corrosion resistance. Grade 2205 is essential for offshore oil rigs and desalination plants.

Key Properties:

- High strength-to-weight ratio

- Excellent stress corrosion cracking resistance

- Good weldability

- Cost-effective for high-performance applications

Achieve optimal mechanical properties through specialized heat treatment. Grade 17-4PH offers exceptional strength-to-weight ratios for aerospace and chemical applications.

Key Properties:

- Ultra-high strength after heat treatment

- Good corrosion resistance

- Excellent mechanical properties

- Suitable for extreme conditions

Detailed Analysis of Major Stainless Steel Grades

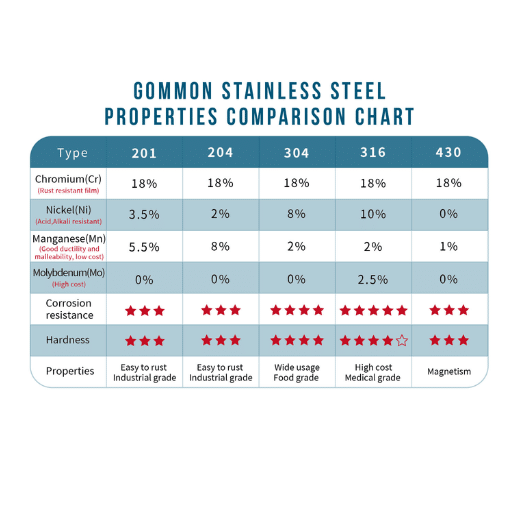

| Grade | Type | Chromium % | Nickel % | Key Features | Primary Applications |

|---|---|---|---|---|---|

| 304 | Austenitic | 18-20 | 8-10.5 | Most versatile, excellent formability | Kitchen equipment, chemical tanks, architecture |

| 316 | Austenitic | 16-18 | 10-14 | Superior chloride resistance (Mo content) | Marine environments, chemical processing |

| 303 | Austenitic | 17-19 | 8-10 | Enhanced machinability | CNC machining, precision components |

| 430 | Ferritic | 16-18 | ≤1 | Magnetic, cost-effective | Automotive trim, appliances |

| 420 | Martensitic | 12-14 | ≤1 | High hardness, heat treatable | Cutlery, surgical instruments |

| 2205 | Duplex | 21-23 | 4.5-6.5 | High strength, excellent SCC resistance | Oil & gas, desalination plants |

Grade-Specific Analysis

304 Stainless Steel: The Most Versatile Grade

304 stainless steel represents the perfect balance of mechanical properties, corrosion resistance, and cost-effectiveness. With approximately 18-20% chromium and 8-10.5% nickel, this austenitic grade offers:

- Excellent weldability: Superior to ferritic and martensitic grades

- Non-magnetic properties: Ideal for electromagnetic applications

- Food-grade compliance: Perfect for hygienic applications

- Temperature versatility: Maintains properties from cryogenic to elevated temperatures

Primary Applications: Kitchen utensils, chemical storage tanks, automotive components, architectural structures, and medical equipment.

316 Stainless Steel: Superior Corrosion Resistance

316 grade stainless steel excels in chloride-rich environments due to its 2-3% molybdenum content, providing enhanced resistance to pitting and crevice corrosion:

- Marine-grade performance: Exceptional resistance to saltwater

- Chemical compatibility: Withstands aggressive industrial chemicals

- Temperature stability: Maintains integrity under thermal stress

- Pharmaceutical compliance: Meets stringent purity requirements

Primary Applications: Marine hardware, chemical processing equipment, pharmaceutical machinery, and surgical implants.

303 Stainless Steel: Enhanced Machinability

Engineered specifically for superior machinability through controlled sulfur content, 303 stainless steel offers:

- Reduced tool wear: Easier cutting and drilling operations

- Improved chip formation: Better surface finish in machined components

- Production efficiency: Faster machining speeds and feeds

- Cost-effective manufacturing: Reduced production time and costs

Trade-off Consideration: Slightly reduced corrosion resistance compared to 304/316 grades due to sulfur content.

Factors Influencing Grade Selection

| Selection Factor | Considerations | Impact on Grade Choice |

|---|---|---|

| Corrosion Environment | Chloride levels, pH, temperature, chemical exposure | Determines minimum chromium/molybdenum requirements |

| Mechanical Requirements | Tensile strength, hardness, ductility, fatigue resistance | Influences choice between austenitic, martensitic, or duplex types |

| Manufacturing Process | Welding, forming, machining, heat treatment needs | Affects formability and processing considerations |

| Temperature Conditions | Operating temperature range, thermal cycling | Determines thermal expansion and oxidation resistance needs |

| Economic Factors | Initial cost, lifecycle cost, availability | Balances performance requirements with budget constraints |

Cost and Availability Considerations

The pricing and availability of stainless steel grades depend on material composition, market demand, and production volumes:

- Standard grades (304, 316): Widely available with competitive pricing due to high production volumes

- Grade 316 premium: Typically costs 20-30% more than 304 due to molybdenum content

- Specialty grades: Duplex and super-austenitic alloys command higher prices due to limited production

- Market factors: Raw material costs (nickel, molybdenum, chromium) significantly impact pricing

Applications Across Industries

Construction and Architecture

- Structural components: Beams, frameworks, and load-bearing elements

- Exterior cladding: Weather-resistant building facades

- Transportation hubs: Airport terminals, train stations

- Architectural features: Handrails, decorative elements

- Roofing systems: Lightweight, energy-efficient solutions

Food and Medical Industries

- Processing equipment: Mixers, tanks, conveyors

- Storage systems: Contamination-free containers and vessels

- Surgical instruments: Scalpels, forceps, scissors

- Medical implants: Orthopedic plates, screws, joint replacements

- Kitchen equipment: Commercial and residential cookware

Industrial Applications

- Chemical processing: Reactors, heat exchangers, piping systems

- Desalination plants: Reverse osmosis units, evaporators

- Automotive industry: Exhaust systems, catalytic converters

- Energy sector: Power plant components, nuclear applications

- Pulp and paper: Digesters, bleaching equipment

Performance Comparison by Application

| Application Area | Recommended Grades | Key Requirements | Performance Advantages |

|---|---|---|---|

| Marine Environments | 316, 316L, 2205 | Chloride resistance, strength | Superior pitting resistance, structural integrity |

| Food Processing | 304, 316, 316L | Hygiene, cleanability | Non-reactive surface, easy sterilization |

| Chemical Processing | 316, 317, 904L | Chemical resistance, temperature stability | Excellent corrosion resistance, long service life |

| Automotive | 409, 430, 304 | Cost-effectiveness, formability | Heat resistance, weight reduction |

| Medical Devices | 316L, 420, 440 | Biocompatibility, strength | Body-safe materials, sterilization resistance |

References

-

Stainless Steel Grade Chart

Stanford University

This document provides a detailed chart of stainless steel grades, including their applications and specifications. -

A Comparison of Stainless Steel Pipe Types

University of Oregon

This paper compares different grades of stainless steel pipes, such as 304 and 316, highlighting their composition and uses. -

Stainless Steel Technical Bulletin

National Institutes of Health (NIH)

This technical bulletin discusses the properties and applications of various stainless steel grades, including 304 and 316, in medical and technical contexts.

Frequently Asked Questions (FAQ)

What are the different types of stainless steel?

Stainless steel exhibits designs and grades, such as austenitic, ferritic, and martensitic stainless steels. Each type possesses its properties and is preferred for certain applications. For example, austenitic stainless steels, e.g., type 304 and type 316, have good corrosion resistance and are very easy to form. This makes them apt for kitchen equipment and chemical processing use.

What is the importance of the American Iron and Steel Institute in stainless steel grades?

The AISI plays an important role in the classification and definition of stainless steel grades. It developed the numbering mechanism to identify various types of stainless steel, such as 304 stainless and 430 stainless, on the basis of their composition and general properties.

What are the properties of 420 stainless steel?

Grade 420 stainless steel is a martensitic stainless steel recognized for its high strength and hardness. It is considered suitable for situations that demand good wear resistance, such as cutlery and surgical tools. The resistance to corrosion is moderate, so it can be used only in particular environments.

How does the corrosion resistance of stainless steel vary among different grades?

The corrosion resistance of stainless steel varies widely among different grades. For instance, type 316 stainless steel resists corrosion better than type 304 stainless steel because it contains molybdenum. Because of this, 316 stainless is best suited for marine applications and high chloride-level environments.

What is the strength of austenitic stainless steel?

Austenitic stainless steel grades, such as type 304 and type 316, possess good strength and toughness even at cryogenic temperatures. Their ability to resist deformation and stress renders them useful in various applications like pressure vessels and structural components.

What are the applications of various stainless steel grades?

Stainless steels of different grades find their applications depending on their properties. For example, 304 stainless steel is used in kitchen appliances, while 316 stainless steel finds use in marine and chemical environments. Ferritic stainless steels like grade 430 find their way into automotive applications and appliances.

What is the chemical composition of stainless steel?

The chemical composition of stainless steel changes from one grade to another. In general, stainless steel consists of iron, chromium, and other alloying elements such as nickel and molybdenum. For instance, type 304 stainless steel typically compromises 18% chromium and 8% nickel, whereas grade 430 stainless steel contains 16% chromium and very little nickel.

What are the differences between austenitic and ferritic stainless steels?

Austenitic stainless steels such as type 304 and type 316 are non-magnetic and have high toughness and ductility, whereas ferritic stainless steels such as grade 430 are magnetic and offer good stress corrosion resistance. The choice between the two stainless steels depends on the application in question and the properties needed.