When selecting materials for construction, fabrication, or industrial applications, stainless steel rectangular tubes stand out as versatile and reliable choices. Among the most popular options are grades 304 and 316 stainless steel rectangular tubes, each offering unique characteristics and advantages for different applications.

This comprehensive guide explores the properties of both grades, comparing their strength, corrosion resistance, and optimal applications. Whether you’re an experienced contractor or business owner exploring material options, this analysis will provide insights to help you make informed decisions that can determine your project’s success.

Introduction to Stainless Steel Rectangular Tubes

What Are Stainless Steel Rectangular Tubes?

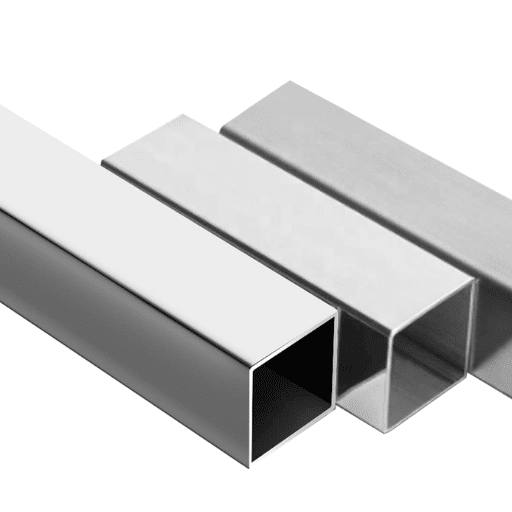

Hollow, rectangular-shaped metal sections made from stainless steel, valued for their structural strength, corrosion resistance, and aesthetic appeal. They feature uniform surface finishes and precise geometrical shapes essential for construction and engineering applications.

Key Advantages

Exceptional durability in indoor and outdoor conditions, easy fabrication capabilities, low maintenance requirements, and versatile applications across construction, automotive, and manufacturing industries.

Common Applications

Structural frameworks, architectural supports, piping systems, decorative elements, and specialized industrial components requiring both functional performance and aesthetic quality.

Material Grade Comparison: 304 vs 316

Understanding the Key Differences

304 Stainless Steel

- Composition: 18% chromium, 8% nickel

- Cost: Most economical option

- Performance: Excellent for general environments

- Applications: Indoor use, standard corrosion conditions

- Market Share: Most popular grade worldwide

Best Choice When: Budget is a priority and environment is not extremely corrosive

316 Stainless Steel

- Composition: 18% chromium, 10% nickel, 2% molybdenum

- Cost: Higher initial investment

- Performance: Superior corrosion resistance

- Applications: Marine environments, chemical processing

- Specialty: Chloride-resistant properties

Best Choice When: Exposure to saltwater, chemicals, or high humidity conditions

Key Characteristics and Properties

Stainless steel rectangular tubes are recognized for their exceptional durability, corrosion resistance, and versatility. The specific grade selection depends on application requirements:

| Property | 304 Grade | 316 Grade | Advantage |

|---|---|---|---|

| Corrosion Resistance | Good | Excellent | 316 for harsh environments |

| Tensile Strength | 515-620 MPa | 515-620 MPa | Similar structural performance |

| Temperature Range | -196°C to 870°C | -196°C to 870°C | Both handle extreme temperatures |

| Weldability | Excellent | Excellent | Both easily fabricated |

| Cost Factor | Standard | 15-20% higher | 304 for budget-conscious projects |

| Marine Applications | Limited | Preferred | 316 essential for saltwater exposure |

Key Insight: Both grades offer excellent tensile strength and lightweight properties compared to traditional materials, while maintaining aesthetic appeal for architectural applications.

Manufacturing Process

Precision Manufacturing for Quality Assurance

1Material Selection

High-grade stainless steel selection ensures optimal corrosion resistance and structural integrity throughout the manufacturing process.

2Melting and Forming

Steel melted in furnaces and poured into rectangular billets, then heated and rolled to required thickness and shape specifications.

3Tube Formation

Piercing creates hollow tubes, followed by cold drawing or extrusion for final dimensions and superior surface finish.

4Advanced Welding

TIG or laser welding joins edges with precision, ensuring both structural strength and aesthetic appearance.

5Heat Treatment

Annealing process relieves internal stresses and optimizes mechanical properties for enhanced performance.

6Surface Treatment

Pickling and passivation enhance corrosion resistance, followed by rigorous quality inspection and testing.

Welding Techniques for Optimal Results

Welding stainless steel rectangular tubes requires precision and expertise to maintain material properties:

Primary Welding Methods:

- TIG Welding (GTAW): Preferred for thin-wall tubes requiring clean, precise welds

- MIG Welding (GMAW): Suitable for thicker materials due to speed and efficiency

- Plasma Arc Welding (PAW): Advanced technique for specialized applications

- Laser Welding: Highest precision with minimal heat-affected zones

Quality Control Standards

Modern manufacturing employs advanced quality control measures:

- Non-Destructive Testing (NDT): Ultrasonic, eddy current, and radiographic evaluation

- Dimensional Inspection: Laser measuring systems ensure precise specifications

- Chemical Analysis: Verify alloy composition and performance characteristics

- AI Integration: Machine learning for predictive analytics and real-time monitoring

Comprehensive Applications

Diverse Industry Applications

Construction & Architecture

Usage: Building frameworks, bridges, structural supports

Benefits: Sleek appearance, weather resistance

Market Share: 30% of global production

Automotive Industry

Usage: Chassis components, exhaust systems, decorative trim

Benefits: High-temperature resistance, lightweight design

Key Advantage: Enhanced fuel efficiency

Healthcare & Medical

Usage: Hospital equipment, surgical instruments, laboratory facilities

Benefits: Meets stringent sanitary requirements

Market Share: 15% of global output

Energy & Power Generation

Usage: Renewable energy systems, oil/gas pipelines, power plants

Benefits: High-pressure resistance, environmental durability

Growth: 10% annual increase expected by 2030

Food & Beverage

Usage: Food-grade piping, storage tanks, processing equipment

Benefits: Prevents contamination, extended operational life

Compliance: 90% of dairy processing equipment

Marine & Offshore

Usage: Offshore platforms, docks, piers, marine structures

Benefits: Saltwater corrosion resistance

Longevity: Decades of safe operation

Structural Applications in Detail

| Application Type | Recommended Grade | Key Benefits | Typical Lifespan |

|---|---|---|---|

| Bridge Construction | 316 (marine), 304 (inland) | Weather resistance, low maintenance | 50+ years |

| Building Frameworks | 304 (standard), 316 (coastal) | Seismic resistance, aesthetic appeal | 75+ years |

| Railway Infrastructure | 304 | High traffic durability, low maintenance | 30+ years |

| Marine Structures | 316 (essential) | Saltwater corrosion resistance | 25+ years |

Ornamental and Decorative Uses

Stainless steel rectangular tubes excel in ornamental applications due to their combination of elegance, strength, and versatility:

- Architectural Elements: Building facades, decorative frameworks, custom installations

- Interior Design: Railings, furniture, contemporary fixtures

- Public Art: Sculptures, monuments, artistic installations

- Commercial Spaces: Retail displays, office environments, hospitality venues

Benefits of Stainless Steel Rectangular Tubes

Why Choose Stainless Steel Rectangular Tubes?

Exceptional Durability

Withstands heavy use and harsh environmental conditions, reducing replacement costs and ensuring long-term performance in demanding applications.

Corrosion Resistance

Chromium forms protective oxide layer, providing excellent resistance to moisture, chemicals, and high temperatures while maintaining structural integrity.

Design Versatility

Suitable for diverse applications from construction frameworks to architectural features, offering both functional strength and aesthetic appeal.

Environmental Sustainability

100% recyclable material supports green building practices and environmental responsibility, making it ideal for sustainable construction projects.

Cost-Effective Long-Term

Higher initial investment offset by reduced maintenance, extended lifespan, and minimal replacement needs, providing excellent return on investment.

Easy Fabrication

Excellent weldability and workability allow for complex designs and custom solutions while maintaining material properties throughout processing.

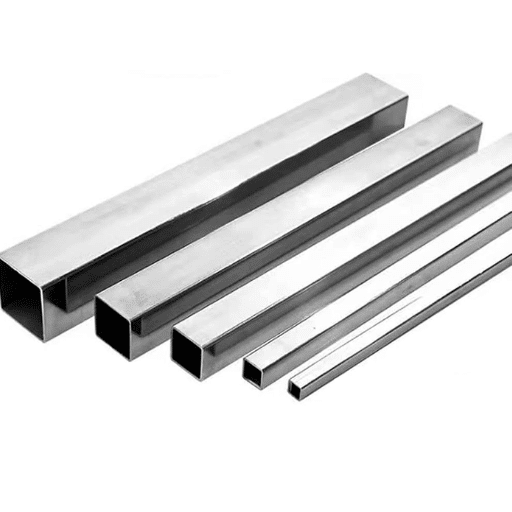

Specifications and Sizing Guide

Standard Size Ranges: Rectangular tubes commonly available from 1″ x 1/2″ up to 10″ x 4″ with wall thickness variations from 0.035″ to 0.5″ depending on structural requirements.

Common Sizes and Wall Thicknesses

| Dimensions (W x H) | Wall Thickness Range | Weight per Foot | Typical Applications |

|---|---|---|---|

| 1″ x 2″ | 0.065″ – 0.125″ | 0.8 – 1.4 lbs | Light framing, decorative |

| 2″ x 3″ | 0.095″ – 0.250″ | 2.1 – 4.8 lbs | Medium structural, furniture |

| 3″ x 4″ | 0.125″ – 0.250″ | 3.8 – 7.2 lbs | Heavy structural, architectural |

| 4″ x 6″ | 0.188″ – 0.375″ | 7.5 – 13.8 lbs | Major structural, industrial |

Understanding A554 Standards

ASTM A554 standards govern welded stainless steel mechanical tubing for architectural, automotive, and structural applications:

- Chemical Composition: Strict limits ensure consistent material properties

- Mechanical Properties: Minimum strength and ductility requirements

- Surface Finishes: Various options to meet aesthetic and functional needs

- Dimensional Tolerances: Precise specifications for critical applications

- International Compliance: Meets global safety and reliability standards

Selection Criteria for Your Project:

- Assess environmental conditions (indoor/outdoor, marine exposure)

- Determine load-bearing requirements and safety factors

- Consider aesthetic preferences and design specifications

- Evaluate budget constraints and long-term costs

- Verify compliance with applicable building codes and standards

Academic and Industry References

- Purdue University – Research Machining Services: Comprehensive documentation on rectangular tube specifications and availability, including stainless steel options

- Academia.edu: “304 Stainless Steel Pipe and Tube” – Detailed analysis of applications and properties for rectangular tube configurations

- Missouri University of Science and Technology: “Material Properties of Cold-Formed High Strength Stainless Steel” – Academic investigation of rectangular hollow section behavior

References

-

Research Machining Services – Materials

Purdue University

This document provides details on the availability and specifications of rectangular tubes, including stainless steel options. -

304 Stainless Steel Pipe and Tube

Academia.edu

This paper discusses the applications and properties of 304 stainless steel pipes and tubes, including rectangular shapes. -

Material Properties of Cold-Formed High Strength Stainless Steel

Missouri University of Science and Technology

This academic paper investigates the behavior of cold-formed high-strength stainless steel square and rectangular hollow sections.

Frequently Asked Questions (FAQ)

What is a stainless steel rectangular tube?

It results from being a hollow section of rectangular cross-section manufactured from stainless steel. It finds innumerable applications due to strength, durability, and corrosion resistance. Available in various grades such as 304 and 316, these tubes are best suited for use in structural and architectural projects.

What sizes does 304 stainless steel rectangular tubing come in?

304 stainless steel rectangular tubing resists corrosion well and is usually high in strength. It meets ASTM standards and comes in a variety of standard sizes and wall thicknesses. This tubing is suited for fabrication projects requiring good mechanical properties and weldability.

How do I select the correct size of stainless rectangular tube for my application?

Choosing the right size stainless rectangular tube will depend on the specifics of your application, including load-bearing requirements, design specifications, and aesthetic considerations. Good suppliers can assist you in deciding which sizes will be most suitable for your needs for one of the many sizes available as standard.

Availability of stainless steel rectangular tubing in stock?

The stainless steel rectangular tubing is available in hundreds of types in the inventory of many large suppliers, offering ornamental rectangular and higher structural options. However, you would probably want to check with the supplier that they keep the size and grade you want.

What are the main uses of stainless rectangular tubing?

The stainless rectangular tubing has uses in various applications-from building structural support to ornamental railings and furniture. That corrosion resistance is suitable for indoor and outdoor jobs, making it a preferred option in many industries.

Can I get a quotation for stainless steel rectangular tubing?

Yes, stainless steel rectangular tubing suppliers furnish quotations. Describe the size, grade, and quantity needed; price will be given against the parameters given by you.

Differences between 304 and 316 stainless steel rectangular tubes?

The difference between 304- and 316-grade stainless steel rectangular tubes is in the composition. They have molybdenum in 316 stainless steel, which enhances its corrosion resistance, especially in a marine environment. Both grades have a wide use, but 316 stands a bit better in situations where corrosion resistance matters most.

Is stainless rectangular tubing available in different finishes?

Depending on finish, the stainless tubular products can be produced in various states such as mill finish, polished, and others. The choice of finish can affect the look of the tubular product and will also determine its corrosion resistance, so it is important that the finish has been chosen in accordance with the requirements of the projects.

How is rectangular stainless tubing fabricated?

Rectangular stainless tubing fabrication is done using welding, cutting, and bending processes. It is easily welded and thus considered an excellent material for structural uses. Fabricators will accommodate a variety of wall thicknesses and sizes to meet the demands of specific projects.