Steel stands as one of the most versatile and widely used materials in the world, favored for its strength, durability, and adaptability. However, when it comes to thermal conductivity, understanding how steel performs relative to other metals and alloys becomes crucial for engineering and manufacturing applications.

This comprehensive guide explores the fascinating world of thermal conductivity in steel under various conditions, comparing steel’s performance to other popular metals and alloys, and examining the critical applications in construction, automotive, and energy sectors.

Introduction to Thermal Conductivity

What is Thermal Conductivity?

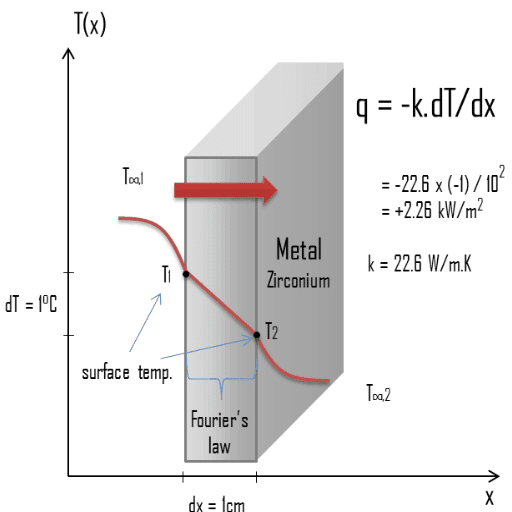

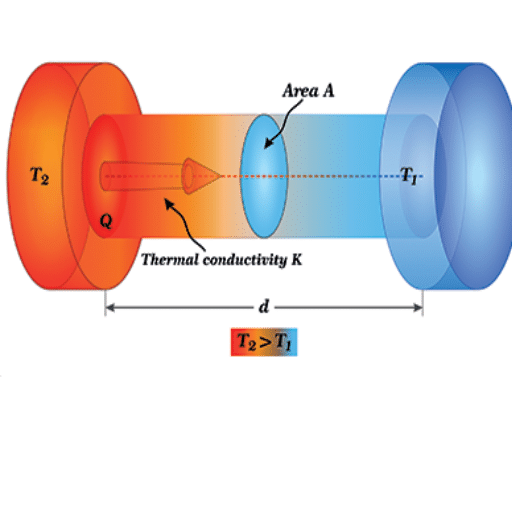

Thermal conductivity measures a material’s ability to conduct heat when there exists a temperature gradient. It represents the rate of heat transfer per unit area per unit temperature gradient, expressed in SI units as W/m·K (watts per meter per Kelvin).

High vs. Low Thermal Conductivity Materials

High Thermal Conductivity

Examples: Copper, Aluminum, Silver

Applications: Heat exchangers, cooling systems, electronic heat sinks

Characteristic: Facilitate rapid heat transfer

Low Thermal Conductivity

Examples: Wood, Rubber, Polystyrene

Applications: Thermal insulation, temperature control

Characteristic: Restrict heat transfer

Overview of Heat Conductivity in Steel

Steel, being an alloy primarily composed of iron with carbon and other elements, exhibits moderate thermal conductivity compared to pure metals like copper or aluminum.

Steel Thermal Conductivity Range

The thermal conductivity of steel varies significantly depending on composition, temperature, and microstructure. This variation makes steel selection critical for specific thermal applications.

Types of Steel and Their Thermal Conductivities

| Steel Type | Thermal Conductivity (W/m·K) | Key Characteristics | Primary Applications |

|---|---|---|---|

| Carbon Steel | 45-57 | High thermal conductivity, affordable | Heat exchangers, boilers, piping systems |

| Stainless Steel | 14-17 | Low thermal conductivity, corrosion resistant | Cookware, aerospace, chemical industries |

| Alloy Steels | Variable | Moderate conductivity, enhanced strength | Automotive engine components |

| Tool Steel | 10-25 | Low conductivity, dimensional stability | Tooling, dies, precision applications |

| HSLA Steel | 20-30 | Balanced thermal/mechanical properties | Structural applications, pipelines |

Carbon Steel Properties

Carbon steel demonstrates the highest thermal conductivity among steel varieties, making it ideal for applications requiring efficient heat transfer. Its properties can be tailored by adjusting carbon content:

- Low Carbon Content: Higher ductility and formability

- High Carbon Content: Increased hardness and strength

- Heat Transfer Applications: Industrial machinery, thermal transport systems

- Cost Efficiency: Excellent performance-to-cost ratio

Stainless Steel Thermal Characteristics

Despite lower thermal conductivity compared to carbon steel, stainless steel offers unique advantages in thermal applications:

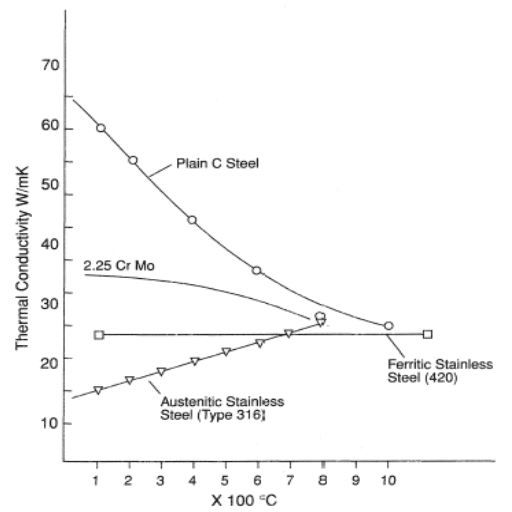

Comparing Different Grades of Stainless Steel

| Stainless Steel Grade | Type | Thermal Conductivity (W/m·K) | Key Features | Applications |

|---|---|---|---|---|

| 304 | Austenitic | 16-25 | Excellent corrosion resistance, formable | Food processing, general applications |

| 316 | Austenitic | 14-16 | Superior chloride resistance | Marine environments, chemical processing |

| 430 | Ferritic | Up to 23 | Magnetic, stress corrosion resistant | Automotive exhausts, architectural |

| 410/420 | Martensitic | Variable | High strength, moderate corrosion resistance | Cutting tools, turbine blades |

| Duplex | Dual-phase | Variable | Excellent strength and corrosion resistance | Petrochemical, offshore applications |

Thermal Conductivity Comparison: Metals vs. Alloys

Comprehensive Metal Conductivity Comparison

| Material | Type | Thermal Conductivity (W/m·K) | Relative Performance |

|---|---|---|---|

| Silver | Pure Metal | 429 | Highest conductivity |

| Copper | Pure Metal | 400 | Excellent conductor |

| Aluminum | Pure Metal | 235 | Good conductor, lightweight |

| Carbon Steel | Alloy | 45-57 | Moderate conductor |

| Stainless Steel | Alloy | 15 | Lower conductor |

| Brass | Alloy | 109-125 | Good conductor |

Measuring and Testing Thermal Conductivity

Common Testing Methods

Laser Flash Analysis

High precision method using laser pulse heating with temperature sensors measuring thermal response. Ideal for solids and offers excellent accuracy.

Transient Plane Source (TPS)

Versatile method suitable for solids, powders, and liquids. Provides direct thermal conductivity measurements using positioned sensors.

Steady-State Methods

Includes guarded hot plate and heat flow meter techniques. Maintains steady temperature gradients for measurement.

Hot Wire Method

Transient method offering rapid testing capabilities across various material types.

Factors Influencing Thermal Conductivity Measurements

Intrinsic Factors

- Material composition

- Crystal structure

- Density

- Temperature effects

Extrinsic Factors

- Impurities and defects

- Porosity levels

- Grain boundaries

- Processing treatments

Applications of Steel’s Thermal Conductivity

Construction and Building Materials

Steel’s intermediate thermal conductivity helps regulate heat transfer in buildings, providing uniform heat distribution through reinforcing structures while limiting thermal stress.

Heat Exchangers

Stainless steel excels in heat exchanger applications, combining good heat transfer properties with durability and corrosion resistance in extreme conditions.

Automotive and Aerospace

High-performance steel alloys in engines, exhaust systems, and thermal shields optimize heat dissipation for improved efficiency and safety.

Cooking Utensils

Stainless steel cookware utilizes moderate thermal conductivity for even heat distribution during cooking while maintaining durability.

Industrial Manufacturing

Steel serves in forging, casting, and welding processes where controlled temperature management is crucial for quality and consistency.

Electronics Cooling

Steel components in thermal management systems help dissipate heat in electronic devices while providing structural support.

Advanced Applications and Considerations

Heat Exchanger Design with Steel

Steel’s role in heat exchanger manufacturing continues to evolve with advanced alloy developments:

- Corrosion Resistance: Stainless steel prevents scaling and rust in harsh environments

- Durability: Extended service life in extreme temperature and pressure conditions

- Efficiency: Optimized heat transfer while maintaining structural integrity

- Compact Design: Enables high-efficiency, space-saving solutions

Building and Construction Implications

Sustainable Construction Benefits

- Recyclability: 100% recyclable without property loss

- Prefabrication: Reduced construction time and costs

- Thermal Management: Controlled heat transfer in building envelopes

- Structural Integration: Combined load-bearing and thermal functions

Future Developments and Trends

Recent developments in material science continue to enhance steel’s thermal applications:

- Advanced Alloy Development: New compositions for specific thermal requirements

- Computational Modeling: AI-enhanced property prediction and optimization

- Sustainable Solutions: Focus on recyclability and environmental impact

- Precision Manufacturing: Improved control over thermal properties

References

-

Thermophysical Properties of Stainless Steels – OSTI (Office of Scientific and Technical Information)

A detailed evaluation of thermophysical properties of stainless steels, including thermal conductivity.

Visit the site -

Thermal Conductivity – Georgia State University

A comprehensive table of thermal conductivity values for various materials, including steel.

Visit the site

Frequently Asked Questions (FAQ)

What is the thermal conductivity of steel?

Steel performs well in conducting heat since it has a relatively high thermal conductivity. Steel, meanwhile, shows variation in its thermal conductivity, typically within a range of 15 to 50 W/m-K, depending on its composition and microstructure.

How does the thermal conductivity of stainless steel bear out in comparison with carbon steel?

Stainless steel generally has less thermal conductivity than carbon steel. Carbon steel is a great conductor of heat, while the thermal conductivity of stainless steel varies more with the alloying elements that reduce its capacity to conduct heat efficiently.

What are the thermal conductivities of metals?

When we compare the thermal conductivities of metals, copper and aluminum possess the highest thermal conductivities, while materials like lead and glass have very low thermal conductivities. Steel varies in the intermediate zones, having an upper hand in being chosen for several applications involving heat transfer.

How can the knowledge of thermal conductivity of metals improve heat transfer?

The knowledge of thermal conductivity of metals empowers an engineer and designer in picking matching materials for specific applications, thus optimizing the heat transfer. For example, highly thermally conductive metals might be used in heat sinks for effective heat dissipation in electronics.

What affects the thermal conductivity of stainless steel?

The factors that affect the thermal conductivity of stainless steel include alloy composition, temperature, and microstructural characteristics. Because changes in one or more of the aforementioned factors produce variation in thermal conductance, stainless steel as a heat transfer material can have varied performance.

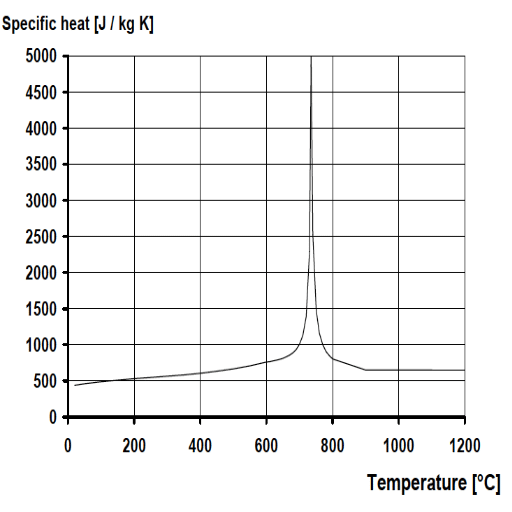

What is the relation between thermal conductivity and heat capacity?

Thermal conductivity and heat capacity are both important thermal properties but they relate to different things. Thermal conductivity is a measure of how well a material is capable of conducting heat whereas heat capacity is a measurement of how much heat must be added in order to increase the temperature of a material. Generally, materials with high thermal conductivity provide quick transfer of heat while those with high heat capacity can store a lot of thermal energy.

How is thermal conductivity measured?

In physics, thermal conductivity is measured in W m-1 K-1 (watts per meter per Kelvin). This unit indicates just how well a given material can conduct heat, pointing to this characteristic for use in applications in which thermal management is of utmost importance.

What are the usual uses of highly thermally conductive materials?

The highly thermally conductive materials such as copper and aluminum find use mostly in heat exchangers, thermal insulation systems, and electronics components like heat sinks. Steel, although, does not conduct heat as much, still finds application wherever strength and definite durability is needed in aid of heat transfer.

What makes some metals good thermal conductors?

Some metals become great thermal conductors due to a high density of free electrons that actually transfer thermal energy. Atomic arrangement and the absence of many different impurities also nicely contribute toward enhancing the capacity of a metal to quickly conduct heat.