Stainless steel rectangular tubing is regarded as one of the most adaptable and solid materials used in numerous industries. These tubes offer unmatched strength, resistance to corrosion and rust, and good looks. But what is the reason for their uniqueness and how can they be used effectively in different applications?

This comprehensive guide will provide you with all the necessary information, including material properties, advantages, and the most common uses, as well as selection tips. If you are a professional looking for practical insights or a DIY enthusiast just checking out your options, this article will give you all the important knowledge to make well-informed decisions.

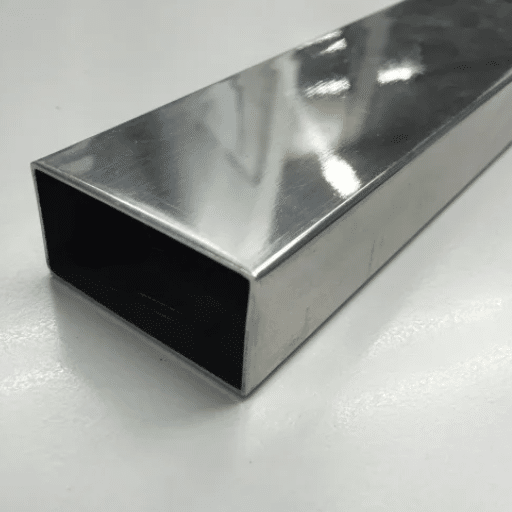

Introduction to Stainless Steel Rectangular Tubes

Stainless steel rectangular tubes are multipurpose and long-lasting parts that find application in numerous sectors. Due to their durability, resistance to rust, and modern appearance, they are frequently used in building, the production process, and art. The tubes perform exceptionally well in different climates and so are considered a dependable option for use in all places both indoors and outdoors. Their constant form and the possibility of customizing them in an easy way add to making them perfect for all kinds of buildings and designs emphasizing beauty or aesthetics.

What is a Stainless Steel Rectangle Tube?

Hollow, elongated structural parts of the rectangle shape made from stainless steel are known to be stainless steel rectangle tubes. They are characterized by their durability, resistance to corrosion, and versatility, hence the wide range of their applications. Their strength makes them suitable for construction, furniture and automotive industries, and architectural framework where they can still be seen even after extreme environments have been prolonged.

One of stainless steel rectangle tubes’ biggest advantages is the fact that they come in a variety of sizes, thicknesses, and finishes meaning one can easily customize them to fit his/her specific project needs. The use of modern fabrication methods and quality materials guarantees not only the long-lasting performance but also the attractive and contemporary look of these components.

Benefits of Using 304 Stainless Steel

304 stainless steel has a remarkable corrosion resistance, which is one of the major advantages of this material, and it can be used in a variety of applications even in the most extreme conditions. The long life and lack of maintenance of the steel are things that I also highly value, as they provide the same reliability over time without regular care. Moreover, the material’s versatility and beautiful surface make it a perfect material for my projects, both in terms of functions and for aesthetic purposes.

Common Applications of Rectangular Stainless Steel Tubing

Construction and Architecture

Rectangular stainless steel tubing, with its solidness and current look, is very suitable for both indoor and outdoor architectural projects. This material is used in various situations like structural frameworks, railings, and supports.

Automotive Industry

High-performance and resistance to harsh conditions are the main requirements for auto parts such as exhaust system, chassis, and structural supports. Therefore, the automotive industry makes use of stainless steel.

Furniture and Interior Design

The rectangle-shaped tubing of stainless steel has a sleek and versatile design that convinces the manufacturers of modern furniture such as tables, shelves, and decorative structures to use it. This material not only gives durability but also elegance in the house.

Industrial Equipment

Stainless steel tubing is applied in the stainless steel conveyor, machine frame, and support systems standard of the industrial equipment due to its high load-bearing capacity and resistance to corrosion even in very demanding conditions.

Marine Applications

The outstanding property that rectangular stainless steel tubing has over other materials in terms of resistance to saltwater corrosion is the reason why it is very much used in the marine industry for components like boat railings, ladder systems, and structural frameworks.

Specifications of Stainless Steel Rectangular Tubes

Stainless steel rectangular tubes are presented in an extensive range of specifications as per various industrial and structural requirements. They are usually made in grades 304, 316, and 409, where each has a specific application based on its resistance to corrosion, strength, and longevity.

Key Specifications:

- Dimensions: From ½ inch to 12 inches in width

- Wall Thickness: 0.5 mm to 20 mm

- Standard Length: 20-foot sections (custom lengths available)

- Tensile Strength: 485 MPa (Grade 304) to 515 MPa (Grade 316)

- Properties: Non-magnetic, weldable, structural integrity across wide temperature ranges

- Surface Finishes: Mill finish, polished, or mirror finishes

These specifications make stainless steel rectangular tubes not only versatile but also reliable for construction, automotive, and marine applications.

Understanding Size and Dimensions

In the case of stainless steel rectangular tubes, their size and dimensions are the main factors that can tell if they are suitable for different applications or not. There is a large variety of standard sizes that can be defined by the width, height, and wall thickness of the tubes.

| Dimension Type | Minimum Size | Maximum Size |

|---|---|---|

| Width x Height | 10mm x 20mm | 100mm x 200mm |

| Wall Thickness | 1mm | 8mm+ |

Recent trends in searches reveal that a number of users ask about the load-bearing capacities of the tubes vis-a-vis their sizes. Data collected so far shows that the structural capacity of a tube is influenced by its dimensions, the grade of stainless steel used, and the stress conditions of the particular application. It is crucial to choose the right size and grade as it guarantees safety and efficiency in construction, automotive, or industrial areas.

Wall Thicknesses in Stainless Steel Rectangular Tubes

Evaluating the wall thicknesses of rectangular stainless steel tubes, one must keep in mind both the application and the stress factors that come with it. The latest search trends and data indicate that one of the most frequent questions users ask is how changing the wall thickness affects the load-bearing capacity and the life of the tubes underneath.

Structurally thicker walls typically increase the load-bearing and stress accepting capacity of the tube. Yet they also cause a lift in the total weight hence the design for efficiency has to take this into account especially in the automotive and aerospace sectors which are using the designs.

Example: A 0.120-inch wall thickness tube may carry moderate loads in light construction but 0.250-inch or more is meant for heavy duty in industrial machines or giving stress realms light like up to 5 times the above-mentioned case.

Corrosion Resistance and Durability

Stainless steel has earned its reputation as a metal that simply does not get rusty, and its ability to last for a very long time even under harsh conditions is the main reason why it is the material of choice in such places that are constantly being contaminated with moisture, chemicals, or extreme heat.

A very recent insight that is drawn from the data provided by Google search trends shows that there has been a substantial increase in the number of people looking for information about which stainless steel grades to use in marine and industrial applications, this indicates that there is a rising need for such materials that could easily resist aggressive corrosive conditions.

Types of Stainless Steel Rectangular Tubing

| Type | Characteristics | Best Applications |

|---|---|---|

| 304 Stainless Steel | Excellent corrosion resistance, durability, versatility | Indoor/outdoor applications with moderate moisture |

| 316 Stainless Steel | Superior resistance to chlorides and corrosive environments | Marine applications, chemical processing, high-salt areas |

| 430 Stainless Steel | Ferritic grade, good corrosion resistance, cost-effective | Aesthetic purposes, less aggressive environments |

| Duplex Stainless Steel | High strength, superior corrosion resistance | Offshore oil wells, chemical processing plants |

| High-Performance Alloys | Highest resistance to stress corrosion cracking, pitting | Extreme conditions, super duplex applications |

304 vs 304L Stainless Steel Rectangular Tubes

304 and 304L rectangular stainless steel tubes are both austenitic stainless steel grades that are very common due to their excellent corrosion resistance, strength, and durability. The main difference between them is the amount of carbon.

| Feature | 304 Stainless Steel | 304L Stainless Steel |

|---|---|---|

| Maximum Carbon Content | 0.08% | 0.03% (Low carbon) |

| Welding Performance | Good | Excellent – reduces carbide precipitation |

| Mechanical Strength | Slightly higher | Standard |

| Cost | Less expensive | Slightly higher |

| Best Applications | General construction, architectural frameworks | Chemical processing, marine environments, heavy welding |

Ornamental Rectangular Stainless Steel Tubes

Rectangular stainless steel tubes have mainly ornamental attributes for use in architecture and aesthetics, which means they can last longer and at the same time have attractive designs. They are used in both modern construction and interior design projects alongside decorative structures where style and functionality are the main concerns.

Current searches show that users’ interest is particularly focused on the benefits of these tubes, such as corrosion resistance, low-maintenance, and adaptability to different finishes, such as brushed or polished surfaces.

Structural vs Industrial Applications

Structural Applications:

- Building Frameworks: Due to their remarkable tensile strength and stability, rectangular tubes are chosen as load-bearing elements in building construction frameworks. They play a role in designs resistant to earthquakes and prolonging the life of the buildings.

- Bridges: These tubes are frequently used in bridge construction as they are not only a very light but also a very strong alternative to traditional materials used thereby giving the structure the ability of being both durable and efficient in carrying the loads under changing stress conditions.

- Facade and Cladding Systems: Rectangular tubes are perfect for modern aesthetics and they are incorporated in facade designs giving not only architectural support but also emphasizing the appeal and sustainability of the structure.

- Canopies and Trusses: The versatility of the tubes has enabled them to build lightweight truss structures for the industrial scale canopies that are wind resistant and eco-friendly.

- Signage and Towers: The tubular structures that are rectangular in cross-section are utilized in the making of large signs and communication towers due to their light weight and strength.

Industrial Applications:

- Machinery Frames: Tubes support the frames of industrial machinery and the machines are kept rigid, aligned properly and able to bear heavy operational stresses.

- Transport and Automotive: The tubes are used in the construction of vehicle chassis and cargo containers to provide enhanced durability while reducing weight hence improving fuel efficiency.

- Storage Racks and Shelving: Industrial storage systems incorporate rectangular tubes because of their great load-bearing ability and resistance to deformation under heavy weights.

- Conveyor Belt Supports: The tubes have become a standard feature in conveyor systems for material handling as they offer both corrosion resistance and mechanical stability.

- Pipelines and Enclosures: Rectangular steel tubes are employed for protective enclosures and pipelines in industries handling fluids, gases, or sensitive equipment, where strength and safety are the primary concerns.

Manufacturing and Welding of Stainless Steel Tubes

The stainless steel tubes manufacturing process comprises several phases that are precise and controlled with the aim, of course, to assure longevity and structural integrity. Firstly, flat stainless steel sheets, often consisting of alloys, such as 304 or 316 grades, are cold-rolled or hot-rolled according to application specifications.

Welding Techniques for Stainless Steel Tubes

Welding of stainless steel tubes is a process where precise methods have to be followed in order to maintain the structure of the weld and at the same time allow the welded part to work properly in its application.

| Welding Method | Advantages | Best Use Cases |

|---|---|---|

| TIG (Tungsten Inert Gas) | Incredible control, high-quality welds, precision | Thin tubing, precision work |

| MIG (Metal Inert Gas) | Faster output, suitable for thicker stock | Higher rate production, thicker materials |

| SMAW (Shielded Metal Arc Welding) | Reliable for field work | Pipes, on-site applications |

| Hybrid (Laser-Assisted TIG) | Combines benefits of multiple techniques | Advanced manufacturing applications |

Common Alloys Used in Rectangular Tubing

- 304 Stainless Steel: One of the most widely used stainless steel grades in rectangular tubing, offering exceptional corrosion resistance, durability, and versatility.

- 316 Stainless Steel: Has good resistance to chlorides and chemicals, mainly used in marine and chemical processing industries.

- Carbon Steel: Very strong and typically a low-cost solution for structural applications. However, requires protective coating to inhibit corrosion.

- 1018 Mild Steel: Popular for precision machining or bending applications due to excellent machinability and weldability.

- 6061 Aluminum Alloy: Strong yet lightweight, corrosion-resistant, used in aerospace, transportation, and architectural applications.

Quality Control in Stainless Steel Tube Production

Stainless steel tube manufacturing is a complex and multifaceted process, quality control of which requires very strict monitoring at every stage. Among the advanced practices adopted:

- Non-destructive testing (NDT)

- Ultrasonic inspections

- Eddy current tests

- Chemical composition analysis via spectrometry

- Automation technologies and machine learning algorithms for real-time defect detection

- Dimensional accuracy checks

- Adherence to standards like ASTM and ISO

Choosing the Right Stainless Steel Rectangular Tube

The correct stainless steel rectangular tube for your application will be determined only after careful evaluation of several critical factors. The main factors are grade of material, the size of the tubing, resistance to rust, and the specific mechanical properties needed for the particular case.

Factors to Consider When Selecting a Tube

- Material Grade: Different grades have different levels of corrosion resistance, tensile strength, and heat tolerance. Grade 304 is versatile, while Grade 316 excels in corrosion resistance for marine or chemical exposure.

- Size and Wall Thickness: Must align with structural load or application requirement specifications to avoid mechanical failures or over-engineering costs.

- Surface Finish: Important for aesthetics or hygiene in applications such as architectural or food processing uses.

- Fabrication Compatibility: Determine if the material will support processes like bending, welding, or machining without affecting integrity.

- Certifications and Compliance: Following standards like ASTM A554 or EN 10219 ensures consistency, safety, and quality.

Obtaining Quotes for Stainless Steel Rectangular Tubes

The securing of quotations requires consideration of several factors:

- Specify the particular type of stainless steel (304, 316, etc.)

- Provide accurate dimensions, wall thickness, and application details

- Verify supplier compliance with international quality standards (ISO 9001)

- Obtain information on compliance certifications and testing procedures

- Analyze bulk order discounts and logistical factors

- Consider shipping lead times and freight costs

Where to Buy Stainless Steel Rectangular Tubing

Several suppliers with excellent reputations provide materials of great quality certified to industry standards:

- Online Metals – Large stock and personalized services

- Metal Supermarkets – Detailed specifications and customer support

- Ryerson – Real-time pricing and technical assistance

- Grainger – Smaller quantities with quick delivery

- McMaster-Carr – Convenience and fast shipping

- AK Steel / ArcelorMittal – Direct manufacturers for large orders or custom dimensions

References

-

Metal Supplier and Tubing Information – Cleveland Institute of Art

Offers details on various tubing shapes, including rectangular stainless steel tubes, and their uses.

Visit the site -

Stainless Steel Pipes and Tubes from Sweden – U.S. International Trade Commission

Discusses the production and specifications of stainless steel tubes, including rectangular welded tubing.

Visit the site -

Research Machining Services – Purdue University

Provides insights into the availability and specifications of rectangular stainless steel tubes, including seamed and seamless options.

Visit the site

Frequently Asked Questions (FAQ)

What exactly is a stainless steel rectangular tube?

A stainless steel rectangular tube is basically a hollow shape that is created with stainless steel and has a rectangular-shaped cross-section. It has become very popular in many different areas such as construction, architecture, and manufacturing because of its robustness and long-lasting nature.

What sizes in standard do 304 stainless steel rectangular tubes come?

Coming in a multitude of standard sizes, 304 stainless steel rectangular tubes are very much suitable for many kinds of applications. Like with different dimensions in widths, heights, and thicknesses of walls, there are different sizes which allow for diversity in design and structural use.

What is the durability against corrosion of rectangular stainless tubing?

The tubing made of stainless steel, particularly that of 304 grade, has the resistance to corrosion owing to the nickel and chromium content prevailing in the alloy. So, it is the best choice for areas with high moisture and chemical exposure.

What are the options specifically regarding the different types of stainless steel rectangular tubing?

The options regarding different types of rectangular stainless tubing are quite extensive, so you have options such as the polished rectangular tubing and the larger rectangular ornamental tubing. Such options open up possibilities for both functionality and aesthetics in the case of industrial and architectural applications.

What is the role of A554 stainless steel in the manufacturing of rectangular tubes?

The usage of A554 stainless steel in the manufacturing of rectangular tubing can be attributed to its mechanical properties and corrosion resistance which are quite favorable. Its being particularly suited for the applications requiring high strength and durability makes it so.

What is the decision-making process for steel grades for rectangular structural tubing?

The decision-making for the steel grades for rectangular structural tubing often comprises 304 and 304L stainless steel. Durability, corrosion resistance, and the ability to fabricate in a variety of environments are the main reasons for these materials being selected.

Is it possible to acquire a price quote for customized sizes of stainless rectangular tubes?

The answer is yes; numerous suppliers give you the chance to get a price quote for customized sizes of stainless rectangular tubes. This option is especially beneficial for those projects that need particular dimensions not found in standard sizes and grades.

Which suppliers carry stainless rectangular tubing in their inventory?

Deliverers of rectangular stainless tubing can be found who offer a variety of steel in the form of standard sizes and finishes. It would be helpful for you to search local stock or online suppliers to locate the product that fits your requirements.