Stainless Steel 304 is among the most widely used materials across industries due to its exceptional combination of strength, corrosion resistance, and versatility. However, one of its critical yet often overlooked properties is its thermal conductivity — a characteristic that directly impacts its performance in various applications, from heat exchangers to cookware.

Understanding the thermal conductivity of Stainless Steel 304 is essential for engineers, designers, and manufacturers seeking to optimize its use in temperature-sensitive environments. This comprehensive guide provides a detailed exploration of how thermal conductivity influences the material’s behavior, its role in practical applications, and why it stands out compared to other grades of stainless steel.

Understanding Stainless Steel

Stainless steel, which is an alloy, is composed of iron, chromium, nickel, and carbon in varying amounts. Its main trait is that it does not rust, which is a result of having at least 10.5% chromium in the alloy. The chromium creates a passive oxide coat on the surface that protects the steel from rusting and degradation due to chemicals.

What is Stainless Steel?

Stainless steel is an alloy that combines several different metals, but its main components are always iron, chromium, and sometimes nickel, molybdenum, or carbon among others. The main feature of this metal is the fact that it is very resistant to both rust and stains and this property is mainly through the addition of chromium in amount not less than 10.5% by weight.

Four Basic Categories of Stainless Steel:

- Ferritic: Magnetic, moderate corrosion resistance

- Austenitic: Non-magnetic, excellent corrosion resistance (300 series)

- Martensitic: High strength, moderate corrosion resistance

- Duplex: Combination of strength and corrosion resistance

Grades of Stainless Steel: Focus on 304

Grade 304 stainless steel is the most versatile stainless steel type and is also the most widely used one. It is considered an austenitic cast, with high chromium (18-20%) and nickel (8-10.5%) content, which together give it superb corrosion and oxidation resistance.

Key Composition: 304 grade has great welding and forming properties, with a tensile strength of around 505 MPa and great elongation at break, maintaining its mechanical strength and ductility.

Common Applications of 304 Stainless Steel:

- Kitchen equipment and cookware

- Chemical containers and storage tanks

- Automotive parts

- Construction materials

- Medical tools and equipment

Comparing 304 and 316 Stainless Steel

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chromium Content | 18% | 16-18% |

| Nickel Content | 8% | 10-14% |

| Molybdenum Content | None | 2-3% |

| Corrosion Resistance | Good for general use | Excellent, especially against chlorides |

| Cost | More economical | Higher cost |

| Best Applications | General purpose, food industry | Marine, chemical processing, surgical implants |

Both types of stainless steel are used extensively in a variety of industries because they offer a remarkable combination of strength, resistance to corrosion, and being easy to work with. However, the primary distinction between them is the makeup of their alloys and the degree of their resistance to particular environmental factors.

Thermal Conductivity of Stainless Steel 304

Thermal Conductivity Value: 16.2 W/m·K at room temperature (20°C)

This characteristic greatly influences its use among different materials, particularly in industries that demand efficient heat transfer management, such as heat exchangers, kitchen utensils, and automotive parts.

Despite having thermal conductivity that is lower than that of aluminum and copper, 304 stainless steel has the advantages of its excellent corrosion resistance, durability, and mechanical strength. Thus, this compromise makes it the most commonly used material where moderate thermal conductivity is enough, but material strength and life are non-negotiable conditions.

Definition of Thermal Conductivity

Thermal conductivity is a property of the material that measures the performance of the substance as a heat carrier. It is the rate at which heat passes through a given material, usually expressed in watts per meter-kelvin (W/m·K). This measure indicates how fast the heat transfer would occur across a material if one side were hotter.

- High thermal conductivity: Material will not resist heat flow, thus more heat can be transferred through it (e.g., copper, aluminum)

- Low thermal conductivity: Material resists heat flow, making it useful as an insulator (e.g., wood, foam)

Thermal Conductivity Values: A Comparative Overview

| Material | Thermal Conductivity (W/m·K) | Application Area |

|---|---|---|

| Diamond | 1000–2200 | Advanced thermal interface materials |

| Copper | 385 | Electrical components, cooling systems |

| Graphite | 200–400 | Thermal interface materials in semiconductors |

| Aluminum | 205 | Heat sinks, solar panels |

| Silicon | 149 | Integrated circuits, photovoltaic cells |

| Carbon Steel | ~50 | Structural applications |

| Stainless Steel 304 | 16.2 | Heat exchangers, cookware, chemical equipment |

| Epoxy Resin (TIMs) | 0.9–2.0 | Bonding layers in electronics |

Factors Affecting Thermal Conductivity in 304 Stainless Steel

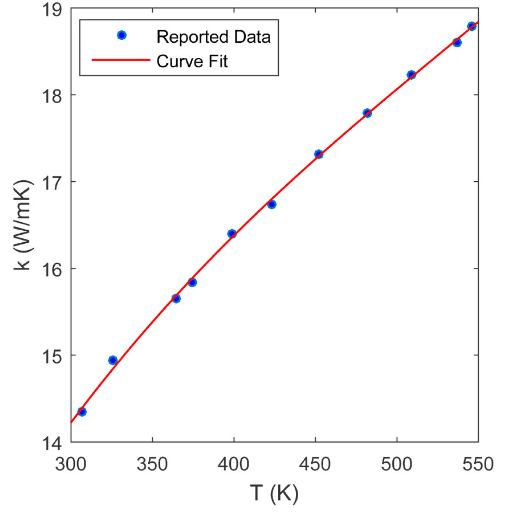

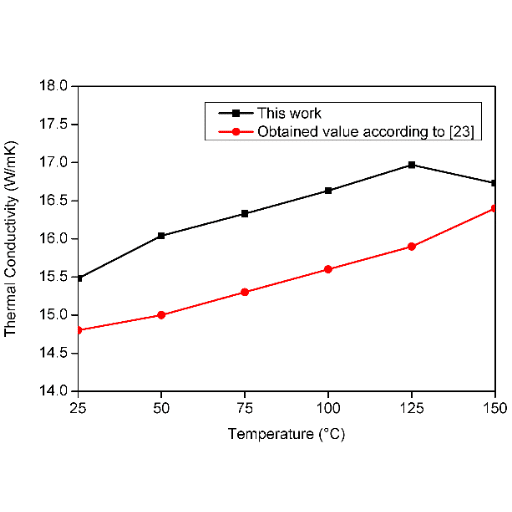

1. Temperature Dependency

Just like most metals, the thermal conductivity of 304 stainless steel reduces with a rise in temperature because the mean free path of electrons decreases as the lattice participates in thermal vibrations to a greater extent.

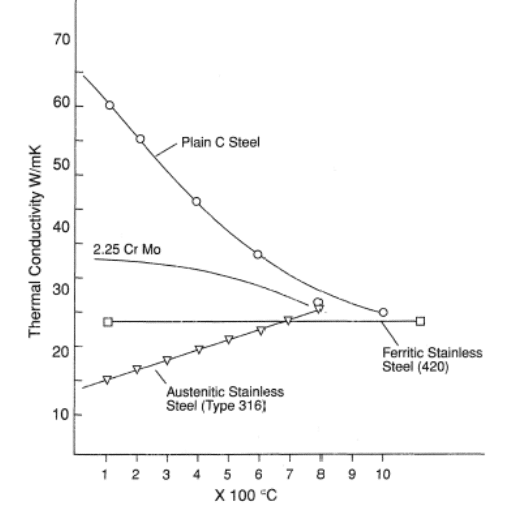

2. Chemical Composition

The presence of alloying elements, for instance, chromium (approximately 18-20%) and nickel (around 8-10.5%), would affect the thermal conductivity very slightly. In addition, impurities or intentional doping for particular applications might change the conductivity even more.

3. Grain Structure

The microstructural properties, such as grain size and the distribution of the grain boundary, are considered the prominent factors of heat transfer. Thinner grain structures virtually offer an unlimited number of borders that can help in the scattering of energy carriers, hence diminishing the thermal conductivity.

4. Cold Working and Mechanical Stress

Cold working or work-hardening methods can cause a change in the crystallographic structure, thus creating defects and dislocations that oppose the flow of thermal energy.

5. Environmental Conditions

These are the surrounding medium and its thermal properties that include whether or not there is contact with heat-conductive surfaces or exposure to insulative materials that can indirectly influence the perceived conductivity in real-life applications.

Properties of 304 Stainless Steel

304 stainless steel is an austenitic stainless steel that has been recognized and appreciated worldwide for its remarkable and good mechanical and chemical properties balance. Generally, its components are 18-20% chromium and 8-10.5% nickel, and these elements are the main reasons for its corrosion resistance and durability in a large spectrum of environments.

Key Properties Overview

| Property | Value/Description |

|---|---|

| Tensile Strength | 505 MPa (500-700 MPa range) |

| Yield Strength | 215 MPa |

| Thermal Conductivity | 16.2 W/m·K (at room temperature) |

| Specific Heat | 0.50 J/g·K |

| Melting Point | 1400–1450°C (2550-2650°F) |

| Density | ~8.0 g/cm³ |

| Magnetic Properties | Non-magnetic (annealed condition) |

Detailed Property Analysis

Corrosion Resistance

304 stainless steel presents high oxidation and corrosion resistance over mild and moderate acids, water, and atmosphere. For example, in case of chloride-rich environments, that is, the susceptibility to pitting corrosion, the use of additional protections or switching to alternative grades (like 316 stainless steel) is the recommended approach.

Mechanical Strength

The tensile strength of about 505 MPa and the yield strength of 215 MPa are the indicators, and thus 304 stainless steel is a structural performance material with reliable quality. These properties provide the alloy the capability of dealing with tough situations; hence its application in construction, automotive parts, and medical devices.

Thermal Properties

At room temperature, the thermal conductivity of 304 stainless steel is about 16.2 W/m·K and this makes it less conductive compared with common carbon steels. But, this character together with its melting point and high-temperature stability (around 1400–1450°C) supports the performance in thermal applications like heat exchangers and kitchenware.

Formability and Weldability

The austenitic structure of 304 stainless steel allows it to be formed and welded easily. It will not lose its internal integrity if it is formed, stretched, or manipulated easily. TIG and MIG welding processes are widely used and give high-quality results without significant risk of cracking or distortion.

Non-Magnetic Properties

304 stainless steel is non-magnetic by nature in the annealed condition. But a slight magnetism may result from cold working because of the formation of martensitic structures.

Specific Heat and Thermal Conductivity Correlation

Key Thermal Relationship:

- Specific Heat: ~0.50 J/g·K – measures energy needed to increase temperature

- Thermal Conductivity: ~16.2 W/m·K – measures how well material conducts heat

The interaction between these two properties guarantees that 304 stainless steel will not fail due to thermal stress. As an example, the material’s moderate thermal conductivity makes it possible for the heat to dissipate efficiently in high-temperature environments, such as in the case of industrial processing or heat exchangers, while its high specific heat capacity allows the material to resist the sudden temperature changes.

Mechanical Properties Impacting Thermal Conductivity

The thermal conductivity of materials such as 304 stainless steel is, to a large extent, dependent on the fundamental mechanical properties:

- Specific Heat Capacity: Determines the energy storage capacity of the material

- Density: Key factor in determining the heat transfer rate

- Thermal Expansion Coefficient: Ensures stability of dimensions even when temperature fluctuates

304 stainless steel’s low to moderate thermal expansion coefficient ensures stability of the dimensions even when the temperature fluctuates, thus the chances of any structural failure are lessened.

Applications of 304 Stainless Steel

Culinary and Food Processing Equipment

304 stainless steel’s non-reactive and corrosion-resistant characteristics make it a perfect choice for the commercial kitchen, cookware, cutlery, and industrial food processing machine. Its stress of acids found in fruits, meats, and dairy products ensures cleanliness and compliance with FDA and NSF norms.

Food Safety: Its smooth surface also aids in cleaning, therefore, reducing the number of bacteria that can contaminate food in the preparation areas.

Medical and Pharmaceutical Equipment

304 stainless steel is chosen for surgical instruments, operating tables, and implantable devices because of its high resistance to sterility compromising factors like chemicals and moisture. Moreover, its biocompatibility guarantees safety during contact with human tissues.

Architectural and Structural Applications

304 stainless steel is widely used in building structures both inside and outside because of its excellent resistance to weathering and tarnishing. It is usually used in:

- Handrails and balustrades

- Façade cladding

- Lift interiors

- Decorative panels

Automotive and Transportation Industry

304 stainless steel is used in everything from decorative trim to exhaust systems and it provides durability and resistance to corrosion even in the harshest of environments. Studies have revealed the material’s capability to resist oxidation even at the highest of temperatures reaching 1,697°F (925°C).

Chemical and Petrochemical Industry

Due to the excellent chemical resistance of 304 stainless steel towards various organic and inorganic chemicals, it is a must in the fabrication of:

- Storage tanks

- Pipelines

- Heat exchangers

- Processing equipment for crude oil refining

- Chemical synthesis equipment

Industrial Applications Requiring Thermal Conductivity

Heat Exchangers

Heat exchangers use materials with the best thermal conductivity to a great extent to quickly transfer heat between two or more fluids. While copper and aluminum dominate due to their high thermal conductivity values, 304 stainless steel offers a balance of thermal performance and corrosion resistance.

Electronics Cooling Systems

Powerful electronic devices like CPUs and GPUs, during operation, produce a large amount of heat. To eliminate overheating and keep the performance at the intended level, thermal interface materials like graphite or thermal paste are used to improve the heat flow from the components to the heat sinks.

Foundry and Casting Processes

Graphite or steel with suitable thermal conductivity used for molds and dies, among others, during the pouring of metals and alloys, facilitate cooling that is performed uniformly. This results in dimensional accuracy and minor defects in the finished castings.

Power Generation Systems

Thermal conductivity is a requirement in steam turbines, boilers, and other components in the power sector. The usage of high-purity ceramics and special alloys has enabled the transfer and resistance of the high-temperature heat energy for electricity generation in the most efficient manner.

Automotive Radiators

Automotive radiators employ aluminum and similar materials, which have high thermal conductivity, to speed up the heat exchange between coolant and air. This makes the engine cooling process efficient, which in turn increases the overall vehicle performance and reliability.

Comparison with Carbon Steel in Heat Applications

| Property | Stainless Steel 304 | Carbon Steel | Aluminum |

|---|---|---|---|

| Thermal Conductivity | 16.2 W/m·K | ~50 W/m·K | 237 W/m·K |

| Density | ~8.0 g/cm³ | ~7.85 g/cm³ | 2.7 g/cm³ |

| Corrosion Resistance | Excellent | Poor (requires coating) | Good (natural oxide layer) |

| Melting Point | 1400-1450°C | 1425-1540°C | 660°C |

| Cost Efficiency | Moderate | Low | Moderate to High |

| Best Use Case | Corrosive environments with moderate heat | Extreme temperature structural applications | High thermal efficiency applications |

Key Comparisons

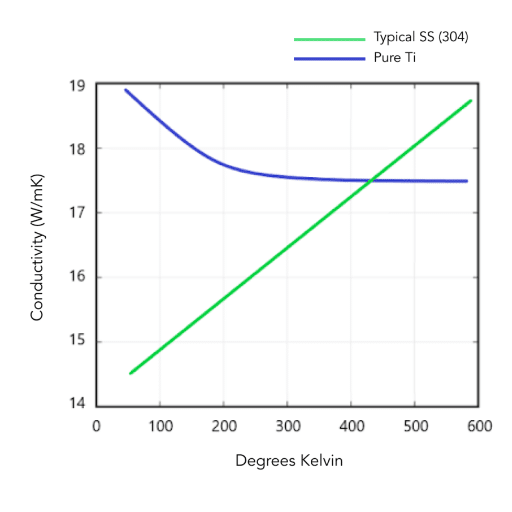

Thermal Conductivity

Aluminum has the highest thermal conductivity level among these metals at 237 W/m·K, almost three times as much as that of carbon steel (around 50 W/m·K), while 304 stainless steel has lower conductivity at 16.2 W/m·K. This fact makes aluminum ideal for heat transfer applications, while 304 stainless steel is chosen when corrosion resistance is equally important.

Weight Efficiency

Aluminum is a very light material with a density of 2.7 g/cm³, while carbon steel has a density of about 7.85 g/cm³ and 304 stainless steel is approximately 8.0 g/cm³. The weight difference makes aluminum preferred in applications where structural mass reduction is important, such as in automotive and aerospace components.

Corrosion Resistance

304 stainless steel and aluminum both have excellent corrosion resistance through natural protective oxide layers. Carbon steel needs to be coated or treated with chemicals to keep it from rusting and deteriorating over time, thereby incurring maintenance and operational costs.

Temperature Tolerance

Carbon steel has the highest melting point (approximately 1425-1540°C), followed by 304 stainless steel (1400-1450°C), while aluminum has a much lower melting point of 660°C. Consequently, carbon steel and stainless steel are considered for extreme temperature resistance applications.

Testing and Data on Thermal Conductivity

Thermal conductivity testing is a process that measures a material’s capacity to conduct heat while keeping the material’s integrity during various conditions. Very accurate instruments are employed for making the calculations, and the outcome of tests consistently validates material performance.

Methods for Testing Thermal Conductivity

1. Laser Flash Analysis (LFA) Method

Process: This method is non-contact and non-destructive, and it consists first, in heating one side of a tiny disc-shaped sample with a brief laser pulse and next, in sensing the temperature increase on the other side.

Applications: Metals, ceramics, and polymers used in critical applications such as aerospace and electronics.

2. Guarded Hot Plate Method

Process: A steady-state practice that requires supporting a sample material on the heated and cooling plates. Rigorously keeping control of the temperature gradients through the sample lets the direct measurement of the thermal flux.

Standards: ISO 8302 and ASTM C177

Applications: Insulation substances, composites, construction materials

3. Advanced Techniques

- Enhanced Infrared Sensors: Improved sensitivity and reduced error margins

- Computational Data Processing: Integration with machine learning algorithms

- Transient Methods: For rapid testing of various materials

Research Data on Thermal Conductivities

Thermal conductivity, the capacity of a substance to carry heat, is a vital factor in numerous engineering and scientific domains. The latest information indicates huge changes in the thermal conductivity coefficients as a result of the material’s makeup and the way the structure is designed.

Recent Research Highlights:

- Metals: Copper and aluminum claim high conductivity (over 200 W/m·K) due to electron movement

- Ceramics: Very low thermal conductivities (often below 10 W/m·K) due to tightly bonded ionic structures

- Graphene-Based Composites: Super thermal conductors with values nearing 5000 W/m·K in perfect conditions

- 304 Stainless Steel: Moderate conductivity (16.2 W/m·K) balanced with excellent corrosion resistance

Practical Implications of Thermal Conductivity Testing

In the design of materials as well as systems for industrial and consumer use thermal conductivity testing is of utmost importance. The exact measurement of thermal conductivity guarantees that the material will satisfy the required thermal performance specifications, especially in demanding application areas:

- Electronics Cooling: Effectively getting rid of heat, avoiding overheating and prolonging device life

- Aerospace Engineering: Maintaining performance under extreme temperature variations

- Renewable Energy Technologies: Optimizing thermal management in solar panels and battery systems

- Thermoelectric Generators: Maintaining temperature gradients necessary for energy conversion

Advanced technologies indicate a growing interest in the creation of nanoengineered materials with adjustable thermal properties. By marrying thermal conductivity testing with computational modeling and machine learning algorithms, engineers and researchers can predict material behavior under varied conditions and accelerate the design of next-generation thermal solutions.

References

-

Determination of Thermal Conductivity of 304 Stainless Steel – University of North Texas Digital Library

Analyzes sensitivity coefficients and experimental designs to estimate the thermal conductivity of 304 stainless steel.

Visit the site -

High-Temperature Characteristics of Stainless Steel – Stanford University

Discusses physical properties, including thermal conductivity and linear expansion, of 300 series stainless steels.

Visit the site -

Material Properties: 304 Stainless (UNS S30400) – NIST

Provides detailed data on thermal conductivity, specific heat, and other material properties of 304 stainless steel.

Visit the site

Frequently Asked Questions (FAQ)

What is the thermal conductivity of stainless steel 304?

Stainless steel 304 has about 16 W/m·K thermal conductivity at room temperature. This feature is playing a significant role in cases where heat transfer is important, for example, in chemical equipment and cooking vessels, like pots and pans.

How does the thermal conductivity of stainless steel compare to other metals?

In the case of thermal conductivity, comparison of stainless steel with other metals shows that stainless steel has lower thermal conductivity compared to metals like copper and aluminum. For instance, the thermal conductivity of copper is around 400 W/m·K and thus it is much more capable of conducting heat than stainless steel.

What are the applications of stainless steel 304 due to its thermal conductivity?

Stainless steel 304’s thermal conductivity is neither too high nor too low that is, it is balanced to a degree, and thus it finds use in a wide range of applications including heat exchangers, cryogenic equipment, and cookware. Moreover, its property of withstanding high temperatures up to 300°C renders it perfectly suited for various engineering applications.

How does the thermal conductivity of 304 stainless steel change at high temperatures?

With the rise in temperature, the thermal conductivity of 304 stainless steel usually increases also. Nevertheless, at much higher temperatures, the material may start to lose some of its structural integrity which is why it is very important to determine the operating conditions in applications like high-temperature industrial processes.

Is the conductivity of stainless steel 304 suitable for engineering applications?

The thermal conductivity of stainless steel 304 is moderate, but its excellent corrosion resistance makes it suitable for many engineering applications. It is often applied in places where thermal and chemical properties are both crucial.

What is the significance of the UNS S30400 designation?

UNS S30400 is the unique designation of a specific type of stainless steel, which is recognized for its resistance to corrosion and extreme durability. The designation also indicates the material’s characteristics, including thermal conductivity, thus helping the engineers and manufacturers in choosing the right one for their applications in different industries.

How does 304 stainless steel perform in cryogenic applications?

In cryogenic applications, 304 stainless steel does not lose its thermal conductivity altogether and hence is still able to transfer heat easily even at very low temperatures thus it is a preferred choice for liquefied gas storage and other applications that require stable condition at cryogenic temperatures.

What factors affect the thermal conductivity of stainless steel 304?

The thermal conductivity of stainless steel 304 can be affected by a number of factors such as its alloying elements, temperature, and grain structure. Furthermore, the existence of impurities or differences in the manufacturing process can also result in variations in thermal performance.

How can I measure the thermal conductivity of stainless steel using an engineering toolbox?

The thermal conductivity of stainless steel 304 can be measured by using instruments that are found in an engineering toolbox like a thermal conductivity meter or a heat flux meter. These devices facilitate precise measurement of heat transfer properties in a range of materials including metals.