Introduction to Stainless Steel

What is Stainless Steel?

Stainless steel is an all-purpose and long-lasting metal mixture consisting mainly of iron, chromium, and sometimes other elements like nickel, molybdenum, and carbon. The element chromium is responsible for the stainlessness of the alloy since it not only forms an oxide that is invisible but also non-reactive and thereby protects the underlying metal from rust and corrosion.

Different grades and types of stainless steel are available including austenitic, ferritic, martensitic, and duplex steel, all with varied properties suitable for the intended applications. Stainless steel enjoys great acceptance and applications in different sectors like construction, medical devices, food processing, and automotive manufacturing due a combination of its strength, hygiene, and aesthetic properties.

Types of Stainless Steel

| Type | Key Grades | Characteristics | Common Applications |

|---|---|---|---|

| Austenitic | 304, 316 | Excellent corrosion resistance, non-magnetic, excellent formability | Kitchen equipment, chemical containers, architectural structures |

| Ferritic | 409, 430 | Moderate corrosion resistance, magnetic properties | Automotive exhaust systems, industrial equipment, appliances |

| Martensitic | 410, 440C | High strength and hardness, heat treatable | Cutlery, surgical instruments, aerospace parts |

| Duplex | 2205 | Great strength, great corrosion resistance | Oil and gas, chemical processing, marine industries |

Importance of Choosing the Right Type

The decision of which stainless steel type to use is very important in determining the project’s success and lifespan. For instance, using a stainless steel grade that is not chloride-resistant in marine applications will eventually bring about very costly failures. Likewise, in the food and drink industry, the use of a non-corrosive grade makes it possible to achieve hygiene and be in line with regulations.

Austenitic Stainless Steel

Austenitic stainless steel is best known for its unrivaled combination of corrosion resistance, strength, and versatility. It is commonly used in the production of medical instruments, automotive parts, and food processing machines because of its capability to keep integrity under the most extreme temperatures and harshest environments.

Properties of Austenitic Stainless Steel

- Excellent Corrosion Resistance: High chromium and nickel content provides superior rust and staining resistance

- Non-Magnetic Properties: Makes it ideal for applications requiring low magnetic interference

- Superior Formability: Excellent for various projects from architectural designs to medical devices

- High-Temperature Performance: Maintains strength and integrity under extreme temperatures

- Durability: Lower maintenance costs in the long run

Common Grades and Their Applications

Grade 304

- Composition: 18% chromium and 8% nickel

- Applications: Food and beverage industry, kitchen equipment, chemical containers, architectural paneling

- Key Features: Best corrosion resistance, formability, and weldability

Grade 316

- Composition: 16% chromium, 10% nickel, and 2% molybdenum

- Applications: Marine environments, medical instruments, pharmaceutical equipment, chemical processing

- Key Features: Superior resistance to chlorides, ideal for harsh environments

Grade 321

- Composition: Similar to Grade 304 with titanium added for improved resistance to intergranular corrosion

- Applications: Aerospace components, exhaust manifolds, heat exchangers

- Key Features: High-temperature resistance and thermal stability

Grade 904L

- Composition: High nickel content (23-28%) and high molybdenum content (4-5%)

- Applications: Oil and gas processing, pollution control, acid manufacturing

- Key Features: Exceptional resistance to aggressive chemical environments

Advantages and Limitations

Advantages

- High Corrosion Resistance: Grades like 304 and 904L withstand critical chemical and environmental conditions

- Durability: Can withstand harsh conditions such as high pressure or high temperature

- Versatility: Different compositions support various applications across multiple industries

- Heat and Oxidation Resistance: Suitable for high-temperature applications

- Excellent Formability: Easy to work with and fabricate into complex shapes

Limitations

- Initial Cost: High-grade stainless steel like 904L can be expensive

- Work Hardening: Hardens quickly during machining, increasing complexity and cost

- Chloride Stress Corrosion Cracking: Some grades like 304 can be sensitive to high chloride levels

- Weight: Heavier than alternatives like aluminum

- Surface Susceptibility: Requires monitoring in aggressive environments

Martensitic Stainless Steel

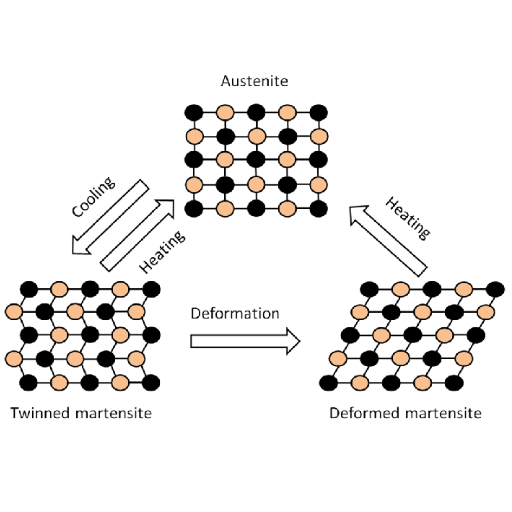

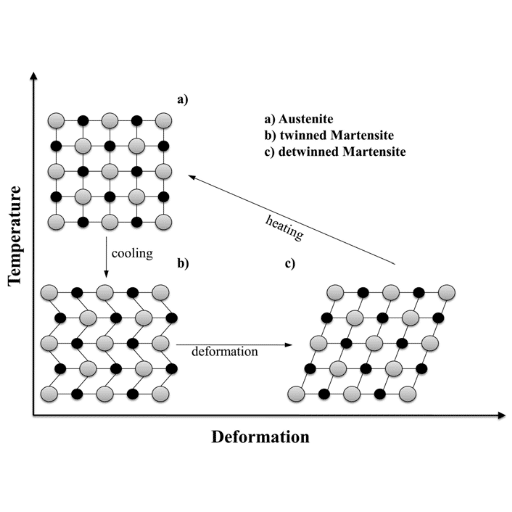

Martensitic stainless steel is classified as a stainless steel that exhibits excellent strength, hardness, and moderate resistance to corrosion as its main features. It consists mainly of iron, chromium, and carbon in a certain proportion that enables it to be heat-treated for improvement to its mechanical properties.

Properties of Martensitic Stainless Steel

- High Strength and Hardness: Best choice for applications requiring durability and wear resistance

- Heat Treatable: Can undergo hardening through quenching and tempering processes

- Magnetic Properties: Ferritic structure makes them magnetic

- Moderate Corrosion Resistance: Chromium content of 12-18%, lower than austenitic grades

- Good Machinability: Easy to machine and weld under certain conditions

Common Grades and Their Applications

| Grade | Properties | Applications |

|---|---|---|

| 440C | High hardness, amazing wear resistance, good corrosion resistance | Knives, tools, bearings, decorative and precision parts |

| D2 Tool Steel | High carbon and chromium content, great wear resistance and edge retention | Cutting tools, dies, industrial blades |

| M2 High-Speed Steel | Excellent toughness, high-temperature softening resistance | Drill bits, saw blades, high-speed cutting tools |

| CPM-S30V | High vanadium and chromium, great corrosion and wear resistance | Knife blades, high-demand tools |

| 17-4 PH | Precipitation hardening, high strength, moderate corrosion resistance | Aircraft, chemical processing, marine equipment |

Advantages and Limitations

Advantages

- High Strength: Unbeatable strength for aerospace and heavy machinery

- Heat Treatment Flexibility: Can be hardened through various techniques

- Dimensional Stability: Maintains precision during heat treatment

- Cost Efficiency: Long-lasting nature reduces replacement costs

- Wear Resistance: Excellent for applications requiring sharp edges and durability

Limitations

- Moderate Corrosion Resistance: Not suitable for extremely corrosive environments

- Brittleness: Can be brittle at maximum hardness, limiting some applications

- Temperature Limitations: Extended exposure above 600°F (316°C) degrades properties

- Fabrication Challenges: Harder to machine and weld than other stainless steels

- Material Cost: Higher than standard stainless steels

Key Differences: Austenitic vs Martensitic

| Characteristic | Austenitic | Martensitic |

|---|---|---|

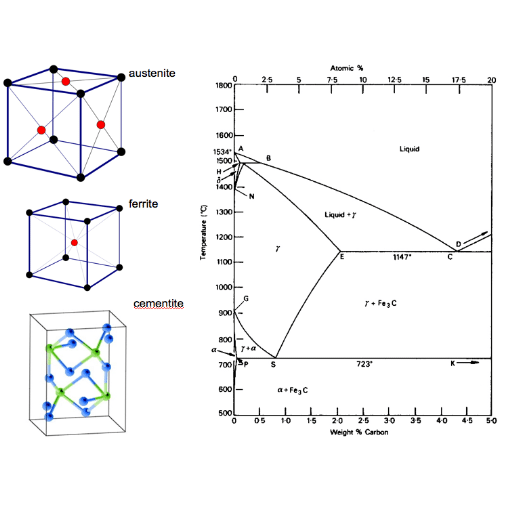

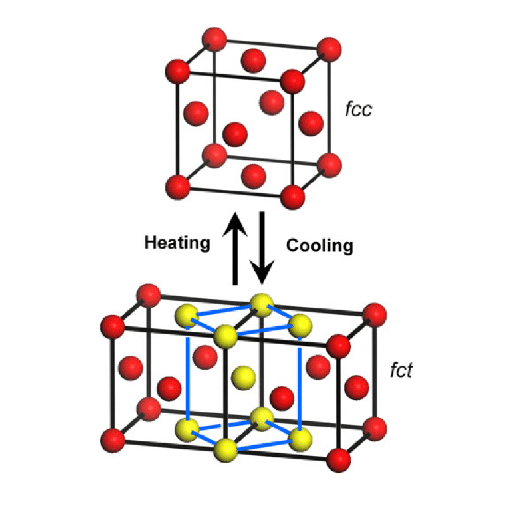

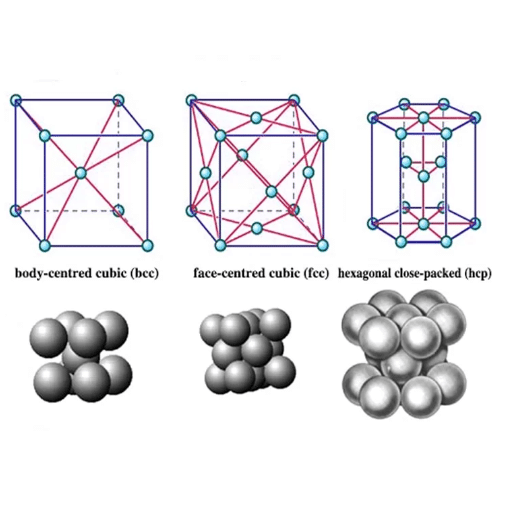

| Crystal Structure | Face-Centered Cubic (FCC) | Body-Centered Tetragonal (BCT) |

| Composition | High chromium and nickel | Higher carbon, lower chromium, little to no nickel |

| Corrosion Resistance | Excellent – ideal for harsh environments | Moderate – suitable for mild environments |

| Strength & Hardness | Lower strength, higher ductility | High strength and hardness after heat treatment |

| Magnetic Properties | Non-magnetic | Magnetic |

| Weldability | Excellent – easy to weld | Challenging – requires special techniques |

| Formability | Excellent | Limited |

| Typical Applications | Kitchen equipment, architectural structures, food processing | Knives, turbine blades, surgical instruments |

Composition and Structure

Austenitic stainless steels consist of high amounts of chromium and nickel which contribute to the face-centered cubic (FCC) crystal structure. This structure allows the alloy to have excellent corrosion resistance and toughness even in very low or very high temperatures. In contrast, martensitic stainless steels are developed from steels with higher carbon content and lower chromium and nickel content, undergoing heat treatment that results in a body-centered tetragonal (BCT) structure with increased hardness and strength.

Mechanical Properties

Martensitic stainless steels are renowned for their remarkable strength and hardness after heat treatment, making them perfect for applications like knives, turbine blades, and surgical instruments. Conversely, austenitic stainless steels offer less strength but more ductility, formability, and impact resistance—typically used in construction, automotive, and food industries.

Welding Austenitic and Martensitic Stainless Steel

The process of welding austenitic and martensitic stainless steels together presents unique challenges due to their different metallurgical properties. Key considerations include:

- Preheating: Essential for martensitic grades to reduce thermal stresses

- Interpass Temperature Control: Prevents formation of brittle phases

- Filler Material Selection: Austenitic alloys with higher chromium and nickel content provide compatible, strong welds

- Post-Weld Heat Treatment: Modern techniques help maintain joint integrity

Applications: When to Use Which Type

Construction and Infrastructure

- Austenitic: Corrosion-resistant and aesthetically pleasing for exterior cladding, railings, and decorative elements

- Martensitic: High-strength structural components requiring durability and wear resistance

Food and Beverage Industry

- Austenitic: Non-reactive and corrosion-resistant for kitchen equipment, storage tanks, and piping systems

- Martensitic: Cutlery and cutting tools requiring sharp edges and durability

Automotive and Transportation Sector

- Austenitic: Heat and corrosion-resistant exhaust systems and trim parts

- Martensitic: High-strength components requiring wear resistance

Marine Applications

- Austenitic: Superior performance in salty and rough sea conditions for shipbuilding and offshore platforms

- Martensitic: Limited use due to moderate corrosion resistance

Industrial Equipment

- Austenitic: Chemical-resistant processing equipment and storage tanks

- Martensitic: Machine parts under high stress with limited corrosive exposure

Ferritic Stainless Steel: A Brief Overview

Ferritic stainless steel falls between austenitic and martensitic in terms of properties. It consists mainly of iron and chromium with very low carbon content, offering:

- Good corrosion resistance (though less than austenitic)

- Excellent oxidation resistance at high temperatures

- Superior thermal conductivity

- Magnetic properties

- Cost-effectiveness

Common Applications

- Automotive exhaust systems (Types 409, 439)

- Kitchen appliances and equipment (Type 430)

- Architectural applications

- Industrial heat exchangers

- Renewable energy systems

References

-

Stainless Steel Microstructure – Princeton University

Explains the microstructure of stainless steels, dividing them into martensitic, ferritic, and austenitic classes, with detailed characteristics.

Visit the site -

Comparison of Stainless Steel Pipe Types – University of Oregon

Provides a comparison of martensitic and austenitic stainless steel pipes, focusing on their strength, hardness, and carbon content.

Visit the site -

High-Temperature Characteristics of Stainless Steel – Stanford University

Discusses the hot-strength characteristics of austenitic, martensitic, and ferritic stainless steels compared to low-carbon unalloyed steel.

Visit the site

Frequently Asked Questions (FAQ)

What is the major difference between martensitic and austenitic stainless steel?

The difference between martensitic and austenitic stainless steels in the main is the crystallographic structure and the resulting attributes. A martensitic stainless steel has a body-centered cubic structure, which gives it high strength and wear resistance, while the austenitic stainless steel has a face-centered cubic structure, which renders it superbly resistant to corrosion and, additionally, ductile.

What are the properties of martensitic stainless steel that make it stand out?

Martensitic stainless steel is characterized by high strength, resistance to wear, and the quality to receive hardness by heat treatment. Its carbon content is typically higher than that of austenitic grades, which, apart from being beneficial for toughness and strength, can also impair the material’s corrosion resistance.

How does 304 stainless steel compare to the other grades of stainless steel?

Stainless steel 304 is one of the most commonly used austenitic stainless steels known for its good resistance to corrosion and easy formability. When compared to martensitic grades, 304 stainless steel shows better resistance to corrosion, but its strength is still generally lower. It belongs to the 300 series of stainless steel, which is characterized by high nickel content.

Is it possible to weld martensitic stainless steel effectively?

Martensitic stainless steel welding is not easy due to the material hardening tendency during the welding process. But with the right methods and filler materials, welding between the two dissimilar steels — austenitic and martensitic — can be done. It requires controlling the heat input and providing the right preheat and post-heat treatments to minimize cracking.

What role do alloying elements play in the case of martensitic and austenitic stainless steels?

Chromium, nickel, and molybdenum, which are the typical alloying elements, are the ones that significantly determine the properties of both martensitic and austenitic stainless steels. For austenitic steels nickel is the element that keeps the austenite phase stable; on the other hand, for martensitic grades, it is the larger carbon content which causes martensite to be formed during heat treatment.

What are the different types of stainless steel in the 300 series?

The 300 series comprises a number of austenitic stainless steels such as 304 and 316 grades. Alloys in this series generally possess very good corrosion resistance and high-temperature strength. The 300 series is often used where good corrosion resistance is needed, unlike the 400 series, which contains more ferritic and martensitic grades and is thus less corrosion resistant.

In what way are 300 and 400 series stainless steel different?

The main difference between 300 and 400 grades of stainless steel is that they have different compositions and characteristics. The 300 series consists of austenitic grades such as 304 which have a high nickel content and are highly resistant to corrosion. The 400 series is less noble and includes martensitic and ferritic steels which are stronger but also less resistant to corrosion.

The key reasons that make austenitic stainless steel popular in many industrial applications?

Austenitic stainless steels have become very popular because of their great resistance to corrosion, ease of processing, and ductility. They are typically employed in fields from kitchen utensils to chemical processing where their durability and resistance to oxidation are indispensable. This characteristic, along with the ability to retain strength at high temperatures, makes them suitable for use in harsh environments.