Overview: The solution annealing process is a critical heat treatment method that significantly enhances the performance and durability of metal parts. This thermal process improves mechanical properties, normalizes material structure, and extends the service life of stainless steel and nickel alloys. Performed at very high temperatures over several hours, solution annealing is an essential technique in aerospace, medical, and industrial applications, ensuring the reliability and strength of critical components.

What is the Solution Annealing Process?

Definition and Overview

Solution annealing is a thermal treatment process designed to improve the characteristics of metal alloys. The process melts specific constituent elements into a single phase at precisely controlled temperatures to achieve uniformity. The metal is then cooled rapidly—sometimes through quenching—to trap elements in their positions and prevent phase separation.

This controlled heating and rapid cooling sequence results in increased corrosion resistance, enhanced strength, and extended material lifetime, making it invaluable for aerospace, medical, and manufacturing sectors.

Historical Background

Annealing is an age-old metallurgical practice that dates back centuries. Ancient blacksmiths discovered that heating metals like bronze and copper, then allowing them to cool slowly, made the metals more workable and stronger. This stress-relieving technique made metals less resistant to hammering and shaping, enabling better fabrication.

Over centuries, this practice has evolved into a scientifically understood process that is now an indispensable component of modern manufacturing. Today’s annealing integrates advanced temperature control and monitoring systems with traditional metallurgical principles.

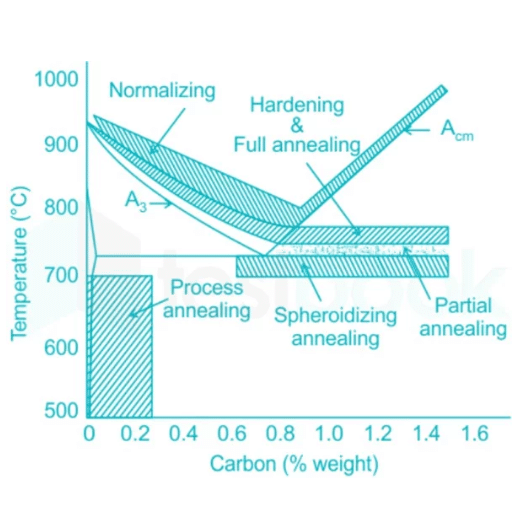

Temperature Ranges for Common Materials

| Material Type | Temperature Range (°F) | Temperature Range (°C) | Purpose |

|---|---|---|---|

| Low-Carbon Steel | 1,200–1,300°F | 649–704°C | Softens material, relieves stress for fabrication |

| High-Carbon Steel | 1,400–1,650°F | 760–899°C | Achieves desired mechanical properties for high-demand applications |

| Austenitic Stainless Steel | 1,850–2,100°F | 1,010–1,150°C | Dissolves carbides, creates homogeneous structure |

Importance of Solution Annealing in Heat Treatment

Solution annealing is a pivotal process in heat treatment, offering extensive advantages critical for industrial applications and material reliability. By heating alloys to specific temperatures and then cooling them rapidly, the process facilitates precipitate dissolution and material structure homogenization.

This treatment significantly improves mechanical properties including tensile strength, ductility, and stress corrosion cracking resistance—properties essential for components exposed to harsh operating conditions. Recent industrial reports indicate that solution annealing is increasingly important in aerospace, medical equipment manufacturing, and power generation sectors, where materials must comply with higher safety and performance standards.

Role in Enhancing Material Properties

Solution annealing has a dramatic impact on material properties by refining the internal structure of metals and alloys. The process works through several mechanisms:

- Elimination of Internal Stresses: Removes residual stresses from previous fabrication or working processes

- Carbide Precipitation Distribution: Alters the distribution of carbide precipitates for improved uniformity

- Ductility Enhancement: Increases material flexibility and resistance to mechanical challenges

- Environmental Resilience: Prepares materials to face environmental challenges and harsh conditions

Modern advancements including computer-controlled temperature cycles and AI-based monitoring systems enable precise tailoring of material properties to meet specific industry requirements, particularly in aerospace, automotive, and medical applications.

Applications of Solution Annealing

Aerospace Industry

Solution annealing is widely acknowledged for enhancing alloy properties in aerospace applications. The process improves corrosion resistance of nickel-based and stainless steel superalloys while strengthening critical components. Turbine blades and aircraft frames—the most stressed parts during operation—are treated to ensure they withstand extreme operational conditions.

Automotive Industry

The automotive sector relies on solution annealing to enhance strength, ductility, and wear resistance of engine and transmission parts. The process is indispensable for producing high-stress environment components with guaranteed reliability and longevity.

Oil and Gas Industry

Pipes, valves, and drilling equipment treated with solution annealing significantly enhance their resistance to chemical corrosion and harsh conditions, thereby prolonging operational life cycles and reducing maintenance requirements.

Medical Devices

Surgical instruments and implants made from medical-grade stainless steel and titanium alloys undergo solution annealing to maximize biocompatibility, corrosion resistance, and durability. This process ensures components meet stringent safety regulations and perform reliably in biological environments.

Power Generation

Power plants employing thermal and nuclear energy use solution-annealed components such as heat exchanger tubes and boiler parts that withstand high temperatures and corrosive conditions, thereby improving efficiency and operational safety.

Industrial Applications of Solution Annealing

| Industry | Key Components | Primary Benefits |

|---|---|---|

| Aerospace | Aircraft parts, turbine blades, engine components, structural elements | Extreme temperature/stress tolerance, superior performance |

| Medical | Surgical tools, implants, medical devices | Strength, precision, biocompatibility, long-term durability |

| Chemical Processing | Heat exchangers, reactors, storage tanks | High-temperature resistance, chemical corrosion protection |

| Automotive | Exhaust systems, engine cylinders, suspension components | Mechanical stress resistance, fatigue durability |

| Oil and Gas | Pipes, valves, drilling equipment, offshore installations | Corrosion resistance, high-pressure performance, reliability |

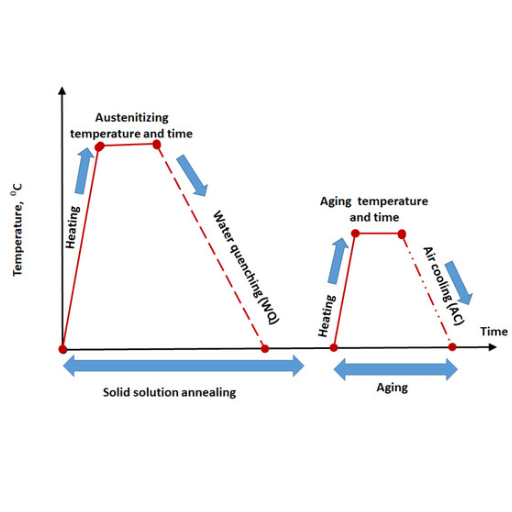

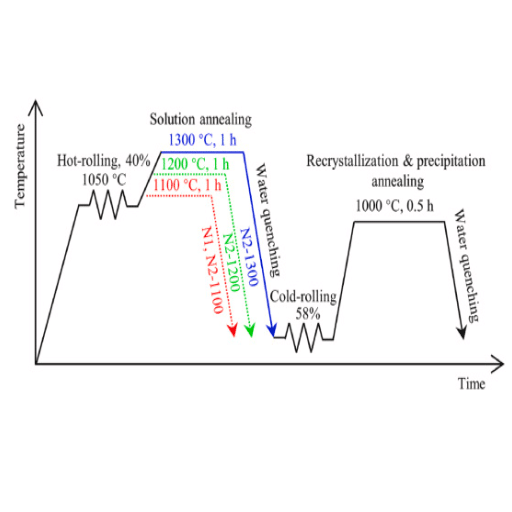

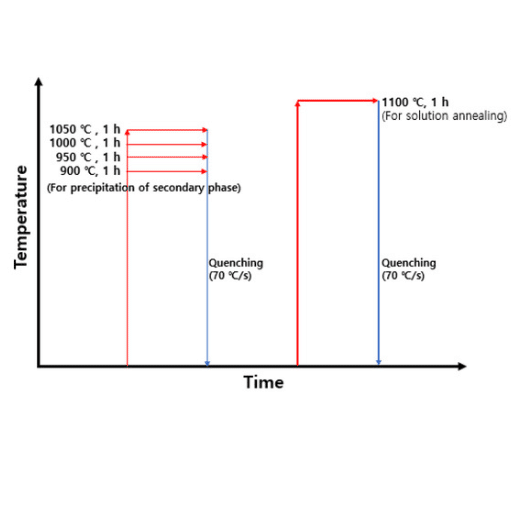

Steps Involved in the Solution Annealing Process

Step 1: Heating

Metal is heated to a specific temperature, generally within the range of 1,850°F to 2,100°F (1,010°C to 1,150°C), depending on alloy composition. This temperature range ensures carbide precipitates dissolve and a homogeneous structure develops.

Step 2: Holding at Temperature

The metal is held at the designated temperature for a specified duration. During this holding period, alloying elements mellow into the matrix, and internal stresses are relieved, resulting in a more uniform material structure.

Step 3: Rapid Cooling (Quenching)

The material is quenched—typically using water, oil, or air—to cool it rapidly and prevent carbide reappearance. This critical step fixes elements in the solid solution, ensuring the material retains improved properties including enhanced corrosion resistance and strength.

Step 4: Finishing

After cooling, finishing processes such as cleaning or descaling remove surface irregularities and prepare the material for subsequent operations.

Materials Commonly Subjected to Solution Heat Treatment

Aluminum Alloys

The most frequently treated materials, aluminum alloys benefit from solution heat treatment due to their widespread use in aerospace, automotive, and building applications. The process significantly increases their strength and durability while maintaining low density.

Magnesium Alloys

Known for low density and excellent heat dissipation properties, magnesium alloys have their ductility and tensile strength upgraded through solution heat treatment. These improvements make them increasingly popular for aircraft and transportation industries, as well as electronic applications.

Titanium Alloys

Renowned for their fantastic strength-to-weight ratio and corrosion resistance, titanium alloys frequently undergo heat treatment to clarify microstructure and optimize properties for critical applications such as medical implants and aerospace components.

Austenitic Stainless Steel

Solution heat treatment dissolves carbides in austenitic stainless steel grades and enhances resistance to intergranular corrosion. This makes the material more reliable for demanding applications where corrosion resistance is paramount.

Nickel-Based Superalloys

These complex alloys benefit significantly from solution heat treatment, optimizing their performance at extreme temperatures. Advanced predictive modeling tools allow engineers to tailor these materials for use in turbines and other high-stress applications.

Cooling Techniques After Annealing

After annealing, cooling techniques are critical to final mechanical and structural properties. Available methods include:

| Cooling Method | Characteristics | Best Used For |

|---|---|---|

| Air Cooling | Slow, natural cooling through air exposure | Metals sensitive to rapid cooling that develop internal stresses |

| Water Quenching | Rapid cooling in water; produces harder material | Materials requiring rapid hardening and strength enhancement |

| Furnace Cooling | Controlled cooling within furnace; best uniformity | Fragile or intricate components requiring consistent properties |

Recent advancements in smart cooling systems have optimized these processes through accurate control of cooling rates, resulting in fewer defects and better overall material performance. The final cooling method selection depends on material composition, required characteristics, and intended application.

Benefits of Solution Annealing

Enhanced Corrosion ResistanceStainless steel’s resistance to localized and general corrosion—including pitting and crevice corrosion—is significantly elevated through even distribution of protective elements like chromium and molybdenum.

Improved Mechanical PropertiesAnnealing creates uniform microstructure, improving ductility and toughness while reducing the probability of brittle fracture during operational stress.

Microstructure StabilizationThe process prevents unwanted carbide or phase formation that could deteriorate material at high temperatures, providing stable microstructure for high-temperature applications.

Prolonged Service LifeSolution-annealed materials demonstrate greater resistance to cyclic loading and harsh environmental conditions, extending operational life and reducing maintenance costs.

Optimized Fabrication PropertiesTreated materials are more convenient to shape, weld, and cut. The process rejuvenates material properties after welding, addressing issues like heat discoloration and sensitization.

Impact Resistance EnhancementPost-treatment materials achieve 20-30% higher impact resistance, making them ideal for applications requiring high structural integrity.

Enhanced Corrosion Resistance in Detail

Enhanced corrosion resistance is an essential outcome of solution annealing, particularly for industries requiring maximum durability and reliability in extreme conditions. The treatment changes alloy microstructure by evenly distributing solute elements like chromium, creating a stable and continuous passive oxide layer on the surface that prevents corrosive agents from reaching the metal interior.

Performance Data: Materials subjected to solution annealing demonstrate as much as 40% improvement in corrosion resistance compared to untreated counterparts. This advancement is crucial in marine engineering, chemical processing, and construction, where materials face regularly harsh environments.

Improvement in Mechanical Properties

Solution annealing significantly improves mechanical properties by restoring ductility, toughness, and tensile strength. The heat treatment process relaxes internal stresses from previous working or fabrication, creating more stable and uniform overall structure.

The process prevents formation of defects like micro-cracking and residual stress concentrations, which could otherwise cause material failure under mechanical loads. These benefits are especially crucial in aerospace, automotive, and power generation industries where precision and material reliability are paramount.

Impact on Fabrication Processes

Solution annealing adoption has significantly influenced current production practices, especially where material durability and structural soundness are key decision factors. Recent statistics indicate growing interest in optimizing fabrication methods to utilize more durable and reliable materials.

Solution annealing solves the challenge of ensuring microstructure uniformity, eliminating stress points, and increasing mechanical properties. The procedure boosts material resistance to environmental degradation and lowers failure rates under high operational loads.

The combination of modern high-temperature treatments with cutting-edge manufacturing methods enables production of parts that endure the most rigorous applications across various industries, reflecting substantial progress in manufacturing innovation.

Material Selection Considerations

Key Factors in Material Selection

When choosing materials for engineering and industrial applications, several interrelated factors must be considered:

- Durability Properties: Tensile strength, ductility, and toughness determine the material’s ability to endure operational stress and strain

- Chemical Properties: Corrosion resistance and reactivity are critical in hot, humid, or chemically aggressive environments

- Cost Considerations: Balance performance requirements against budget constraints to ensure economic viability

- Sustainability Factors: Environmental impact during production, use, and disposal increasingly influences material selection

- Regulatory Compliance: Meeting industry standards and certifications is essential for safety and reliability

Sustainability Trends

Sustainability has become a growing concern in material selection. Current trends show increased adoption of eco-friendly materials and recyclable alloys across industries. This shift reflects tougher environmental regulations and industry commitment to reducing carbon footprints.

Material selection practices now incorporate lifecycle assessments that examine environmental impact throughout production, usage, and end-of-life disposal phases—a significant evolution from previous approaches focused solely on technical specifications.

References

-

“Solution Anneal Heat Treatments to Enhance Mechanical Properties” – A detailed academic study on solution annealing treatments and their effects on mechanical properties.

-

“The Effect of Solution Annealing on the Microstructural Evolution” – A research paper discussing the microstructural changes during solution annealing.

-

“Simulated Annealing” – While this focuses on simulated annealing in optimization, it provides insights into annealing principles.

Frequently Asked Questions (FAQ)

What is the solution annealing process?

The solution annealing process is a heat treatment method that is mostly applied to austenitic steels and copper alloys. The procedure consists of heating the metal up to a certain temperature that is high enough to dissolve any existing precipitates in the metal, keeping the metal at that temperature for a certain time, and finally, cooling down the metal quickly to ambient temperature. This process is performed to make the material more ductile and to improve other mechanical properties as well.

What is the solution annealing temperature for austenitic stainless steels?

The solution annealing temperature for austenitic stainless steels usually lies between 1000°C and 1150°C, depending on the exact composition of the alloy. These temperatures are being used to melt, as well as to produce, the single-phase structure that is necessary for the best performance of the material.

How does the cooling process work in the solution heat treatment?

In the solution heat treatment, after the metal has been heated to the solution annealing temperature, it is cooled quickly, usually by quenching in water or oil. This cooling process is very important because it makes sure that no precipitation occurs as the metal is cooled down through the temperature range it has just come from; in this way, the microstructure made earlier during solution annealing is preserved.

What are the benefits of solution annealing for metal alloys?

The advantages of solution annealing for metal alloys consist of better ductility, higher strength, and more consistent microstructure. The process melts away any resistant particles that might have been in the metal matrix, thus, reducing the overall metal hardness and increasing the metal’s plasticity and stress corrosion resistance, particularly in the case of austenitic stainless steels and copper-based alloys.

Can solution annealing be applied to duplex stainless steels?

Absolutely, solution annealing can be applied to duplex stainless steels. The treatment is heating the alloy to a given temperature to get a proper phase distribution which will make the material stronger and give it better corrosion resistance. The proper solution annealing temperature and cooling rate management is very important so that the precipitate does not form as the metal is cooling down.

What role does diffusion play in the solution annealing process?

Diffusion is a very important factor in the solution annealing process because it enables atoms’ mobility within the metal at high temperatures. Such movement is crucial for the elimination of any existing precipitates and the formation of a uniform microstructure. The diffusion process is further facilitated when the alloy is kept at the solution annealing temperature for a specified duration before cooling.

How does the solution annealing process affect the microstructure of copper alloys?

A great impact of the solution annealing process on copper alloys is the uniformity of phase distribution followed by the reduction of undesirable precipitate existence. With the application of solution annealing, the alloy becomes richer in mechanical properties and corrosion resistance through heating to solution annealing and cooling to the room temperature.

What heat treatment services are available for solution annealing?

Heat treatment services associated with solution annealing generally include heat treatment at customer sites, furnace-based annealing, and custom heating solutions made specifically for certain alloys. The objective of providing these services is to carry out the solution annealing process in a controlled manner, thereby, obtaining the desired properties and microstructure for the metal or metal alloy under treatment.