In order to control the flow and maintain the system efficiency, industrial valves are one of the most important elements of many processes. These are important mechanical instruments that are constructed to regulate, divert or handle the flow of fluids, gases and other substances which is critical for the oil and gas, pharmaceutical, power generation, and water treatment industries. Therefore, how do these simple devices impact the effectiveness of big sophisticated operations?

Here, they will discuss what industrial valves do, what types are available, and how important they are in controlling industrial processes. Whether you’re a professional working in the industry or a student with an interest in this exciting field, we’ll give you some relevant information that is worth your while.

Introduction to Valves in Industrial Applications

The industrial valves are used widely in the process industry for the valve is to begin flow regulation or end it, as well as regulating the distribution pressure and adjusting the velocity of flow to enhance operational efficiency as well as the cautiousness of the system. It is possible to ensure that the flow begins or stops, is put under a certain pressure, or is changed in any other way for the sake of efficiency and safety.

Key Insight: In all available valves, whether the gate, ball, check, or butterfly valves, the preferred one is most often determined by the type of fluid flow and other operating parameters. As the possibility of accurate and stable adjustment increases, the valves are significant in terms of process performance and protection while performing any gas works.

Definition and Importance of Industrial Valves

Industrial valves: a control device used in systems and processes to let gases, liquids or slurries flow in a manner that is safe and efficient, includes regulate or incorporate fluid pathways. The basic purpose is to facilitate the flow or no flow or partial blockage of a pipe or ducts as the operational need vary.

Valve operation is key in almost every droplet industry you may think of:

- Oil and gas operations

- Chemical manufacturing plants

- Power plants

- Water and wastewater treatment facilities

- And many more industrial applications

Modern Smart Valve Technology

Recent statistics emphasizes the crucial chain of process automation and safety operations. The modern day industrial valves are smart and having sensors/IoT enables real time control and monitor as well as predictive maintenance functions. As a result, this enhances the operational efficiency and cuts downs levels of downtimes operations and associated costs.

It is vital for industrial valves to maintain steady state for safety, health and environment that entails process injuries and or equipment damage and or regulatory concerns in very sensitive services where safety is core.

Types of Valves Used in Industrial Processes

| Valve Type | Description | Primary Use |

|---|---|---|

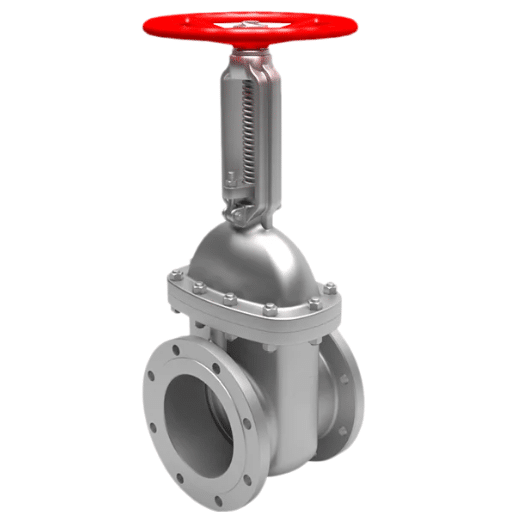

| Gate Valves | Stop valves that don’t foresee throttling; minimal head loss | On/off control with minimal pressure drop |

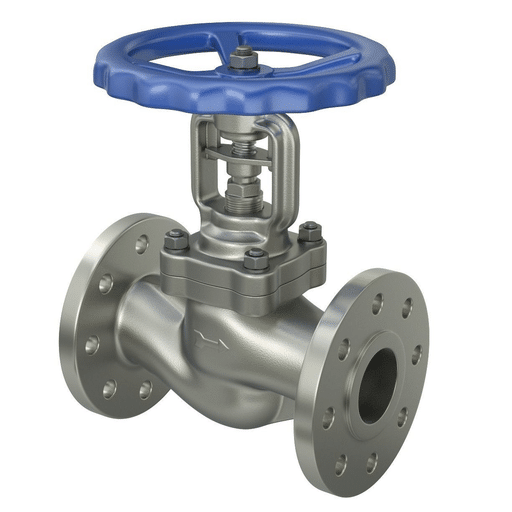

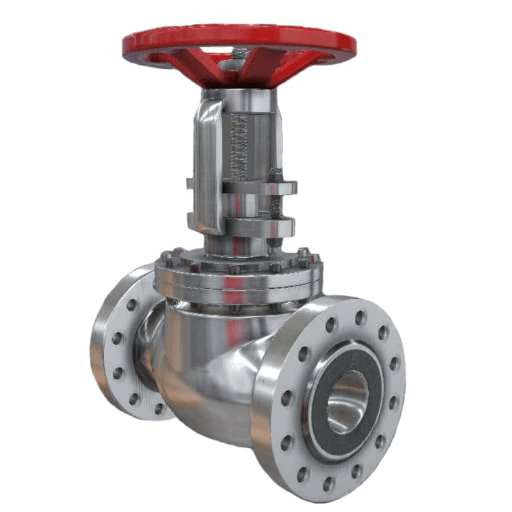

| Globe Valves | Spherical body design for mechanical throttling | Flow regulation, temperature control |

| Ball Valves | Hollow ball design enabling flow adjustment | Positive shutoff in oil and gas pipelines |

| Butterfly Valves | Rotating disc to control flow; lightweight and compact | HVAC systems, water distribution |

| Check Valves | Restricts backward flow of medium | Petrochemical and sewage industries |

| Diaphragm Valves | Uses diaphragm as primary component | Corrosive or dense fluids handling |

| Safety Relief Valves | Opens automatically at established parameters | Chemical processing, power generation |

Overview of Valve Products

Ball Valves

Thanks to their versatility and the fact that they are among the more durable valves used today, ball valves find application in numerous industrial valve systems where shut-off functions are required as in oil and gas, water, lensing, and even petrochemical industries. With a revolving ball inside a shell and a cylindrical hole in the middle, a very basic construction, these units allow a significant degree of adjustment and do not require time-consuming care.

Gate Valves

In situations where a low-resistance straight flow is desirable and preferred, gate valves are the most appropriate for liquid leakage prevention aids. Such valves usually work on the principle of lifting or lowering of the inside flat gate in the opened or closed position of the gate valve. Gate valves are common in industries like municipal water supply, mining, and oil and gas.

Butterfly Valves

Butterfly valves come in handy, cost-effective tools that are used to regulate and control the flow passage. They are equipped with a rotating disc to allow crossing fluid or gas. Butterfly valves are used in heating, ventilation, and air conditioning systems as well as water pipelines because of their functionality and compactness. Trends point at an increasing incorporation of such products in green energy sources such as wind and solar power systems.

Check Valves

These devices allow and partly restrict the flow of the liquid effectively making sure the flow takes place without unwanted backflow. In industrial pumps or pipelines such as sewerage treatment or oil refinery or Marine industry, such non-return valves become very important. Nevertheless, the development of non-return check valves is moving forward with solutions that would meet new age demand.

Industry Insight: According to modern technological developments and reliance on strategically gathered data such as search results provided by Google, the demand for long lasting, highly functional and special purpose valve products is rapidly rising, along with various industrial processes introduced worldwide. The valve industry is engaging in research and development activities to introduce new products made of superior materials, better designs which are eco-friendly.

Ball Valves: A Key Component of Industrial Control

Ball valves have always been recognized as the most important in the list of industrial valves owing to their wide application, effectiveness, and durability in regulating the flow of any fluid. You will find them in the oil and gas industries, chemical industries, water treatment facilities, and manufacturing industries to name a few. Their design is very simple but employs powerful concepts such that the valves are always close fitting hence preventing stress from leakage keeping the operating efficiency at its highest levels possible.

What is a Ball Valve?

We are sure that when you hear the expression “a ball valve,” the very first thing that comes to your mind is the mechanical component of the industrial valves used to control fluids or gases. The name comes from the Valve’s feature which is the crucial part, namely the ball, which is disc shaped and has a hole in the middle.

How It Works: Once the ball or the plug is turned in such a way that the hole remains along the pipeline, flow to the pipeline is unobstructed and flow is flushing out the pipeline. In a 90-degree rotation with respect to the position outline, the hole becomes perpendicular thus forbidding or cancelling every form of flow in the pipeline.

Industrial valves have found use in several sectors of activity, such as the oil and gas, water and water wastewater, paper, chemical, food and beverage operations because of their performance levels, unique service life and tight shut-off capabilities.

Advantages of Using Ball Valves

Superior Sealing

Industrial valves help prevent leakage, even under high pressure or temperature conditions. For this reason, they are used for mission critical functions in sectors such as oil and gas and petrochemical processing.

Strength and Durability

With the use of materials such as Stainless Steel and Brass, the use of Ball valves comes with the guarantee of durability, resistance to wear and tear, and most importantly, corrosion.

Quick Operation

Fluid can be opened and closed quickly within a second in a simple step, because of the quick quarter-turn design of ball valves. Such effectiveness is relevant when shut-off is immediate and critical.

Versatile Applications

These valves can handle different substances. The substances can be in gaseous, liquid or even corrosive form. With these capabilities, they find suitability in various sectors including water purification and food processing.

Lower Pressure Drop

The construction of ball valves has been optimized to reduce pressure loss across the system, thereby ensuring continuous fluid flow. This capability is very important in sustaining the ideals of any process for its efficiency.

Applications and Typical Uses of Ball Valves

| Industry | Application | Key Features |

|---|---|---|

| Petroleum and Natural Gas | Managing flows of oil, gas, and petroleum products | Withstand high pressure and temperatures |

| Manufacturing of Chemicals | Control harsh and dangerous liquid substances | Tolerance to chemical attack, long service life |

| Supply and Treatment of Water | Flow restriction, segregation, cleaning activities | Highly important for water networks |

| Energy Sector | Cooling circuits, feed water systems, steam systems | Operate in severe conditions for guaranteed performance |

| Food Industry | Control and regulate fluid in production plants | Low hygienic requirements, easy maintenance and cleaning |

Control Valves: Ensuring Precise Flow Control

The importance of industrial control valves cannot be underestimated since they enable precise control of the fluid, pressure and temperature to the required level in order to maintain the systems in the industry. Such industrial valves ensure a higher degree of safety, effectiveness and reliability of the process in the oil and gas, chemical, and water treatment industries.

Understanding Control Valves

Industrial valves are very important in most of the industries and are mostly found in manufacturing processes. They are used for changing the rate and pressure or direction of fluid flow or gas. In this case, one may wonder how the latest technological innovations have enhanced the function and effectiveness of these valves.

Smart Control Valves: Smart control valves are now available with the incorporation of new sensors technology as well as Internet of Things (IoT) technology. Based on Google insights, remote control capabilities seem to be a growing trend. This enhancement helps in monitoring the performance of a particular valve in question in real-time, preventing failure occurrences through diagnostics and predictive maintenance, and to define effective maintenance operations.

Types of Control Valves and Their Functions

- Globe Valves: Used for the purpose of flow control; spherical in shape and used where throttling of fluid is desired. Cases, where high pressure or heat is expected, use these types of valves.

- Ball Valves: Called ball valves due to their round and hollow body with a ball insert and a stem for ease of turning towards flow. Very popular in the OFF/ON functionality.

- Butterfly Valves: Similar to ball valves but instead of a ball a rotating disc join the pipe bore. Usually used in applications where large diameters are involved.

- Diaphragm Valves: Has flexible membrane as the throttling element. Aimed at controlling the flow of fluids that can be very corrosive or viscous.

- Plug Valves: Come with a conical or cylindrical plug that regulates the flow of fluids. The cut off function is included a lot of the times.

- Control Ball Valves: A hybrid of the traditional ball valve, designed for flow modulation and not just on/off operation. Very common because of improved accuracy.

Benefits of Implementing Control Valves in Systems

An important feature of today’s systems is that control valves enhance the system and allow accurate control of fluid quantities. Key benefits include:

- Increased accuracy of controlled flow rates

- Energy conservation through reduced pressure losses

- Enhanced automation capabilities

- Minimized human involvement and reduced operational costs

- Real-time feedback and diagnostics through smart sensors

- Improved maintenance strategies and reduced turnaround time

- Enhanced system reliability and equipment durability

- Reduced pressure and flow surges

Automation and the Role of Valves

The Automation Revolution

Automation and new valve technologies have brought about a revolution in industry, efficiency, and safety. Majority of present-day valves have now been automated with sensors, actuators, and internet of things in their design. Because of such developments, operators are able to perform long distance process control with such a level of accuracy that there is instant feedback.

It can be observed from search data analysis that there is an increase in the need for smart solutions on valves in industries such as oil and gas, water, or manufacture. The connection between valves and automation in essential engineering tasks is commonly questioned. However, this can be explained by the integration of intelligent valves within automation systems.

How Automation Enhances Valve Functionality

The evolution of industrial valves is on the move due to sophisticated innovations like automation with the help of sensors, actuators, and real-time monitoring devices. Key enhancements include:

- Real-time Data Collection: IoT supported valves have the capability of collecting and reporting data in terms of pressure, temperature and the amount of flow for immediate actions

- Error Reduction: Automation at work eliminates the chances of someone making a mistake

- Predictive Maintenance: Utilization of data analytics for maintenance planning and break down prevention

- High-Risk Operations: Operation of high risk services with accuracy without the need to do it by hand

- Energy Efficiency: Automated systems help in resource efficiency and wear resistance

Smart Valves: The Future of Flow Control

The importance of industrial valves for contemporary systems is significantly high given their efficient, accurate, and reliable appropriateness in completely different industries. These valves are composed of sensors, actuators and advanced analytics which enhance the monitoring and regulation of fluid flow in real-time.

Market Trends: Based on the analysis of Google search trends, it is clear that there is an increase in demand for smart valve equipment in industries that face problems with energy usage, operational downtime, and even safety issues. There are a number of reasons for smart valves being essential in systems – they improve operational efficiency, reduce maintenance expenditure and handle the complexity of current infrastructure’s operation.

Cost-effective Solutions through Automation

Studies have shown that smart valves when integrated with automation laid the foundation for the most efficient systems applicable in different commercial settings over the years. Since the proliferation of data confirms that the use of smart valves together with the advances in IoT technologies has facilitated the effective supervision as well as control of activities in any given organization, this stands as the greatest improvement as regards wastage or energy utilization.

Ensuring Long-lasting Performance of Industrial Valves

Anyway, there are several key issues to consider if you want industrial valves to remain in good working condition. Proper maintenance and inspections are necessary so as to identify early warnings of wear and tear with educators before it becomes unbearable. This condition can be prevented, especially in aggressive environments, by using high-performance materials and coatings in accordance with high wear resistance and anti-corrosive properties.

Factors Affecting Valve Longevity

| Factor | Impact on Longevity | Solutions |

|---|---|---|

| Material Quality | Corrosion-resistant alloys provide better protection | Use stainless steel or specialized coatings |

| Maintenance | Routine checks prevent wear from getting worse | Implement regular inspection schedules |

| Operating Conditions | Pressure, temperature, and fluid type affect lifespan | Select valves designed for specific conditions |

| Predictive Maintenance | Early detection prevents failures | Use IoT-enabled sensors and analytics |

Maintenance Practices to Reduce Downtime

Limited idle times and satisfactory functioning of the valvular system can only be achieved by employing proper mechanisms for upkeeping. Modern technology in form of IoT devices and prediction tools complements the existing ones and enhances the reliability.

Essential Maintenance Practices:

- Regular inspections for wear, corrosion, or leakages

- Adjustments according to working practices

- Regular cleaning and greasing to prolong productive life

- Predictive maintenance using real-time analytical engines

- Incorporating artificial intelligence and machine learning

- Strategic component substitution in advance

- Ensuring fluid compatibility with components

Recent Developments: Findings from Google’s search trends underscore the increased importance of incorporating artificial intelligence alongside machine learning to predict problems of industrial valves as opposed to correcting them. Implementing these tools, businesses can optimize maintenance activities and manage scheduled and unscheduled downtimes.

Choosing Valves Designed for Durability

When it comes to selecting rugged valves, it is prime importance to factor in the environment and the specific application where the valve has been designed. If valves are going to be used in high pressure, high temperature or very corrosive conditions, they have to be constructed of stainless steel, bronze, exotic alloys or any other such material suitable to sustain the said conditions.

Key Considerations:

- Environment and specific application requirements

- High pressure and temperature capabilities

- Corrosion resistance for harsh conditions

- Advanced coatings for wear resistance

- Predictive analytics tools for performance monitoring

- Compatibility with products and location

References

-

University of Oklahoma: Provides a detailed overview of various valve types, including control, pressure relief, on-off, check, gate, ball, and plug valves. Read the document.

-

University of Michigan – Visual Encyclopedia of Chemical Engineering: Explains the role of valves in regulating fluid flow and isolating piping, covering main types like linear motion, rotary, and self-actuated valves. Explore the encyclopedia.

-

Anna University: Discusses the use of industrial valves as mechanical devices for controlling the flow and pressure of liquids, gases, and slurries. View the resource.

Frequently Asked Questions (FAQ)

What are the primary valve alternatives for use in industrial processes?

Valves in industrial processes are appropriate for the control of different fluids or gases in the respective processes. The systems consist of various industrial valves such as ball valves majority of the time, isolation valves and control valves which help in smooth operations in industrial plants or units. Efficient flow control performed with the precise choice of valves prevents the unnecessary stoppage of work and helps to improve overall function of the system.

In what ways are valves important components of industrial operations?

Valves have important functions in industrial operations which involves controlling the fluid movement within the pipelines. They are very useful in allowing for the commencement or cessation of any flow, providing a good seal as well as a means to permit passage in only one direction. Proper valve systems can result in increased efficiency, improved protection and reduced leaks in extreme pressure systems where the preservation of the system is critically important.

Which are the best types of valves for high pressure conditions?

In high pressure conditions, heavy-duty valves such forged steel or flanged ball valves are the best. Valves of this nature are also designed to perform in high pressure conditions and also close tightly to protect against leakages. Designed for high pressure, such valves out of the durable materials and constructions have found widespread use in all industrial valves applications.

Why does the size of a valve matter in industrial applications?

The size of a valve in an industrial system matters because it defines the rates of fluid and gas flows. If the system is to function properly in spite of the existing pressure, the sizes of the valves used should be such that the flow requirements are met. The diameters of the pipes and the requisite nature of a given application must also be taken in together when choosing the size of valve in order to make that particular application effective.

In what ways does the technology of automation and actuation improve the performance of a valve?

The main advantage of automation and actuating technology in relation to the valve performances that some importance should be given is the concerning ability to control flow rates and avoid intervention manually to some sizeable extent. It is the pneumatic and hydraulic technologies that are for the most part used in such actuation types providing very fast response times and uniform performance useful in those cases where there is a necessity to perform quick modifications within the processes. The above-mentioned advanced technology offers increased capacity and reliability in various domains of use involving industrial valves.

Why should full-port valves be considered?

Valves with full ports have various benefits, such as lesser restriction of the flow of liquid and enhanced flow as compared to valves with reduced ports. The architecture of the valves is such that water and other fluids flow easily making them suitable for flows that need to deliver high performance. Valves that have full ports are ideal in machines where the rate of flow should not change for the purpose of maintaining an efficient operation.

What kind of industrial valves can be used in corrosive environments?

Valves for corrosive fluids are typically manufactured from materials like carbon steel or certain alloy materials. The corrosion resistant valves are known for being in a position to sustain the chemical action that occurs during operation without breaking down or leaking. Do not forget to purchase those valves that are fit for use with corrosive fluids for durable purposes in order not to realize system lapses.

How are flow control valves helpful in promoting exact flow rates in industrial procedures?

The inability to control the flow rate causes loss of industrial productivity. This is because it is hard to control processes without altering results depending on the process operations in question or the requirements. In other words, industrial valves allow for, rather than controlling the flow rate by closure of the cross-sectional area. Appropriate control and added flexibility through a range of valve positionings would allow the correct flow conditions to be maintained regardless of the application; compressors, heat-exchangers, hydraulic systems and etc., all of whom require optimum performance and efficiency.