The heat treatment processes are very important and decisive in determining the attributes and the use of metals and alloys, however, not all processes are of the same nature. The two widely applied techniques, solution heat treatment and annealing, in their turn, draw attention because of their different applications and outcomes. Therefore, it is very important for the engineers, manufacturers, and other people involved in materials science to know the differences between these two processes. This article explores the key differences between solution heat treatment and annealing and explains their respective influences on the final material properties along with the mechanisms involved and the purposes. Thus, whether you are trying to upgrade your technical knowledge or to make well-informed decisions in your projects, this guide will guarantee a clearly and practically understanding of these crucial heat treatment methods. So be ready to uncover the manner in which each of these processes works and when to prefer one over the other!

Introduction to Heat Treating Processes

Heat treating processes are a set of techniques that are used to change the physical and mechanical properties of materials, usually metals, so that they will be more suitable for different applications. The processes that are most widely used are annealing, quenching, and tempering. Annealing is a process in which the material is softened so that it can be easily machined and the internal tensions can be relieved. Quenching is the process of rapidly cooling the material, which results in increased hardness and strength. Tempering which follows quenching, is the process of reducing brittleness while retaining some of the hardness that has been gained. These processes are vital in the industries from automotive to construction assuring that materials can meet the requirements of specific strength, durability, and flexibility.

What is Heat Treating?

Heat treating is nothing but a controlled process that completely alters the properties, both physical and sometimes chemical, of a material, mostly metals and alloys. The main goal of heat treating is to get the desired characteristics such as hardness, strength, ductility, and wear resistance to mention some. This is done by putting the material through specific heating and cooling cycles at very precise temperatures.

Modern Technology in Heat Treating: Along with heat treating technology, modern tools like computer-controlled furnaces and advanced metallurgical models are already a helping hand for industries to optimize these procedures and meet the strictest performance standards. No matter whether it is an automotive component, an aerospace application or a construction material, heat treating is the process that allows the material to be subjected to operational stresses without losing its reliability and efficiency.

Overview of Heat Treatment Types

| Heat Treatment Type | Process Description | Primary Purpose |

|---|---|---|

| Annealing | Material is heated to a certain level and cooled slowly | Lessen hardness, increase ductility, eliminate internal stresses |

| Quenching | Material is heated to high temperature and cooled rapidly in water, oil, or air | Harden and strengthen materials, especially steel |

| Tempering | Done after quenching; heating to lower temperature then natural cooling | Give toughness, reduce brittleness, enhance reliability under stress |

| Normalizing | Heating above critical point, followed by air cooling | Refine grain size, augment machinability, structure consistency |

| Case Hardening | Alters only the outer layer while core remains soft and ductile | Hard, wear-resistant surface with tough, elastic interior |

Importance in Materials Science

Material treatments like grain refining and case hardening are imperatively the fundamental techniques in modern materials science. Using these techniques, the engineers and researchers can adjust the characteristics of metals and alloys for certain applications, for instance. Additionally, gaining strength, durability, and resistance to wear, through the combination of different treatments and chemical modifications, is making the materials more suitable for their use.

Industry Impact: In the automotive, aerospace, and manufacturing sectors, these improvements are said to be the basis of the production of long-lived and, at the same time, economical components. Material sciences have progressed to the extent that they not only offer better performance but also environmental benefits by lessening waste during production and lowering energy use. The use of advanced techniques makes the materials science an ever-present force behind innovation in all areas, solving the industrial challenges and the technological ones at the same time.

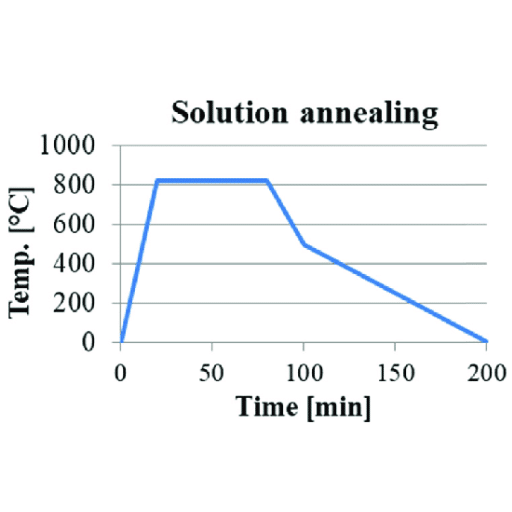

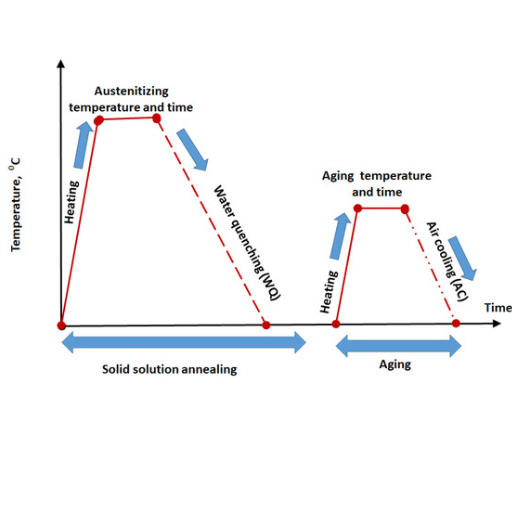

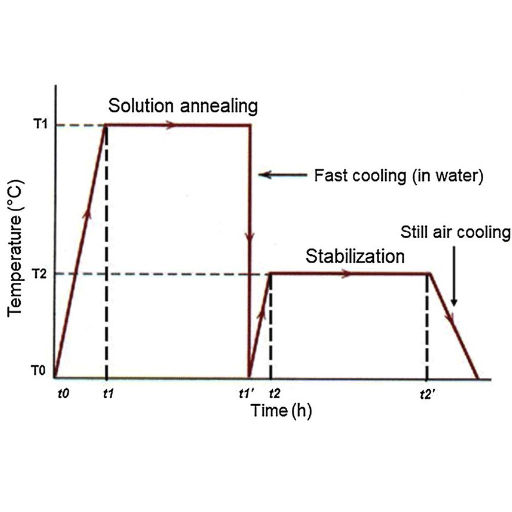

Defining Solution Heat Treatment

The heat treatment solution is a metallurgical operation that mainly aims to improve the properties of metals and especially alloys like aluminum very much. In the course of this operation, the alloy is brought to a certain temperature that is normally just lower than its melting point and maintained at that temperature for a predetermined time. This step facilitates the dissolution of the alloying elements and their even distribution in the matrix which results in a uniform solid solution. After this, the material undergoes rapid quenching in order to trap the alloying elements and thus to avoid their separation.

Key Benefits: This method is very important to increase the hardness, strength, and resistance to corrosion in metals. The aerospace, automotive, and construction industries are using solution heat treatment to make light but strong components. Innovations in the field of monitoring and process control have helped to improve the accuracy of solution heat treatment which in turn has resulted in better performance and eco-friendly manufacturing.

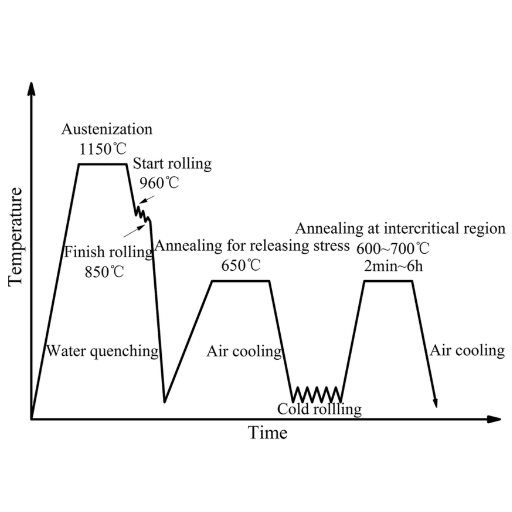

Process and Steps Involved

Step 1: Heating

The first step is to bring the material to the desired temperature in a controlled atmosphere. The choice of temperature is generally determined by the particular alloy type and it is of utmost importance for the dissolving of the alloying elements into the solid solution.

Step 2: Quenching

After the material has reached the desired temperature and the alloying elements were totally dissolved, it is then quickly cooled down by water, oil, or air. The cooling is so fast that it traps the mixing of the alloy elements in the metal.

Step 3: Aging (Optional)

If necessary, the material may be exposed to aging where it is reheated to a lower temperature and kept there for a specific time. This process leads to the formation of fine particles which increase the hardness and durability of the material.

Applications of Solution Heat Treatment

| Industry | Applications | Benefits |

|---|---|---|

| Aerospace Sector | Wings, body’s outer shell, engine parts | Boosts strength and resistance to fatigue of aluminum and titanium alloys for high altitude and high temperature conditions |

| Automotive Industry | Wheels, suspension units, engines | Creates lightweight but strong parts; better fuel efficiency and vehicle performance |

| Shipping Industry | Propellers, hulls, ship components | Guarantees corrosion resistance in hostile saltwater environments |

| Medical Instruments | Surgical tools, implants, prosthetics | Improved biocompatibility and strength for titanium alloys |

| Energy Generation | Turbine blades, boiler pipes, heat exchangers | Improved heat resistance and structural quality for maximum efficiency |

Benefits and Drawbacks

Advantages

- Enhanced Durability: Treatments considerably increase the durability, resistance, and efficiency of materials

- Improved Performance: Better biocompatibility and stronger materials result in lower risks and longer life cycles

- Thermal Resistance: Enhanced thermal resistance allows for smooth operations in hot environments

- Extended Lifespan: Direct improvement in performance and lifespan of critical components

Disadvantages

- High Costs: Advanced treatment processes entail significant expenses that add to manufacturing costs

- Accessibility Issues: Requires specialized machinery and know-how, limiting accessibility for smaller operations

- Material Limitations: Some materials may still struggle with very harsh or unpredicted conditions

- Balance Required: Cost, accessibility, and effectiveness must be carefully balanced

Exploring the Annealing Process

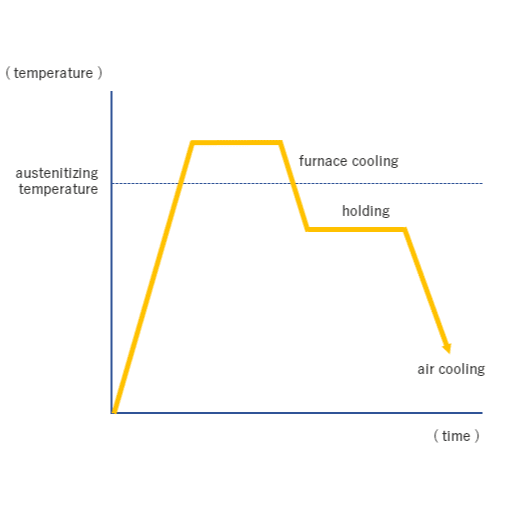

Annealing is an important heat treatment process that is applied to metals and alloys in different industries to raise their physical properties. The procedure comprises three steps: the material is heated to a predetermined temperature, held at that temperature for a certain period, and then cooled down slowly. The steps of controlled heating and cooling change the microstructure of the material, which in turn, releases internal stresses, increases ductility, and ultimately makes the material tougher.

Industry Application: Google’s search engine reports that the annealing process is mostly applied to the production of materials for the next mechanical operations such as shaping or cutting. It does so by making the materials less brittle and more workable. The automotive, construction, and aerospace industries are the biggest consumers of the process in terms of improving the performance of the most critical components. The method’s success depends on several factors including the heating rate, peak temperature, holding time, and cooling medium choice, which may differ according to the material and the desired properties.

Steps in the Annealing Process

1. Heating

First the material is heated at a slow pace until it reaches a certain temperature called the recrystallization temperature. This temperature is different for each material that is annealed, but the common aim is to reach a condition that the internal stresses are no longer in shape but still without melting or deformation.

2. Holding (Soaking)

The material is brought to the desired temperature and then kept or “soaked” at that temperature for a specified duration. A holding period is said to be the material’s structural transition in time to acquire the mechanical and thermal properties targeted. The length of this period is determined by the material’s thickness and composition.

3. Cooling

Controlled cooling is the last step in the process to make sure that the material will have the desired features. This can be done through either rapid cooling (quenching) or gradual cooling, which is mostly done in air, water, or oil, depending on the requirements of the end product.

Common Applications of Annealing

- Metalworking Industry: Improving ductility and reducing hardness of metals for easy metal working like stamping, forging and machining. Common in steel used for car parts like engine and transmission gears.

- Electronics Manufacturing: Essential for semiconductor and electronic component production. Removes defects in silicon wafers and enhances electrical properties, guaranteeing reliability in integrated circuits.

- Glass Industry: Major manufacturing process that builds up glass resistance against internal stresses. Used for optical lenses to architectural glass, ensuring uniform internal structure and increased durability.

- Aerospace Engineering: Improves mechanical properties of alloys like aluminum and titanium, making them more resistant to stress and flexible for aircraft frames, turbine blades, and critical components.

- Tool and Die Making: Very important step for obtaining necessary toughness and desired wear resistance. Applied to high-carbon and alloy steels to improve machinability and increase lifespan in harsh working environments.

Advantages of Soft Annealed Metals

Soft annealed metals are a great technical material with many benefits that make it ideal for industrial applications:

- Improved Machinability: The annealing process lowers the hardness of the metal, making it easier to be cut, shaped, or formed. This is an advantage in industries that require very precise manufacturing.

- Enhanced Ductility: Soft annealed metals are even more ductile, which means that they can be stretched or bent without breaking at all. Very important for automotive and aerospace industries.

- Great Toughness: These metals have the ability to survive in very demanding environments when it comes to impact and wear.

- Stress Relief: Annealing eliminates residual stresses from past manufacturing processes, yielding higher durability and longer life for the parts.

- Consistent Quality: Contemporary advances in annealing techniques and strict observing of temperature and cooling profiles guarantee consistently high-quality results.

- Cost-Effective: Industries use soft annealed metals for superior performance while reducing manufacturing costs.

Key Differences Between Solution Heat Treatment and Annealing

| Aspect | Solution Heat Treatment | Annealing |

|---|---|---|

| Purpose | Strengthening, increasing hardness, prolonging lifespan of alloys like aluminum and titanium. Dissolving alloying elements into uniform solution for aging and enhanced performance. | Softening metal, freeing up internal stresses, increasing ductility to make material easier to use in subsequent manufacturing stages. |

| Process Temperature | Very high temperature above the metal’s solvus line for complete solution. Followed by rapid cooling (quenching) to retain alloying elements. | Lower temperatures than solution heat treatment. Controlled, slow or gradual cooling rate until softness is attained. |

| Applications | Aerospace and automotive industries where strong but light components that can endure high stresses are needed. | Manufacturing and tooling industries where there is need to form, machine, or weld metals with less difficulty. |

| Microstructural Changes | Produces a metastable phase favorable for hardening through aging afterwards. | Metal’s microstructure defects are eliminated by recrystallization, creating a more uniform, stress-free state. |

Comparative Analysis of Processes

In metallurgy, one must be aware of the different functions and uses of annealing and solution heat treatment when they are compared. The main goal of the annealing treatment is the reduction of hardness, the relaxation of internal stresses, and the increase of ductility which indeed facilitates the shaping or machining of metals. However, solution heat treatment is meant to dissolve the alloying elements into a solid solution thus allowing the process of precipitation hardening to take place during aging later on.

Industry Trend: Recent findings indicate that the industries are opting for a combination of both processes more and more for the purpose of performance and durability optimization. It occurs, for instance, in the case of aerospace metals, that the latter ones show improved microstructural consistency, resistance to fatigue and mechanical properties all due to the treatment by both processes. This demonstrates the point that application of both annealing and solution heat treatment according to the specific needs can result in excellent manufacturing and engineering outcomes.

Impact on Material Properties

The process of annealing combined with solution heat treatment significantly raises the bar for the material properties and the enhancement is particularly noticeable in the areas of ductility, strength, and resistance to corrosion. The procedure of annealing alleviates internal stresses and simultaneously, the grain structure gets refined making the material stronger in terms of being able to endure deformation. On the other hand, the solution heat treatment not only strengthens the material but also by dissolving the soluble phases and making the material harder through aging.

Modern Manufacturing: The latest data show that the manufacturers in the aerospace and automotive industries are among the first to apply these processes to create new alloys that are mechanically strong and durable at the very same time. This resulted in a great reduction of material failures in these sectors, thus, portraying the importance of these treatments in modern material science and the high safety and efficiency standards that these sectors have to comply with.

Cost and Efficiency Considerations

The new technologies in the aerospace and automotive sectors are a great advance if the cost and efficiency of the advanced materials and processing treatments are weighed. Manufacturers are reducing materials that are not used by employing new technologies such as additive manufacturing and heat treatments that allow for accurate usage of materials. The recent information shows that although the first cost of these technologies is very high, the savings in operational costs, which are commensurate with increased efficiency, and the initial investments are being compensated in the long run. This is very critical as the industries are under pressure not only to deliver the highest quality products with the least possible negative impact on the environment, but also to keep the operating costs low.

Selecting the Right Process for Your Needs

In making the choice of the most suitable process for your operation, it is imperative to weigh the factors of tech efficiency, environmental respect, and cost-effectiveness in one scale. The most recent data mined from Google search trends point out the fact that the majority of factories have started to give up short-lived gains and to invest in sustainable techniques with long-term advantages. For example, the use of robots and AI in production is not only exacting but also cutting waste and power use down to a minimum. If your company’s decisions are in line with what the market requires and the trends that predict the future, then your investments will not only have the chance of survival through the years but will also satisfy the environmental friendliness requirements.

Factors to Consider in Choosing Heat Treatment

- Material Composition: Think about the material makeup of the component. Treatments for different metals and alloys vary in order to attain various qualities such as hardness, strength, or ductility.

- Treatment Objective: Determine the treatment objective—hardening, softening, stress relieving, or perhaps wear resistance improvement. This choice will be greatly affected by the application of the material.

- Component Size and Shape: The size and shape of the component play a significant role since uneven heating is likely to lead to deformation or cracking in intricate parts.

- Cost and Environmental Impact: Consider not only the costs but also the resource consumption and the environmental impact of the treatment method chosen. Environment-friendly processes such as induction or vacuum heat treatment are becoming more popular due to their accuracy and lower energy consumption.

- Technical Innovations: Always keep abreast of technical innovations like AI-assisted heat treatment systems which make it possible to have better precision and predictability, thus meeting industry trends and sustainability goals.

Case Studies: When to Use Each Method

Case Study 1: Automotive Industry – Quenching for Hardness and Durability

One of the biggest manufacturers of automotive parts faced the hard task of developing engine parts that could handle even very high pressure and still not wear out after a long time. To be able to win the needed hardness they had to use quenching methods which consisted of cooling the heated steel parts down in a matter of seconds. Cool process! It is so cool that they also benefited from the high resistance to mechanical stress and durability that quenching could be turned out to be a great need in auto parts manufacturing through the constant search data being confirmed.

Case Study 2: Aerospace Sector – Annealing for Stress Relief

A company specializing in aerospace applying lightweight metal frames relied on annealing to improve ductility and relieve internal stresses. Annealing gave them the opportunity to shape their parts with accuracy and at the same time avoid chemicals which is of utmost importance to safety and performance-Maintaining standards. The data from Google shows consistency in the need for annealing when there is a demand for precision in forming aerospace materials.

Case Study 3: Toolmaking Industry – Tempering for Toughness

A tool-making company specializing in cutting equipment decided upon using tempering procedures as the means of attaining their desired mix – hard plus tough. Quenching followed by tempering was the method they used to lower the brittleness of their steel and at the same time make it possible for their tools to withstand prolonged use without chipping. This goes hand in hand with the search trends that point to tempering as a crucial step in producing high-performance tools.

Key Takeaway: These instances display that the selection of the best heat treatment technique should be based on the requirements of specific applications, material properties, and industry trends. Companies can improve their processes for the sake of the environment and product quality if they rely on the combination of modern innovation and data insights.

Future Trends in Heat Treating Techniques

A mix of cutting-edge technology, green practices, and data analytics will determine the fate of heat treating methods in the near future. One of the notable trends is the gradual acceptance of hybrid heat treating techniques whereby induction heating is paired with the conventional method thus producing a greater level of accuracy and energy efficiency. Furthermore, there is a noticeable inclination towards the utilization of eco-friendly heat treating options like low-carbon heating systems, which is motivated by the objective of minimizing industrial emissions.

Emerging Trends

- Hybrid Heat Treating Techniques: Induction heating paired with conventional methods for greater accuracy and energy efficiency

- Eco-Friendly Options: Low-carbon heating systems to minimize industrial emissions

- Energy-Efficient Practices: Growing demand for sustainable heat treatment solutions

- AI and Robotics: Instant supervision and alteration for efficient operations

- Data-Driven Optimization: Using real-time data from Google Trends and other sources to discover new materials and techniques

Google’s query data shows an important increase in the number of searchers asking for energy-efficient and heat treatment sustainable practices. This situation not only implies that there is a larger audience to be served but also that industries are looking for such techniques that are fast and confirm to eco-friendly throats. Businesses that make use of the instantaneous data coming from instruments such as Google Trends are going to be the ones leading the pack by discovering new materials, techniques and cravings of the market which, consequently, will be translating the unending development of heat treating. The incorporation of robots and AI tools in the procedure is also being propelled as it would mean instant supervision and alteration of certain needs in an efficient manner.

References

-

Heat Treatment Overview – NJIT: A detailed academic resource on heat treatment processes, including annealing and solution heat treatment.

-

Metal Processing – University of Washington: An educational webpage explaining annealing and other metal processing techniques.

-

Aluminum Heat Treating – FAA: A government document comparing annealing and solution heat treatment processes for aluminum alloys.

Frequently Asked Questions (FAQ)

What exactly is solution heat treatment?

Solution heat treatment refers to a set of procedures where metal alloys, specifically austenitic stainless steel ones, are taken to the phase transition temperature. After that, is done a quick cooling, most commonly water quenching, to partition the microstructure and also to change the physical and chemical properties of the material to the desired state.

What are the differences between solution heat treatment and annealing?

The use and efficiency of annealing and solution heat treatment are expressed through their distinctive objectives and techniques. While, in the case of Annealing, one is heating the metal to a certain temperature and making it cool down slowly, thus relieving the stresses and increasing ductility, the solution heat treatment is mainly focused on dissolving the existing carbides and other precipitates to gain further strength and hardness.

What are the common annealing temperatures for metals?

Temperature ranges at which annealing takes place are dependent on the type of metal subjected to the procedure. To give an example, austenitic stainless steel alloy’s annealing temperature might reach up to 950 °C, whereas, on the other hand, aluminum alloys generally require quite lower thermal conditions to get the desired mechanical properties.

Why is it necessary to know the difference between annealing and solution heat treatment?

Knowing the difference between annealing and solution heat treatment is of paramount importance for selecting the right heat treatment technology for a certain application. Different processes impose different material properties, such as, for example, strength, hardness, and ductility, which are the main considerations for various engineering uses.

What are the main heat treatment technologies applicable to metal alloys?

Heat treatment technologies that can be applied to metal alloys are the following: annealing, solution heat treatment, material hardening and tempering. Every single one of these treatments is meant to change the microstructure of the alloy to generate a certain set of mechanical properties which, in general, would be stronger and more pliable.

What is soaking time in heat treatment?

Soaking time in the context of heat treatment is considered to be the duration at which the alloy is maintained at a specific temperature. In a process such as solution heat treatment, soaking is done for a sufficient period to ensure complete dispersal of carbides and other precipitates, thereby making it easier for the material to have uniform properties throughout.

What happens to austenite during water quenching?

Water quenching after solution heat treatment cools down the material at a very fast rate, causing a transformation of the austenite phase into martensite; this turns into stronger but less ductile material. This operation is significant when it comes to manufacturing by-products that demand very tight control over mechanical properties like structural components and tools, among others.

What is the role of grain boundaries in heat-treated metals?

Grain boundaries are one of the most important factors in the overall properties of heat-treated metals. In practices such as Annealing and Solution Treatment, the Grain size and structure are manipulated in such a way that the metals can acquire certain characteristics such as strength, hardness, and ductility that are very important for the material’s performance in its specific application.