The article offers a deep dive into the allure of solution treatment and annealing, revealing their diverse properties, uses, and advantages. By the end, you will have a good understanding of how these methods can turn metal into a custom-made material that is ready for the challenges of modern-day engineering.

Overview of Heat Treatment Processes

Heat treatment processes are crucial techniques for the improvement of metal properties. The very nature of these processes is to heat and cool the metal in a controlled manner so as to change its microstructure and make it better in terms of hardness, strength, ductility, or wear resistance.

Among the heat treatment processes, annealing is most widely used as it softens the metal making it more workable. Another one is solution treatment, which combines the two properties of strength and corrosion resistance. By utilizing the right process, engineers can customize the metals to the specific performance standards, hence making them usable in various industries.

Definition of Heat Treatment

Heat treatment is a controlled technique for changing the physical and sometimes chemical properties of a material, mostly metals and alloys. It involves the heating and cooling of the material, which in turn affects its internal structure. The heat treatment aims to enhance hardness, strength, ductility, toughness, or wear resistance but varies with the material and its application.

The latest developments in heat treatment technology, supported by data on industry practices, show that processes like induction hardening, carburizing, and cryogenic treatment are more and more being used to satisfy the need for high-performance materials in the aerospace, automotive, and manufacturing industries. By carefully adjusting the internal properties of metals through these processes, engineers can achieve unmatched efficiency and longevity in a wide range of applications.

Importance in Metallurgy

Metallurgy has a key function in the progress of contemporary industries, thus, it is the metallurgical engineering that makes the materials to be up to the high standards of performance, safety, and durability. Together with the traditional skills, the engineers have the latest innovations in heat treatment processes which enable them to fine-tune the metal properties such as hardness, toughness and wear resistance.

Recent statistics show that processes like induction hardening and carburizing are increasingly becoming essential in industries like aerospace and automotive, where precision and reliability are paramount. Google’s search trends reveal that interest in sustainable metallurgical practices has increased significantly, signaling worldwide attention on reducing energy usage and material waste.

Common Heat Treatment Methods

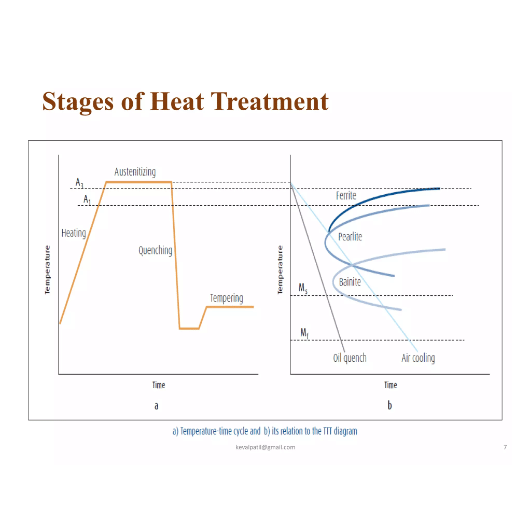

Heat treatment in metallurgy is an essential process that changes the physical and, at times, the chemical properties of the material in order to obtain remarkable characteristics. The principal heat treatment processes include:

| Method | Process | Primary Purpose |

|---|---|---|

| Annealing | Heating to precise temperature and slowly cooling down | Increases ductility, reduces hardness |

| Quenching | Rapid cooling, usually in water or oil | Boosts hardness and strength |

| Tempering | Heating to lower temperature after quenching | Reduces brittleness while maintaining strength |

| Normalizing | Similar to annealing but with air cooling | Provides combination of strength and ductility |

According to the most recent data, interest in sustainable and energy-efficient heat treatment methods has become increasingly evident. Topics like vacuum heat treatment and advanced induction heating enhance process efficiency and considerably lower energy requirements. This trend highlights the industry’s embrace of greener practices and environmentally-friendly innovations.

What is Solution Heat Treatment?

Solution heat treatment is an important process for aluminum, among other metals, and has been mostly used to enhance their mechanical properties and resist corrosion. This treatment consists of heating the material to a very high temperature, which is usually just below the melting point, and holding it at that temperature for the dissolving of the alloying elements into a uniform solid solution.

Next, the material undergoes rapid cooling or quenching, which traps the elements, thus forming a structure that can be changed again by aging or precipitation hardening. The most recent discoveries show that during the process of solution heat treatment, not only energy efficiency, but also precision control, have improved significantly, thus the performance of the materials is at the highest level and the impact on the environment is minimal.

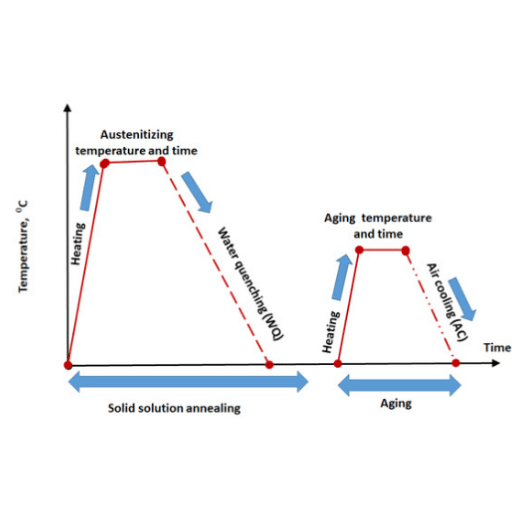

Process Description

- Heating Phase: Material is heated to high temperature (usually just below melting point)

- Holding Phase: Temperature maintained to dissolve alloying elements into uniform solid solution

- Quenching Phase: Rapid cooling to trap elements in desired structure

- Optional Aging: Further treatment for precipitation hardening if needed

The significant measures in solution heat treatment are now being powered by AI and predictive modeling. These technologies ensure accurate temperature control and optimization of the cooling process. By adopting such progressive methods, the durability of materials in industry is enhanced and waste is minimized, thus conforming to eco-friendly production aims. The application of latest data analytics keeps manufacturing processes flexible and energy-efficient.

Applications of Solution Heat Treatment

| Industry | Application | Benefits |

|---|---|---|

| Aerospace Industry | Aluminum alloys in aircraft components | Up to 30% stronger tensile strength; improved corrosion resistance; safer, more durable structures |

| Automotive Manufacturing | Lightweight aluminum and magnesium alloy parts | Weight reduction up to 20%; less fuel consumption; more eco-friendly |

| Construction & Infrastructure | Steel alloys for bridges and skyscrapers | Improved flexibility and load-bearing capacity; long-lasting infrastructure |

| Energy Sector | Turbine blades and nuclear reactor components | 40% increase in fatigue resistance; withstands heat and mechanical stress |

| Medical Device Production | Titanium alloys for implants (hip, dental) | Enhanced biocompatibility; reduced material degradation; extended implant longevity |

Benefits of Solution Heat Treatment

- Enhanced Mechanical Strength: Great improvement in mechanical strength and resistance to fatigue, crucial for aerospace parts where durability and safety are paramount

- Superior Corrosion Resistance: Homogenizing alloy composition ensures performance is maintained even in unfavorable environments for extended periods

- Improved Biocompatibility: In medical device manufacturing, increases biocompatibility while minimizing material degradation risk, extending implant life

- High-Temperature Performance: Develops material properties for energy sectors where both performance and toughness are critical (e.g., turbine blades)

- Sustainability: Modern techniques achieve highest performance levels while promoting sustainable practices

Understanding Annealing

Annealing is a thermal treatment technique that alters both the physical and in some cases chemical properties of a material, to the benefit of making it more malleable and less hard so that it can be more easily worked. The process consists of heating the material to a predetermined temperature, holding it at that temperature for a certain amount of time, and then cooling it, usually slowly and under control.

It helps to organize the internal strains, refine the microstructure, and improve the mechanical properties of a material like toughness and wear resistance.

With the latest data and trends, annealing still plays a very important role in improving various industrial areas. For instance, the medical industry has benefited from this development, as the process of annealing makes materials used in implants more compatible with the body and prolongs their life. Recent research in the energy industry implies that annealing is a very important factor in the performance of high-stress components like turbine blades.

Process Description

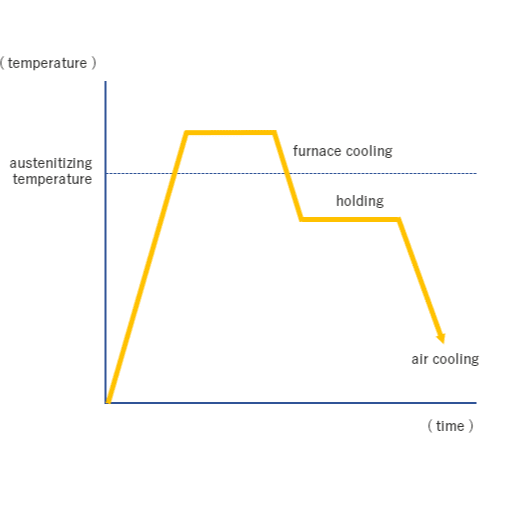

- Heating Phase: Material heated to certain temperature

- Holding Phase: Maintained at temperature for specified duration

- Cooling Phase: Controlled, slow cooling process

- Result: More ductile, softer, and internally stress-free material

Current annealing practices take advantage of controlling temperature and providing monitoring technologies to always get optimum results. Google’s search patterns show the process still manages to attract growing interest, particularly in renewable energy and additive manufacturing domains, which hunt for innovations in material strength and durability.

Applications of Annealing

Metallurgy and Manufacturing

One of the basic applications of annealing in metallurgy is to boost the ductility of steel, aluminum, and copper while lowering their hardness. Steel that has undergone heat treatment has its stresses relieved and rendered into stress-free states. Automotive applications favor areas where steel’s capacity to endure stress is increased through heat treatment. Industry sources report that nearly two-thirds of metalworking processes rely on the product reliability assurance given by annealing.

Additive Manufacturing

The advent of 3D printing technology has made it imperative for annealing to play a significant role in improving the mechanical properties of printed parts. Annealing after manufacturing relieves internal stresses in the material and improves uniformity of metal powders and polymers, ensuring precision and durability in components like aerospace parts and medical implants.

Renewable Energy Systems

The solar energy system’s efficiency growth is assured by continuous and efficient use of annealing in photovoltaic cell production. Research has shown that annealed wafers can outperform non-annealed ones by as much as 5%, thus strengthening the case for renewable energy sources.

Electronics Industry

Semiconductor production is one area where annealing is indispensable as it helps control the electrical nature of semiconductor material. The process repairs defects in wafers and improves conductivity, supporting manufacturing of highly reliable microchips and processors. The semiconductor industry, with a global worth over $550 billion in 2023, is highly dependent on annealing techniques.

Glass Industry

Annealing glass makes it stronger and less vulnerable to breaking by distributing internal stresses created during manufacture. This procedure is vital for producing glass used in windows, bottles, and smartphone displays. Annealed glass represents a huge part of the $200 billion global glass market.

Benefits of Annealing

- Enhanced Durability: Makes glass much more durable and stronger by relieving internal stresses, suitable for construction, automotive, and consumer electronics

- Thermal Stability: Glass that has undergone annealing possesses thermal stability property, important for thermal insulation and glasshouse heaters

- Improved Workability: Facilitates later manufacturing stages such as cutting, shaping, and drilling

- Precision Engineering: Makes material suitable choice for precision engineering applications

- Market Reliability: Advanced measures deployed satisfy world market demand for strong glass products

Comparing Solution Heat Treatment and Annealing

Solution heat treatment and annealing are two heat-based processes mainly employed to modify the mechanical properties of metals and other materials. They, however, have significant differences in the area of application, method, and result.

Solution heat treatment is a process in which the strength and durability of alloys, especially aluminum and titanium, are improved through a mechanism where the alloying elements are completely dissolved in a solid solution. The material is first heated to a very high temperature, then kept at that temperature to allow maximum solubility, and rapidly cooled (quenched) to lock the alloying elements in position. This results in formation of a homogeneous microstructure that increases tensile strength and wear resistance.

Annealing majorly deals with relieving internal stresses of a metal or alloy to increase its ductility and make the material more workable. This procedure consists of heating the material to a predetermined temperature, keeping it there for a specified time, and then letting it slowly cool down in a controlled environment. The main purpose is to soften the material and make it more machinable rather than strengthening it.

Recent data from Google’s search engine indicates increasing interest in combining these processes to obtain preferred mechanical properties for particular industrial applications. For example, solution heat treatment is often followed by aging to bring about hardness, whereas annealing finds widespread acceptance in the automotive industry to ensure materials won’t break while undergoing shaping and forming.

Key Differences

| Aspect | Solution Heat Treatment | Annealing |

|---|---|---|

| Primary Purpose | Enhance strength and performance | Improve workability and relieve stress |

| Process Method | High temperature heating + rapid cooling (quenching) | Controlled heating + slow, controlled cooling |

| Temperature Range | Very high (often above 1000°C, depending on material) | Lower (e.g., 600-700°C for steel) |

| Cooling Method | Rapid (quenching in water/oil) | Slow, gradual cooling |

| Resulting Properties | Increased strength, hardness, wear resistance | Increased ductility, softness, workability |

| Typical Applications | Aerospace, automotive components requiring high strength | Manufacturing, construction, metalworking for forming |

| Microstructure Effect | Creates homogeneous, supersaturated solid solution | Refines grain structure, relieves internal stresses |

When to Use Each Method

The decision regarding solution heat treatment and annealing is made according to the material in question and the application intended for it.

Use Solution Heat Treatment When:

- High Stress Requirements: Materials will be subjected to extreme stress conditions

- Elevated Temperatures: Components must operate in high-temperature environments

- Corrosive Environments: Materials need enhanced corrosion resistance

- Strength Priority: Applications where strength and durability are paramount (aviation, automotive engine parts)

- Performance Reliability: Components must maintain reliability under difficult conditions

Use Annealing When:

- Workability Needed: Material’s flexibility and ductility are most important

- Forming Operations: Preparing metals for shaping or forming processes

- Stress Relief: Internal stresses need to be reduced

- Machinability: Increased machinability is required (metal sheet production, wire drawing)

- Manufacturing Prep: Materials need preparation for subsequent processing

Considering the end use and operational demands of the material, engineers and manufacturers can skillfully decide which method is most beneficial in terms of technical and economic priorities, thus leading to optimized results in different industrial processes.

Impact on Material Properties

The annealing process is one of the most influential factors altering material properties. The mechanical characteristics of the material are noticeably changed with annealing treatment:

- Softness & Ductility: Material becomes softer and more ductile, better for forming and cutting

- Crystalline Structure: Dislocations in crystalline structure are reorganized and reduced

- Grain Structure: Improves material’s grain structure and overall uniformity

- Strength & Durability: May increase overall strength and durability in some cases

- Thermal Properties: Customizes thermal properties for specific applications

Recent information suggests that the automotive and aerospace industries are among the major ones that depend on this process as they often need components with very specific mechanical and thermal properties. Manufacturers, by adjusting annealing conditions to sync with production requirements, get superior results customized for various applications.

References

-

“Heat Treatment” – Provides an overview of heat treatment processes, including controlled heating and cooling to alter material properties.

-

“Metal Processing” – Explains annealing as a softening process and compares it with other heat treatment methods.

-

“Understanding Different Types of Heat Treatment: Annealing” – Discusses various annealing techniques and their differences.

Frequently Asked Questions (FAQ)

What are the distinctive features of the solution heat treatment and annealing?

The key factors that set solution heat treatment apart from annealing are their applications and methods. Solution heat treatment, also called solution anneal, is performed by taking a metal, usually austenitic stainless steel, up to a high temperature to melt the carbides and precipitates while at the same time creating a supersaturated solid solution. Then quick cooling is done, often by quenching in water, to preserve the solid solution. On the other hand, annealing is a heat treatment method that seeks to relieve stress, increase ductility, and enhance the material’s workability, mostly through gradual cooling after heating to a predetermined temperature.

What temperatures are involved in the process of annealing?

The temperature of annealing is different for each kind of material. For example, for steel, the annealing temperature is usually between 600°C and 700°C. The method requires keeping the material at this temperature for a certain period of time to allow recrystallization, and then the material is slowly cooled down to room temperature. As a result, hardness is reduced and ductility is increased.

In what way does solutionization improve the strength of materials?

Solutionization improves materials’ strength by dissolving the alloying elements and producing a supersaturated solid solution. The material is taken to a high temperature, which is the solvus temperature, where the carbides and other phases disappear into the matrix, thus creating a supersaturated solid solution upon rapid cooling. The presence of the dislocation movement’s impediment is what causes the increased strength and hardness; thus, crystallites have gotten smaller, which is the result of the dissolution of the phases and the supersaturation.

What is the significance of soaking time in heat treatment?

In heat treatment sometimes it is the case that soaking time is the most important factor. Soaking time is significant throughout the heat treatment processes; this applies to both solution treatment and annealing. Soaking time is the length of time the material is kept at the desired temperature. Complete phase dissolution and homogeneous temperature distribution throughout the material are some of the benefits accrued from a lengthy soaking time. Incomplete transformation and compromised materials with less than optimal properties can result from insufficient soaking.

How cooling rates affect the properties of metal during heat treatment?

Cooling rates are one of the main determinants of the microstructure and mechanical properties of metals after heat treatment. By quenching the sample treated with solution, the cooling is so rapid that it does not allow the dissolving of interstitials to occur. In contrast, the slow cooling of the samples during annealing facilitates stress relief and softer microstructure formation which doubles the ductility and formability.

Is it possible to explain the difference between the heating in solution treatment and annealing?

The heating in solution treatment is generally at higher temperatures than in the case of annealing. For example, the material may need to be heated above 1000°C in solution treatment, depending on its composition, to get phase dissolution whereas this usually takes place at lower temperatures in the case of annealing, which which is sufficient to relieve internal stresses without changing the microstructure too much.

Explain the term ‘gamma prime’ as it pertains to heat treatment?

The phrase gamma prime indicates a certain state that can arise in nickel-based superalloys in the process of heat treatment. Gamma prime is the reinforcing phase which makes the metal stronger and more resistant at high temperatures. In solution treatment, controlling the amount of gamma prime can greatly influence the properties of the alloy, allowing it to be used in more demanding high-temperature applications.

What is the role of carbon content in the processes of heat treatment?

Content of Carbon is one of the main parameters for selecting the heat treatment processes for steel and alloys. High carbon contents may help in forming carbides during solution treatment which in turn affects the hardness and strength of the material. In the case of annealing, carbon content determines the treatment temperature for the material to be able to obtain the desired mechanical properties which include increased ductility and enhanced formability.