Understanding the Solution Anneal Process

Solution annealing is a heating procedure that brings about uniformity, strength, and corrosion resistance in stainless steel. The workpiece is gradually and uniformly heated to a high temperature, often exceeding 1,850°F and going up to 2,100°F (1,010°C to 1,150°C). After this, the metal is quenched in water or treated quickly with another coolant to capture the desired traits.

What is Solution Annealing?

Solution annealing is a thermal treatment technique primarily applied to enhance the corrosion resistance and mechanical properties of metal alloys, particularly stainless steel and nickel-based alloys. During this treatment:

- The metal is subjected to high temperatures, generally ranging from 1,850°F to 2,350°F (1,010°C to 1,290°C)

- It is maintained at that temperature for a specific duration to allow dissolution of precipitated carbides or other phases into the base metal

- A uniform, homogeneous microstructure is obtained

- The metal undergoes rapid cooling or quenching, usually in water, to prevent reprecipitation of carbides

This method is broadly applied in industries that require materials to be resistant to extreme environmental or chemical conditions, such as aerospace, chemical processing, and power generation.

Steps in the Solution Annealing Process

1. Heating

The first step involves raising the temperature of the material to a certain level, generally between 1,900°F and 2,100°F (1,040°C and 1,150°C) depending on the alloy type. The purpose is to dissolve precipitates and ensure alloying elements spread equally.

2. Holding

Once the desired temperature is attained, the material is maintained at this temperature for a specific duration. During this holding period, the solutionizing process is completed at the microstructural level, ensuring full homogenization.

3. Rapid Cooling (Quenching)

The material undergoes rapid cooling, normally through immersion in water, oil, or air cooling. This fast quenching freezes the microstructure and blocks the reappearance of precipitates responsible for the material’s ductility and corrosion resistance.

4. Post-Process Testing

After the solution annealing process, the material is tested to ensure it conforms to specifications. Testing methods may include hardness tests, tensile tests, or corrosion resistance evaluations.

Key Temperatures in Heat Treatment

| Heat Treatment Type | Temperature Range | Purpose |

|---|---|---|

| Annealing Temperature | 800°F – 1600°F (427°C – 871°C) | Softens the material for easier machining |

| Quenching Temperature | Above 1500°F (815°C) | Increases hardness through rapid cooling |

| Tempering Temperature | 400°F – 1200°F (204°C – 649°C) | Reduces brittleness while maintaining strength |

| Normalizing Temperature | 1600°F – 1700°F (871°C – 927°C) | Refines grain structure |

| Solution Annealing Temperature | 1850°F – 2050°F (1010°C – 1120°C) | Dissolves carbides and improves corrosion resistance |

Advantages of Solution Annealing for Stainless Steel

Solution annealing offers multiple benefits that enhance the performance and reliability of stainless steel:

Enhanced Corrosion Resistance

One of the key benefits of solution annealing is enhanced corrosion resistance. The process:

- Restores the microstructure of the material

- Eliminates stress points, leading to a more uniform structure

- Enables steel to withstand extreme environments such as highly saline or chemically aggressive locations

- Reduces maintenance costs significantly

- Improves safety of critical infrastructures

Improved Mechanical Properties

Solution annealing significantly alters the mechanical properties of stainless steel:

- Refines the microstructure, making it more ductile and tougher

- Eliminates residual stress from processing

- Enhances ability to withstand mechanical loads

- Reduces likelihood of breakage or structural failure

- Improves performance under repeated stress cycles

Stabilization of Microstructure

Microstructure stabilization is essential for long-lasting performance and reliability. Properly managed cooling and annealing processes:

- Align grain structure properly

- Reduce internal tensions

- Maintain material integrity under environmental and mechanical stressors

- Enable predictable performance through digital modeling and AI-based simulations

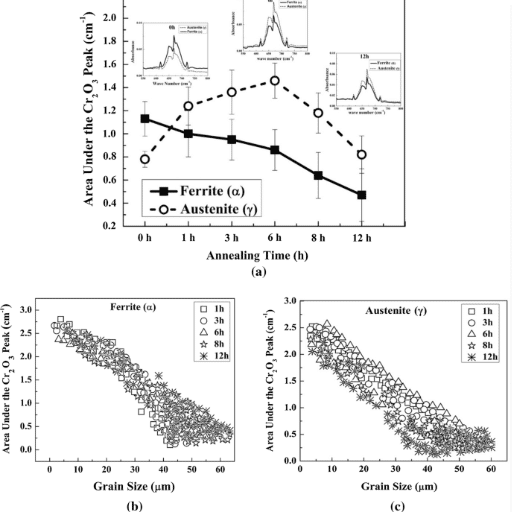

Microstructure of Solution Annealed Stainless Steel

Formation of Austenitic Structure

The microstructure of solution-annealed stainless steel is primarily composed of a single-phase austenitic structure. Key characteristics include:

- Minimum composition of 16% chromium and 6-12% nickel

- Stabilized austenitic phase at room temperature

- Enhanced strength and corrosion resistance through nitrogen addition

- Uniform distribution of alloying elements

- Improved weldability and high-temperature performance

Impact on Alloy Composition

The composition of austenitic stainless steels continuously evolves based on:

- Application-specific requirements for corrosion resistance, mechanical strength, and thermal stability

- Cost and supply considerations (e.g., reduction in nickel content)

- Addition of compensating elements like manganese or nitrogen

- Incorporation of higher chromium or rare earth elements for harsh environments

Applications of Solution Annealed Stainless Steel

| Industry | Applications | Key Benefits |

|---|---|---|

| Aerospace Industry | Turbine blades, fasteners, structural elements | Excellent strength-to-weight ratio, high resistance to thermal and environmental stresses |

| Chemical Processing | Storage tanks, piping systems, reactors | Superior resistance to acids, bases, and salts; extended operational life |

| Marine Applications | Shipbuilding, offshore platforms, desalination plants, propellers, shafts | Remarkable resistance to chloride-induced pitting and crevice corrosion |

| Medical Equipment | Surgical instruments, orthopedic implants, medical devices | Biocompatibility, resistance to sterilization, prevents material degradation |

| Energy Sector | Heat exchangers, boilers, superheater tubes | Endures extreme temperatures and pressure, ensures efficient energy generation |

| Automotive Industry | Engine components, exhaust manifolds, turbochargers | Withstands thermal cycling, resists oxidation, ensures reliability and safety |

Applications in Chemical Processing

Heat Exchangers

Heat exchangers utilize stainless steel and superalloys for superior thermal conductivity and corrosion resistance. Stainless steel Grade 316 withstands chemical corrosion in saline or acidic environments. Superalloys in heat exchangers can increase operational life by up to 40%.

Reactors and Pressure Vessels

Chemical reactors depend on titanium and Hastelloy materials for withstanding high pressures and corrosive environments. Titanium reactors in chlorine formulation can achieve service life beyond 30 years.

Piping Systems

Nickel alloy piping systems (such as Alloy 600) are essential for transporting highly reactive chemicals. These systems can reduce maintenance frequency by 25% compared to conventional materials.

Storage Tanks for Hazardous Chemicals

High-quality steel grades and aluminum alloys are used for storing hazardous chemicals. Lined carbon steel tanks for hydrochloric acid storage can lower the probability of leakage by 98%.

Catalyst Supports

Platinum or palladium-coated supports play a vital role in industrial catalysis. Palladium-based catalyst supports can increase reaction rates by almost 50%, optimizing production in processes such as hydrogenation.

Choosing the Right Heat Treatment Services

Factors to Consider in Service Providers

- Technological Capabilities: Advanced digital technologies, real-time process monitoring, and data analytics for consistency and quality assurance

- Certifications: ISO 9001 or AS9100 certifications validate quality and traceability commitment

- Sustainability Practices: Energy-efficient machines, low-waste methods, and environmental compliance

- Cost Structures and Turnaround Times: Alignment with production schedules and financial limitations without compromising precision

- Customer Service: Thorough reports, easy access to support, and good communication throughout the service process

Customization of Heat Treatment for Specific Alloys

Heat treatment processes must be customized for each alloy to optimize properties like hardness, tensile strength, and ductility. Key considerations include:

- Specific composition and microstructure of each alloy

- Precise control of temperature cycles, cooling rates, and hold times

- Use of predictive modeling and machine learning for real-time adjustments

- Alignment with phase diagrams and thermal behavior of the alloy

Comparison with Other Heat Treatments

| Heat Treatment Method | Primary Focus | Key Advantages |

|---|---|---|

| Traditional Annealing | Internal stress relaxation and ductility improvement | Improves workability but limited surface protection |

| Quenching and Tempering | Hardening and toughness increase | Enhanced hardness but may lack corrosion resistance |

| Solution Annealing with Alloying | Corrosion resistance and structural integrity | 30-50% durability increase under extreme conditions |

References

-

“Metallurgical Evaluation of Cast Duplex Stainless Steel” – Evaluates duplex stainless steel in various conditions, including solution annealed states.

-

“Influence of 40% Cold Working and Annealing on Stainless Steel” – Explores the effects of solution annealing and subsequent water quenching on material properties.

-

“Hardenable Stainless Steels and Their Effect on Mechanical Properties” – Covers various heat treatments, including solution annealing, and their influence on stainless steel fabrication and performance.

Frequently Asked Questions (FAQ)

What does the solution annealing process entail when it comes to stainless steel?

The solution annealing process for stainless steel consists in an important thermal treatment which includes heating the metal to the solution temperature of about 1000 to 1150°C, and then subjecting it to a fast cooling, which mostly is done by water quenching or other rapid cooling methods. Ultimately, this procedure makes it possible to dissolve the carbide and precipitate particles that were formed during the heat treatments and thus, obtain a completely homogenous solid solution and also reduce the grain size via minimizing grain growth.

What are the pros of solution annealing for stainless steel elements?

The pros of solution annealing for stainless steel parts come in the form of better-corrosion resistance, better-mechanical properties, and reduced stresses inside the part. On top of that, this heat treatment method is very effective in preserving the alloys from sensitization which leads to intergranular corrosion in the case of stainless steel like 316L or high-nickel alloys.

In what way do temperature and cooling influence the solution treatment of stainless steel?

Temperature and cooling are the main factors in the solution treatment of stainless steel. The heats that the steel is to be subjected must reach the point of recrystallization and retain it for a sufficient time so that all the carbide comes to dissolve. Afterward, a very fast cooling takes place, e.g., the process of water quenching, which is vital in keeping the single-phase microstructure and preventing the growth of grains.

Which types of stainless steel alloys are suitable for solution annealing?

Stainless steel alloys subjected to solution annealing treatments mostly include 300 series and its members like 304L and 316L central stainless steels. They are austenitic steels that need the process to their advantage as they become strong and corrosion-resistant while at the same time the carbide precipitation if that does not occur, is minimized.

To what extent do grain boundaries influence the performance of solution annealed stainless steel?

Grain boundaries are decisive factors for solution annealed stainless steel in terms of characteristics. The annealing treatment helps the recrystallization which results in the division of the grains into smaller pieces and their increasing of uniformity. The thickness of grains is already a factor that has to do with the corrosion resistance and hence, the mechanical properties. Thus, this material becomes suitable for a wider range of applications, making even the case of stainless steel pipes.

Is it possible that the solution annealing process will alter the mechanical properties of stainless steel?

There is a possibility that the solution annealing process will greatly change the mechanical properties of stainless steel. Gradually doing away with residual stresses and at the same time refining the microstructure, the process opens up the way to ductility and strength. Likewise, the vanishing of precipitates offers the benefit of superior toughness and fatigue resistance.

What is the significance of the issue of sensitization concerning austenitic stainless steel?

Sensitization in austenitic stainless steel is the occurrence of conditions where, during the heat treatment intervals effectively the material subjected to high temperatures, leads to the formation of carbides at the grain boundaries. This condition, in turn, opens the way for intergranular corrosion. Among the many ways wherein solution annealing comes to the rescue, one effective way is by doing away with carbides thus, it guarantees a fair and spread out solid solution which in turn boosts the corrosion resistance of the alloy.

How is age hardening in relation to solution annealed stainless steel?

Age hardening is a method of strengthening that can be developed in some stainless steel alloys after solution annealing as a side effect. Athough the whole process essentially is about dissolving precipitates and enhancing grain structure, some alloys may still be subjected to low temperature aging to improve hardness and strength without the risk of losing ductility.