Annealing and solution annealing are heat treatment processes that rank first in order of importance for their influence on performance, durability, and structural integrity of metals and alloys. Though they share some similarities, there are many differences between these two methods. This article presents a thorough comparison of both processes, their principles, applications, and the different industries where they are used.

Who should read this? Whether you are an engineer, a metallurgist, or simply interested in material science, this guide will help you identify the major differences and gain practical insights necessary for understanding heat treatment processes that enhance material properties for various applications.

What is Annealing?

Annealing is a heat treatment technique typically performed on metal and glass to change their physical and sometimes chemical properties, improve their ductility, relieve internal stresses, and refine their microstructure.

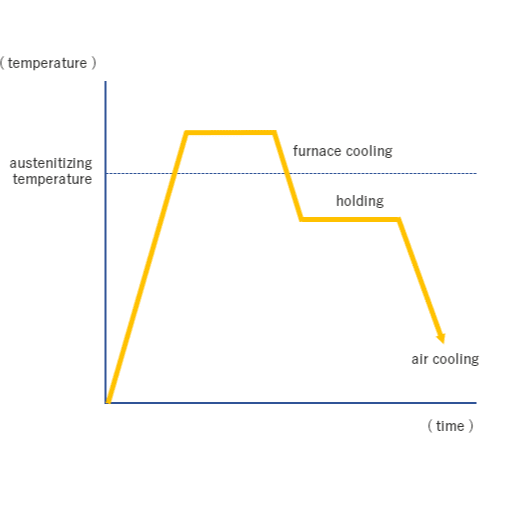

The Three-Stage Process

- Heating: The material is heated to a specific temperature

- Holding: The material is maintained at that temperature for a certain period

- Cooling: The material is cooled down, usually in a controlled manner to achieve the desired properties

Key Insight: Recent research indicates that precise control of both temperature and cooling rates is crucial, as they directly affect the final grain structure and strength of the material. This process remains essential in industries like automotive, aerospace, and manufacturing, where material performance is directly related to operational success.

Definition and Purpose

Heat treatment is characterized by a controlled series of heating and cooling operations applied to metals or alloys in their solid state to modify their physical and mechanical properties without changing their shape. The main goals include:

- Improving hardness and ductility

- Enhancing tensile strength

- Increasing resistance to wear and corrosion

- Optimizing material behavior for intended applications

Types of Annealing Processes

1. Full Annealing

Purpose: Refine metallographic structure, increase ductility, and relieve internal tensions

Best for: Low and medium carbon steels

Process: Metal temperature is raised above the critical point, held for a specific time, then cooled very slowly (usually inside the furnace)

Benefits: Provides uniform microstructure and increases machinability

2. Stress-Relief Annealing

Purpose: Eliminate residual stresses from welding, machining, or cold forming

Temperature: Below critical temperature

Process: Material is heated and then slowly cooled

Applications: Large workpieces and complicated machine parts requiring dimensional stability

3. Spheroidizing Annealing

Purpose: Alter carbide particles into spherical shape for improved toughness

Best for: High-carbon steels

Process: Long-term heating at temperatures just below the critical range

Industries: Automotive and tooling sectors where machinability and durability are crucial

4. Recrystallization Annealing

Purpose: Remove work hardening effects from cold working

Temperature: Above recrystallization threshold but below critical temperature

Process: New grains form without residual strain

Common materials: Aluminum and copper alloys

Applications in Metal Treatment

| Process | Materials | Temperature Range | Primary Benefit |

|---|---|---|---|

| Stress Relieving | Steel, Stainless Steel | 500°C to 650°C | Eliminates internal stresses, prevents warpage |

| Recrystallization Annealing | Aluminum, Copper Alloys | 300°C (Cu), 350°C (Al) | Forms strain-free grains, enables further processing |

| Normalization | Iron and Alloys | 850°C to 950°C | Uniform grain size, enhanced toughness |

| Solution Heat Treatment | Aluminum Alloys (6061, 7075) | 480°C to 530°C | Supersaturated solution for precipitation hardening |

| Precipitation Hardening | Titanium, Nickel Superalloys | ~480°C (Ti alloys) | Increases strength while retaining ductility |

Understanding Solution Heat Treatment

Solution heat treatment is a crucial step in the metallurgical processing of precipitation-hardenable alloys, aimed at obtaining a uniform solid solution prior to aging. This process is fundamental in producing high-performance materials for demanding applications.

Temperature Ranges

- Aluminum alloys: 900°C to 1050°C

- Nickel-base superalloys: Higher temperatures depending on specific composition

Recent Advances: Modern solution heat treatment technology features rapid heating rates and precise thermal control to avoid overheating or underheating. Real-time thermal sensors and computational techniques now play a major role in predicting and optimizing treatment cycles. Advanced quenching techniques with controlled cooling rates prevent early phase precipitation and achieve high solute supersaturation.

Definition and Importance

Solution heat treatment involves heating an alloy to a temperature high enough to create a one-phase material, then cooling it rapidly (quenching) to retain this uniform structure. This process is critical in industries where quality and reliability cannot be compromised.

Industry Applications

- Aerospace: Manufacturing jet engine turbine blades that withstand high stress and extreme conditions

- Automotive: Lightweight alloys for improved fuel efficiency

- Energy sector: Components requiring superior performance under operational stress

Benefits of Solution Heat Treatment

- Enhanced Mechanical Properties: Dissolution of precipitates and even distribution of alloying elements improve tensile strength and ductility

- Increased Corrosion Resistance: Critical for components exposed to harsh environments like marine settings and chemical processing plants

- Uniform Material Structure: Softens metal while ensuring consistency throughout the material

- Preparation for Further Treatment: Creates optimal conditions for subsequent hardening or tempering stages

- Lightweight Alloy Development: Supports eco-friendly manufacturing technologies and sustainable materials

Comparison: Traditional Annealing vs Solution Heat Treatment

| Aspect | Traditional Annealing | Solution Heat Treatment |

|---|---|---|

| Primary Purpose | Eliminate internal stresses, improve ductility, refine grains | Dissolve alloying elements uniformly, prepare for precipitation hardening |

| Temperature | Moderate temperatures | Specific high-temperature range for solubility |

| Cooling Method | Slow, controlled cooling | Rapid quenching |

| Material Effect | Softer, more workable structure | Stronger, tougher, more corrosion-resistant |

| Alloying Elements | Limited effect on atomic-level distribution | Uniform solid solution distribution |

| Applications | Preparatory processes, machining operations | High-performance components in aerospace, automotive, energy |

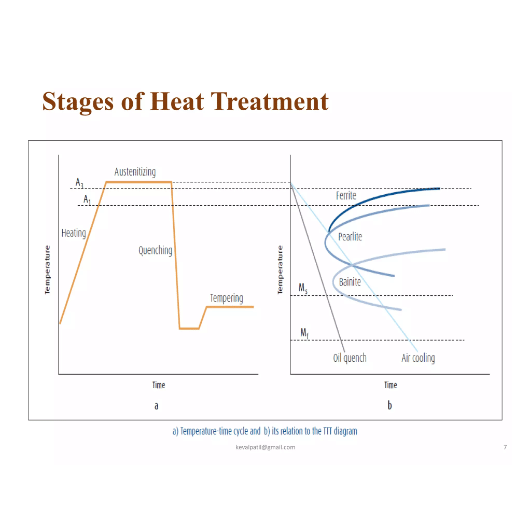

The Process of Solution Heat Treatment

Solution heat treatment is a highly controllable metallurgical process primarily used with heat-treatable alloys like aluminum, magnesium, and titanium. Recent data shows a notable increase in interest regarding solution heat treatment applications, driven by growing demand for lightweight, high-strength materials in aerospace, automotive, and renewable energy industries.

Steps Involved in Solution Annealing

1Heating

Material is heated to a specific temperature, typically within the range of 1850°F to 2150°F (1010°C to 1175°C), depending on alloy composition. Temperature is carefully controlled to ensure all alloying elements reach their solubility limit in the base metal.

2Holding Period

Once the material reaches the desired temperature, it is maintained at that temperature for a specific duration. This allows proper diffusion of alloying elements into the base matrix, ensuring homogenous distribution and dissolution of any undesired precipitates.

3Rapid Cooling (Quenching)

Material is cooled rapidly using water, oil, or air jets to lock the dissolved elements in the crystal lattice. Rapid quenching inhibits re-precipitation of carbides or other compounds that may negatively impact mechanical or corrosion-resistant properties.

4Post-Quenching Treatment

Though not always required, post-quenching methods such as tempering or stress relief may be utilized to adjust material properties according to specific application needs.

Furnace Types for Solution Heat Treatment

| Furnace Type | Best For | Key Features |

|---|---|---|

| Batch Furnaces | Small production volumes, complex geometries | Precise temperature control, programmable controllers, stringent metallurgical specifications |

| Continuous Furnaces | Large-scale, high-production applications | Automated workflow, conveyor systems, consistent heating, efficient for automotive/aerospace |

| Vacuum Furnaces | Extremely low oxidation requirements | Oxygen-free environment, prevents contamination, ultra-clean heat treatment, high-performance alloys |

Heating Techniques and Temperature Control

Modern vacuum furnaces employ resistance heating elements made from molybdenum, tungsten, or graphite due to their high-temperature stability. Advanced control systems include:

- Programmable Logic Controllers (PLCs): Coupled with strategically placed thermocouples

- Machine Learning Algorithms: Enable real-time process monitoring and temperature regulation

- Multi-zone Heating Configurations: Allow control of different furnace sections for complex structures

- Instantaneous Temperature Adjustments: Minimize deviations that could alter material quality

Bright Annealing vs Other Annealing Methods

Bright annealing stands out among annealing techniques for its unique ability to produce superior surface quality and corrosion resistance. Unlike regular annealing methods that often result in oxidized and discolored surfaces, bright annealing is performed under a controlled atmosphere (typically hydrogen or nitrogen) that prevents oxidation and discoloration.

Definition of Bright Annealing

Bright annealing is a thermal treatment procedure for metals or alloys—such as stainless steel, nickel, and other corrosion-resistant materials—to improve ductility, corrosion resistance, and surface quality. The process is performed in an oxygen-free environment, maintaining a clean and shiny surface finish.

Advantages of Bright Annealing

Enhanced Corrosion Resistance

The controlled inert gas atmosphere removes all surface oxides, leaving a perfect surface. Research confirms that bright annealed stainless steel has better resistance to pitting and stress corrosion cracking in harsh environments.

Superior Surface Finish

Provides a direct, smooth surface finish requiring no additional mechanical or chemical treatment. Critical for industries where precision and aesthetics matter, such as medical device and semiconductor sectors.

Improved Mechanical Properties

Precise control of annealing temperature and cooling rates produces optimal mechanical properties like tensile strength and elongation. Bright annealed austenitic stainless steel can be drawn into very small diameter wires while retaining ductility.

Energy Efficiency

Completed in a single controlled cycle, using less energy than traditional methods requiring additional pickling or grinding steps. Results in significant cost savings for high-volume production operations.

Reduced Contamination Risk

The fully enclosed environment protects material from moisture, carbon, and other oxides, ensuring product purity and longevity. Essential for medical and food-grade equipment manufacturing.

Applications in Ferrous and Non-Ferrous Metals

- Stainless Steel Tubing: Pharmaceuticals, food processing, oil & gas—oxide-free surface for corrosion resistance and hygiene

- Copper Wiring and Components: Maintains conductivity and purity, eliminates performance-blocking oxidation

- Aluminum Foils: Packaging and insulating applications with smooth, defect-free surfaces and enhanced heat reflectivity

- High-Carbon Alloy Tools: Preserves strength and flexibility, prevents brittleness, extends tool life

- Nickel-Based Superalloys: Turbine blades and aircraft engine parts requiring oxidation and thermal degradation resistance

Choosing the Right Heat Treatment Method

| Method | Primary Benefit | Typical Performance Improvement | Best Applications |

|---|---|---|---|

| Vacuum Heat Treatment | Advanced temperature/atmosphere control | Reduces oxidation rates to ~1% of conventional methods | Aerospace, medical, high-precision components |

| Induction Hardening | Localized surface hardening | 30% increase in surface hardness vs conventional quenching | Shafts, gears, high wear components |

| Cryogenic Treatment | Enhanced toughness and wear resistance | 2-3x increase in part lifespan | Tool steels, precision instruments |

| Carburization | Surface hardening with tough core | 25% higher fatigue resistance | Automotive gears, industrial parts |

| Plasma Nitriding | Surface hardness without toxic waste | Eco-friendly with superior wear resistance | High-strength applications, green manufacturing |

Industry Trend: Recent data indicates a significant shift towards methods emphasizing efficiency, environmental sustainability, and superior results. Plasma nitriding exemplifies this trend, providing increased surface hardness, wear resistance, and fatigue strength while producing minimal toxic waste and aligning with global green technology initiatives.

References

-

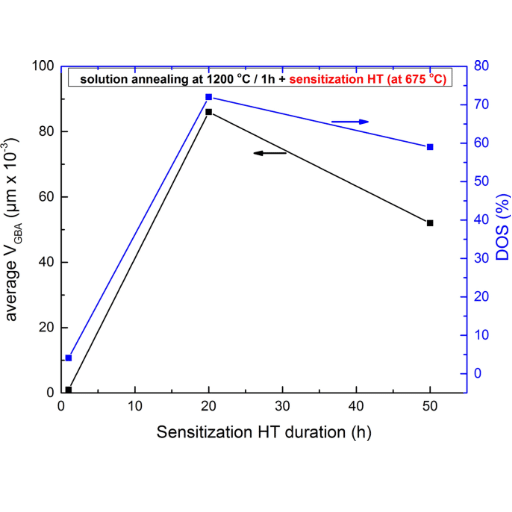

The Effect of Solution Annealing on the Microstructural Properties

This study explores the impact of solution annealing on microstructural changes and precipitate dissolution.

Read more here -

Influence of Thermo-Mechanical and Solution Annealing Treatments

This research compares solution-annealed conditions with other treatments, focusing on yield stress and tensile properties.

Read more here -

Effects of Annealing/Solution Treating and Aging on Material Properties

This paper examines the effects of annealing and solution treating on material properties, including temperature and cooling methods.

Read more here

Frequently Asked Questions (FAQ)

What is the goal of solution annealing in metal treatment?

The solution annealing goal in metal treatment is to improve the material properties by integrating solute elements into the base metal matrix. The metal is heated to a certain solubility annealing temperature during this process, forming austenite, and then rapidly cooled to keep the single phase. The treatment gives the metal increased formability and strength, while also making the microstructure more uniform.

What are the differences between solution heat treatment and traditional annealing?

The primary difference between solution heat treatment and traditional annealing is the temperature and their respective objectives. While traditional annealing is focused on allowing internal stresses to dissipate and making the material softer, solution heat treatment has the dissolution of the alloying elements and a uniform microstructure as its goal. The process of solution heat treatment involves heating the metal to a very high temperature and cooling it rapidly, which is contrary to the slower cooling techniques that are often used in conventional annealing.

What are the benefits of solution heat treatment for ferrous metals?

The advantages of solution heat treatment for ferrous metals consist of better mechanical properties, higher resistance to corrosion, and greater toughness. Through treating ferrous alloys with this heat process, manufacturers can get a microstructure that is no more varied than the areas of strength and weakness and longevity of the material, thus the versatility of the products.

What is the heating process involved in bright annealing?

Bright annealing heating process is a heat treatment that is controlled and which takes place in a non-oxidizing atmosphere furnace. It allows the metal to be heated to a certain temperature to allow the formation of austenite and then the metal is cooled quickly. This process not only gives the material better characteristics but also keeps its bright and shiny surface because of the non-oxidizing atmosphere and contamination prevention.

What is the significance of slow cooling in annealing?

Slow cooling during the annealing procedure is vital for metal because it allows the metal to convert to a more stable microstructure. The internal stresses are relieved, grain growth becomes more even, and the material has the required characteristics of softness and ductility. In contrast, high cooling rates are usually applied in solution heat treatment to the metal to prevent it from losing the desired microstructure.

How is the solvus line connected with metal heat treatment?

In phase diagrams, the solvus line is a significant factor which shows the maximum temperature at which the solid remains as a single phase. It is important to understand solvus line for all the processes of metal heat treatments, including solution annealing, since it helps decide solution annealing temperature for keeping the metal in the single-phase state. It is the proper maintenance of this temperature which is essential to acquire the desired metal mechanical properties.

What is the technique used to reach the solution annealing temperature?

The technique used to reach solution annealing temperature is to heat the metal alloy to a specific temperature that the desired phase transformation would occur, typically leading to austenite formation. After that, the material would be held at that temperature for a certain amount of time to ensure the total dissolution of the solute’s elements. Finally, the metal would be rapidly cooled, usually by quenching, to keep the single-phase and thus its overall properties.