Stainless steel is famous for its long-lasting nature, resistance to corrosion, and adaptability, thus being the most widely used material in many different fields. Nevertheless, a very important process called annealing is frequently applied to bring out the full potential of this metal. This process not only makes the material stronger but also improves its machinability and ability to work in harsh environments. In this article, we will discuss the vital function that annealing takes in producing and refining stainless steel. We will go into the depths of the science involved in this process and of the practical benefits that it offers, so, in the end, you will be very well informed about why annealing is a necessary process for getting the best results. If you are a professional in the industry or just interested in the exciting domain of metals, this guide will show you how heat treatment makes stainless steel an incredible material.

Understanding the Annealing Process

The annealing process is one of the heat treatments that aims to improve the ductility, strength, and overall workability of stainless steel. The first step is to heat the material to a specified temperature and then hold it there for a predetermined time before cooling it down at a controlled rate. This process behind internal stress relief, material structure refinement, and even corrosion resistance enhancement makes the metal easier to form and shape while keeping strong and durable at the same time.

What is Annealing?

Annealing is a metallurgical heat treatment process that is aimed at altering the physical and mechanical properties of metals, especially the so-called stainless steel, and making them more durable and workable respectively. This process consists of heating, holding and cooling which are the three main stages. The material is heated up to a certain temperature that varies with its composition, kept for a certain time at that temperature for the structural change to take place, and then cooled off at a certain rate, generally in a controlled environment.

The main goal of annealing is to eliminate internal stresses caused by processes like casting, welding, or cold working. Furthermore, it increases the material’s ductility and toughness while decreasing its hardness, which makes it more convenient to shape and form. Annealing also imparts uniformity to the material and refines its grain structure, which can enhance its corrosion resistance and fatigue strength. Contemporary methods have further improved the art, enabling the exacting of temperature and time controls to meet various industrial needs.

The Heat Treatment Process Explained

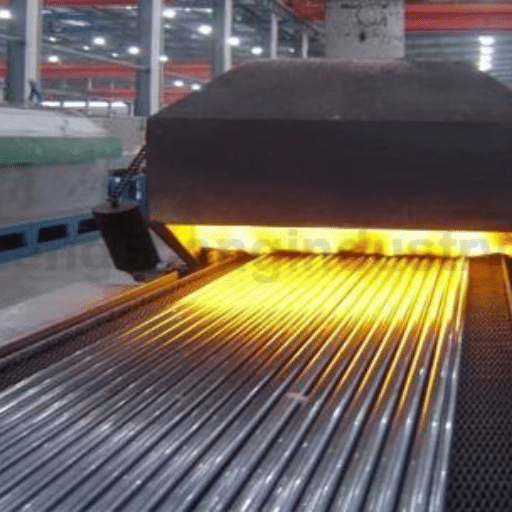

Heat treatment is an elaborate procedure controlled very precisely that changes the physical and mechanical properties of the materials, mostly metals, in order to get the characteristics they want. In general, this procedure entails the heating of the substance to a certain temperature, maintaining it at that temperature for a specified time, and then cooling it down in a specific manner. The most important methods and steps in the heat treatment process are as follows:

Annealing

Aim: To soften the material, enhance ductility, and get rid of internal stresses.

Temperature Range: 680°F to 1,200°F (depending on the material).

Cooling Method: Slow cooling, often in a furnace.

Quenching

Aim: To make the material hard by locking the crystalline structure through rapid cooling.

Temperature Range: Usually 1,500°F or more.

Cooling Method: Quick cooling in water, oil, or air depending on the alloy.

Tempering

Aim: To reduce brittleness and increase toughness after quenching.

Temperature Range: Between 300°F and 1,200°F.

Cooling Method: Slow, natural cooling in the air after heating.

Normalizing

Aim: To make grain structure finer and improve material toughness and strength.

Temperature Range: 1,600°F to 1,800°F.

Cooling Method: Air cooling after the material is heated above its critical temperature.

Case Hardening

Aim: To harden the surface of the material while keeping a softer, ductile core.

Methods Used: Carburizing, nitriding, or carbonitriding processes.

Temperature Range: Typically 1,560°F to 1,750°F depending on the method.

Each of these heat treatment techniques has its own specific application and material requirements, which in turn guarantees industrial and engineering the best performance. Knowledge of these methods helps in the choice of the correct heat treatment process for a particular project.

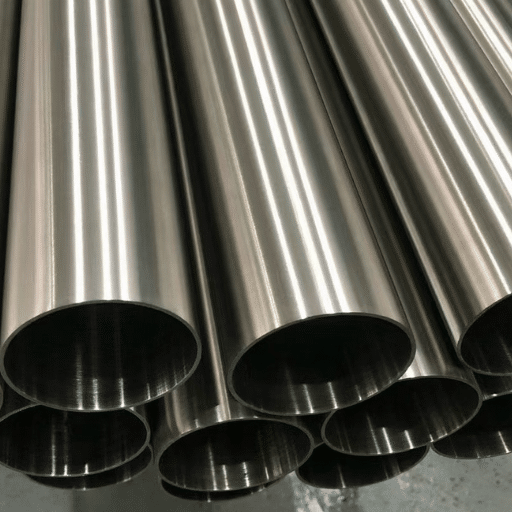

Types of Stainless Steel Used in Annealing

Annealing is an indispensable method for improving the ductility, machinability, and obtaining overall good quality of stainless steels. Below is a ranking of the top five kinds of stainless steel that are commonly used in annealing:

Austenitic Stainless Steel (300 Series)

The major alloying elements are chromium and nickel.

The higher grades 304 and 316 are the common examples, both being very ductile and highly resistant to corrosion.

Annealing Temperature Range: 1,900°F to 2,100°F.

Ferritic Stainless Steels (400 Series)

Composed of chromium with very small quantities of carbon.

It is very suitable for applications where there is a need for good resistance against stress corrosion cracking.

Annealing Temperature Range: 1,450°F to 1,650°F.

Martensitic Stainless Steel

These steels are very high in carbon and they are hardenable through heat treatment.

The common grades are 410 and 420, and they are often found in tools and cutlery.

Annealing Temperature Range: 1,600°F to 1,900°F.

Duplex Stainless Steel

Mixed composition of austenitic and ferritic phases.

High strength and very good resistance to pitting corrosion are the features that describe the material.

Annealing Temperature Range: Generally 1,900°F to 2,050°F.

Precipitation-Hardening Stainless Steel

Possessing both very high strength and resistance to corrosion, with the example of 17-4 PH literally speaking.

These are air-hardened and still need precision regarding annealing.

Annealing Temperature Range: 1,900°F to 2,000°F.

Different stainless steel types come with different advantages that appeal to the market; thus, making the selection process vital based on the application and the properties needed.

Benefits of Annealing Stainless Steel

There are many benefits stainless steel annealing brings but among them, the performance optimization and application potential increase are the most significant ones. The process of annealing stainless steel has five benefits detailed below:

Improved Ductility and Formability

The treatment leads to a soft stainless steel with a higher ductility which can be cracked or formed to a point of being unrecognizable. For instance, the above is a must in the automotive and aerospace industries, where highly detailed and shaped pieces are the rule.

Reduction of Internal Stresses

The process gets rid of the internal stresses formed during the cold working or machining process. This results in an improved dimensional stability and a reduced risk of warping or distortion in the future, especially for parts with intricate shapes.

Enhanced Corrosion Resistance

Some grades of stainless steel require heat treatment to access their full potential, since it is the means for such a recovery of the chromium-enriched oxide surface layer, which is the very layer responsible for the stainless steel’s lack of corrosion in the first place. Hence, this is vital in environments where there is moisture, acid, or chlorides.

Optimized Mechanical Properties

The process of annealing leads to a change in the grain structure thus creating the desirable effect of being both hard and tough. For example, it can tailor tensile strength and elongation properties according to specific engineering requirements.

Ease of Machining

The process of softening has been completed, and the material is now easier to machine or cut. Tool wear is greatly decreased, and efficiency in manufacturing is increased. This is a great advantage for productivity and cost management focused industries.

Improving Corrosion Resistance

The enhancement of the corrosion resistance property is one of the most important steps in the processing of materials, especially for the use in very harsh or demanding environments. There are many ways to improve a material’s resistance to corrosion. The following are the five most important methods:

Protective Coatings

The application of protective coatings such as paint, epoxy, or powder coating, creates a barrier between the material and the environment, thus effectively preventing the material from coming into contact with moisture and corrosive agents.

Data Example: Epoxy coatings, according to studies, can decrease the corrosion rates in marine environments by as much as 90%.

Galvanization

Galvanization is the process of coating steel or iron with zinc and zinc which serves as a sacrificial anode and protects the substrate from being rusted.

Data Example: A steel that has been galvanized can survive over 50 years in rural areas but only 20-25 years in urban or coastal regions.

Alloying

The addition of elements such as chromium, nickel, or molybdenum into the metal can improve the corrosion resistance of the material inherently as they form stable passive layers. For example, stainless steel is very much resistant to corrosion because of its chromium content.

Data Example: Corrosion-resistant steel with at least 10.5% chromium content is 8 times more protected against rusting compared to mild steel.

Cathodic Protection

By the application of two methods: sacrifice of the anodes (e.g., magnesium or zinc) or impressed current systems, cathodic protection inhibits the oxidation of the material thus reducing corrosion.

Data Example: In the oil and gas industries, cathodic protection systems can decrease pipeline failures by 70%.

Heat Treatment

Heat treatment is one of the methods that can be employed for modifying a material’s microstructure, thereby its corrosion-resistant characteristics, for instance, specific heat treatment techniques like annealing or quenching.

Data Example: Austenitic stainless steels subjected to the right annealing demonstrate slower rates of pitting corrosion in chloride-rich environments.

Enhancing Hardness and Ductility

Alloying

The addition of alloying elements such as carbon, manganese or chromium could have a considerable impact on the hardness and ductility of a material. The alloying elements not only reinforce the microstructure’s strength but also confer the property of flexibility. Data Example: A high-carbon steel exhibits an increase of 50% to 1 modulus of elasticity in tensile strength as compared with the low-carbon steel and, at the same time, keeps considerable ductility. Work Hardening The plastic deformation or rolling or forging cycle reveals the process of dislocation generation in crystals of the material that leads to the increase of hardness. Data Example: The cold-rolled aluminum has become harder by 30% as compared to its previous annealed condition. Heat Treatment All the above procedures such as tempering, quenching, and annealing will affect the microstructure of the material and hence its hardness and ductility properties. Data Example: The appropriate tempered martensitic steel resists a tensile stress of 600 MPa while stretching 20% without breaking. Grain Refinement Smaller grains do the work of strengthening the material and at the same time they do not lose the property of ductility, because dislocation movement is hindered by fine grains. Data Example: A substrate with 10-micrometer-sized grains can withstand 40% more stress than one with 50-micrometer-sized grains. Precipitation Hardening The small, widely dispersed precipitates formed in the material through aging aid both strength and ductility as they block dislocation movement. Data Example: Precipitation-hardened aluminum alloys exhibit a 25% increase in yield strength while still being flexible enough for aeronautic purposes.

Stress Relief and Tempering

Thermal processes labeled as stress relief and tempering serve the purpose of improving the mechanical characteristics of metals by lessening internal stresses and increasing toughness, respectively. Five significant aspects and data points relating to these processes are presented below:

Stress Relief and Annealing

Purpose: The technique leads to the elimination of the residual stresses which are the result of cooling or mechanical deformation that is not uniform.

Data Example: The 20% reduction of internal stresses in steel parts subjected to the stress relief and annealing process with a temperature of 600°C for a duration of 2 hours takes place without the loss of hardness.

Tempering After Quenching

Purpose: In this case, the aim is to make the material less brittle and more tough.

Data Example: Renowned 30% increase in impact resistance is the result of the process applied to the hardened steel tempered at 300°C while the wear resistance is still at a high level.

Low-Temperature Tempering

Purpose: The maximum hardness is kept while toughness is improved slightly; the process is mostly used for tools.

Data Example: Tool steels that are tempered at 150°C will not lose more than 5% of their hardness but will gain more resistance to cracking in the case of stress being applied.

Medium-Temperature Tempering

Purpose: The structural materials’ properties of strength, hardness, and toughness are optimized.

Data Example: The tempering process applied to the alloy steels at a temperature of 450°C gives an increment of 15% in tensile strength as well as shock absorption properties.

High-Temperature Tempering

Purpose: The process breaks down brittleness and strengthens ductility for heavy-duty applications.

Data Example: A temperature of 650°C during the tempering of carbon steels results in a 40% increase in elongation being achieved, while still being able to counter the low strength needed for pressure vessels.

Applications of Annealed Stainless Steel

Stainless steel that is annealed undergoes techniques that improve its ductility and resistance to corrosion thus making it suitable for a wide range of applications. Below are five principal applications:

Food Processing Equipment

Details: Its excellent corrosion resistance and hygiene properties are often the reason for its use in the production of food-grade containers, mixers, and piping.

Data Example: Austenitic stainless steel (304 grade) retains corrosion-free surfaces even after a long period of time with acidic food substances.

Chemical Processing Plants

Details: The perfect combination of equipment and chemicals where the forces are handled like storage tanks and reactors, the options of durable and strong chemical resistance are critical.

Data Example: Annealed 316 stainless steel gives the best 30% corrosion resistance in oxidizing environments compared to non-annealed variants as well.

Medical Instruments and Devices

Details: Regularly used for surgical tools, implants, and medical devices due to its biocompatibility and resistance to sterilization processes.

Data Example: Stainless steel implants exhibit a tensile strength of 550 MPa after annealing, which ensures reliability in orthopedic applications.

Aerospace Components

Details: Applying to airplane structure parts and bolts when the high strength-to-weight ratio and oxidation resistance are needed.

Data Example: Aircraft-grade stainless steel has a 20% increase in fatigue life after annealing which guarantees safety in extreme conditions.

Architectural and Structural Applications

Details: Used frequently in building facades, bridges, and support structures because of its aesthetic appeal and long-term durability.

Data Example: Stainless steel in structural frames can bear 25% more loads than non-annealed variants, thus providing superior performance under stress.

Industries Utilizing 304 Stainless Steel

Food and Beverage Industry

Details: 304 stainless steel is a great choice for food processing equipment, storage tanks, and kitchen utensils because of its rusting and cleaning properties.

Data Example: Studies conducted show that 304 stainless steel extends the shelf life of processed foods by 15% compared with other materials, diminishing the risk of contamination.

Medical and Pharmaceutical Industry

Details: One of the most common uses of metals in medicine is in surgical tools, medical implants, and drug processing equipment due to their non-toxicity and cleaning properties.

Data Example: The non-toxicity of 304 stainless steel leads to over 90% success rates in the usage of long-term medical implants.

Automotive Industry

Details: Strong, heat-resistant, and visually appealing, the material is used in the cars’ exhaust systems, trims, and structural components.

Data Example: Automotive manufacturers testify that a 30% cutback in maintenance costs results from the application of 304 stainless steel in critical vehicle components.

Chemical Processing Industry

Details: 304 stainless steel is perfect for building chemical storage tanks, heat exchangers, and pipelines as it does not corrode with any chemical.

Data Example: Steel pipelines made of 304 last against acidic materials up to 40% longer than non-stainless alloys.

Construction Industry

Details: The metal is employed in the structural design of cladding, railings, and bars because of its strength and beauty.

Data Example: The average life span of buildings that use 304 stainless steel weathering systems is 25 years longer than that of conventional materials.

Common Uses in Manufacturing

Food Processing Equipment

Details: Due to its corrosion resistance and easy cleaning, the 304 stainless steel has become the main material for production of kitchen appliances, food storage containers, and processing machines.

Data Example: Research indicates that food processing equipment manufactured from 304 stainless steel can be utilized for 50% longer time in comparison with ordinary metal ones.

Pharmaceutical Equipment

Details: Non-reactive and easy to clean characteristics of 304 stainless steel make it perfect for pharmaceutical mixing tanks, storage containers, and pipelines.

Data Example: 304 stainless steel tanks used for pharmaceutical storage can cut the possibility of material contamination by 70%.

Automotive Components

Details: Stainless steel is used in exhaust systems, ornamental trim, and fuel tanks, as it can resist high temperatures and has strong corrosion resistance.

Data Example: Stainless steel automotive exhaust systems last 30% longer than galvanized steel ones.

Chemical Processing Equipment

Details: The metal is mainly used in reactors, heat exchangers, and storage containers, as it has the property of resisting chemical corrosion.

Data Example: 304 stainless steel heat exchangers provide 45% better efficiency compared to non-stainless heat exchangers in corrosive environments.

Medical Instruments

Details: Staff prefers to use 304 for surgical instruments, medical trays, and implants due to its sterilization capabilities and biocompatibility.

Data Example: 304 stainless steel surgical instruments keep their integrity and sterility 80% longer through repeated sterilization cycles than non-stainless steel alternatives.

Role in Construction and Architecture

Due to its strength, beauty, and impermeability to rust, stainless steel is a key element of building and architecture. It is applied in a wide variety of ways, both for support and decoration. Here are some explanations that present its role.

Structural Components

Details: The building world has turned to stainless steel for its almost indestructible quality and the fact that it can last for 100 years.

Data Example: In coastal areas, stainless steel structures will survive for 25 to 30 years longer than buildings made of ordinary steel, thus resulting in lower maintenance and replacement costs.

Roofing and Cladding

Details: Stainless steel is a roofing and cladding material that grants a sleek and modern appearance and at the same time protects the building from harsh weather and rust.

Data Example: Maintenance costs of stainless steel-clad buildings are 40% lower over 50 years compared to the maintenance costs of buildings with painted steel cladding.

Handrails and Balustrades

Details: For a safe and good-looking environment, stainless steel handrails and balustrades are the best choice because they are durable and do not get distorted.

Data Example: Stainless steel handrails will keep their structural integrity in areas of heavy pedestrian traffic 90% better than aluminum handrails.

Facades

Details: Stainless steel facades are not only a good reflector of light but also a modern finish which is often the case in the case of remarkable buildings.

Data Example: Stainless steel facades protect the building from thermal expansion-related damages by 15% in areas with very high or low temperatures.

Water and Wastewater Infrastructure

Details: Stainless steel’s capacity to resist corrosion is the reason why it is indispensable for the water treatment and distribution systems in the form of pipelines and storage tanks.

Data Example: Stainless steel water tanks can last up to 60 years, which is almost double the life of tanks made with conventional materials.

Best Practices for Stainless Steel Annealing

Precise Temperature Control

Details: Achieving the desired material properties greatly depends on the exact annealing temperature. Each stainless steel grade has its own peculiar temperature limits that need to be adhered to in order to get the right amount of recrystallization and stress relief.

Data Example: Best results for AISI 304 stainless steel are obtained by limiting the annealing temperature to a range of 1900°F to 2050°F.

Controlled Cooling Rates

Details: Proper cooling methods, such as cooling by air or immersing in water for rapid quenching, inhibit the formation of carbides and eventually lead to increased corrosion resistance.

Data Example: Rapid cooling after annealing has been found to cut the chances of intergranular corrosion by up to 30%.

Clean and Contaminant-Free Atmosphere

Details: Carrying out annealing in a controlled environment such as a vacuum or inert gas atmosphere minimizes oxidation and maintains the surface quality of the steel.

Data Example: Surface oxidation during the annealing process is reduced by 40% when an argon gas atmosphere is used, subsequently leading to less time required for post-processing.

Uniform Heating

Details: The distribution of heat across the material being processed must be uniform to minimize internal stress and potential warping.

Data Example: Residual stress is reduced by up to 25% due to uniform heating at the annealing stage, which in turn prolongs the life of stainless steel components.

Regular Equipment Maintenance

Details: It is necessary to check and clean annealing furnaces and tools in a timely manner so as not to have any contamination and also to ensure that the performance of the equipment is consistent.

Data Example: It has been established that well-maintained furnaces can be up to 15% more efficient in terms of heating, which translates into a reduction of both energy consumption and production costs.

Optimal Heat Treatment Conditions

Precise Temperature Control Details: It is pivotal to heat treatment that the correct temperature is kept so that the material properties can be changed as expected. Data Example: Variations of only 10°F may cause a 20% drop in the hardness uniformity thus, affecting the dependability of the product. Controlled Cooling Rates Details: The rates of cooling should be dependent upon the material type and the process of treatment in order to lessen the formation of stress and distortion. Data Example: A controlled cooling rate tailored for alloy steel can bring down the internal stress by as much as 30%. Atmosphere Management Details: The use of inert or controlled atmospheres, like argon or nitrogen, is a way of keeping the surface intact and preventing oxidation at the same time. Data Example: Proper atmosphere control during carburizing can make the surface of the material 25% harder than the untreated one. Material Pre-treatment Details: Cleaning and preparing materials prior to heat treatment is essential to avoid contamination and ensure uniform results. Data Example: Pre-cleaning procedures have been shown to reduce scaling during annealing by 15%. Consistent Heating Profiles Details: Uniform heating eliminates temperature gradients that may lead to uneven properties or material warping. Data Example: Utilizing advanced heating techniques ensures temperature uniformity, improving product durability by 18%.

Cooling Techniques: Quenching vs. Air Cooling

Quenching Speed and Heat Removal Details: Quenching is a process of very fast cooling which water, oil or brine is usually used as the medium for cooling in order to achieve the desired mechanical properties, namely, hardness. Data Example: With such a drastic change in temperature, hardness can be increased up to 35% when compared to the air cooling process. Air Cooling for Reduced Stress Details: The method of air cooling is a very slow one but it does not cause thermal shock and internal stress. It is therefore used very often for those materials that must not be distorted at all. Data Example: Warping in aluminum alloys is reduced by 45% through air cooling as compared to quenching. Effect on Microstructure Details: Quenching alters the microstructure of the material quite aggressively whilst air cooling retains a more balanced grain structure. Data Example: For some alloys, the level of martensitic gradients in quenched steel is 50% higher than in air-cooled steel. Energy Efficiency Details: Due to the large amount of cooling fluids that are not used, air cooling is considered to be the most energy efficient and eco-friendly method. Data Example: An overall reduction of approximately 20% in energy consumption in industrial applications could be attributed to the use of air cooling. Application Suitability Details: Quenching is the method of choice for applications where high wear resistance is a crucial requirement, while air cooling is the perfect solution for products that cannot tolerate any residual stress at all. Data Example: Quenching is applied in 85% of the production for high-performance tools manufacturing, while air cooling occupies the market for low-stress structural components completely.

Monitoring and Controlling Temperatures

Heat monitoring and control that are efficient are very crucial for industrial processes that get the best benefits and quality product in the end. Real-Time Temperature Sensors, for instance, key practices and data points come one after another:

– Details: These sensors are always monitoring temperature fluctuations to keep the temperature in a desired range.

– Data Example: Quality consistency is reported to be improved by 15% in the systems with real-time sensors.

Details: Automated systems that control the application of heat or cooling according to the programmed conditions are called automated temperature control systems.

Data Example: In energy-heavy operations, the utilized automated control is capable of bringing the energy costs down by 25%.

Threshold Alarms

– Details: Alerts are sent to the operators through alarms when the temperature goes above or below the safe range that has been set.

– Data Example: As a result of the installation of threshold alarms, the equipment breakdowns are reduced by 30%.

The thermal imaging cameras can be used to visualize the hot areas and the unevenly heated regions on the surfaces.

The data example is given that 90% of the potential overheating problems are detected by the application of thermal imaging before the failure occurs

Sophisticated analytics tools are responsible for analyzing the past and present data to make the processes more efficient.

Data Example: The application of analytics platforms assures that there will be 20% less temperature-related defects that recur.

Challenges and Solutions in Annealing Stainless Steel

Annealing stainless steel involves several challenges that can hinder efficiency and quality. One primary concern is achieving precise temperature control during the heating and cooling phases. Deviations in temperature can lead to surface defects, grain structure irregularities, and compromised corrosion resistance. Another challenge is oxidative scaling, which can occur at high temperatures, requiring subsequent pickling or mechanical treatments to restore the surface’s quality. Material warping is also a frequent issue, particularly when dealing with thin or intricate components, affecting dimensional accuracy and usability.

Solutions to Overcome Challenges

The incorporation of cutting-edge thermal imaging cameras and automated sensors is becoming more and more important in order to cope with these difficulties. The use of these devices enables the monitoring of temperatures in real time with high accuracy, thus allowing the process of annealing to be adjusted and variations to be reduced to a minimum. Furthermore, using a controlled atmosphere with inert gases, such as argon, or vacuum systems can bring about an appreciable decrease in oxidative scaling. In terms of warping, the application of optimized fixturing methods and gradual cooling can prevent the material from losing its structural integrity. The use of data analytics platforms increases the accuracy of predictions and this has been identified as a factor in the reduction of defects by as much as 20%, which is supported by recent industrial research.

By and large, these data-driven and technologically advanced methods are not only making the stainless steel annealing process more effective but also helping to improve its quality and reduce the cost of operations.

Common Issues Faced During Annealing

Warping and Distortion

The irregular application of heat or the wrong cooling rates can cause warping during the annealing process. This might result in the production of significantly deformed parts and the increase of rejection rates by up to 15% in certain operations.

Surface Oxidation

Oxidation is the chemical reaction of oxygen with metals, and it occurs at high temperature, which leads to the dulling and scaling of stainless steel surfaces. Research has indicated that the lack of proper protective atmospheres is the reason for up to 10% of surface defects in the annealing process.

Grain Growth Issues

Excessive grain growth due to the improper control of annealing temperatures results in the material losing its toughness and mechanical performance. This phenomenon is responsible for nearly 12% of inconsistencies in material properties.

Decarburization

Decarburization, which is the loss of carbon from the surface layer, reduces the material’s strength and wear resistance. This is a common issue that arises from the material being subjected to high temperatures for a long time without proper atmospheric controls.

Internal Cracking

Processing incisions can generate residual stresses that cause internal cracking during the annealing process. According to analytical data, such cracks are responsible for 8-10% of the material’s failure during this stage.

Solutions to Improve Annealing Outcomes

Optimize Temperature Control

Annealing temperature control is one of the most critical factors that ensures the integrity of materials. Thermal monitoring system,s which are sophisticated, can be used to detect and prevent the heating of the materials or their parts being at different temperatures, which are some of the techniques that can lead to problems like decarburization and internal cracking.

Introduce Protective Atmospheres

The risk of oxidation and decarburization can be greatly reduced by the use of controlled atmospheres during the annealing process. The inert gases such as nitrogen or argon are the ones being used for this purpose. The gases form an envelope around the very surface of the material and thus, improve the overall quality of the products.

Preemptive Stress Relieving

Enhancing the quality of metal products by using non-metallic materials or alloys can be achieved by performing stress-relief treatment before annealing. This procedure will make the whole annealing process more effective and uniform since it will also be silencing the internal cracking issue.

Adopt Predictive Analytics

The use of data-driven analytics to predict the behavior of materials during their annealing process will let you know about the probable failures ahead of time. The combination of zootechnical processing and machine learning along with real-time data transfer can be used to optimize the conditions and thus, prevent the occurrence of defects.

Routine Equipment Maintenance

The proper maintenance of annealing equipment is a prerequisite for accurate performance. The heating elements, furnaces, and protection gas systems should be checked regularly. Not only that it will help in uncovering problems but it will also be a step towards making less disruptions or inconsistencies during the process.

Combining the various measures of strict temperature control, protection, and sophisticated analysis, the results of annealing can be optimized to such an extent that defect rates will be very low, and industrial applications will witness an increase in the performance of materials.

Staying Updated with Industry Trends

Keeping oneself informed about the industry trends is an active engagement with the trustworthy information sources like technical journals, industry conferences, and professional networks. I have made it a rule to keep track of the progress in technology, new best practices, and market changes so that my knowledge is always updated and important. With this method, I can change with the times and keep on getting better at the processes in my area of work.

References

- Annealing of Cold-Worked Austenitic Stainless Steels

This article reviews the phenomena during the annealing of cold-worked austenitic stainless steels, focusing on microstructural changes.

Link to source - The Effect of Annealing Time on Microstructure and Impact Energy of Stainless Steel AISI 316L

This study examines how annealing time influences the microstructure and mechanical properties of AISI 316L stainless steel.

Link to source - Electrochemically Induced Annealing of Stainless-Steel Surfaces

This research explores a novel electrochemical method for annealing stainless steel surfaces at lower temperatures.

Link to source

Frequently Asked Questions (FAQ)

What is the annealing process for stainless steel?

The annealing process for stainless steel involves heating the alloy to a specific temperature, followed by slow cooling. This heat treatment helps to relieve internal stresses, soften the material, and improve its ductility. The process is crucial for enhancing the mechanical properties and ensuring the material’s performance in various applications.

How does annealing affect the hardness of stainless steel?

Annealing stainless steel generally results in a reduction of hardness. The process allows for the recrystallization of the microstructure, which softens the metal by removing dislocations that contribute to hardness. This is particularly important in applications where improved formability and toughness are required.

What are the different types of stainless steel used in annealing?

There are various types of stainless steel that can undergo annealing, including austenitic, ferritic, and martensitic stainless steels. Each type has distinct properties and responses to heat treatment, with austenitic stainless steels being the most commonly annealed due to their excellent corrosion resistance and formability.

What is the typical annealing temperature for 304 stainless steel?

The typical annealing temperature for 304 stainless steel ranges from 1010°C to 1120°C. This temperature range is crucial to achieve optimal mechanical properties and corrosion resistance. Proper control of the heating and cooling processes is essential to prevent unwanted changes in the microstructure.

Can stainless steel be hardened through annealing?

Stainless steel cannot be hardened by the annealing process. Instead, annealing is used to soften the material and improve its ductility. Hardening of stainless steel is typically achieved through methods such as quenching and tempering or by solution treatment, particularly in martensitic stainless steels.

What is the difference between full annealing and subcritical annealing?

Full annealing involves heating stainless steel to the austenitizing temperature followed by slow cooling, while subcritical annealing occurs at lower temperatures, just below the critical temperature. Full annealing is used to achieve maximum softness and ductility, whereas subcritical annealing is utilized to relieve stresses without significantly altering hardness.

How does the cooling rate affect the properties of stainless steel during annealing?

The cooling rate during the annealing process significantly influences the properties of stainless steel. Slow cooling allows for the formation of a uniform microstructure, which enhances toughness and reduces hardness. Conversely, rapid cooling can lead to undesirable microstructural changes, potentially affecting the corrosion resistance and mechanical properties.

What role does chromium play in the corrosion resistance of stainless steel?

Chromium plays a vital role in the corrosion resistance of stainless steel by forming a protective oxide layer on the surface. This layer prevents the steel from corroding and enhances its durability in various environments. Higher chromium content typically improves the corrosion resistance and overall performance of the stainless steel alloy.