Stainless steel is a favorite among all industries due to its long-lasting nature, unbeatable corrosion resistance, and shiny appearance, which is why it is commonly used in almost every area, like construction and kitchenware. Nevertheless, proper surface treatment is essential to sustain its quality and ensure long-life performance. Pickling and passivation are the processes that together form a two-step treatment, necessary for these metals to enhance their protective properties. This article is destined to be an interesting read for anyone who wants to know the details of pickling and passivation, their application, and what gains they provide. Whether you are a producer, an engineer, or simply a person interested in metal surface treatments, this guide will definitely give you precious knowledge about these processes and their role in preserving the globally renowned stainless steel attributes.

Introduction to Pickling and Passivation

Pickling and passivation are chemical treatments used for cleaning and protecting stainless steel surfaces. Through the application of acid solutions, pickling removes impurities like oxide scales and welding residues. The surface of the metal is restored by removing the contaminants that would otherwise cause corrosion. In contrast, passivation improves the stainless steel’s natural protective oxide layer, making it more resistant to corrosion in the long run. The combination of these two processes plays a vital role in keeping stainless steel durable, attractive, and performance-wise excellent across various applications.

What is Pickling?

Pickling is a treatment of metal surfaces mainly applied in the industrial sector for cleaning and preparing metals such as stainless steel and other alloys for their use or fabrication. The process comprises dipping the metal into a solution of strong acids, which can be hydrochloric or sulfuric acid. These strong acids can easily remove impurities like oxide scales, rust, and welding residues. Pickling makes the metal’s surface clean and refined again, ensuring it will perform well in its application. This process not only prepares the surface for next treatments like passivation or coating but also helps eliminate layers of potential contaminants, thus preventing future corrosion. This characteristic makes the pickling process a very important step in industries where metal components’ strength and durability are priorities.

What is Passivation?

Passivation is a chemical process used to polish the corrosion resistance of metal surfaces, especially that of stainless steel, by virtue of a thin, protective oxide layer. This oxide layer is obtained by excluding free iron and other surface contaminants by means of an acid solution, usually nitric acid or citric acid. The same metal, however, has now become less susceptible to rust and corrosion in case of air, moisture, or harsh environmental conditions. Thus, the process is widely accepted in different fields like aerospace, medical, and food processing, where the durability and hygiene of metal parts are of utmost importance. As per the newest discoveries, passivation not only prolongs the life of metal parts but also, through a gradual reduction of maintenance costs, becomes an efficient solution for material performance enhancement.

Importance of Pickling and Passivation in Stainless Steel

Pickling and passivation are two very important processes that keep stainless steel components performing well and intact. These two treatments allow for the removal of impurities to the maximum, such as surface contaminations, rust, and scale, and they also come to the rescue by restoring the oxide layer. The entire process results in a product that is highly corrosion-resistant. Here are major points highlighting the importance of pickling and passivation for stainless steel:

1

Enhanced Corrosion Resistance

The elimination of impurities from surfaces and the building up of the passive layer make stainless steel more resistant to corrosion—especially in severe environments such as the marine and chemical industry.

2

Improved Cleanliness

The treatments help get the surface smooth and clean, vanishing many contaminants that were there; thus, it has a very soft and gentle touch and is ready for the toughest hygiene standards in the food and pharmaceutical industries.

3

Prolonged Service Life

Stainless steel parts that were treated by pickling and passivation have a much longer life and are thus less frequently replaced, which reduces maintenance costs in the long term.

4

Prevention of Surface Defects

Pickling removes the colors and the scaling which are caused during the manufacturing processes like welding and adds to the visual and structural quality of the metal.

5

Better Weld Seam Integrity

The welded area is particularly susceptible to corrosion. Through pickling and passivation, these areas get the same level of corrosion resistance, thus extending the life of the welds.

✨ These processes are the backbone of stainless steel being able to keep and thus being the most widely used material for different applications.

The Process of Pickling Stainless Steel

Pickling of stainless steel is an intentional and supervised controlled chemical treatment procedure that eliminates the impurities, usually oxides, and other contaminants from the surface of the metal. By this process, the material’s natural corrosion-resistant properties are restored, and moreover, it gives a clean, smooth surface. The key steps of pickling stainless steel are summarized as follows:

Cleansing the Surface

The pickling process does not start until the stainless steel surface is entirely cleaned to get rid of dirt, oils, and grease. Usually using detergents or cleaning solvents makes it very sure that the surface is free of any obstacles that might inhibit the execution of the pickling process.

Chemical Treatment

The chemical treatment of stainless steel is done by immersing it into a bath comprised of specific acids, the mixture of nitric acid (HNO₃) and hydrofluoric acid (HF) being the most notable one. These acids jointly work by loosening the surface oxides and impurities. The acids are in varied concentrations and the time of the immersion depends on the grade of the stainless steel and the amount of the impurities.

Washing

The rinsing of stainless steel is an important step as it is done with water of high purity to get rid of the remaining acids, sometimes even deionized water being used to circumvent any contaminants coming in through deposition during this step. Washing is an extremely important step to be properly done, as it prevents acid residues that would give rise to the material going faulty later.

pH Neutralizing

In order for there to be no trace of acidic residue left on the surface, a neutralizing agent in the form of a weak alkaline solution is almost always applied. This procedure aids in the reestablishment of the material’s pH and in avoiding any further changes.

Visual Check and Finishing

The material after being through the pickle bath process is inspected directly. The impurity factor has to comply with the standards set by the company. The surface must show cleanliness, uniformity, and with no defects whatsoever. A passivation treatment is sometimes done by the manufacturers as the last step in the process to further improve the stainless steel’s resistance to corrosion.

Key Data and Benefits

⚡ Efficiency

Through pickling, the stainless steel surface is cleaned of up to 85-90% of dirt and impurities, thus the anti-corrosive properties and the aesthetic appearance are regained.

🌱 Environmental Considerations

Contemporary pickling methods make use of waste treatment facilities that neutralize the acids and eliminate the risk of environmental pollution, thus adhering to very strict rules.

✨ Surface Consistency

Research indicates that pickling not only improves the surface finish quality but also increases the durability and uniformity of the surfaces to be used. For example, the treated metal has much better resistance against pitting corrosion.

🏭 Industry Usage

Pickling is commonplace in various industries like building, food processing, pharmaceuticals, and chemical equipment manufacturing, where stainless steels are vital to the integrity of the process, such as in the case of the manufacture of reactors and vessels.

🔬 Technology Advancement: New technology advancements in the area of pickling include the use of eco-friendly acid alternatives and the optimization of processes with the goal of minimizing waste and energy consumption. Such developments make sure that stainless steel is a reliable and sustainable material for many different applications while being environmentally responsible.

Common Acids Used in Pickling

There are several acids that are used in the pickling process, each having different properties that make them efficient in removing impurities and improving the quality of the material. A comprehensive list of the most common acids is given below:

Hydrochloric Acid (HCl)

Hydrochloric acid is the most common choice due to its powerful and rapid action. It can remove rust and scale from carbon steel and low-alloy steel with great effectiveness.

Sulfuric Acid (H₂SO₄)

This acid is highly economical and is often used in the pickling of steel in a large-scale manner, especially when the surface is heavily scaled, as it is effective at high temperatures.

Nitric Acid (HNO₃)

Nitric acid is mostly employed with hydrofluoric acid and is the perfect choice for the stainless steels and high-alloy materials. It not only cleanses but also assists in the creation of a passive protective surface area.

Phosphoric Acid (H₃PO₄)

Phosphoric acid is less potent than other acids and thus is a safer option for pickling. It is especially useful for surface treatment, as it can be applied for removing light rust and preparing the surface for further treatments.

Acetic Acid (CH₃COOH)

A weak acid alternative that is used in specific applications. Acetic acid is often selected because its lower environmental impact and its gentleness to the materials which are thus preserved are reasons for its use.

The selection of acids for specific types of materials and the intended results has made their choice an important part of the pickling process.

Effects of Pickling on Stainless Steel

Pickling has a very important role in stainless steel, not only improving its looks but also its functioning. Listed below are key effects of the pickling process on stainless steel in detail:

Surface Cleanliness Improvement

The method does a good job of getting rid of all surface dirt, such as scale, rust, and the remains of welding, thus bringing back the smooth and clean look of the stainless steel.

Passivation Layer Restoration

Pickling actually facilitates the formation of the protective chromium oxide layer on the stainless steel surfaces, thus providing better corrosion resistance and making the material last longer.

Improved Weld Area Quality

The welding process may cause discoloration and the weakening of the stainless steel product. Pickling, on the other hand, not only removes the burnt tint but also guarantees the homogeneity of the material’s composition and properties.

Enhanced Surface Aesthetics

Pickling gives a surface that is uniform, sparkling, and smooth, which is suitable for use in places where the visual appeal is of great importance, like in architectural or decorative applications.

Residual Stress Minimization

Removing chemical impurities and stress-causing contaminants, pickling lessens the chances of stress corrosion cracking in stainless steel products.

The Process of Passivating Stainless Steel

Passivation is a chemical process that treats stainless steel surfaces to improve their corrosion resistance. It removes the free iron and other impurities from the surface to get a protective oxide layer. Below are the five main actions done in the process of passivation:

Surface Cleaning

The surface of the stainless steel is cleaned very well to wipe off grease, oil, dirt, and other materials that might get in the way of the process. It is done by using alkaline or solvent-based cleaning agents.

Pickling (Optional)

In case it is necessary, the surface gets pickled which means the heavy oxide and tough contaminants are completely removed. This process cleans the stainless surface and is very important if the metal has been heat-treated or welded.

Chemical Treatment with Acid Solution

The surface of the cleaned stainless steel is treated with an acid solution such as nitric or citric acid to completely dissolve free iron and other impurities. This step is important as it helps to remove the dead areas which would lead to corrosion.

Rinsing and Neutralization

The stainless steel gets flooded with deionized or distilled water after acid treatment to wash away acid residues. Neutralization might be done to make sure the surface has no acidic remains and is pH balanced.

Formation of the Passive Oxide Layer

A very thin and even oxide layer is formed by the stainless steel once the surface is cleaned and free of impurities. The layer acts as a barrier offering protection and thus increasing the corrosion resistance and longevity of the material in difficult conditions.

Benefits of Passivating Stainless Steel

To unlock stainless steel’s full potential one must go through a passivation process which is advantageous in several ways. The list below presents major benefits of passivation treatments for stainless steel:

Enhanced Corrosion Resistance

The process of passivation gives origin to a robust and very uniform oxide layer of stainless steel which reduces to a great extent the risk of corrosion. This is a very helpful quality especially when it comes to aggressive environments like marine or industrial settings where moisture, chemicals, and salts can be present in large amounts during the exposure.

Increased Longevity

The passivation treatment boosts up the service life of stainless steel components by improving their resistance against corrosion and wear. Furthermore, it cuts the replacements and maintenance down to the minimum, which in turn results in long-term savings on costs.

Maintaining Surface Cleanliness

The passivation process effectively eliminates all forms of contamination, impurities, and free iron from the surface, which in turn is a very hygienic and clean material. Therefore, the use of passivated stainless steel is very suitable for the food processing, pharmaceutical, and medical equipment manufacturing industries.

Enhanced Aesthetic Appearance

The process of passivation smoothens the surface and makes it very uniform, thus aesthetically stainless steel is improved and any discoloration or imperfection resulting from welding or fabricating has been completely removed.

Compliance with Industry Standards

The treatment with passivation protects and regulates the quality and performance standards compliance of the stainless steel and that it is ASTM A967 and AMS 2700 among others. This is of particular significance in the aerospace, automotive, and medical areas where reliability and safety are priorities.

Different Methods of Passivation

The passivation process can be accomplished through a variety of different methods, all customized to meet individual needs and applications. Here are typical methods of passivation, each with a description of the process and the advantages of the method:

1. Nitric Acid Passivation

The passivation of nitric acid is one of the oldest techniques, which consists of the application of a mixture of water and nitric acid to the stainless steel surface for the removal of free iron and at the same time to remove the contaminants. This method is very powerful and is being used in the industries where general corrosion protection is the main concern.

- Concentration Range: 20-50% nitric acid

- Temperature Range: 20°C to 60°C (68°F to 140°F)

- Duration: 20 minutes to 2 hours

2. Citric Acid Passivation

Citric acid is a greener and less hazardous alternative to nitric acid, and in fact, it is likely to give similar results. This practice is especially useful for cases where environmental regulations must be followed.

- Concentration Range: 4-10% citric acid

- Temperature Range: 25°C to 70°C (77°F to 158°F)

- Duration: 30 minutes to 1 hour

3. Electropolishing

Electropolishing is a process that is designed to simultaneously remove the surface layer of the metal and leave it so smooth that it will not attract any corrosion. This is done through the electrochemical process of electricity and forming a corrosion-resistant oxide layer on top that is thick and durable. This method is especially suited for manufacturing parts that have complex shapes and need to be of the highest quality.

- Voltage Applied: 5-30V

- Duration: 5 to 45 minutes

4. Mechanical Passivation

The method uses a combination of physical polishing and/or abrasive blasting in order to get rid of surface contaminants and make the base metal ready for oxidation. Although this technique is quite simple, it is often used as a supplementary method by companies who employ chemical techniques for complete passivation.

- Techniques Used: Grinding, polishing, or blasting

- Applications: Heavy-duty parts or equipment

5. Alkaline Cleaning Followed by Acid Passivation

In this two-stage procedure, the alkaline cleaning step is used first to get rid of all oils, greases, and spilled organic materials. This is followed by an acid bath that guarantees complete passivation. Thus, the method assures that the surface is devoid of both organic and inorganic impurities.

- Alkaline Cleaner pH Range: 8.5-13

- Acid Used: Nitric or citric acid

- Duration: Varies according to the contamination levels

💡 Each passivation method has its own particular requirements, i.e. general corrosion resistance or ultra-clean and aesthetic surface for specialized applications. What will be the most appropriate method will depend on the material, requirements of the industry, and specific needs.

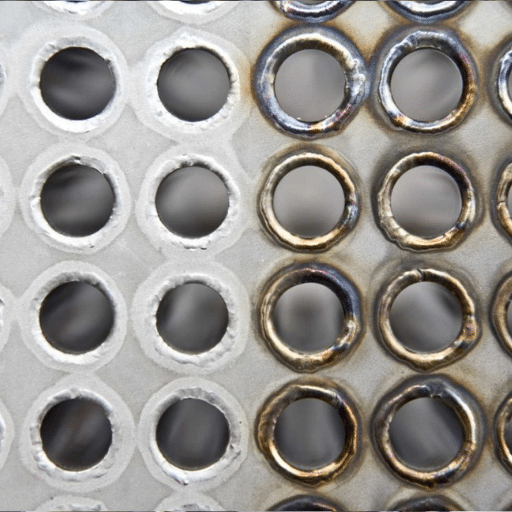

Difference Between Pickling and Passivation

Pickling removes surface impurities and oxide layers, while passivation enhances the protective chromium-oxide layer without removing metal.

| Parameter | Pickling | Passivation |

|---|---|---|

| Purpose | Remove impurities | Enhance protection |

| Key Function | Metal removal | Oxide layer formation |

| Chemicals Used | Nitric, hydrofluoric | Nitric, citric acids |

| Surface Effect | Dulls surface | Retains appearance |

| Corrosion Impact | Restores resistance | Improves resistance |

| Application | Post-welding, scaling | Post-cleaning, polishing |

Key Differences Explained

The five principal differences between pickling and passivation are listed below with a more in-depth explanation:

Purpose

Pickling: To a great extent aims at purifying the surface by means of chemically dissolving the latter. The surface impurities to be removed include scale, rust, etc.

Passivation: The objective is to increase the corrosion resistance of the material by means of applying a thin oxide layer on the surface of the material.

Key Function

Pickling: The main operation is to remove unwanted metal layers or contamination with a view to bringing back the basic properties of the material.

Passivation: Strengthens the material that is already there by having a stable and inert oxide layer formed over it, thereby improving its endurance without the need for metal removal.

Chemicals Used

Pickling: The solution used contains strong acids such as nitric acid or hydrofluoric acid that are very effective in the dissolution of contaminants.

Passivation: Milder acids like nitric or citric acid are used to clean and treat the surface, rather than to etch or remove it significantly, as in pickling.

Surface Effect

Pickling: The surface after pickling usually looks dull because of the vigorous removal of material layers. This is perfect for removing discolored welding but alters the texture at the same time.

Passivation: The passive layer will be formed on the surface of the metal without affecting its original color and will produce a uniform and clean finish without changing its texture.

Corrosion Impact

Pickling: Works as a kind of natural corrosion resistance booster for the metal because it gets rid of the contaminants that could otherwise hasten the rusting process.

Passivation: Goes one step further, making the metal impervious to rust through the building of a passive film that guards it against harmful environmental factors like humidity or chemicals.

💡 These differences reveal the fact that both pickling and passivation are employed in a way that is still complementary but at the same time they serve different purposes in metal surface treatment. Depending on the desired outcome for specific applications, both processes are indispensable.

When to Use Pickling vs. Passivation

The selection of metal surface treatment between pickling and passivation chiefly depends on the application intended for the metal surface and the metal surface’s requirements. Below are instances where each process is the most appropriate:

🔥 Post-Welding Cleanup

Pickling is perfect for the elimination of heavy oxide layers, weld scale, and discoloration that have been caused by high-heat processes such as welding. The surface thus is rendered not only clean but also ready for further treatments. Passivation might be carried out after pickling for the purpose of further improving the corrosion resistance by the process of creating a protective oxide layer.

🛡️ Restoring Corrosion Resistance

Passivation is of great importance in the treatment of stainless steel industrial parts as it allows for the reformation of their chromium oxide layer thereby enhancing their corrosion resistance after such treatments as machining or grinding. Pickling can also be utilized as a method to get rid of surface particles that might otherwise make it impossible for a uniform passive layer to be formed.

🧹 Heavy Contamination Removal

The use of pickling is very efficient in the eradication of heavy scales, iron particles that have been embedded, and other hard-to-remove contaminants from the metal surface, especially that of stainless steel. In these cases, passivation is usually not very effective but can be used as a final step to provide protection in the long run.

🎨 General Surface Preparation

In the case of preparing metal parts for different treatments such as coating, painting, and others, pickling will make sure that mill scale and deposits are removed, thus providing a smoother and cleaner surface. In this respect, passivation would not be able to render the same degree of cleanliness since it deals with microscopic protection rather than visible surface imperfections.

🌊 Applications in Aggressive Environments

If metal components are to be exposed to harsh chemicals or marine environments, the best choice is passivation to improve the overall resistance against localized corrosion such as pitting or crevice corrosion. It should be noted that pickling can take place before passivation if the surface is covered with heavy contaminants that in these circumstances would undermine the integrity of the metal.

💡 Key Takeaway: These considerations illustrate that the better understanding of the purpose and limitations of each process plays a central role in the selection of the most effective treatment for a particular case.

Impact on Welded Areas

Welded joints in stainless steel have the potential of raising distinct difficulties that result from change in the metal’s microstructure and surface due to the heat applied during welding. The furnace can get the material’s corrosion resistance and life expectancy greatly affected. The list below shows five such chief impacts along with their consequences:

Heat-Affected Zone (HAZ) Sensitization

Welding operations can lead to a depletion of chromium in the vicinity of the weld due to high temperatures. This in turn can cause the formation of chromium carbides. The ‘sensitization’ process can thus, lower the welding’s most resistant to corrosion and elevate the susceptibility of the weld to intergranular corrosion.

Surface Oxidation

Stainless steel welding normally leads to the creation of a layer of oxides or ‘heat tint’ on the surface however, this is not always the case. A zone that has been oxidized will be less corrosion resistant and it will possibly need a post-welding treatment such as pickling or mechanical cleaning.

Stress Corrosion Cracking (SCC)

Welding introduces residual stresses which can make it easier for welded areas to suffer from SCC. Particularly, this is the case in the presence of chlorides or when the welds are subjected to mechanical stress.

Distortion and Warping

Welding heats up the metal workpiece and, this results in localized expanding and contracting, thus giving rise to a warped or distorted finished product. The quality of the product in terms of structural integrity and geometrical precision may be affected.

Reduced Passivation Layer

The weld may alter the passive oxide layer that gives the natural corrosion resistance to stainless steel. The issue then will be the application of post-weld passivation processes to recapture the protective properties.

✨ It is only through the handling of these specific challenges that the appropriate post-weld treatments and design considerations will be able to guarantee the long-term durability and good performance of stainless steel welded parts in different applications.

Benefits of Pickling and Passivating Stainless Steel

Restores Corrosion Resistance

Pickling and passivation are the processes that are used to remove surface contaminants, among which are iron particles and welding residues, and as a result, the protective chromium oxide layer is restored. This process of removal and restoration is very significant in terms of material’s opposition to pitting and general corrosion.

Prevents Contamination

Cleaning the surface thoroughly through these processes is a very effective way of minimizing the risk of cross-contamination with other metals, which could result in galvanic corrosion or even compromise the structural integrity of the part.

Extends Service Life

Components made of stainless steel that have undergone pickling and passivation treatments do not just have a longer life but also a major part of it attributed to the factor of surface quality and resistance offered to environmental factors like moisture, chemicals, and salt.

Improves Aesthetic Appearance

The application of treatments plays a major role in cleaning and smoothing the surface as well as in making it free from discoloration, stains, or scale. Thus, the visual appeal gets enhanced, which is very crucial for exposed or decorative stainless steel products.

Enhances Cleanliness in Sensitive Applications

For the sectors of food production, pharmaceuticals, and healthcare, pickling and passivation are the methods that guarantee a hygienic surface and also the reduction of possibilities of bacterial growth and contamination, thus satisfying the stringent requirements of government and industry regulations.

Enhanced Corrosion Resistance – Key Data

The method of pickling and passivation contributes a lot to the corrosion resistance of stainless steel. These treatments make sure that the chromium oxide layer, which is a protective layer, forms properly by cleaning the surface of contaminants, imperfections, and even iron particles. Below are essential facts and figures that demonstrate how these methods increase the resistance to corrosion:

📊 Restoration of Chromium Oxide Layer

Pickling and passivation construct the chromium oxide layer, which is the main reason that stainless steel has corrosion resistance. Research tells that this layer can prevent oxidative damage up to 80% even in the sea environment.

🎯 Protection Against Pitting Corrosion

By removing the iron impurities and debris that can form crevices, you still get the risk of localized corrosion to a minimum and thus improve the material life even in chloride-rich conditions.

⚗️ Enhanced Resistance to Harsh Chemicals

Pickling and passivation not only make stainless steel chemicals poor resistant, but they also render it powerful to withstand even the most aggressive chemicals, including acids and alcohols, which are the most suitable environments for chemical processing.

💧 Extended Durability in High-Humidity Environments

Passivated surfaces have been found to be very effective in rust and corrosion resistance through controlled studies, being up to 30% better in areas with high humidity or coastal areas.

✅ Compliance with Industry Standards

Plant surfaces obtained through pickling and passivation not only comply with industry standards but they also exceed them, such as ASTM A380 and ISO 15730, thus ensuring the best possible performance and life in corrosive environments.

References

Improvement of Corrosion Resistance and Electrical Conductivity of Stainless Steel 316L Bipolar Plate by Pickling and Passivation

This study explores the effects of pickling and passivation on stainless steel 316L, focusing on corrosion resistance and conductivity.

Electrochemical Method for Pickling and Passivation of Austenitic Steel Welds

Discusses the electrochemical approach to enhance corrosion resistance in austenitic stainless steel welds.

Kinetics of Passive Film Growth on 304 Stainless Steel in H₂SO₄ Pickling Solution Under Chemical Oxidation

Investigates the kinetics of passive film growth and corrosion resistance improvement after pickling.