Copper is the second most used metal worldwide after aluminum and is present in most of the electronic devices, industrial machines, and electric wires. Along with its widespread use, the question to be answered by most people remains unchanged: “Is copper magnetic or nonmagnetic?” At first, the response might seem easy, but on the contrary, the whole process of how copper acts magnetically is both fascinating and very complicated. The article, therefore, takes a closer look at the distinct features of copper, how it interacts with magnets, and eventually clarifies the whole magnetic nature of copper. If you are a science buff, a student just starting to learn about metals, or you are just inquisitive, this article will surely give you a good grasp of copper’s magnetism and its important role in our day-to-day life.

Copper: An Overview

Copper is one of the most versatile and highly prized metals due to its unique characteristics that are the reason for its wide use in different industries. Here are five important facts and figures about copper that support its importance:

Excellent Conductivity

Copper is the best electrical and thermal conductor after silver, thus it is extensively used in electrical wiring, electronics, and even household lighting. Its good conductivity is the main point why it is so extensively used in such applications.

Corrosion Resistance

Owing to its high resistance to corrosion, the metal is sure to last as a material for pipes, roofing, and other building components. The layers of protection that the metal’s natural patina gives over time are also very important.

Malleability and Ductility

The metal exhibited so much malleability and ductility, which means it can easily be crafted into and drawn into wires or sheets without the risk of snapping; this is a characteristic of metal that is crucial in the manufacturing processes.

Antimicrobial Properties

Copper is endowed with natural antimicrobial properties, which enable it to kill germs and viruses on surfaces. As a result, the metal has been used in hospitals and on surfaces that are frequently touched, such as doorknobs, faucets, etc.

Abundance and Availability

Copper is ranked among the top three most abundant and recycled metals on earth. About 80% of the world’s copper has been produced and is still in use which points to its sustainability and economic influence.

Properties of Copper

Copper has been sown with marvellous properties and turned out to be a modern-day miracle for many different applications. This metal’s top-notch electrical conductivity property has led to its being used in the manufacturing of wiring and electronic devices, with the demand for copper continually to grow as the markets for renewable energy and electric vehicles are expanding. Moreover, copper is a notable element in solar panels, wind turbines, and noise-free batteries, which not only making the future of green energy more vibrant but also stressing its participation in this transition that is towards greener energy.

On the other hand, the heat property of copper is used in the heating, cooling, and refrigeration industries, the hospital sector is the biggest user of the metal’s antimicrobial properties, especially during world health crises. Copper alloys are a mix of metals that are not corroded easily and are thus used in the construction and manufacturing industries for their strong characteristic, hence, the critical infrastructures such as bridges and pipelines remain durable.

Copper’s versatility, together with its sustainable development, because of its huge recycling rates has greatly contributed to the metal’s acceptance as an indispensable mate of technology that shapes the devised works and environmental goals.

Historical Uses of Copper

Copper has been the most important metal in human history, with its use by man going back to the very first civilizations. Lately, archaeological research has concluded that copper was first used more than 10,000 years ago in the Neolithic period for making simple tools and adornments. The rise of the Bronze Age around 3300 BCE was an important turning point since the mixing of copper with tin to make bronze changed the whole scenario for tools, weapons, and art. In this way, civilizations like the Mesopotamians, Egyptians, and Indus Valley were able to develop their societies by using copper.

Later on, during the time of the Roman Empire, copper was a major factor in the money, plumbing, and military equipment. The metal’s versatility was still seen in the Middle Ages, when copper was widely used not only for building but also for making bells and musical instruments.

According to recent studies, copper has changed from being a part of ancient artifacts to being extremely specialized in modern technology, thus taking a long way through the ages. Its unrivaled conductivity and malleability are still very much vital for the progress of electronics, renewable energy systems, and high-tech infrastructure projects. It is indeed a thrilling thought to consider the lasting legacy of copper and its uninterrupted evolution during the different periods.

Applications in Modern Technology

The metal copper is a great conductor of heat and electricity, one of the main reasons why it is still very much in demand and used in a lot of modern technological applications. Besides these properties, copper also has a very long life span and is very eco-friendly due to its being recyclable. Here are five major applications that highlight the copper’s importance in the tech area:

- Electrical Wiring and Electronics

The reason why copper is such a huge driver of electrical wiring production is that its electrical conductivity is so much better than that of other materials that it can even guarantee the best possible performance in terms of energy loss. The electrical, that is, the power grids, the circuit boards, and the household electronics, accounts for nearly 65% of the total world copper consumption. - Renewable Energy Systems

Copper is a key component in the renewable energy technologies such as wind generators, solar cells, and electric vehicles (EVs). For instance, the total copper content of a single wind turbine can be as much as 5 tons thereby underlining copper’s significance in environmental-friendly energy initiatives. - Telecommunications Infrastructure

Highly efficient data transmission in telecommunications is primarily made possible by copper cables and wiring. Moreover, the application of the latest technology like fiber-optic networks still includes copper due to its flexibility and impressively constant performance. - Medical Equipment

The highly resistant to germs property of copper is one of the reasons why the metal is actually widely used in the medical field, particularly for the manufacturing of medical devices, covering of hospital surfaces, and even round the clock availability of hygienic imaging equipment that nobody would mind being used simply because it is good and safe. - HVAC Systems (Heating, Ventilation, and Air Conditioning)

Due to copper’s excellent heat conduction properties, it is the main choice of material for heat exchangers, which are the leading component in HVAC systems that control the indoor climate of both residential and industrial areas.

Magnetism Explained

Magnetism is a natural force that can be described through the movement of electrical charges and the formation of opposing or attractive forces between two objects. It has a great impact and importance on a wide range of situations in both science and technology as it directs the later from the former, even though industrial machines and everyday tools, for instance, are all affected by it. The following are the five main characteristics of magnetism:

Natural Magnets

Natural magnets generated by the earth’s magnetic field, like lodestones, are found in certain kinds of rocks with a high content of magnetite. Their magnetic properties are due to the orderly arrangement of their atomic structure, which causes them to have a uniform magnetic field.

Electromagnets

When a wire coil is wrapped around a ferromagnetic core and electric current is allowed to pass through it, an electromagnet is formed. The intensity of the magnetic field can be mastered by increasing or decreasing either the current or the number of wire turns. Devices like electric motors, generators, and MRI machines are among the various applications of electromagnets.

Permanent Magnets

To make permanent magnets, a combination of materials such like neodymium, samarium-cobalt, or ferrite is used, which after being magnetized, keep on being magnetized forever. These are found in high-range applications including, but not limited to, loudspeakers, magnetic storage, and locking systems.

Magnetic Fields

Magnetic fields are the terms used to denote the spaces around a magnet, where presence of magnetic forces is detectable. The magnetic fields are represented by flux lines moving from the north pole of a magnet to the south. Magnetic fields are one of the main factors that make one understand the electromagnetic principles and are measured with the unit of Teslas (T).

Earth’s Magnetic Field

Earth has its own magnetic field which is referred to the geomagnetic field and is the result of the movement of molten iron in its outer core. The field not only acts as a shield against solar radiation that is harmful to the planet but also forms the basis of compass navigation.

What is Magnetism?

Magnetism is a physical force that arises from electric charges moving, thus producing magnetic fields. The fields influence the other materials present by attracting or repelling them, with the strongest effect on materials that have iron, nickel, cobalt or other magnets in them. The fundamental reason for magnetism is the intention of atomic particles, primarily electrons, to simultaneously spin and revolve around the nucleus of the atom. The result is a magnetic material whenever a great number of atoms are able to line up their magnetic moments in one direction. Magnetism plays an important role in a variety of processes that are both natural and technological, such as the generation and usage of electric current, the orienting of navigation systems, and the exploration of the Earth’s geomagnetic field. Its applications are diverse and keep changing as the progress in science and technology reflects on these areas. Thus, magnetism remains one of the driving forces of innovation in energy, health, and communication sectors.

Types of Magnetic Materials

Magnetic materials are divided into categories according to their reaction to an external magnetic field and their magnetic properties. There are five main types of magnetic materials:

| Material Type | Characteristics | Examples |

|---|---|---|

| Ferromagnetic Materials | The strongest magnetization is shown by this group of materials, and they also have the ability to keep their magnetic characteristics even after the external magnetic field has been removed. This feature makes them very suitable for permanent magnets. | Iron, nickel, cobalt, and their mixtures or alloys |

| Paramagnetic Materials | Magnetic fields exert only a slight force on these materials, which means they are not fully receptive. Moreover, they do not keep the magnetic property when the field is no longer present. | Aluminum, magnesium, and platinum |

| Diamagnetic Materials | The interaction between these materials and magnetic fields is very weak, so they are said to be non-magnetic. | Copper, gold, and bismuth |

| Ferrimagnetic Materials | Their moments are unequal but in opposite directions thus the resultant field is positive. These are heavily utilized in inductors and transformers. | Magnetite and similar compounds |

| Antiferromagnetic Materials | These materials are the opposite of ferromagnetic ones in that their moments are aligned antiparallel and of equal strength, hence no net magnetization is produced. | Manganese oxide |

How Materials Interact with Magnetic Fields

The interaction of materials with magnetic fields varies according to their magnetic characteristics. Different ways of such interaction can be grouped under five important types and those are as follows:

Diamagnetism

Diamagnetic substances do not allow the penetration of magnetic fields and produce a very faint magnetic field in the opposite direction instead. The phenomenon is the result of the induction of minute currents around the material when the external magnetic field is applied, which in turn, causes a weak counter-magnetic field. The range of diamagnetic susceptibility is between -10⁶ to -10⁵, and the best-known substances are copper, silver, and bismuth.

Paramagnetism

Paramagnetic substances are the ones that have at least one unpaired electron in their orbitals. This gives them a weak attraction to the magnetic fields. The magnetic susceptibility of such materials is positive and is usually between 10⁵ and 10³. Aluminum, platinum, and magnesium are a few examples of this category. The magnetic attraction, however, usually ceases shortly after the magnetic field is turned off.

Ferromagnetism

Ferromagnetic substances are the most magnetic materials that besides being attracted by the fields have the capability to hold the magnetization as well. This is all because of the unification of their magnetic moments in one direction. Iron, nickel, and cobalt are the most common ferromagnetic materials, they are used to make permanent magnets and are also a part of many electronic devices.

Antiferromagnetism

Antiferromagnetic materials have their magnetic moments aligned oppositely, which results in zero effective magnetization. Manganese oxide is one of the most known antiferromagnetic materials. These materials show a change of behavior at critical temperatures, for example, the Néel temperature, where they lose their magnetic ordering.

Ferrimagnetism

Ferrimagnetic materials are characterized by opposite magnetic moments that are unequal in strength, resulting in a net magnetic field. Magnetite (Fe₃O₄) is a classic example of ferrimagnetic material. Due to their special properties, these materials are heavily applied in various technologies, including but not limited to magnetic recording and transformers.

The review of these five types of materials reveals various responses to magnetic fields that mainly determine their practical use both in day-to-day life and advanced technology. It is essential to have a better understanding of the interactions as it will be a key factor in the endeavor to upgrade materials in the fields of electronics, power generation, and data storage solutions.

Copper Magnetic Properties

Copper is a non-magnetic metal that usually does not display any remarkable magnetic properties. Notwithstanding, its interaction with magnetic fields uncovers certain peculiarities which are of paramount importance in various fields. The following are the five most significant features of the magnetism of the copper:

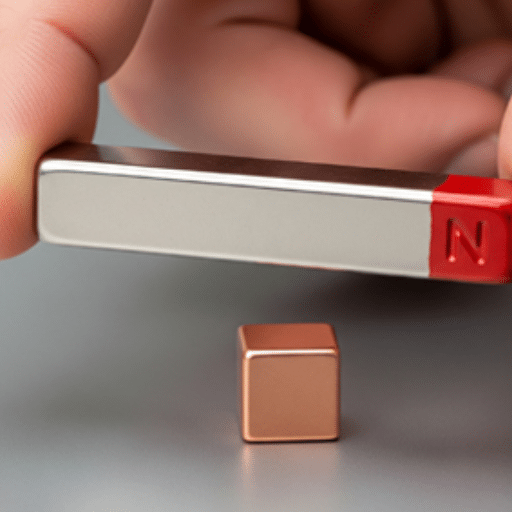

Diamagnetic Nature

Copper is characterized as a diamagnetic substance which signifies that it opposes the external magnetic field by inducing a very weak magnetic field. This characteristic results in the slight repulsion of magnetic fields by copper.

Low Magnetic Permeability

Copper’s magnetic permeability is exceptionally low when compared with parameters of ferromagnetic materials. Consequently, copper is preferred in such applications that demand operation to be free from magnetic fields or that need reducing electromagnetic interference (EMI) impacts).

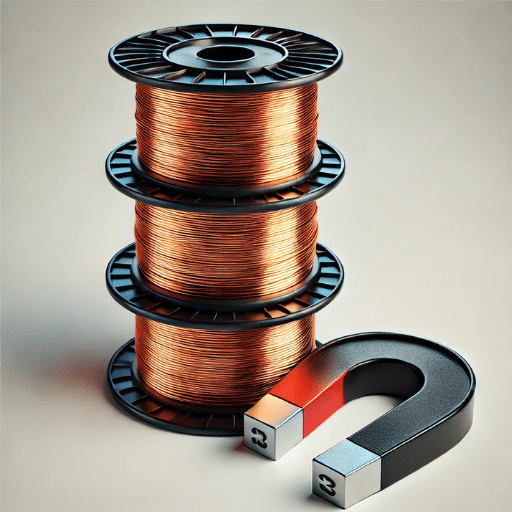

High Electrical Conductivity

While copper is not a magnetic material, its high conductivity is taken advantage of in electromagnetism ever so often. It is widely used in windings and coils for motors and generators magnetic fields.

No Permanent Magnetism

Copper is devoid of magnetic properties after the external magnetic field has been cut off. This means that it is a godsend in high-frequency electrical applications since it does not cause any magnetic interference.

Behavior in Strong Magnetic Fields

Taking the example of being in a very strong magnetic field, copper demonstrates behaviors like eddy current generation that are not seen in others. This property of copper is often used in applications such as magnetic braking and induction heating.

The discussed properties emphasize copper’s adaptability and its essential function in electronic and power systems industries. Its nature of being non-magnetic, in combination with the ability to conduct electricity exceptionally well, creates a scenario where copper is the only material that can be used in both consumer products and sophisticated technology areas.

Copper and Magnetism: The Basics

Copper’s magnetism over the years has been marked with a number of peculiar nature traits that define its role as a material of choice in a great variety of industries and applications. Hereby, we will go through five major properties that are astoundingly revealing of the copper’s character traits in the light of magnetism:

Diamagnetism

Copper is a diamagnetic metal, thus when its magnetism is exposed to an external magnetic field it produces a very weak counter magnetic field that is eventually negated. This particular characteristic leads to the non-acceptance of the metal by magnets which makes it quite useful in areas that need non-magnetic but rather copper-like conducting material.

Eddy Current Production

Whenever copper comes in contact with the varying magnetic field it produces eddy currents as a result of its very good electric conductor. These eddy currents find widespread application in various electromagnetic devices like electromagnetic brakes and damping systems.

Extremely Low Magnetic Permeability

Copper’s permeability to magnetic fields is so low that it virtually ignores the effect of magnets around it. This quality makes copper an indispensable material for the protection of electronic parts against the effects of EMI (electromagnetic interference).

Induction Heating

Copper’s high conductivity enables it to generate a large amount of heat efficiently when subjected to an alternating magnetic field. This property is used in induction heating systems not only for industrial processing but also for cooking.

Magnetic Non-Influence

Unlike the case of ferromagnetic materials, copper after a magnetic field is removed does not show any residual magnetism. which implies copper can be used in applications demanding no fluctuation of magnetic behavior at all times as, for instance, in some measurement devices where sensitivity is the issue.

It is this unique set of properties that made copper so important and a highly sought material in practice and technology; especially in situations where the issue of magnetism had to be handled positively.

Why Copper is Non-Magnetic

Copper is non-magnetic thanks to its atomic structure and electron configuration. When a magnet is brought near to a non-magnetic material, it does not attract it on account of the absence of unpaired electrons. Copper has indeed a completely filled the d-subshell and a relatively stable electron configuration that does not have these unpaired electrons. Thus, copper does not exhibit any magnetic moments, and it is classified as diamagnetic. When copper and other diamagnetic materials are subjected to magnetic fields, they experience very slight repulsion.

To this, the crystal lattice of copper adds about its non-magnetic properties. The electrons that are the charge carriers in copper can move freely but this movement does not allow them to become aligned with the external magnetic field which is another reason for its being diamagnetic. Therefore, the combination of electronic and structural factors not only prevents the occurrence of magnetic moments in copper but also makes it a very useful material in the areas where magnetic interference should be kept to a minimum.

Comparing Copper to Iron and Nickel

Concise Answer:

Copper is non-magnetic, while iron and nickel are ferromagnetic, meaning they strongly attract magnetic fields.

Summary Table:

|

Key Point |

Copper |

Iron |

Nickel |

|---|---|---|---|

|

Magnetism |

Non-magnetic (diamagnetic) |

Strongly magnetic |

Strongly magnetic |

|

Electron Alignment |

No alignment |

Aligned magnetic moments |

Aligned magnetic moments |

|

Applications |

Electrical wiring, plumbing |

Magnets, transformers |

Batteries, stainless steel |

|

Magnetic Strength |

Weak |

High |

High |

|

Behavior |

Repels weakly |

Attracts strongly |

Attracts strongly |

Copper Alloys and Their Magnetic Behavior

On the one hand, pure copper is a material that has no magnetism at all, so it barely interacts with the magnetic fields around it, but on the other hand, the mixing of copper with other metals can change its metal-like behavior in terms of magnetism. The following is a comprehensive outline of the five most significant copper alloys along with their magnetic properties:

Brass (Copper-Zinc Alloy)

Percentage: Generally Copper 60-70% and Zinc 30-40%.

Magnetic Characteristics: The interaction of brass with magnetism is very slight and restricted to the introduction of very small amounts of magnetism through impurities or manufacturing processes.

Utilization: Connecting electrical circuits and making tools that do not attract magnets.

Bronze (Copper-Tin Alloy)

Percentage: Generally Copper 88-90% and Tin 10-12%.

Magnetic Characteristics: The high copper content makes bronze non-magnetic, which is an excellent property for bronze’s application in non-magnetic environments.

Utilization: Found in bearings, springs, and ship propellers.

Copper-Nickel Alloy (Cupronickel)

Percentage: Copper 75-90% and Nickel 10-25% is the normal proportion.

Magnetic Characteristics: At the highest concentrations of nickel, it has weak magnetism but is still generally accepted as non-magnetic.

Utilization: In marine, coins, and resistors applications.

Copper-Beryllium Alloy (Beryllium Copper)

Percentage: Copper 97-98% and Beryllium 2-3% is the standard ratio.

Magnetic Characteristics: Conductive and strong but still non-magnetic regarding the followed processing for the added elements.

Utilization: Tools for use in areas with explosions and devices for accurate measuring are perfect examples.

Aluminum Bronze (Copper-Aluminum Alloy)

Percentage: Typically Copper 80-90% and Aluminum 10-12%.

Magnetic Characteristics: At higher aluminum levels, it is slightly paramagnetic but still has a large number of characteristics of being non-magnetic.

Utilization: This is typical for areas in aerospace, naval, and industrial machinery.

While the magnetic nature of copper can be very subtly changed by the different alloying elements, still, the copper’s property of being diamagnetic by nature usually prevails.

Common Copper Alloys

Copper alloys have distinctive properties and hence, are considered priceless in numerous industries. A list of five commonly used copper alloys is given below, along with their details and data:

Brass (Copper-Zinc Alloy)

Composition: Over 60-70% Copper and Under 30-40% Zinc.

Magnetic Behavior: Non-magnetic.

Applications: Its corrosion resistance and machinability make it a popular choice in the production of musical instruments, plumbing fixtures, and decorative metalwork.

Bronze (Copper-Tin Alloy)

Composition: About 90% Copper and 10% Tin.

Magnetic Behavior: Non-magnetic.

Applications: Its power and resistance to wear make it among the materials mostly used for medals, statues, and machine parts.

Beryllium Copper (Copper-Beryllium Alloy)

Composition: Predominantly 98% Copper and 2% Beryllium.

Magnetic Behavior: Non-magnetic.

Applications: It is used in electrical contact, spring, and non-sparking tool manufacture because of its high strength, conductivity, and resistance to fatigue.

Copper-Nickel (Cupronickel)

Composition: Normally 70-90% Copper and 10-30% Nickel.

Magnetic Behavior: Non-magnetic.

Applications: The alloy is often used in marine applications, minting coins, and in desalination plants as it possesses good resistance to seawater corrosion.

Nickel Silver (Copper-Nickel-Zinc Alloy)

Composition: Usually 60% Copper, 20% Nickel, and 20% Zinc.

Magnetic Behavior: Non-magnetic.

Applications: It is mostly used in cutlery, jewelry, and components of musical instruments due to its longevity and appealing silver-like look.

The remarkable versatility of copper in alloying with other elements is demonstrated by these alloys that support diverse usages that are based on its mechanical, thermal, and electrical properties.

Magnetic Properties of Copper Alloys

Copper as well as its alloys generally feature weak paramagnetic characteristics, which implies that their attraction to a magnetic field is not very strong. Nonetheless, the magnetic characteristic of copper alloys depends on the particular blend of the alloy. Below are five instances of copper alloys along with their corresponding magnetic properties:

Brass (Copper-Zinc Alloy)

Mix: Usually around 60-70% Copper and 30-40% Zinc.

Magnetic Behavior: Non-magnetic, mainly because of the high copper content and facilities have no ferromagnetic elements like iron.

Use: They are widely installed in decorative purposes, musical instruments, and plumbing fixtures.

Bronze (Copper-Tin Alloy)

Mix: Typically 88% Copper and 12% Tin.

Magnetic Character: Non-magnetic because the material has neither iron nor nickel in it.

Application: It is used in bearings, bushings, and statues.

Cupronickel (Copper-Nickel Alloy)

Mix: Often 70% Copper and 30% Nickel.

Magnetic Character: Weakly magnetic, due to nickel, but the overall susceptibility to magnetism is still low.

Application: It finds usage in marine hardware, coinage, and desalination plants.

Beryllium Copper (Copper-Beryllium Alloy)

Mix: Roughly 98% Copper and 2% Beryllium.

Magnetic Character: Non-magnetic, but beryllium does modify it for better strength and longevity.

Application: Aerospace components, electrical connectors, and tools are the main applications.

Aluminum Bronze (Copper-Aluminum Alloy)

Mix: Usually it is 90% Copper and 10% Aluminum.

Magnetic Behavior: Weakly magnetic property is due to aluminum’s effects through induction, but is still far less than steel.

Applications: The metal is a common choice for shipbuilding, heavy machinery, and industrial uses.

These particular instances reveal that though the majority of the copper alloys are non-magnetic, the minor changes in their chemical composition can result in a weak magnetic reaction. This characteristic is critical in ascertaining the appropriateness of certain alloys for the applications that are requiring little magnetic interference.

Applications of Copper Alloys in Magnetic Fields

Copper alloys are indispensable to certain applications where controlling or at least minimizing magnetic properties is a must. The following are the five main applications:

Electromagnetic Shielding

Copper alloys, namely brass and copper-nickel, are the materials of choice when it comes to protecting delicate electronic parts from electromagnetic interference (EMI). The main reasons to select these metals are their great conductivity and relatively low magnetic response that will secure the electronic systems’ integrity.

MRI Machines

Non-magnetic copper alloys are vital to the setup of magnetic resonance imaging (MRI). They are incorporated in shielding layers and coils to lessen magnetic interference and at the same time ensure that imaging results are accurate.

Precision Measurement Devices

Instruments of precision measurement such as sensors or analytical devices very often make use of copper alloys to counteract the effects of magnetic fields. The quality of measurement is thus made better and less affected by magnetic distortion during operation.

Aerospace Electronics

Copper alloys are used in case of aerospace applications that need non-magnetic properties to prevent interference with navigational and communication systems. Such applications are characterized by high reliability and stability in magnetic fields.

Transformer Windings

The practice of using copper alloys possessing high conductivity and controlled magnetic response in transformer windings facilitates efficient energy transfer while at the same time minimizing the adverse effects of magnetic interference.

These instances underscore how copper alloys are purposefully designed to cater to the needs of industries where the taming or reduction of magnetic effects is paramount. Their capability and the quality of being tailored to suit different applications significantly propelled the development of technology.

Conclusion: The Role of Copper in Magnetism

Copper and its alloys are the materials of choice in applications where magnetic effects can be exactly controlled, thus revealing their versatility in different areas of technology. The following myths and data points will outline the critical role played by copper in magnetism:

High Electrical Conductivity – Copper’s outstanding electrical conductivity causes energy losses to be almost zero and devices such as transformers and motors particularly those operating in close to zero magnetic interference to be very efficient. It also keeps more than 99% of its conductivity in pure forms.

Low Magnetic Permeability – Copper alloys usually show low magnetic permeability thus they can be used in shielding delicate electronic devices and preventing them from being affected by external magnetic fields.

Applications in MRI Machines – Non-magnetic copper alloys are standard in medical imaging devices like MRI machines where magnetic interference is reduced and consequently accurate imaging results are obtained.

Transformer Windings – Special copper-based alloys with controlled magnetic properties are utilized in transformer windings. These alloys guarantee effective energy transfer and also assist in power loss reduction due to stray magnetic fields.

Durability and Reliability – The corrosion and wear resistance of copper not only improves but also extends the life of components used in sensitive magnetic environments thus ensuring the reliability of such industrial applications.

The above mentioned are a few instances that highlight the diverse character of copper in responding to complex technological needs, especially in the areas where magnetic properties need to be controlled.

Summary of Key Points

- High Conductivity – The unmatched performance of copper in both electrical and thermal conductivity serves as the main reason to use it in the efficiency improvement of applications operated in controlled magnetic environments. To illustrate, copper wires and parts lead to a noteworthy decrease in power losses.

- Magnetic Neutrality – The non-magnetic quality of copper allows for the reduction of interference in the case of very weak magnetic applications and thus it guarantees the accuracy in the industries of electronics and telecommunications.

- Thermal Efficiency – The great heat dissipation quality of copper makes it a must in the prevention of overheating and in the maintenance of system efficiency, especially in applications that require very tight thermal control.

- Power Loss Reduction – The high conductivity of copper allows the electrical engineers to minimize the power losses that are caused by stray magnetic fields, thus leading to the more effective and reliable operation of the industrial sector.

- Durability and Longevity – The inherent characteristics of copper, such as its resistance to corrosion and mechanical wear ensure its strong performance and long-lasting reliability, so it is a trustworthy choice for the critical industrial field.

- These arguments state the case for copper being the indispensable element in the technology and industrial applications where magnetic control and efficiency are essential.

Future Research Directions

In coming years, I would lay emphasis on the research of advanced alloys and composite materials containing copper to further improve its magnetic shielding properties. Besides, the study of new methods of manufacturing could lead to possibilities in the case of copper-based solutions thus encouraging efficiency and scalability. By using the new technology like nanotechnology, I plan to bring in the new applications and have the copper’s performance optimized in the most challenging industrial and technological environments.

Final Thoughts on Copper as a Non-Magnetic Metal

Copper’s contribution as a non-magnetic metal is of utmost importance for the advancement of technology and industrial processes in different areas. The metal’s unsurpassed combination of properties makes it functional and reliable to a great extent. The following are the five aspects that detail copper’s importance:

Outstanding Conductivity – Copper is known for its great electrical and thermal conductivity, which makes it very suitable for electrical wiring, power generation, and industrial heat transfer.

Non-Magnetic Property – Copper’s non-magnetic quality is a plus in environments and devices where there would be a magnetic interference concern, like in MRI machines and precision electronic equipment.

Corrosion Resistance – Copper is naturally resistant to corrosion; thus, it lasts longer in harsh or high-moisture environments, and its use enhances the longevity of components and structures.

Ductility and Application – Copper’s ductility allows it to turn into wires, sheets, and very detailed designs easily without losing its structural strength and thus meeting a variety of manufacturing needs.

Environmental Friendliness – Copper can be recycled 100% repeatedly without any degradation of its properties, thus playing a role in sustainable industry practices and a reduction of the environmental impact.

All these qualities together make copper a very important material in all the fields like medical technology to heavy industry and as such its continued use in both current and future applications is guaranteed.

References

1. Copper (II) Complexes with Subnormal Magnetic Moments

This study explores the magnetic properties of copper(II) compounds under various conditions.

2. Factors Affecting the Magnetic Properties of Dimeric Copper (II) Complexes

Published on ScienceDirect, this paper examines the factors influencing the magnetic behavior of copper(II) complexes.

3. Magnetic vs. Nonmagnetic Ion Substitution Effects in Copper Systems

This research investigates the effects of substituting copper ions with other metals in specific systems.

Frequently Asked Questions (FAQ)

Is copper a magnetic material?

No, copper itself is not magnetic. It does not have unpaired electrons, which are necessary for a material to exhibit magnetism in the traditional sense. Instead, copper is classified as a diamagnetic material, meaning it creates a magnetic field that opposes an external magnetic field.

How does copper interact with magnetic fields?

Copper interacts with magnetic fields through its diamagnetic property. When exposed to a strong magnetic field, copper generates a magnetic field that opposes the external magnetic field, but it is not attracted to magnets like iron or nickel.

Can copper wire create magnetic fields?

Yes, when electric current flows through copper wire, it generates a magnetic field around it. This phenomenon is due to the movement of electrons within the copper, which creates a magnetic moment that can influence the surrounding area.

What are the magnetic properties of copper?

The magnetic properties of copper are characterized by its diamagnetic nature. This means that copper has a very weak response to external magnetic fields and does not retain any magnetism after the external field is removed.

How does the magnetic behavior of copper compare to iron or nickel?

Copper’s magnetic behavior is significantly different from that of magnetic metals like iron or nickel. While iron and nickel are ferromagnetic and can be strongly attracted to magnets, copper does not exhibit this attraction and is classified as non-magnetic.

What is the interaction between copper and magnets?

The interaction between copper and magnets is primarily based on copper’s diamagnetic property. When a permanent magnet is brought near copper, the copper does not get attracted but instead creates a very weak opposing magnetic field.

Are copper alloys magnetic?

Copper alloys can vary in their magnetic properties depending on their composition. Some copper alloys may exhibit slight magnetic behavior, particularly if they contain magnetic metals like iron or nickel, but pure copper remains non-magnetic.

What applications might require consideration of magnetic interference with copper?

Applications where magnetic interference is a concern include electrical engineering, where the interaction of copper with strong magnetic fields can affect the performance of devices. This is particularly relevant in applications involving changing magnetic fields, as copper can respond to these conditions despite being non-magnetic.