Heat transfer stands as a fundamental mechanism playing a vital role across numerous industries including electronics, engineering, cookware, and energy systems. Selecting the appropriate metal for efficient heat transfer proves crucial in improving performance, reducing power consumption, and achieving desired results in a multitude of applications. With so many metals available, each possessing unique thermal properties, determining the most suitable option for specific tasks becomes essential. This comprehensive guide delves into thermal conductivities and reveals the most efficient conductive materials, providing valuable insights whether you’re designing a next-generation heat sink, selecting materials for industrial machinery, or simply exploring the science of heat transfer.

Introduction to Heat Transfer and Metals

The unique atomic structure of metals explains their exceptional heat conductivity, featuring free electrons that move easily throughout the material. This electron mobility enables rapid thermal energy transfer. Among all metals, copper and aluminum stand out as superior choices for heat transfer applications due to their high thermal conductivity combined with affordability and durability. These characteristics make them ideal materials across diverse industries including electronics, automotive, and manufacturing. When selecting metals for heat transfer purposes, factors such as thermal conductivity, cost, and corrosion resistance must always be considered to guarantee optimal performance.

Definition of Heat Transfer

Heat transfer refers to the exchange of thermal energy between physical systems, determined by temperature differences and the medium used for energy transfer. As a key thermodynamics concept, it critically impacts both natural phenomena and industrial processes. Heat transfer operates through several distinct modes, each characterized by different mechanisms and properties:

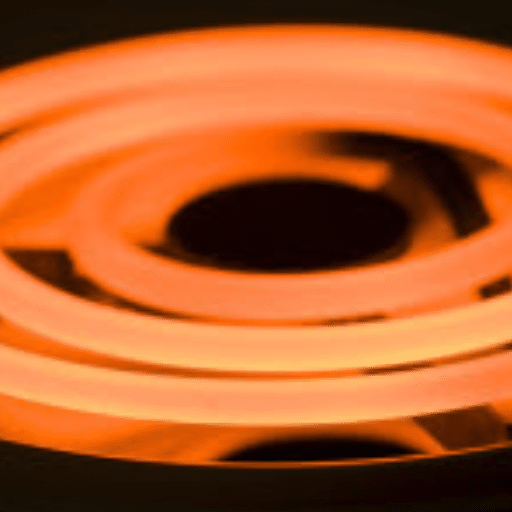

Conduction

Definition: Heat transfer within solid materials caused by molecular or atomic vibration and interaction.

Example: Heat conducting through a metal rod when one end is heated.

Key Data: Copper’s thermal conductivity (400 W/m·K) significantly exceeds that of wood (0.04 W/m·K), making copper a far more effective conductor.

Convection

Definition: Heat transfer in liquids or gases caused by fluid movement.

Example: Hot air rising from a radiator and circulating as it cools.

Key Data: Natural convection in air typically ranges from 2-25 W/m²·K, while forced convection spans 50-10,000 W/m²·K.

Radiation

Definition: Thermal energy emission as electromagnetic waves, capable of occurring even in a vacuum.

Example: Solar heat traveling to Earth.

Key Data: The Stefan-Boltzmann constant (σ): 5.67 × 10⁻⁸ W/m²·K⁴ governs radiation heat transfer rates.

Phase Change

Definition: Heat transfer accompanying matter transitions such as melting, boiling, or condensation.

Example: Heat absorption during water boiling.

Key Data: Water’s latent heat of vaporization measures approximately 2260 kJ/kg.

Thermal Diffusion

Definition: Gradual heat transfer within objects where temperature differences exist over time.

Example: A hot spot on a flat iron plate gradually transferring heat to cooler areas over a specific duration.

Key Data: Thermal diffusivity (α) indicates heat propagation rates, with metals like aluminum showing high values (97.1 × 10⁻⁶ m²/s).

Understanding these processes with accurate data enables engineers and scientists to create energy-efficient heating, cooling, and energy management systems across various sectors.

Importance of Thermal Conductivity in Materials

Thermal conductivity significantly influences material behavior in designated applications, particularly within thermal management systems. Understanding this characteristic allows engineers to select appropriate materials based on specific requirements, ensuring efficiency, sustainability, and safety. Below are five examples illustrating thermal conductivity’s significance across various materials and industries:

| Material | Thermal Conductivity | Primary Uses |

|---|---|---|

| Copper | ~390 W/m·K | Electrical wiring and heat exchangers due to rapid heat transfer capability |

| Aluminum | ~205 W/m·K | Radiator fins, beverage cans, and aerospace components, combining lightweight properties with excellent heat dissipation |

| Steel | ~43 W/m·K | Structural building components and heavy industries where heat resistance and mechanical strength are required |

| Glass | ~1.0 W/m·K | Insulating windows and specialized laboratory equipment to prevent heat transfer |

| Ceramics | ~0.5 – 1.5 W/m·K | Thermal insulation in high-temperature environments including kilns, turbines, and electronics |

Applying proper thermal conductivity criteria enables industries to enhance material selection, opening channels for energy conservation, performance improvement, and operational limit expansion.

Overview of Metals and Alloys Used in Heat Transfer

Metals and alloys play paramount roles in situations requiring efficient heat transfer processes. These materials possess qualities such as high thermal conductivity and durability, making them highly suitable for manufacturing, electronics, automotive, and power generation industries. Below is a comprehensive overview of the five most popular metals and alloys with their properties:

Copper

Thermal Conductivity: ~398–400 W/m·K

Properties: Excellent thermal and electrical conductivity, corrosion resistance, and high malleability

Uses: Heat exchangers, radiators, cooling systems, and electrical wiring

Aluminum

Thermal Conductivity: ~205–235 W/m·K

Properties: Lightweight, excellent corrosion resistance, cost-effective with good thermal conductivity

Uses: Automobile heat exchangers, electronic cooling systems, and air conditioning units

Silver

Thermal Conductivity: ~410–430 W/m·K

Properties: Highest thermal conductivity among metals, though expensive which limits applications

Uses: Advanced electronics, superconductors, and precision temperature management systems

Brass (Copper-Zinc Alloy)

Thermal Conductivity: ~109–125 W/m·K

Properties: Corrosion resistant, durable, and more affordable than pure copper

Uses: Heat exchanger tubes, radiator cores, and industrial piping

Stainless Steel

Thermal Conductivity: ~15–25 W/m·K

Properties: Excellent strength, corrosion resistance, and high-temperature tolerance, despite lower thermal conductivity

Uses: Chemical industry heat exchangers, kitchen appliances, and structural applications requiring thermal resistance

Materials are selected based on thermal performance, cost, and operational conditions, ensuring efficiency and reliability across different heat transfer applications.

Types of Metals and Their Thermal Conductivities

Material selection for heat transfer applications largely depends on metals’ thermal conductivity. Below is a detailed list of five widely utilized metals along with their thermal conductivities:

🥇 Silver

Thermal Conductivity: ~429 W/m·K

With the highest thermal conductivity among all metals, silver typically finds use in specialized applications, thermal interfaces, and high-performance electrical components where optimal heat conduction is absolutely essential.

🥈 Copper

Thermal Conductivity: ~400 W/m·K

Copper ranks among metals with the highest thermal conductivities, making it extensively used in electrical conductors, heat exchangers, and cooling systems. It exhibits excellent heat transfer characteristics and corrosion resistance.

🥉 Gold

Thermal Conductivity: ~318 W/m·K

Gold possesses high thermal conductivity though expensive. The combination of high thermal conductivity and excellent corrosion resistance makes it indispensable in precision electronics and aerospace industries.

Aluminum

Thermal Conductivity: ~237 W/m·K

Aluminum, being lightweight and affordable, offers good thermal conductivity and is widely used in electronics cooling systems, radiators, and other applications requiring effective heat dissipation.

Steel (Stainless)

Thermal Conductivity: ~16 W/m·K to ~30 W/m·K (varies by type)

Although other metals have much higher thermal conductivities, stainless steel’s durability and versatility make it frequently used in structural and chemical processing applications where mechanical strength outweighs thermal performance.

These metals are selected according to their thermal properties, cost-effectiveness, and specific application requirements, ensuring optimal materials are employed for efficient heat transfer.

Aluminum: The Leading Conductive Metal

Due to its unique combination of thermal and electrical conductivity, lightweight nature, and cost-effectiveness, aluminum stands as the most efficient and widespread conductive material among all metals. Its applications span entire industries including construction, automotive, aerospace, and electrical. Below are key points with data elucidating aluminum’s superior characteristics:

- ⚡

Thermal Conductivity: Aluminum’s thermal conductivity measures around 235 W/m·K, rendering it highly efficient in heat transfer and suitable for heat exchangers and cooling systems. - 🔌

Electrical Conductivity: Aluminum possesses approximately 61% of copper’s electrical conductivity, but its significantly lighter weight makes it ideal for overhead power lines and various electrical applications. - 🪶

Lightweight: One of aluminum’s most remarkable features is its density of only 2.7 g/cm³. This lightweight property makes it indispensable for industries where weight reduction is critical, such as aerospace and transportation. - 🛡️

Corrosion Resistance: Aluminum effectively resists corrosion, particularly in harsh environments, due to the naturally formed oxide layer that builds and maintains protection. - ♻️

Recyclability: Aluminum can be completely recycled up to 100% without property loss, making it a sustainable alternative in production processes and contributing to reduced environmental impact.

Aluminum’s combination of high performance, versatility, and sustainability continues making it a prime choice for various thermal and structural applications globally.

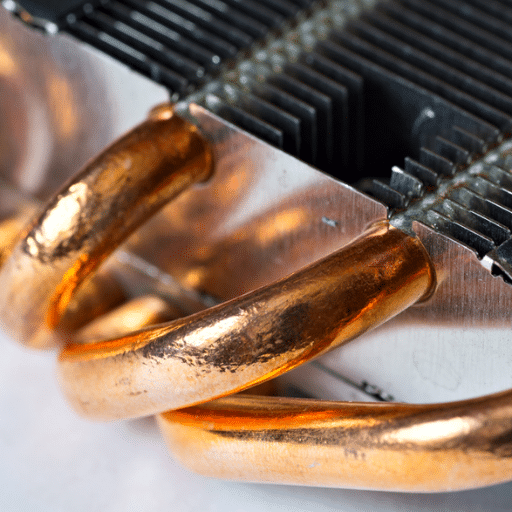

Copper: Properties and Applications

Copper is an exceptionally adaptable metal used across many fields, distinguished by its conductivity and toughness. Its exceptional traits render it necessary in myriad applications spanning industrial, electrical, and architectural sectors. Below are five of copper’s most important properties and uses:

Electrical Conductivity

Copper has the highest electrical conductivity rating after silver, making it the preferred material for wires and electrical components in energy production, telecommunications, and electronic devices.

Thermal Conductivity

Due to its high thermal conductivity, copper is extensively used in heat exchangers, radiators, and industrial cooling systems for efficiently transferring heat.

Corrosion Resistance

Copper slowly develops a natural patina that functions as a protective layer, making it highly resistant to corrosion and suitable for outdoor applications like roofing and pipes.

Malleability and Ductility

Copper’s excellent malleability and ductility allow easy transformation into sheets, wires, and tubing, providing versatile applications in construction and production.

Antimicrobial Properties

Copper possesses inherent antimicrobial characteristics that stop bacteria and virus development, making it a preferred option for medical institutions, public spaces, and frequently touched surfaces.

The combination of copper’s attributes with its recyclability and aesthetic qualities firmly establishes its status as one of the most indispensable materials across different sectors.

Comparative Analysis of Mild Steel and Other Metals

Mild steel, also referred to as low-carbon steel, has widespread application due to its affordability, adaptability, and mechanical properties. Its advantages and disadvantages become clearer when compared side by side with other metals. Below is a thorough exposition of contrasts between mild steel and five other popular metals:

Mild Steel vs. Stainless Steel

| Factor | Comparison |

|---|---|

| Composition | Mild steel contains about 0.05–0.25% carbon, while stainless steel comprises large proportions of chromium (at least 10.5%), providing corrosion resistance. |

| Corrosion Resistance | Stainless steel with its chromium content consistently outperforms mild steel in rust and oxidizing environments. |

| Strength | Mild steel is softer and more ductile; stainless steel is harder and more rugged, capable of handling heavy-duty applications. |

| Cost | Mild steel is significantly cheaper than stainless steel, making it the go-to metal for large-scale projects where price is the main consideration. |

Mild Steel vs. Aluminum

| Factor | Comparison |

|---|---|

| Weight | Aluminum is extremely light compared to mild steel, with density only around one-third of steel’s. |

| Corrosion Resistance | Aluminum has a natural oxide layer protecting it from rust, while mild steel requires coating or treatment to prevent rusting. |

| Strength-to-Weight Ratio | Aluminum, though weaker in plain strength, has a high strength-to-weight ratio suitable for aerospace and automotive industries. |

| Machinability | Aluminum is relatively easy to work with compared to mild steel, which is more difficult to machine. |

Mild Steel vs. Copper

| Factor | Comparison |

|---|---|

| Electrical Conductivity | Copper is an excellent conductor of both electricity and heat, far superior to mild steel in both cases. |

| Cost | Mild steel is cheap but copper is costly; copper is often reserved for special applications like wiring and electronics where its high price is justified. |

| Malleability | Copper is more ductile than mild steel, therefore easier for shaping and forming. |

| Corrosion Resistance | Copper outlasts mild steel in terms of corrosion and forms a protective patina as it ages. |

Mild Steel vs. Brass

| Factor | Comparison |

|---|---|

| Composition | Brass, an alloy of copper and zinc, attracts consumers through its decorative and corrosion-resistant properties. |

| Aesthetic Appeal | Brass is more refined than mild steel, chosen for installations where visual aspect is as important as functionality. |

| Strength | Brass, although softer and less durable than mild steel, proves its strength in low-load and decorative applications. |

| Applications | Brass is primary material for musical instruments, fittings, and decorative items, while mild steel is utilized in structural applications. |

Mild Steel vs. Titanium

| Factor | Comparison |

|---|---|

| Strength and Weight | Titanium has excellent strength-to-weight characteristics, considered better than mild steel in heavy-duty applications. |

| Corrosion Resistance | Titanium, unlike mild steel, is highly resistant to corrosion even in very harsh conditions. |

| Cost | Titanium is highly priced, not suitable for many applications where mild steel would suffice. |

| Applications | Due to cost and characteristics, titanium is mainly used in aerospace, medical devices, and high-performance industries. |

Key Takeaway: The comparison of mild steel with other metals clearly indicates that mild steel’s low price and adaptability to various applications are its strong points. Nevertheless, the choice of metal is determined not only by price but also by factors like weight, corrosion resistance, and strength, which might make other metals the best alternative.

Factors Influencing Heat Transfer in Metals

Heat transfer within metals has multiple factors affecting it, which dictate the efficiency of energy flow through the material. The following are the five leading factors that influence heat transfer in metals:

1. Thermal Conductivity

Thermal conductivity, the ability of a material to be a heat transfer medium, turns out to be the most important factor in heat transfer performance. Copper and aluminum among metals have the highest thermal conductivity, allowing greatest heat flow in applications like heat exchangers and electrical lines.

Example Data: Copper has thermal conductivity around 400 W/m·K, quite a lot more than steel at about 50 W/m·K.

2. Density

Metal density can impact its ability to transfer and store heat. Heavier metals can absorb and hold more heat before transferring it outward. Take lead as an example; its high density makes it behave differently than lightweight metals like aluminum in terms of heat dissipation.

3. Specific Heat Capacity

Specific heat capacity measures the amount of heat energy that can be stored or removed in a material per unit of mass. Materials with higher specific heat capacities require more energy to change their temperature, thus responding slower to temperature variations.

Example Data: Aluminum possesses specific heat capacity of roughly 0.9 J/g·K, considerably higher than steel at about 0.49 J/g·K.

4. Surface Area and Thickness

The surface area and thickness of metallic objects have a large effect on heat transfer rate. Greater surface area provides more heat sources in contact with the metal, and thinner sections allow quicker heat transfer because of shorter distances for energy transfer.

Application: This principle is widely used in heat sinks incorporated in cooling systems.

5. Environmental Conditions

Factors around a metal piece, such as ambient temperature, air movement, and pressure, are very important in heat transfer. For example, a metal will cool down rapidly in a less warm and highly ventilated environment, while forced air like from a fan will help cool the metal quickly.

In combination, these factors determine the metal’s thermal application effectiveness, depending on the rate and efficiency of heat transfer needed.

Physical Properties Affecting Conductivity

Heat and electric current conduction through metal is not random; rather, it’s governed by crucial physical characteristics. Conductance of a particular metal is determined by the following five major factors:

| Property | Description | Example Data |

|---|---|---|

| Thermal Conductivity | Quantifies a material’s ability to transfer heat. Metals like copper and silver have very high thermal conductivity, preferred for heat exchangers and electrical parts. | Copper: ~400 W/m·K Silver: ~430 W/m·K |

| Electrical Conductivity | Signifies a material’s capability to permit electric current movement. Silver, copper, and gold excel most in this aspect. | Silver: ~63 × 10⁶ S/m Copper: ~59 × 10⁶ S/m |

| Density | Influences heat and electricity conduction, since denser materials usually allow closer atomic and electron interactions. Aluminum, less dense than copper, still has high conductivity due to free electron mobility. | Varies by metal composition |

| Melting Point | Good conductors with high melting points can be used in very hot conditions without losing properties. Tungsten has the highest melting point among pure metals, employed in high-temperature environments. | Tungsten: 3,422°C |

| Crystal Structure | The internal atomic arrangement (crystal lattice) profoundly influences electrical conductivity. Metals with simple structures like face-centered cubic (FCC) usually have lower resistance against electron flow. | Aluminum and copper: FCC structure |

These properties, each contributing uniquely, form the basis for metal choice in thermal and electrical applications, ensuring a perfect combination of efficiency and performance.

Impact of Alloying on Thermal Conductivity

Thermal conductivity of metals can be extraordinarily affected through incorporating alloying elements. Alloying disturbs the regularity of metal’s crystal lattice structure, creating scattering sites for charge carriers and heat phonons, leading to decreased effective heat conduction. Yet the magnitude of this decline depends on specific alloying elements and their concentration. The following are five alloy systems and their thermal conductivity changes due to alloying:

Copper-Silver Alloy

Base Metal: Copper (very high thermal conductivity)

Alloying Element: Silver

Outcome: Silver causes lattice imperfections in copper decreasing conductivity but simultaneously increasing mechanical properties.

Aluminum-Silicon Alloy

Base Metal: Aluminum (medium thermal conductivity)

Alloying Element: Silicon

Outcome: Silicon while decreasing thermal conductivity around 50% provides good wear resistance, suitable for engine parts.

Stainless Steel (Iron-Chromium-Nickel)

Base Metal: Iron (intermediate thermal conductivity)

Alloying Elements: Chromium and Nickel

Outcome: Chromium and nickel incorporation leads to considerable thermal conductivity drop, yet counterbalances with enhanced corrosion resistance and mechanical strength.

Brass (Copper-Zinc Alloy)

Base Metal: Copper (very high thermal conductivity)

Alloying Element: Zinc

Outcome: Proportionate thermal conductivity decrease due to zinc can be compensated by improved machinability and strength.

Titanium-Aluminum-Vanadium (Ti-6Al-4V)

Base Metal: Titanium (very low thermal conductivity)

Alloying Elements: Aluminum and Vanadium

Outcome: Alloying not only decreases thermal conductivity but greatly increases strength-to-weight ratio and heat resistance, hence used in aircraft structures.

The unique characteristics of each alloy result in an optimal combination of thermal and mechanical or chemical properties, highlighting the important and sophisticated role that alloying has in developing new materials.

Temperature and Its Role in Heat Transfer

Temperature is a major factor in the whole heat transfer process, serving as the main element that can alter the direction of energy movement between systems. Where temperature differences exist, heat transfers with energy flowing from higher-temperature areas to lower-temperature areas. Different factors including thermal conductivity, specific heat capacity, and the type of heat transfer mechanism — conduction, convection, or radiation — determine temperature effects on heat transfer. Here is a detailed explanation of five important aspects:

⚠️ Critical Factor: Thermal Gradient

Heat transfer is directly proportional to the temperature difference between two systems or regions. The greater the gradient, the faster the heat flow.

Example Data: A 50°C temperature difference allows for a much higher rate of conduction than a 10°C difference.

-

Thermal Conductivity of the Material

Metals, which are materials with high thermal conductivity, transfer heat very well compared to insulators that block heat flow.

Example Data: Copper (401 W/m·K) transfers heat efficiently, while wood (0.12 W/m·K) acts as an insulator.

-

Specific Heat Capacity

Heat transfer rates are affected by substances with high specific heat capacity requiring more energy to change their temperature.

Example Data: Water (4,186 J/kg·K) is able to store and retain heat more than iron (450 J/kg·K).

-

Surface Area for Heat Exchange

A higher heat transfer rate comes from larger surface areas, particularly in convection and radiation processes.

Example Data: Longer fins on car radiators provide more area, resulting in better heat dissipation.

-

Nature of Heat Transfer Mechanism

The heat transfer mode varies greatly concerning efficiency. Solids use conduction, fluids use convection, and radiation needs no medium at all.

Example Data: The Sun radiates energy that reaches Earth even through the vacuum of space.

The combination of these elements not only shows the importance of temperature but also the properties that come alongside it for controlling and optimizing heat transfer in various applications.

Practical Applications of Conductive Metals

The outstanding electrical and thermal conductivity of conductive metals makes them indispensable across various industries. Here are five applications of conductive metals along with corresponding industry data:

🔌

Electrical Wiring

Copper is the most common metal employed in electrical wiring because of its excellent electrical conductivity and high corrosion resistance.

Industry Data: More than 90% of residential and commercial buildings worldwide are equipped with copper wiring.

🌡️

Heat Exchangers

Copper and aluminum are the most popular metals used in heat exchangers which separate hot and cold fluids while improving thermal efficiency in HVAC systems and radiators.

Industry Data: Up to 30% more energy can be saved with aluminum heat exchangers in air conditioners.

📱

Electronics and Circuit Boards

Gold, silver, and copper are necessary for making printed circuit boards and microprocessors due to their top-notch conductivity and reliability.

Industry Data: Around 0.034 grams of gold and 0.35 grams of silver are used in the electronics of a modern smartphone.

🍳

Cooking Utensils

The ability of metals such as aluminum and copper to distribute heat more evenly is one reason why they’re preferred in cookware, eventually leading to better cooking results.

Industry Data: Copper pots take roughly 25% less time than stainless steel alternatives to get hot.

🚗

Electric Vehicles (EVs)

Copper and aluminum, being conductive metals, are the main materials for producing EV motors, batteries, and charging infrastructures.

Industry Data: The average electric vehicle uses around 183 pounds of copper, almost twice the amount used in a traditional internal combustion engine vehicle.

These cases illustrate the flexibility and critical significance of conductive metals in daily use and future technology.

Heat Exchangers and Their Materials

Heat exchangers are key players in different industrial applications and the core part of heating, ventilation, and air conditioning (HVAC) systems. By making it possible to cool or heat systems, they keep entire processes running smoothly and thus the efficiency of whole systems depends on them. Material choice for heat exchangers is a careful process considering thermal conductivity, durability, corrosion resistance, and cost. Below are five materials widely used in making heat exchangers:

| Material | Key Properties | Primary Applications | Technical Data |

|---|---|---|---|

| Copper | Excellent thermal conductivity and corrosion resistance | HVAC exhausts and water heating sites | Thermal conductivity: ~400 W/m·K |

| Aluminum | Lightweight and low-cost with decent thermal conductivity | Automotive applications like radiators and intercoolers | Cost-effective solution |

| Stainless Steel | Great corrosion resistance and mechanical strength | High-pressure and high-temperature systems like chemical processing | Suitable for harsh environments |

| Titanium | Incredibly high corrosion resistance, even in offshore environments | Desalination plants and cooling systems for seawater | Premium material for extreme conditions |

| Carbon Steel | Low-cost and applicable for moderate-temperature settings | Industrial boilers and condensers | Most economical option |

Each material plays its own crucial role in securing heat exchanger efficiency under various operational conditions.

Electronics Cooling Solutions

Electronic devices must maintain optimal performance and reliability, so efficient cooling systems are essential. Technology continuously evolves and, consequently, the need for advanced cooling methods has grown significantly. The following are five of the most common cooling methods for electronics:

💨 Air Cooling

- ✓ Very simple and less expensive method

- ✓ Heat dissipated using fans or passive heat sinks

- ✓ Most common in desktops and laptops

💧 Liquid Cooling

- ✓ Thermal conductivity and cooling efficiency considerably greater

- ✓ Hot components cooled via coolant transfer liquid

- ✓ Common in gaming PCs, data centers, and high-performance servers

⚡ Thermoelectric Cooling

- ✓ Peltier devices cause heat flux for cooling

- ✓ Good for applications needing tight temperature control

- ✓ Used in medical devices and portable coolers for electronics

❄️ Phase-Change Cooling

- ✓ Employs refrigerants going through phase transitions to absorb heat

- ✓ Characterized by high cooling capacity

- ✓ Often employed in critical electronic setups or overclocked ICs

🌊 Immersion Cooling

- ✓ Direct and complete component immersion in heat-conducting dielectric liquid

- ✓ Best for very high-density computing environments

- ✓ Minimal noise plus excellent thermal performance for cryptocurrency mining or supercomputers

Each solution aims to cope with particular cooling challenges, ensuring best performance and longest lifetime of electronic systems.

Automotive and Aerospace Applications

Cooling systems are very important for automotive and aerospace technologies. They keep machines working well and remaining dependable. These industries require thermal management solutions that are both extremely efficient and durable, as they must operate in very tough conditions. The following five cooling applications are the most important ones in these areas:

🚗 Engine Cooling Systems

Prevents engine overheating by keeping the engine at its best working temperature. Employs radiators, coolant fluids, and thermostats for regulating temperature. Makes engines able to work at their best in very different conditions.

🔋 Battery Thermal Management in Electric Vehicles (EVs)

Lithium-ion batteries are always properly temperature-controlled so that their lifespan and safety are maximized. Liquid cooling systems are combined with thermal insulation to achieve very small temperature variations and stability. This is very important in the future of EVs and the growth of electric vehicles.

✈️ Aircraft Cabin Cooling Systems

A comfortable climate for passengers and crew is created through managing cabin temperatures. The use of advanced air conditioning units and refrigeration cycles specifically designed for high-altitude efficiency is being done. Airliner passenger safety during long-haul flights is paramount.

🛩️ Aerospace Avionics Cooling

High-performance aircraft are protected from overheating of sensitive electronic equipment by cooling methods. Advanced air-cooled or liquid-cooled systems provide lightweight and efficient options. The reliability of avionics in extreme operational conditions is being improved by this technology.

⚙️ Turbocharger and Intercooler Cooling

Temperatures in turbocharged engines are maintained in the optimal range to increase both efficiency and power output. The use of air-to-air or liquid-to-air intercoolers is very common. Engine performance is enhanced while emissions reduction is achieved.

Industry Impact: Cooling applications are indispensable to modern automotive and aerospace industries, providing safety, efficiency, and optimal system performance in extreme conditions.

Conclusion: Selecting the Best Metal for Heat Transfer

Selecting the right metal for heat transfer purposes involves taking into account factors such as thermal conductivity, corrosion resistance, weight, and cost. High thermal conductivity metals are very efficient in heat transfer, thus they are the best choices for cooling and heating across different industries. Below is a comprehensive comparison of five commonly used metals along with their important properties:

Final Verdict: Every metal has its own advantages and disadvantages in combination with others which determine the field of their applications. The ultimate choice of metal depends on performance characteristics for that particular project, exposure to the environment, and budget. Being familiar with these characteristics will enable you to select a reliable and effective heat transfer solution.

Summary of Key Findings

Thermal Conductivity of Metals: The case of copper and aluminum is that they are very good thermal conductors, so they are chosen for heat transfer applications. Copper is about 400 W/mK in thermal conductivity, while aluminum is about 235 W/mK in consort.

Corrosion Resistance: Stainless steel’s quality of being highly resistant to corrosion is a great advantage in terms of its use in harsh environmental conditions. This is a great advantage as it increases the material’s life in heat exchangers and piping systems, for instance, very significantly.

Mechanical Strength: Among metals, we have stainless steel and titanium which are the strongest ones. A typical example of titanium is that it has a high strength-to-weight ratio, which makes it suitable for very demanding industrial and aerospace applications.

Durability and Antimicrobial Properties of Copper: Copper arguably has the longest lifetime of all materials in sanitary areas because of its non-corrosive nature, but then it is also very expensive and difficult to handle. Owing to these traits non-metallic materials like plastics have to be used with great care in plumbing and the cost of maintaining metal standards is not only borne by the water suppliers but also by the consumers.

Cost-Effectiveness of Aluminum: Aluminum is very cost-effective in different heat transfer applications and gives a perfect combination of low price, light weight, and decent thermal performance, especially in massive or lightweight systems.

The significance of knowing the characteristics of materials to the enhancement of performance, longevity, and costs in a range of industrial and environmental settings is demonstrated by these outcomes.

Future Trends in Thermal Conductive Materials

The rapid development in the thermal conductive materials sector is mainly driven by the requirements of the present-day industries and the advanced technologies. The following are the five main trends that will determine the future of this sector:

Development of Graphene-Based Materials:

Graphene, with its unique thermal conductivity property of over 4000 W/m·K, has become a revolutionary material. The researchers are working hard to merge the graphene with the composites and coatings so it can be used for heat dissipation in electronics and high-performance systems.

Advancements in Nanotechnology:

Nanomaterials are such as carbon nanotubes and nanofluids, are being researched and studied a lot for the purpose of thermal performance improvement. The significant improvement in the heat transfer efficiency of the cutting-edge applications, like the cooling systems in microelectronics, are due to these materials.

Recyclable and Sustainable Materials:

The manufacturers’ preference for environmentally friendly materials has increased the emphasis on the development of recyclable thermal conductors. Metal alloys, like aluminum, and biodegradable composites have started being the go-to materials and their thermal properties are almost the same as those of plastic.

High-Performance Ceramics:

High technology ceramics, such as silicon carbide (SiC) and boron nitride, are extensively researched in demanding industries like aerospace and defense, which require materials with high thermal conductivity and resistance to extreme environmental conditions.

Phase-Change Materials (PCMs):

PCMs are able to absorb and release heat during the phase transitions and hence are always in demand for thermal energy storage. Such materials are a necessity for renewable energy systems like solar power plants and energy-efficient buildings.

The above-mentioned trends are indicative of the merging of new materials, sustainability, and cutting-edge technology, which in turn, will keep on supporting the thermal applications process across different sectors.

Final Recommendations for Best Metals

Metals like aluminum, copper, and stainless steel, in my point of view, are the most suitable ones to look after in regard to thermal usage metals. Aluminum is highly preferred for its lightness and excellent thermal conductivity, which makes it perfect for heat exchangers and cooling systems. Besides that, copper by its superior thermal and electrical conductivity,y is always present in the applications that demand heat transfer efficiency. Stainless steel, on the other hand, is not as good a conductor as aluminum or copper but instead gives properties like strength, corrosion resistance, and durability which make it a good choice for high-temperature area. That way, these metals can be used in various ways and they are also high in performance throughout different industrial requirements.

References

1. Thermal conductivity of metals and alloys

Published by Taylor & Francis Online

Explores the relationship between thermal and electrical conductivity in metals.

Link to source

2 .The thermal conductivity of metals at low temperatures

Published by Royal Society Publishing

Provides systematic data on the heat conductivity of metals under low-temperature conditions.

Link to source

3 .Thermal conductivity of metals and alloys at low temperatures: a review of the literature

Published on Google Books

Includes summary tables and references to research papers on thermal conductivity.

Link to source

Frequently Asked Questions (FAQ)

What is the best metal for heat transfer?

The best metal for heat transfer is typically considered to be copper due to its high thermal conductivity. However, aluminum is also a strong contender, offering a good balance of weight, cost, and thermal properties. Both metals are commonly used in heat sinks and cookware due to their ability to conduct heat effectively.

How does aluminum compare to other metals in terms of thermal conductivity?

Aluminum has a high thermal conductivity, making it an excellent conductor of heat. While copper surpasses aluminum in thermal conductivity, aluminum is often preferred in applications where weight and corrosion resistance are important. Its conductivity values are still quite impressive, making it suitable for various heat transfer applications.

What are the thermal properties of mild steel?

Mild steel has lower thermal conductivity compared to metals like aluminum and copper, which means it does not transfer heat as efficiently. However, its strength and durability make it suitable for applications where high thermal conductivity is not the primary concern. It is often used in structural applications rather than in heat transfer devices.

Which types of metal are considered good conductors of heat?

Good conductors of heat include copper, aluminum, silver, and gold. Among these, copper is often regarded as the best due to its superior thermal conductivity, while aluminum is favored for its lightweight and cost-effectiveness. These metals are commonly used in various industries for making heat sinks and radiators.

What is the significance of thermal conductivities in heat transfer?

Thermal conductivities are crucial in determining how efficiently a material can transfer heat. Materials with high thermal conductivities, such as copper and aluminum, facilitate heat movement quickly and efficiently. Understanding these properties helps in selecting the right materials for specific heat transfer applications, ensuring optimal performance.

How does the conduction process work in metals?

Conduction in metals occurs when thermal energy is transferred through collisions between free electrons and atoms within the material. Metals are effective conductors of heat because they have a high density of free electrons that can move easily, allowing heat to flow rapidly from one part of the metal to another.

What are the corrosion resistance properties of aluminum?

Aluminum has excellent corrosion resistance due to the formation of a thin layer of aluminum oxide on its surface, which protects it from further oxidation. This property makes aluminum a preferred choice in heat transfer applications exposed to harsh environments, as it maintains its integrity and thermal performance over time.

What is the role of heat sinks in heat transfer applications?

Heat sinks are devices designed to dissipate heat away from electronic components or other heat-generating sources. They are typically made of metals with high thermal conductivity, such as aluminum or copper, which help transfer heat quickly and efficiently to the surrounding air, preventing overheating and ensuring optimal performance.

What factors influence the choice of metal for heat transfer applications?

Several factors influence the choice of metal for heat transfer applications, including thermal conductivity, weight, cost, corrosion resistance, and specific heat capacity. Depending on the application requirements, engineers must balance these properties to select the most suitable metal that will efficiently conduct heat while also being cost-effective and durable.