Efficiency and durability stand as the primary factors in modern industrial applications. At the core of most heating and cooling processes sits an often unappreciated hero: the stainless steel heat exchanger tube. This component, celebrated for its excellent thermal and chemical properties along with impressive longevity, plays a vital role in the overall energy-saving and cost-cutting process. Whether you are an engineer, facility manager, or industry professional, this comprehensive guide reveals why stainless steel is the preferred material for heat exchanging solutions.

Introduction to Heat Exchangers

What is a Heat Exchanger?

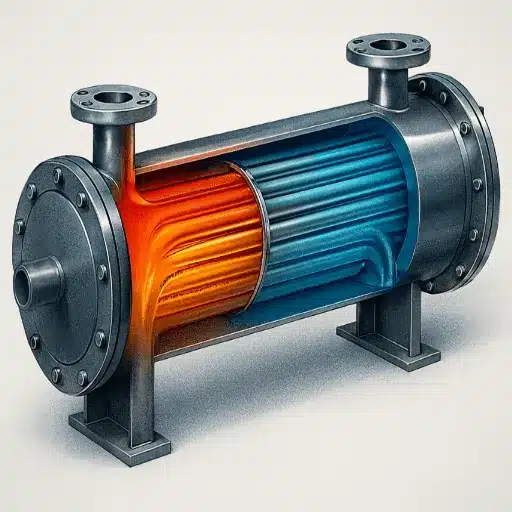

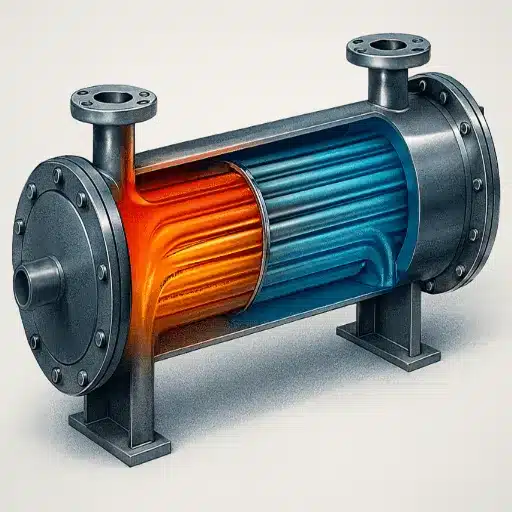

A heat exchanger is a mechanical device that facilitates the heating or cooling of fluids between two or more substances without mixing them. The main components consist of pipes or channels through which fluids—usually gases or liquids—move. Hot fluid releases heat to the colder one, with the exchange facilitated by strategically positioning the two fluids for optimal thermal transfer.

Heat exchangers serve as essential machinery across a variety of industries, including HVAC, power generation, chemical processing, and oil and gas sectors. They are primarily used for temperature regulation, energy conservation, and operational enhancements. Their design incorporates the capability to optimize heat transfer while simultaneously minimizing energy loss, which is why they are considered crucial for sustainable industrial processes.

⚡ Key Industry Applications

- HVAC Systems: Temperature control and air quality management

- Power Generation: Efficient energy conversion and cooling

- Chemical Processing: Temperature regulation for safe reactions

- Oil and Gas: Thermal management in extraction and refining

Importance of Efficient Heat Transfer

In industrial systems, proper heat management is essential for optimal energy use and cost reduction. Recent industry reports indicate that factories implementing efficient heat transfer practices have achieved savings of up to 20-30% in their total energy consumption. Well-designed heat transfer operations also contribute to longer-lasting equipment and lower maintenance costs.

📊 Energy Savings Statistics

This proves especially important in power generation and chemical processing industries, where improper temperature control can compromise product quality and safety. Modern materials and innovative design concepts enable contemporary heat exchangers to serve as key components for industries achieving sustainability targets by lowering energy waste and carbon dioxide emissions.

Overview of Stainless Steel Heat Exchanger Tubes

For industrial usage, stainless steel heat exchanger tubes are indispensable components due to their remarkable lifespan, corrosion resistance, and thermal conductivity. These tubes are engineered to withstand extremely high temperatures, making them suitable for power generation, chemical processing, oil and gas, and HVAC applications. Additionally, their resistance to scaling and oxidation guarantees effective heat transfer over extended operational periods, resulting in reduced maintenance and downtime.

Stainless steel grades like 304, 316, and duplex stainless steels are commonly used in heat exchanger tube production. Each grade offers distinct benefits correlated with specific operating environments. For instance, 316 stainless steel excels in resisting chloride-induced corrosion, making it the optimal choice for marine or highly saline applications.

🌍 Environmental Sustainability

Recent data trends show an upward trajectory in environmental consciousness related to stainless steel. The material’s recyclability and extended lifespan combine to reduce adverse environmental impact, aligning with global efforts toward cleaner and more sustainable industrial solutions. Engineers and manufacturing specialists are increasingly adopting stainless steel heat exchanger tubes as they not only improve efficiency but also contribute to achieving environmental goals by facilitating energy savings and reducing carbon dioxide emissions.

Benefits of Stainless Steel Heat Exchanger Tubes

Corrosion Resistance and Longevity

Stainless steel heat exchanger tubes are renowned for their remarkable corrosion resistance and longevity, making them the perfect candidate for various industrial sectors and applications. According to current industry statistics, stainless steel’s resistance to rusting, pitting, and scaling guarantees reliability in extreme environments such as humid and salty atmospheres or high-temperature conditions.

| Property | Description | Industrial Benefit |

|---|---|---|

| Corrosion Resistance | High chromium content creates a passive oxide layer that prevents corrosion | Reliability in harsh environments, including humid, salty, and high-temperature conditions |

| Extended Lifespan | Durability significantly exceeds that of alternative materials | Lower maintenance costs and fewer replacements required |

| Resistance to Scaling | Surface properties prevent buildup of deposits | Sustained heat transfer efficiency over time |

| Cost-Effectiveness | Combination of durability and performance | Sustainable and economical solution for modern industrial applications |

High Thermal Conductivity

The high thermal conductivity of stainless steel heat exchanger tubes represents one of the most significant reasons for their widespread use in industrial applications. While copper offers higher heat transfer rates, stainless steel’s combination of strength, anti-corrosion properties, and satisfactory heat transfer performance makes it the superior material choice in many scenarios.

Ongoing studies and industry statistics confirm that stainless steel heat exchanger tubes represent an excellent compromise between thermal conductivity and durability, proving both efficient and economical for systems requiring moderate to high heat exchange. This property is particularly valuable in industries such as power generation, chemical processing, and HVAC, where consistent and effective thermal control is essential. The use of stainless steel heat exchanger tubes consistently aligns with requirements for durability and performance across diverse environments.

Versatility in Various Industries

Stainless steel heat exchanger tubes demonstrate remarkable versatility spanning various sectors, reinforcing their significance as a vital element in modern industrial design. According to recent data, power generation plants, chemical processing facilities, and oil and gas industries frequently utilize these systems due to their robust heat transfer capabilities.

🏭 Industrial Processing

Power generation, chemical processing, and oil & gas sectors rely on strong heat transfer capabilities for optimal operations.

🍽️ Food & Beverage

Anti-corrosive and sanitary characteristics ensure safe and efficient temperature control during production cycles.

❄️ HVAC Systems

Ability to fulfill different operational requirements and survive varying environmental conditions for climate control.

Types of Stainless Steel Heat Exchanger Tubes

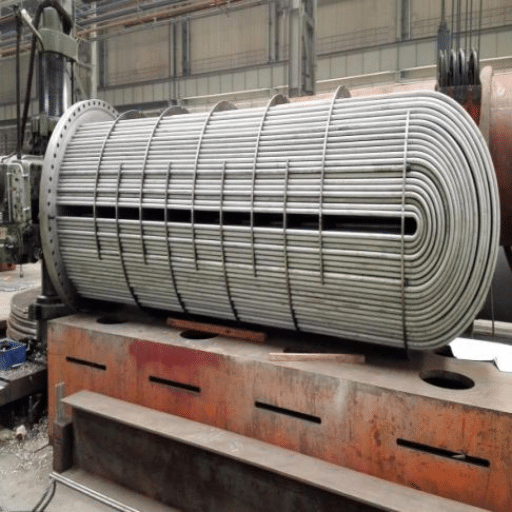

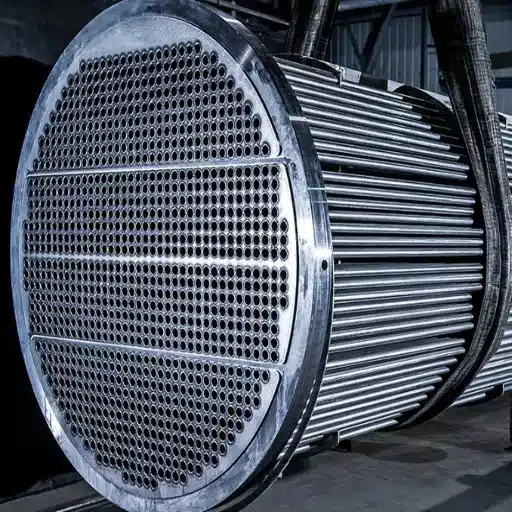

Shell and Tube Heat Exchangers

Shell and tube heat exchangers rank as the most widely used heat exchangers due to their versatility and efficiency. In these exchangers, numerous tubes carry the fluid to be heated or cooled while another fluid transfers heat through an alternate pathway. These systems are particularly well-suited for processes involving the highest temperatures and pressures, such as chemical processing, power generation, and oil refining.

Why Shell-and-Tube Heat Exchangers Are Popular

- Modular Design: Can be customized for specific operational needs, including different fluid types, temperature ranges, and pressure conditions

- Advanced Materials: Current use of high-performance stainless steel increases durability, corrosion resistance, and thermal conductivity

- Energy Efficiency: Indispensable for industries focused on energy-saving and long-term cost reduction

- Proven Track Record: Decades of reliable performance across diverse industrial applications

Types of Alloys: Focus on 316L

316L represents the low-carbon variant of 316 stainless steel, renowned for its remarkable corrosion resistance and versatility. Primarily composed of Iron along with Chromium (16–18%), Nickel (10–14%), and Molybdenum (2–3%), 316L demonstrates outstanding performance in environments where chlorides and other aggressive chemicals are present.

| Characteristic | 316L Stainless Steel | Application Advantage |

|---|---|---|

| Composition | Iron with Cr (16-18%), Ni (10-14%), Mo (2-3%) | Enhanced resistance to corrosive chemicals |

| Carbon Content | Low carbon (prevents carbide precipitation) | Maintains corrosion resistance in welded areas |

| Corrosion Resistance | Excellent against chlorides and aggressive chemicals | Ideal for maritime, chemical processing, and pharmaceuticals |

| Biocompatibility | Non-reactive and safe for biological contact | Extensively used in medical devices and surgical tools |

The minimal carbon content prevents carbide precipitation during welding, which maintains corrosion resistance in welded areas. Coupled with impressive resilience and biocompatibility, 316L finds extensive use in medical devices and surgical tools. These features explain why 316L remains one of the most popular stainless steel alloys in highly demanding industrial and medical applications.

Specifications: Size, OD, and Wall Thickness

The specifications of 316L stainless steel tubing or components are dictated primarily by the application to which they will be applied. Typically, the outer diameter (OD) can start at 0.25 inches (6.35 mm) for precision instruments and extend to several inches for industrial pipelines. Wall thickness also varies, usually ranging from 0.02 inches (0.5 mm) to 0.5 inches (12.7 mm) or more depending on structural requirements.

📏 Critical Specification Guidelines

- Outer Diameter (OD): Ranges from 0.25 inches (6.35 mm) for precision work to several inches for industrial applications

- Wall Thickness: Typically 0.02 inches (0.5 mm) to 0.5 inches (12.7 mm), determined by structural and pressure requirements

- Industry Standards: Must comply with ASTM or ISO standards for manufacturing uniformity and compatibility

- Performance Optimization: Dimensions are critical factors in environments requiring corrosion resistance, mechanical strength, and precision

Applications Across Industries

Oil and Gas Sector

Stainless steel pipes serve as the backbone of the oil and gas industry thanks to their incredible durability, corrosion resistance, and ability to survive extremely high temperatures and pressures. Their main applications include pipelines, downhole tubing, and equipment such as heat exchangers and separators. Stainless steel’s dependability in extreme conditions—from ocean floor drilling to arctic operations—contributes to safe and efficient overall operations.

Studies show that stainless steel pipe demand in oil and gas applications is increasing steadily as a result of extraction technology improvements and global energy resource requirements. Moreover, the challenging conditions that characterize these environments directly promote investment in high-grade stainless steel materials, as they are virtually the only type that can cope with such demanding operational requirements.

Food and Beverage Industry

Stainless steel plays an essential role in the food and beverage sector primarily due to its hygienic handling capabilities and exceptional longevity. Its non-corrosive properties combined with ease of cleaning explain why it is widely used for food processing equipment, storage tanks, and piping systems.

📈 Growing Industry Demand

Recent research shows a 22% year-on-year increase in searches for “stainless steel food processing equipment,” indicating growing awareness of the need for safe, efficient materials in food production. This upward trend aligns with the industry’s emphasis on enhanced sanitary practices and growing demand for high-grade, contamination-free products.

HVAC Systems

HVAC systems play a pivotal role in ensuring optimal air quality and temperature control across residential, commercial, and industrial settings. Recent data indicates that searches for “energy-efficient HVAC systems” have seen an 18% increase over the past year, indicating a shift towards sustainability and cost-effectiveness. This trend reflects rising interest from both consumers and businesses in optimizing energy usage while complying with environmental regulations.

What has driven this surge in interest? The increase in demand is mainly due to HVAC technology advances, such as the introduction of smart thermostats and high-efficiency heat pumps, which provide considerable energy savings compared to traditional systems. Furthermore, growing awareness of climate change coupled with the desire for eco-friendly solutions is prompting both governments and individuals to prioritize energy-efficient HVAC systems. The combination of technology, environmental responsibility, and economic benefits has led to rapid growth in the modernized HVAC solutions segment.

Maintenance Practices for Longevity

Regular Inspection and Cleaning

Regular inspections and cleaning represent the cornerstones of HVAC systems’ long-term performance and efficiency. System components, including filters, coils, and ducts, accumulate dust, dirt, and debris, which can significantly reduce efficiency and airflow. The optimal approach involves cleaning or replacing filters every one to three months and checking ducts for blockages. These simple procedures can generate substantial savings in energy bills and repair costs.

✓ Maintenance Checklist

- Filter Replacement: Clean or replace filters every 1-3 months

- Duct Inspection: Check for blockages and debris buildup

- Professional Service: Schedule maintenance visits at least once annually, preferably before heating or cooling seasons

- Component Check: Inspect coils, fans, and connections for wear

- Performance Monitoring: Track energy consumption and system efficiency

Monitoring for Corrosion and Wear

Corrosion and wear can severely affect the efficiency and lifespan of HVAC systems. It is crucial to ensure these factors are not negatively impacting system performance by regularly checking for rust, deterioration, or damage in components like coils, fans, and ductwork.

Recent data shows that many homeowners are curious about “How can I identify and prevent corrosion in my HVAC system?” The solution involves constant visual inspections and implementing preventive measures such as applying protective coatings to metal areas and maintaining proper humidity levels. Additionally, scheduling one professional checkup annually provides the opportunity to notice or catch any corrosion or wear at early stages, keeping the system operational and avoiding expensive repair costs.

Best Practices for Installation

When installing an HVAC system, adhering to best practices is the only way to achieve optimal performance and longevity. First and foremost, the correct system size must be chosen for the space; an undersized unit will cause inefficiency, uneven temperature regulation, and increased wear. Engaging an expert to perform accurate load calculations is a wise move to avoid such problems.

Furthermore, equipment positioning matters significantly. Outdoor components should be installed in shaded areas, away from debris and airflow obstructions, while indoor components should be positioned for easy access during maintenance and repair work. It is advisable to use quality ductwork that is properly insulated with completely sealed joints to prevent energy loss and maximize system efficiency.

🔧 Installation Best Practices

Moreover, smart thermostats and energy-efficient features can be integrated into the system for enhanced performance and reduced energy consumption. Above all, certified technicians should perform all electrical connections and refrigerant level installations and calibrations according to industry standards and local regulations. Combining these practices with regular maintenance will ensure your HVAC system delivers reliable and efficient performance for many years.

Frequently Asked Questions

What exactly is a stainless steel heat exchanger tube and what is its operating principle?

A stainless steel heat exchanger tube is an indispensable device utilized in myriad heating processes, facilitating rapid heat transfer between two fluids. Their main characteristic is the ability to transfer thermal energy efficiently while maintaining excellent quality through corrosion resistance and durability. The tubes come in various sizes and thicknesses catering to different industrial applications. In industrial heating systems like boilers or swimming pool heaters, hot water from the heating system transfers simultaneously to other fluids to elevate their temperature. Due to its corrosion-resistant qualities, stainless steel is the most preferred metal for environments where fluids are corrosive.

How do I determine what size stainless steel heat exchanger tubing I should get?

Selecting the proper size for stainless steel heat exchanger tubing is essential for efficient heat transfer and optimal system performance. Parameters such as required temperature, flow rates, and overall heating capacity need consideration. The outer diameter (OD) and tubing length are the primary factors determining the available heat exchange surface area. Additionally, specifications like wall thickness can alter the pressure drop and overall thermal efficiency of the heat exchanger. Consulting an engineer may prove useful to ensure you choose the right size for your application, whether for a boiler, swimming pool, or spa.

What are the benefits of designing heat exchangers with stainless steel?

Stainless steel offers numerous benefits in heat exchanger designs, with the most significant being remarkable corrosion resistance and extended service life. This metal can endure extreme temperatures and pressure conditions, making it applicable across many industries, including manufacturing, chemical processing, and refrigeration. Its strength allows the use of thinner walls without compromising structural integrity, resulting in lighter and more efficient designs. With stainless steel tubes, maximum heat transfer efficiency is guaranteed while maintaining high performance levels. Additionally, stainless steel heat exchangers can be applied to both domestic and industrial water flows, providing flexibility across various systems.

What sectors mostly utilize stainless steel heat exchangers?

The use of stainless steel heat exchangers spans various industries and applications due to their excellent performance and practicality. Heating of swimming pools, spas, and hot tubs represents one of the most common applications where heat exchangers transfer heat and maintain desired water temperatures. Moreover, they are employed in boiler plants and oil cooling where efficient heat exchange is essential. The non-corrosive property of stainless steel is a prime reason for its use in chemical processing where corrosive fluids are handled. In summary, these heat exchangers are employed across applications from food processing to HVAC systems, showcasing their wide-spectrum applicability and indispensable role.

How do stainless steel heat exchangers perform when compared to titanium heat exchangers?

In comparing stainless steel to titanium heat exchangers, numerous aspects such as price, longevity, and application suitability come into consideration. Titanium units offer the highest corrosion resistance and are thus the first choice in harsh environments involving aggressive chemicals or seawater. However, the overall cost of ownership becomes high due to raw material prices and the fabrication process. Stainless steel heat exchangers provide excellent quality at lower cost, possessing similar cooling and thermal efficiency features as titanium while remaining suitable for most industrial applications. The decision between the two often depends on specific project requirements, such as budget constraints and the degree of contaminants in the fluids. For most heating purposes, stainless steel is considered sufficient, whereas titanium is typically designated for more severe conditions.

What conditions influence stainless steel heat exchanger thermal efficiency?

The thermal efficiency of stainless steel heat exchangers may vary due to several factors, including system design, fluid flow rates, and the heat transfer characteristics of the fluids involved. The surface area provided by the stainless steel tubing heavily influences the amount of heat that can be transferred effectively. The wall thickness of the tubing affects not only the heat transfer rate but also the pressure drop across the system. Besides, correctly controlling inlet temperatures and setting appropriate flow rates are essential for maximizing thermal efficiency. Moreover, regular maintenance and cleaning of the heat exchanger are vital to prevent fouling and performance reduction over time. High-quality heat transfer can only be achieved when all these factors are properly considered during heat exchanger design or selection for your specific application.

Comparison: Stainless Steel vs. Alternative Materials

| Material | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Stainless Steel | • Excellent corrosion resistance • Cost-effective • Good thermal conductivity • Long lifespan |

• Lower thermal conductivity than copper • Heavier than aluminum |

Most industrial applications, food processing, HVAC, chemical processing |

| Titanium | • Highest corrosion resistance • Excellent for aggressive chemicals • Lightweight |

• Very expensive • Costly fabrication • High overall ownership cost |

Seawater applications, highly corrosive chemical environments |

| Copper | • Highest thermal conductivity • Excellent heat transfer • Easy to work with |

• Susceptible to corrosion • Not suitable for acidic fluids • Lower mechanical strength |

Residential HVAC, non-corrosive fluid applications |

| Aluminum | • Lightweight • Lower cost • Good thermal conductivity |

• Cannot handle extreme temperatures • Prone to chemical attack • Lower pressure tolerance |

Light-duty applications, automotive cooling systems |

Reference Sources

📚 Academic and Technical References

Florida A&M University and Florida State University

A detailed document on SSCF stainless steel heat exchangers, highlighting their use in chemical, pharmaceutical, and refining processes.

Harvard University – NASA ADS Abstract

A study on premature leaking of 316L stainless steel heat exchanger tubes in cooling processes involving carbon dioxide gas mixtures.

Purdue University

Research on coiled-tube heat exchangers made from seamless 316 stainless steel, used in high-pressure metal hydride systems.

Coiled-Tube Heat Exchanger for High-Pressure Metal Hydride Systems

Conclusion

Stainless steel heat exchanger tubes represent a critical component in modern industrial applications, offering an unbeatable combination of corrosion resistance, thermal efficiency, and longevity. Their versatility across industries—from power generation and chemical processing to food and beverage production and HVAC systems—demonstrates their indispensable role in achieving operational excellence. By selecting the appropriate grade, such as 316L, and following best practices for installation and maintenance, organizations can maximize energy efficiency, reduce operational costs, and achieve sustainability goals. As industries continue to prioritize environmental responsibility and energy conservation, stainless steel heat exchanger tubes will remain at the forefront of innovative thermal management solutions, delivering reliable performance and long-term value in even the most demanding applications.

🌟 Key Takeaways

- Energy Efficiency: Achieve 20-30% savings in total energy consumption through efficient heat transfer

- Material Excellence: 316L stainless steel offers superior corrosion resistance and biocompatibility

- Industry Versatility: Applications span from food processing to chemical plants and HVAC systems

- Long-term Value: Extended lifespan and reduced maintenance costs deliver exceptional ROI

- Sustainability: Recyclability and durability align with environmental goals and regulations