When one wants to make the right choice material-wise in industries like aerospace, construction, or even everyday consumer products, one has to understand the properties of materials first. Among the most compared materials are titanium and aluminum, which are the subject of continuous debate on their qualities. In the case of weight, however, one would be mistaken to think it was just a simple question of which is the lighter one. This paper presents a most fascinating comparison of titanium and aluminum by analyzing their specific properties, applications, and the aspect of their weights’ being a performance and design factor. Manufacturers, engineers, or simply curious about the science of materials, this will be a great and valuable insight for you to still be able to better evaluate your needs.

Introduction to Lightweight Metals

The Importance of Material Selection in Various Industries

The materials choice is the main factor for the project success in the various industries that range drastically. For example, in the aviation industry, the usage of lightweight but strong metals like titanium or aluminum can help a lot in decreasing the fuel consumption and therefore increasing the overall production. The same holds for the automotive industry where the metal’s usage has increased by a considerable amount owing to its potential to enhance the fuel efficiency while also helping to meet the safety requirements. The most recent updates reveal that the demand for lightweight materials is still on the rise and so is the focus of manufacturers on sustainability and performance. Material selection is also a major factor in these areas of construction, medical devices, and consumer electronics since strength, corrosion resistance, and weight are all attributes that directly affect the functionality and life span of products. Hence, it is very important for designers and innovators to be enlightened about the material properties as well as the technological advancements trends in order to design and innovate optimally.

Weight’s Role in Efficiency and Performance

Weight is one of the most important factors in determining efficiency and performance in all industries. For example, in automobiles and planes, cutting down weight directly means better fuel economy but also requires some quality maintenance; hence, the use of heavy materials is slowly being banned in these industries. The ultra-lightweight materials, such as aluminum alloys, carbon fiber, and advanced composites have become very much in demand to attain this balance. The same goes for gadgets where weight reduction results not only in the enhanced portability but also in better user experience. Recent data showed a significant increase in the interest of “lightweight materials for electric vehicles” which is the sign of a great and conscious effort towards the designing aspect of the products which is environmentally friendly and energy-efficient. Such a trend prompts to think about how giving priority to weight factors might lead to the giant leaps in innovation closely integrated with technological advancement and market requirements.

Key Insight

The push toward lightweight materials is driven by sustainability goals and performance optimization, making material selection a critical decision in modern engineering and design.

Titanium vs Aluminum: A Weight Comparison

Weight Metrics of Titanium

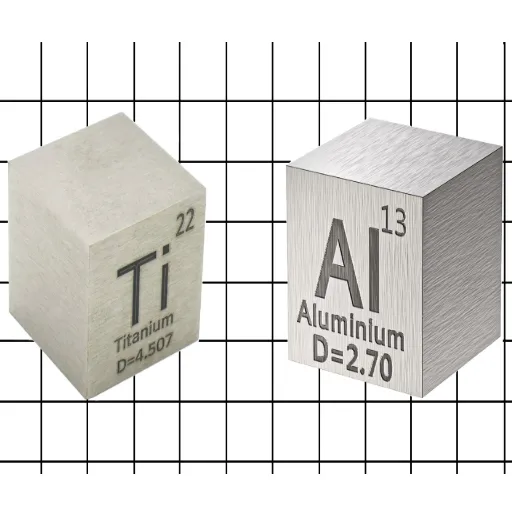

Titanium has been recognized for its remarkable strength-to-weight ratio and that is the reason of its wide usage in the aerospace, car making, medical sectors, and many others. Titanium has a density of about 4.5 g/cm³ on average, thus still being a bit heavier than aluminum (2.7 g/cm³) but at least significantly lighter than most steels. Its lightness along with high strength offers a definite advantage in those applications which need both durability and weight reduction.

Based on recent search data, the inquiry “Is titanium lighter than aluminum for electric vehicles?” has become popular probably as a result of the increase in the usage of sustainable vehicle materials. The fact that titanium is not as light as aluminum doesn’t imply that its greater strength will not lead to thinner and more efficient designs for certain structural applications. In such a case, titanium can sometimes compete with aluminum in terms of weight efficiency when its load-bearing capacity is taken into account.

Weight Metrics of Aluminum

In the discussion among aluminum and titanium regarding the future of electric vehicles, aluminum has an edge due to its remarkable weight-to-strength ratio and low density of 2.7 g/cm³. These properties make aluminum to be one of the lightest metals commonly used in vehicle manufacturing. The latest search data support the fact that aluminum is largely used in this sector. Even though aluminum possesses less strength than titanium, its lightness, cost-effectiveness, and ease of working with the material are three factors that significantly contribute to its use in parts such as battery casings, frames, and body panels. Its supply and flexibility are further reasons that the material can be claimed to be a good one for sustainable vehicle development.

Comparative Analysis of Weight

Aluminum has a lower weight compared to the other materials during the manufacturing process, and this continues to be the main reason why it is always considered a lightweight material. The most recent data shows aluminum has a density of around 2.7 grams per cubic centimeter which is much less than that of steel (7.8 grams per cubic centimeter) and even titanium (4.5 grams per cubic centimeter). This huge difference in weight gives aluminum a clear advantage in sectors such as automotive and aerospace where there is a direct relationship between the weight of components and fuel efficiency and performance. By taking this weight advantage, manufacturers can design their products in a more eco-friendly and less costly manner, which is in line with the increasing global demand for energy-efficient innovations.

Key Properties of Titanium and Aluminum

Strength and Durability of Titanium

Titanium is famous for its incredible strength-to-weight ratio, which is why it has earned the status of the strongest and lightest of metals. Depending on the alloy, its tensile strength is approximately 434 MPa to 1400 MPa, thus surpassing most of its metallic counterparts. Moreover, titanium features excellent resistance to corrosion, even in extreme conditions, like seawater or acids, which gives it the property of durable metal. Its ability to keep the bond even in cases like extreme temperatures and thus being used in aerospace, medical devices, and marine industry is further strengthened. Advances in titanium alloys have been one of the strongest reasons behind all this, which makes it easier to make use of its strength in the cutting-edge engineering projects. The exclusive features of titanium as a material solidify the idea that it is best suited for the application areas where only extreme light weight with durability can be tolerated.

Strength and Durability of Aluminum

Aluminum has developed a great reputation for its unique strength-to-weight ratio, making it a friendly metal in the transportation, construction, and consumer-goods industries. It may not be as strong as steel, but still, aluminum’s strength-to-weight ratio makes it highly effective for applications that give priority to durability without significant weight addition. The recent improvements in aluminum alloys have further enhanced its structural integrity, allowing it to face extreme conditions, including high stress and fluctuating temperatures. Moreover, aluminum’s innate resistance to rust and its capability to develop a protective oxide layer over time do help it survive long even in harsh environments. The features of aluminum along with its high recyclability make it a sustainable and versatile material for modern engineering and manufacturing.

Corrosion Resistance in Titanium and Aluminum

Both titanium and aluminum have the reputation for providing very good corrosion resistance, and for this reason, they are often called to play the key role in the industries such as aerospace, automotive, and construction. Titanium is especially regarded for the environments that come in direct contact with seawater or have a lot of acids since it can form a thick and non-existent oxide layer that prevents degradation. In the same manner, aluminum has a good resistance to oxidation because of its thin but strong surface oxide layer, which not only protects the metal from corrosion but also does not easily get destroyed.

The latest research shows that the corrosion resistance properties can be improved even more if the metals are used together in the manufacturing of alloys for example titanium-aluminum alloys. The alloys possess properties that are not only lighter because of aluminum but also have the incredible strength and anti-corrosive features of titanium. Different studies hint that these alloys do exceptionally well when exposed to extreme conditions like marine areas and high-stress situations. Therefore, these alloys are not only used for the technologies like aerospace components and medical implants where both durability and lightweight properties are critical but also for the development of such technologies.

Cost-Effectiveness of Each Metal

When we talk about the cost-effectiveness of titanium and aluminum, it is vital to consider their performance advantages alongside their market prices. Aluminum is a lot cheaper, due to its lower price per pound and high availability, it is the first choice for large-scale projects that require budget considerations. In other words, titanium has a higher price because of its extraction and processing costs, plus its superior qualities of being strong and lightweight and of opposing corrosion. Nevertheless, in recent times, the benefit of new techniques in manufacturing like 3D printing and more efficient methods of extraction has led to a drop in production costs, making titanium the option for specific high-performance applications. Combining these metals together into the making of alloys is a wise step, it not only exploits their strengths but also minimizes costs, thus providing a balanced solution for industries that are in need of durability and cost-effectiveness.

💡 Cost Comparison Summary

- Aluminum: Lower cost, high availability, budget-friendly for large-scale projects

- Titanium: Higher initial cost but offers superior performance in specialized applications

- Combined Alloys: Balanced solution that optimizes both cost and performance

Practical Applications of Titanium and Aluminum

Use in the Aerospace Industry

Titanium and aluminum are the two metals that are responsible for aerospace industry gears that are powered up due to their peculiar high strength and low weight pairing. The first one, titanium, is characterized by excellent corrosion resistance plus the ability to tolerate high temperatures; thus, it becomes the main ingredient in the production of jet engines, landing gears, and airframe parts. The second one, aluminum, has a lightweight coin that makes it the only thing to be used for making fuselages and wing structures most of the time. When mixed up to create different alloys, these metals become materials that fulfill even the toughest requirements of the modern aerospace engineering.

The recent reports reveal that the global aviation sector is turning its back on traditional materials and moving towards titanium-aluminum alloys in order to get the most out of their fuel efficiency and to lower the amount of emitted gases. This transformation, in a way, enhances the eco-friendliness and innovativeness of the sector. Moreover, the manufacturing technologies are also getting the credit with the latest advancements such as the trend of Additive Manufacturing and Precision Machining that have further facilitated the usage of these materials by minimizing the waste and increasing the production efficiency. The cooperation of both metals is the reason why the aerospace industry is still able to come up with new solutions that are not only safe but also light and super-efficient thereby making aircraft of the future.

Applications in Medicine

The medical application of titanium and aluminum is not restricted to the aerospace industry alone rather have been dipped in high tech ways in the medical field, more so in implants and surgical tools. Titanium for instance is very much a compatible, light-heavy metal and hardly gets corroded which makes this metal most suitable for use in orthopedic implants, dental implants, and prosthetics. Aluminum alloys that have been known for their highly light-weight and durable properties are being used in the creating of advanced medical devices like wheelchairs and surgical equipment. The recent trends show that there is a marked rise in the demand for titanium-based 3D-printed implants, which facilitate the personalization of the implant and also lead to quicker recovery of the patient. There is no doubt that these materials have had a remarkable impact on patient care, through which medical technology has obtained precision and reliability.

Construction and Structural Uses

Titanium has turned out to be a miracle metal for the construction and structural engineering sectors because of its unique quality of being very strong and at the same time very light, along with its great resistance to corrosion. With the passing of time, the curiosity surrounding the use of titanium in sustainable architecture and infrastructure has been escalating quite a bit. The users often ask questions such as, “How is titanium used in modern construction to provide durability?” which is one of the signs of increasing consciousness about its merits. Titanium is often employed in constructions of bridges, skyscrapers, and, yes, even spacecraft, which require top-quality materials that can bear conditions of the utmost severity while still keeping the physical structure intact. It also plays a role in eco-friendly construction practices, since its durability and recyclability mean that over time its environmental impact is much less.

Industry Applications at a Glance

✈️ Aerospace

Jet engines, airframes, landing gears, fuselages

🏥 Medical

Implants, prosthetics, surgical tools, wheelchairs

🏗️ Construction

Bridges, skyscrapers, sustainable architecture

Pros and Cons of Titanium vs Aluminum

Advantages and Disadvantages of Titanium

✅ Advantages of Titanium

- Strength and Durability: Titanium has established its power-to-weight ratio as very exceptional, thus it is very strong and at the same time very light. This situation is very advantageous especially in construction and in the aerospace industries, where the integrity of the structure is very important.

- Corrosion Resistance: Due to its nature of being corrosion resistant, titanium, among others, can withstand rust and chemical wear and tear which makes it highly suitable for use in harsh or extreme environments like coastal structures and industrial facilities.

- Longevity: The long lifespan of titanium-based structures is due to the fact that they require less frequent replacements or repairs taking into consideration their durability and resistance to wear, which, in turn, translates into lower long-term costs.

- Recyclability: Titanium is among the materials that can be recycled with utmost ease, thus modern sustainability goals are met. Reusing titanium is a major contributor to the eco-friendliness of construction and manufacturing practices.

- Heat Resistance: Titanium is able to retain its qualities even when subjected to very high temperatures, thus, it is suitable for operations that come with having to deal with very extreme heat.

❌ Disadvantages of Titanium

- High Cost: Titanium cost is much more than that of materials such as aluminum or steel, the main reason being its extraction and manufacturing processes, which are complicated.

- Processing Difficulty: Titanium’s hardness and strength come with the drawback of making it hard to machine and fabricate, thus increasing labor and production costs.

- Limited Availability: Titanium supply is sometimes limited due to the rare ores being hard to find or due to geopolitical issues that affect supply chains.

- Brittleness at Low Temperatures: Titanium is strong but can be brittle when subjected to extremely low temperatures. This situation may limit its use in certain specialized environments.

Based on the most recent data and trends, titanium’s amazing properties make it a perfect material for use in modern and high-performance construction projects. Its plus points such as unmatched durability, corrosion resistance, and sustainability very often surpass the downsides, especially in critical applications like bridges, skyscrapers, and aerospace engineering. However, due to the high cost and difficult manufacturing process, it is best to use it selectively in those areas where its unique properties can provide the greatest value.

Advantages and Disadvantages of Aluminum

Aluminum is a lightweight and expensive material widely used across various industries due to some of its unique properties and benefits. It has been developed into an absolutely coherent and very strong corrosion resistant material because of the natural growth of a defensive oxide film on the surface. Aluminum is also very malleable and very conductive making it ideal for its doings for electrical applications, transportation, and packaging. Another reason for its popularity lies in its environmentally friendly recycling. Aluminum can be recycled indefinitely without loss of quality.

While aluminum does have some advantages, it also comes with a long list of drawbacks as well. This lightweight option may rank high in terms of strength, but in comparison with other materials like steel, the level of strength is comparatively low and, therefore, heavy-duty applications are impractical for it. Further adding to its negative image are the issues related to extraction, refining, and handling, of which intensively consuming energy is a significant contributor to pollution if caution is not exercised. Furthermore, the prices of aluminum are on the higher side when measured against other materials, which unfortunately may prove a deterrent to its use in quick-cost-sensitive scenarios.

Consequently, aluminum wins over these disadvantages from several other viewpoints from lightweight durability to many points of recyclability. However, the utmost importance is to consider the given set of needs and circumstances (when material’s cost and strength are dealing with close deadlines).

Frequently Asked Questions (FAQ)

How do the conductivity levels of electricity compare?

Aluminum is a far better conductor of electricity than titanium. And, in general, it is the preferred common metal for electrical wiring and busbars. Titanium has really less electrical conductivity. Therefore, it is rarely used where high conductivity is desired as against aluminum. Aluminum oxide, however, does not significantly impede electrical conduction when metal is properly connected. Aluminum offers better performance and low cost over titanium in case of performing loads. When it comes to components in which conductivity is secondary to one of strength or corrosion resistance, titanium may still be preferable in most cases.

Which alloy is a better heat conductor?

Thermal conductivity in Al is substantially higher than in Ti, which is why Al alloys are usually employed where heat transfer is important. The thermal conductance of Ti-alloyed workpieces is much less than the heat-conducting nature of Al workpieces; hence, once Ti workpieces become heated, they will retain the heat more, thus rendering it less effective in counteracting heat. More over, thermal expansion may vary: aluminum, for one, expands more with temperature than does titanium, something that seems to be more important on components needing to be heated and cooled. Aluminum is highly recommended for applications requiring quick heat dispersion compared to titanium. However, when attempting high-temperature strength or corrosion resistance at high temperatures, Ti can have some advantages.

Which has better corrosion resistance?

Biodegradable polymer alkyl changes increase its biodegradability- thus enhancing the hydrophobic/hydrophilic properties of the materials. On the other hand, glassy polymers are inflexible and disallow a diverse range of stimuli-responsive pores. Conversely, worked thermoplastic polymerization enhances flexibility and results in an easily healed matrix plasticization-induced hydrodynamics. This simple scaffold retains the biometal imide in one specific area while providing a soft matrix for drug release.

Is Al easier to Machine and Use?

Al is easier to cut and form than titanium, thereby making it a popular alloy on the rapid manufacturing and prototyping platforms. Here, it tends to weigh lighter and is pretty much more affordable than titanium in general hence going to counterbalance for the use of more aluminum in a variety of products, lightening the utility concerns related to the metals for consumer and industrial parts. Aluminum displays conductivity and allows good current heat transfer which is sufficient in heat exchange and casing duties. On the other hand, titanium is stiffer, having the advantage of its lightweight ratio over Al, in places where one needs to rely upon different data for higher resistance than what Al can afford. With this in mind, the use of Al rather than Ti is common in creating a mantle between the different elements or features of cost, machinability, and the proportion of performance that is acceptable.

How much do titanium grades cost?

Titanium grades and titanium alloys attain higher tensile strength relative to that of aluminum alloys, which further resist corrosion, justifying the high cost in applications where they are demanded. Titanium light-weight and resilient are typically selected when higher strength, elevated temperature performance, or biocompatibility is needed, similar to aerospace, medical implants, and corrosive chemical handling. Although titanium is heavier than aluminum, exceptional strength and fatigue resistance are the reasons less titanium is needed in some design. Titanium is also more costly compared to aluminum and hard to machine; hence, the decision of employment of titanium parts is driven by the performance needs and budget. For application wherein higher strength and corrosion resistance are required, metallic materials like titanium outdo aluminum, despite the higher cost.

When to use one over the other?

No metal is superior in all respect for all types of criteria but the choice between aluminum and titanium depend on the application and its criteria of interest such as weight, conductivity, corrosion resistance, and cost. If weight reduction is critical for a product, and cost or conductivity is also of utmost importance, aluminum is the best option as it is lighter and is also a terrific cost-effective material for making many products. Titanium better suits applications that will need higher strength-to-weight ratio, higher corrosion resistance, or some biocompatibility, though it is denser and costlier. So for areas where steel and aluminum could be thought of as alternatives, titanium offers much where these fall short. This depends on the material properties, manufacturability, and lifecycle cost comparison between aluminum and titanium.

Can Aluminum Replace Titanium in Applications?

Indeed, aluminum can more often then not be substituted with titanium without a major drawback, though the use of titanium might not be economically viable if aluminium retains enough strength and is affordable. Further, aluminum is lighter in weight and easier to fabricate, but, by and large, its fatigue strength and maximum strength are lower when compared with titanium-thin aluminum dishes bowing out on the same load. In applications that require high tensile strength and excellent corrosion resistance, any less than titanium or titanium alloy would have to be used, notwithstanding the fact that such materials usually command a higher price compared to aluminum. Titanium, also for cost-considerate applications, is either sure-choice raw material ideally suited for aerospace as well as medical applications. Ultimately, the appropriateness of using aluminum in place of titanium will depend on how and where its properties relate to titanium requirements of performance.

Reference Sources

-

Embry-Riddle Aeronautical University – Aerospace Materials: This resource discusses the weight and strength differences between aluminum and titanium, highlighting their applications in aerospace.

Aerospace Materials – Embry-Riddle Aeronautical University -

Exploratorium – Science of Cycling: Frame Materials: This article explores the qualities of aluminum and titanium, focusing on their strength-to-weight ratios and applications in cycling.

Science of Cycling: Frame Materials – Exploratorium -

ScienceDirect – Influence of Aluminum and Titanium Content: This study examines the effects of titanium and aluminum on the properties of superalloys, providing insights into their material characteristics.

Influence of Aluminum and Titanium Content – ScienceDirect