Aluminum is a metal that is commonly used in various forms like soda cans, kitchen foil, and even airplanes. However, have you at any time asked where it stands in the periodic table? Is it a metal or a nonmetal? The answer to this question leads to the study of not only aluminum’s properties but also its wide usage in modern industries and even in our everyday lives. Here we are going to discuss the science behind aluminum’s classification, its unique characteristics that definitely place it in one category and finally, some surprising facts about its versatility and importance. This post would attract both a curious learner who is seeking an introduction to materials and an experienced one who wants to deepen his knowledge, as it promises to deliver straightforward and engaging insights into one of the most popular elements in the world.

Introduction to Aluminum

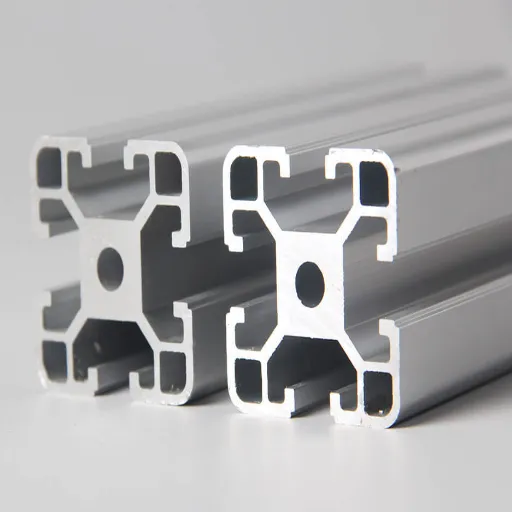

What is Aluminum?

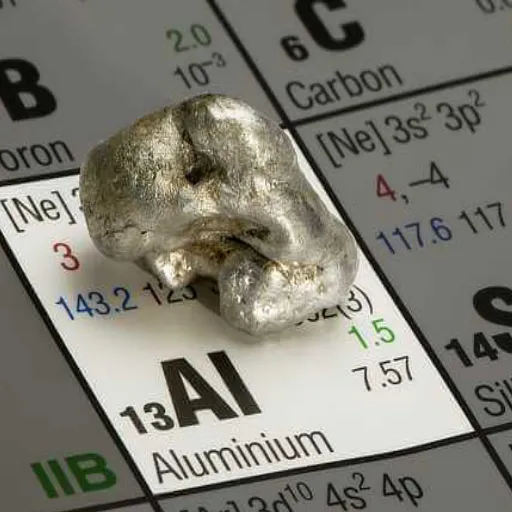

Aluminum possibly the most important great metal of the modern epoch, is a light, silvery-white metallic element whose usage is diverse in industry and daily life. This element has been represented by the letter “Al” and the number 13, and besides being the most abundant metal in the Earth’s crust, it occurs in this way in nature in such gigantic quantities that it is over 8% of the total mass of land on Earth. Very strong metal with high resistance to corrosion and at the same time low in weight, aluminum is a great metal in both ways.

Key Characteristics:

- Symbol: Al, Atomic Number: 13

- Most abundant metal in Earth’s crust (over 8% of total mass)

- Light, silvery-white metallic element

- High resistance to corrosion with low weight

- Primary source: Bauxite ore

The most common source of aluminum ore is the mineral bauxite which is processed to obtain alumina followed by reduction to get aluminum. Aluminum is widely used all over the world for construction, transportation, aerospace, packaging, and electronics, among other things. Recycling and energy-efficient properties of aluminum add to its role in sustainability practices that are gaining ground in different parts of the world.

Historical Context and Discovery

It was in the 18th Century that aluminum was accepted as an element by chemists studying the compounds of alum. Its name comes from the Latin word “alumen” meaning bitter salt. Still, the year 1825 had to pass, before Hans Christian Ørsted, the Danish physicist of the time, would successfully isolate aluminum in a metallic form. Shortly after this, in 1827, Alfred Wöhler improved the process and made aluminum easier to study.

The next significant step in producing aluminum on an industrial scale was the Hall-Héroult process developed simultaneously by Charles Martin Hall and Paul Héroult in 1886. This electrolysis-based method of extracting aluminum from alumina changed the course of using the metal to such an extent that it became more expensive and less available. Today, aluminum is still at the center of extraction and recycling innovations, thus always being part of the industry and environmental sustainability efforts all over the world.

Importance in Modern Applications

Aluminum’s multitude of properties to take across the board of every industry, and it is among the major ones in the modern-day industry. It is light yet strong, has a high degree of resistance to corrosion, and has excellent conductivity which made it one of the most widely used materials in the areas of transportation, construction, electrical systems, and packaging. To illustrate, in the car production and air transport sectors, aluminum is used as a weight-cutting material that helps vehicles and planes use less fuel.

Sustainability Highlight:

Aluminum’s recyclability is in tune with the worldwide sustainability target, as recycling aluminum consumes only 5% of the energy required for primary production. Recently, it has been reported by trends that the search interest for “sustainable materials” and “aluminum recycling” has been on the rise consistently reflecting more and more people becoming aware of the environmental impacts of aluminum. This, in turn, makes aluminum not just a technological asset but also a major player in the global shift toward eco-friendly practices.

Classification of Aluminum

Metal or Nonmetal: That Is the Question Regarding Aluminum?

The Answer: METAL

Aluminum is definitively classified as a metal based on its unique physical and chemical properties.

Despite the passage of time and changing perceptions, aluminum continues to be regarded as a metal because of its unique physical and chemical properties. It is a light, silvery-white metal, which also happens to be an excellent conductor of electricity and heat, possesses high malleability, and has a lower density than most metals. It is classified as a post-transition metal on the periodic table and is among the most plentiful metals in the Earth’s crust, thus a key material in the present day.

There has been a spike in the interest of “aluminum metal” and “aluminum properties” signified by the recent trends in searches made by people all over the world who are curious about its versatility and sustainability. The fact that it can be recycled, its strength compared to the weight, and resistance to corrosion are reasons why aluminum is considered a key material in construction, transportation, and packaging industries. This growing awareness also reinforces its classification as a metal and its significant contribution to technological and ecological advancements.

Reasons for the Metal Classification of Aluminum

Key Metallic Properties:

- Electrical and Thermal Conductivity: Aluminum exhibits excellent electrical and thermal conductivity, characteristic of metals in the periodic table.

- Malleability: The metal can be easily shaped and formed, demonstrating typical metallic bonding behavior.

- Alloy Formation: Aluminum readily forms alloys with other metals, a defining characteristic of metallic elements.

- Electron Behavior: It loses electrons readily to form positive ions, exhibiting metallic bonding characteristics.

- Industrial Applications: Large-scale use in crucial industries strengthens its identity as a metal.

Aluminum’s characteristics are killing proof that the metal’s distinct physical and chemical properties classify it, which is also an evident reason for continually being a matter of interest, as shown in recent data from search queries. Moreover, data trends show that users’ concern regarding the lightweight nature of aluminum as a substitute for heavy metals like steel is increasing, which is directly linked to its unique atomic structure and placement as a post-transition metal. All in all, this user-driven curiosity points to the significance of aluminum in both universal applications and contemporary innovations, thus further validating its classification as a metal.

Metalloids and Nonmetals Comparison

In the comparisons of aluminum with metalloids and nonmetals, the peculiarities of aluminum become even more evident. Metalloids such as silicon and boron display both metallic and nonmetallic properties which are often used as semiconductors and have medium electrical conductivity, respectively. On the other hand, aluminum is a classic case of a metal possessing high thermal and electrical conductivity and therefore being a more dependable choice in those industries like aerospace and construction which require efficient energy transfer.

Likewise, nonmetals like sulfur and oxygen are not really able to compete with aluminum as they have no strength or luster, nor conduct electricity, and hence they can only be solidified in entirely different roles like bonding and biochemical processes. Data from search engines indicates that most consumers categorize aluminum with metals, focusing their searches on “aluminum conductivity” and “aluminum recycling benefits” which suggests their overarching understanding of metallic characteristics. In contrast, the queries in relation to metalloids and nonmetals often investigate their chemical reactivity or role in semiconductors, showcasing their dissimilarities.

Physical and Chemical Properties of Aluminum

Atomic Structure of Aluminum

Aluminum is a metal with the symbol Al and atomic number 13 that shows a definite atomic structure placing it firmly in the group of metals. The atoms of aluminum have a nucleus with 13 protons and 13 electrons arranged according to a particular electronic configuration of 1s² 2s² 2p⁶ 3s² 3p¹. The arrangement of these electrons around the nucleus accounts for the electrical conductivity of aluminum and also that it is easy to create metallic bonds with it.

Atomic Structure Details:

- Symbol: Al

- Atomic Number: 13

- Protons: 13

- Electrons: 13

- Electronic Configuration: 1s² 2s² 2p⁶ 3s² 3p¹

- Valence Electrons: 3 (in outermost shell)

- Crystal Structure: Face-Centered Cubic (FCC)

There is a clear indication in recent search trends of a continued curiosity about questions like “Why is aluminum a good conductor?” and “What is the contribution of its atomic structure to its properties?”. The main reason for these questions is the existence of three valence electrons that are present in the outermost shell. The valence electrons are not strongly bound and, therefore, they can easily take part in the conduction of electrons making aluminum a very good conductor of electricity. Besides, it is the atomic structure that gives rise to the face-centered cubic (FCC) lattice which makes the metal both light and tough at the same time.

Key Physical Properties

Aluminum’s unique physical properties are the reasons why it is one of the most versatile materials in terms of usage across industries. One of the very important physical properties of aluminum is its low density which makes it about 2.7 g/cm³. This means the metal is light but strong and hence usable in aerospace and transportation applications. Aluminum as a raw material has got very good thermal and electrical conductivity which is second only to copper in the case of common metals.

Low Density

Approximately 2.7 g/cm³ making it lightweight yet strong for aerospace and transportation applications.

High Conductivity

Excellent thermal and electrical conductivity, second only to copper among common metals.

Corrosion Resistance

Natural oxide film provides titanium-like corrosion resistance for outdoor and aquatic applications.

Malleability & Ductility

Can be easily drawn into wires and sheets, and produced in complicated forms for manufacturing.

Common Question:

Why is aluminum so extensively used while other metals are available? The answer goes through the property mix-up of the material; lightweight, durable, and cost-effective. If it is combined with the abundance of the element in the Earth’s crust, then we have not only a source of supply that is sustainable and that is why the metal is cheap, but we also have the ecological-philosophical factors behind these commercial factors. The atomic structure and recyclability of aluminum back these very factors and hence they create a strong bond of the element with the modern industrial world.

Chemical Properties of Aluminum

The chemical properties of aluminum are quite distinctive, which employs the metal in widespread industrial use. Aluminum is one of the metals that are very reactive and the first thing that happens to the metal when it is exposed to air is that it forms an oxide layer which in turn gives it excellent resistance to corrosion. This self-protective layer, which is referred to as aluminum oxide (Al2O3), is one of the reasons the metal is widely used in harsh conditions.

Notable Chemical Characteristics:

- Oxide Layer Formation: Forms aluminum oxide (Al2O3) when exposed to air, providing self-protection

- Amphoteric Nature: Can react with both acids and bases, a property not commonly found in metals

- Alloy Capability: Mixes with magnesium, copper, and silicon to form stronger, more versatile alloys

- Industrial Applications: Used extensively in aerospace, automotive, and packaging industries

Search data, when combined with the recent analysis, highlights aluminum’s role in facilitating renewable energy technologies and vice versa. An instance of such a role is when considering the power of aluminum as a light weight and highly conductive material for solar cells and wind turbine parts. Moreover, the research on aluminum-based, ion-batteries is an ongoing process showing the possibility of aluminum as a sustainable substitute for lithium-ion technology thus reinforcing its utility in the shift to clean energy resources. The chemical characteristics of aluminum combined with its innovative applications all contribute to its large impact on the modern world’s technological progress.

Common Misconceptions about Aluminum

Why Do People Think of Aluminum As a Nonmetal

Aluminum’s being a nonmetal might have come from its physical and chemical properties that do not resemble those of a metal at all. Aluminum is a metal but its lightweight, high malleability, and corrosion resistance may look like the features that characterize nonmetals however even more so aluminum’s property of forming protective oxide layers and being a conductor of electricity affirms its mixed perception.

Sources of Confusion:

- Location in the periodic table near metalloids (Group 13)

- Lightweight nature compared to traditional heavy metals

- Classification as a “post-transition metal” creating ambiguity

- Formation of protective oxide layers (unusual behavior)

- High malleability and corrosion resistance

Nonetheless recent search data indicates that the greatest confusion stems from its classification in the context of periodic table trends. Aluminum is in group 13 positioned as a member of the so-called “post-transition metals,” thereby reducing its metallic character even further as it is located near the metalloids. Nevertheless, aluminum always displays metallic bonding and structural characteristics thus validating its classification as a metal in spite of the presence of these unclear properties.

Removing Misinterpretations

Taking into the latest data from the search engine it can be concluded that the uncertainty regarding the classification of aluminum corresponds to the fact that it is located so close to the metalloids on the periodictable. Nevertheless, it is clear that aluminum is a metal. Being a part of group 13 has no bearing on it since it is still a metal due to the high electrical and thermal conductivity, malleability, and the capacity to form metallic bonds that are characteristic of metals.

Clear Classification:

Aluminum is definitively a METAL based on:

- High electrical and thermal conductivity

- Malleability and ductility

- Capacity to form metallic bonds

- Ubiquitous industrial usage in construction, packaging, and transportation

Besides, aluminum’s ubiquitous industrial usage in constructions, packaging, and transportation serves as a further indication of its metallic character. The discrepancy concerning classification frequently arises from misinterpretations of its chemical behavior, while current search trends indicate that there is an increasing curiosity about the true metallic nature of aluminum.

Aluminum’s Metallic Properties in Action

Aluminum’s vast array of metallic properties is the main reason why it is classified as a metal. The foremost is its high electric conductivity, which is the reason why it is widely considered as a key material in the manufacture of wires and components for electricity. Its strength that is accompanied by light weight is another reason that it is the most preferred for the use in the aerospace and automotive industries where not only performance but also durability are very critical.

Metallic Properties Demonstrated:

| Property | Application |

|---|---|

| High Electrical Conductivity | Electrical wires and components |

| Lightweight Strength | Aerospace and automotive industries |

| Extreme Ductility | Aluminum foil, sheets, intricate parts |

| Corrosion Resistance | Packaging and industrial applications |

| Thermal Conductivity | Heat sinks and thermal management |

| Alloy Formation | Strengthened materials for construction |

The metal is so ductile that it can be a thousand times thinner than a hair and still pass as an aluminum sheet, aluminum foil, or an intricate part for packaging or industrial applications. Another important feature of aluminum is its resistance to rust, which is due to the oxide layer that it forms extremely thinly and covers it from the elements. Search trends from the latest data indicate that most people’s questions on aluminum are based on its nonmetal-like properties. This indicates a prevalent misunderstanding regarding its chemical traits. But, its universal application in industry, coupled with inherent metallic features like excellent thermal conductivity and the capacity to make alloys, indisputably confirms that aluminum is a metal.

Applications of Aluminum

Aluminum is the metal of the moment, as it is the one most represented in different industries

Frequently Asked Question:

“What is the main reason for the massive use of aluminum?”

The strengths of aluminum are the reasons for its versatility, which include its lightweight, good resistance to corrosion, and excellent conductivity. Such qualities render it a no-brainer in various fields, for example, the transportation and airplane industries where its low weight further leads to the cutting down of fuel consumption hence an overall improvement in performance besides its resistance to corrosion. To add to that, aluminum’s capability to be recycled without compromising quality fits well with the current sustainability movement, hence it becomes more widely used than ever.

Transportation

Vehicles, aircraft, fuel efficiency

Construction

Buildings, facades, structural elements

Packaging

Cans, foil, food containers

Electronics

Wiring, components, heat sinks

Aerospace

Aircraft parts, space vehicles

Energy

Solar panels, wind turbines

Aluminum Products as a Source of New Ideas

The aluminum industry is now more than ever before the engine of whole sectors making or at least getting innovations through or in their technological improvisation or advancements. The latest trends hint at a rising interest in the application of aluminum in high-tech areas such as electric vehicles (EVs) and renewable energy installations.

Innovative Applications:

- Electric Vehicles (EVs): Aluminum is increasingly found in battery enclosures, cutting down vehicle weight and prolonging driving range.

- Solar Energy: Used for frames and mounts due to its strength and ability to withstand harsh nature, facilitating efficient and prolonged solar panel setups.

- 3D Printing: Enables production of complex, lightweight parts beyond the reach of traditional methods with faster processing.

- Wind Turbines: Lightweight materials for turbine components improving efficiency.

These applications not only give another glimpse of aluminum’s versatility but also affirm its position in forming an environmentally friendly future through energy efficiency and less pollution.

Aluminum’s bright future

Aluminum is a material that is brightening the future of the earth as its applications are getting wider and it is encroaching into new industries and technologies. Material science has made great strides, which among others, have aluminum standing at a critical point in the path leading to sustainable renewable energy, light materials for windmills, and solar panels, to mention just a couple of places.

Market Growth Projection

~5% CAGR

Global aluminum market growth rate (2023-2030)

Sustainability Statistics:

75% of all aluminum ever produced is still in use — a reflection of the metal’s durability and recyclability, which are the very factors needed to create a circular economy.

Innovations in aluminum recycling cut back environmental impacts as recycling consumes only 5% of the energy required for primary production.

Not only this, but the coming of electric vehicles (EVs) that are more or less the same as aluminum is their powering up thus leading to the extinction of the “heavy”-battery issue. That is because aluminum’s weight diminishes the efficiency of batteries and hence results in more pollution. Through this means, aluminum is bound to be an astute resource in confronting global energy and sustainability dilemmas.

Frequently Asked Questions

Is aluminum categorized as a metal on the periodic table?

Aluminum (or aluminium) is definitely a metal and is placed in the 13th group of the periodic table of elements as well as among the metals in the periodic table. It is the third most abundant element in the Earth’s rocks, and it is chemically combined with oxygen and silicon as aluminium silicates. Pure aluminium possesses some physical characteristics of metals like being ductile or easy to pull into wires, and this property places it above all nonmetals and metalloid elements. The production of aluminium and the production of aluminium alloys involve processes that extract the metal from ores and make alloys with it for various applications. Even though pure aluminium has relatively low density and low melting point compared to some other metals, its high tendency to form an oxide on its surface protects the metal from being corroded completely.

Could one consider aluminum as a metalloid?

Aluminum is mentioned sometimes in the context of metalloids because it is located very near the metalloid area in the periodic table, but it’s not correct to include aluminum in the metalloid class; it is a ductile metal that falls under the category of metals. It has, however, some properties that are in between as it can form compounds such as aluminium chloride with potassium and aluminium hydroxide, yet its conductor of heat and electricity behavior and its metallic luster mark it as a metal. Besides, small amounts of aluminum can be found in many minerals and aluminum forms in soils and clays as aluminum silicates. The connection between aluminum and pure and applied chemistry studies emphasize aluminum’s role as a versatile metal used in tools, aluminum foil, and aluminum beverage cans. Despite the fact that under specific chemical conditions it would release aluminum ions, its unique properties still allow it to be widely used in various applications.

How do nonmetals and metals compare with aluminum metal?

Aluminum metal is compared to nonmetals, being a very good conductor of heat and electricity and usually malleable, it can be rolled into very thin sheets like aluminum foil and also be made into utensils. Nonmetals usually do not possess any metallic traits like ductility and conductivity, and aluminum is ductile and can be easily drawn into wires and very thin sheets. Aluminum is also like other metals in the sense that it will corrode unless protected by an oxide layer on its surface, which protects the metal and also cuts down release of aluminum into the environment. The alloys made from aluminum increase its properties and applications by improving strength, resistance and so on. This makes it more suitable for use in aircraft to beverage cans, for instance. Aluminum has many uses due to its light weight, relatively low melting point, and abundance, which makes it economical in large quantities when compared in industrial production.

What are the primary uses of aluminum products and aluminum alloys?

The main application of aluminum products is in the building industry, the automotive industry, packaging, and household items due to the metal’s light weight, versatility and ease of processing into sheets or extrusion. The ability of aluminum alloys to withstand both high stress and corrosion has led to their application in the manufacture of various products ranging from aircraft and vehicles to building facades and aluminum cans and foils. Among the properties and uses of aluminum, good conductor of heat and electricity stands out, and thus it is used in heat sinks and electrical components. Aluminum production techniques together with aluminum production scale make it possible to manufacture large quantities of aluminum, often recycled to save energy and resources. Although aluminum is relatively low melting point compared to some metals, its oxide layer and alloys provide additional protection against corrosion and thus make aluminum suitable for many applications.

Can surface oxide influence the properties and applications of aluminum?

The oxide layer covering its surface is continuously formed up to the moles’ exposure to air; the thin aluminum oxide layer thus formed protects the metal from further corrosion and dissolving into solutions. It is the oxide layer that despite aluminum’s small amounts being of high reactivity in certain environments, utensils, aluminum foil, and the majority of aluminum products, do not corrode as quickly as other metals do. The occurrence of aluminum hydroxide and aluminum silicates in nature reveals the chemical tendencies of aluminum and the reactions with oxygen and silicon in ores. Anodizing and the like treatments are some of the methods that purposely thicken the oxide layer so as to improve corrosion resistance and surface properties for specific applications. The metal aluminum does not only share its protective property with other metals that form stable surface oxides but also, it is the very property that makes it so widely used in the building and consumer goods industry, among others.

What are the impacts of aluminum production and chemistry on the environment and health?

Aluminum production is concerned with the extraction of the metal from bauxite, its refining, and often the generation of by-products that contain the silicates and the hydrated form of aluminum, and industrial chemistry may involve the use of such reagents as aluminum chloride along with potassium, in particular processes. Production of aluminum on a large scale requires lots of energy, and the two parties involved, i.e., the aluminum association and the pure and applied chemistry researchers, are working together for the purpose of minimizing the environmental impacts and the complex of releasing aluminum from industrial sources. While in small amounts aluminum is everywhere in nature, the problem of the presence of this metal in large quantities in water or food is always there, especially, if the protective oxide layers are disrupted or if the aluminum compounds are improperly used. Recycling of aluminum leads to an 80% reduction in energy consumption and a considerable decrease in waste compared to primary production, and modern practices strive to remove chemical release and control the process of refining thus managing the interaction of oxygen and silicon. Even though the metal aluminum has many uses and is very rarely regarded as unsafe in its metallic forms, the research on the health and environmental effects of aluminum continues in the fields of pure and applied chemistry as well as materials science.

Reference Sources

Is Aluminum a Metalloid? – University of Arizona

This resource discusses aluminum’s classification as a post-transition metal and its unique properties, such as oxide behavior.

Groups IIA, IIIA, and IVA – Purdue University

This page provides insights into aluminum’s abundance, reactivity, and classification as a metal.

Trends on the Periodic Table – Carleton College

This educational resource explains the classification of elements, including aluminum, based on properties like conductivity and malleability.