Aluminum is a peculiar element for a like metallic given the broad use of elements in general but at the same time how one ranks it as an element remains a topic for debate. is aluminum a metal or nonmetal or some weird ratio of both? Equally critical to understanding its position in the periodic table is to appreciate the physical properties of aluminum which distinguish it. The paper shows that aluminum is a metal while stressing that some unique features are characteristic of this particular material. So if the question concerns whether aluminum belongs to any, sub answer is yes, while its significance in modern society will be elaborated further.

Introduction to Aluminum

What is Aluminum?

Aluminum exists as a metal which displays both lightweight properties and a silvery-white appearance, yet it contains exceptional characteristics that make it one of the most frequently used elements throughout the periodic table. Aluminum exists as a post-transition metal which belongs to the boron group and has the chemical symbol Al and the atomic number 13. The element occurs as the third most common element in the Earth’s crust, where it exists at a weight percentage of 8% and primarily appears as bauxite ore.

Aluminum has high reactivity owing to its nature, yet its surface gets covered in oxide layer which inhibits any corrosion. This material combines high corrosion resistance with high electrical conductivity and plasticity, to weight strength which makes it necessary for various industrial applications. The material still proves to be indispensable in modern engineering in detail and also present environmental issues considering that the aluminum is reuse as such practices do not proceed to the nature’s depletion.

Historical Context of Aluminum

It is within the eighteenth and nineteenth centuries when an aluminum compound was discovered and in which bauxite was categorised as one of its minerals. In 1825, for example, aluminum was retrieved as a metal by the Danish physicist named Hans Christian Ørsted, although the amounts of the metal created were quite small. The Hall Héroult process was born out of necessity in 1886 for obtaining aluminum by electrolysis without the use of aluminum oxide developed by Charles Martin Hall and Paul Héroult. At this stage, the emergence of aluminum as a material for the manufacture and consumption of goods occurred.

Due to modern methods of extraction and processing, aluminum continues to rank among the most extensively produced non-ferrous metals. Statistics for 2023 suggest that the annual output of aluminum is more than 65 million felts because the need growth in the international economy, meaning transportation, construction as well as aerospace and renewable energy sectors, is ever increasing. Important achievements have been realized in the industry in terms of recycling technology development because The Aluminum Association predicts that about 75 per cent of the entire volume of aluminum ever produced is utilized productively in modern times. This is good for the economy, it is also good for the planet.

Importance in Modern Industry

The reason why aluminum is so much in demand is that it is light and corrosion-free as well as conductive so widely used in manufactures. At least that’s what researches say, metal has always been a crucial component in the construction of electric cars while paying particular attention to renewable energy sources. The need for heavier materials is traeated with great, or distrust and this in turn enhances efficiency in energy. Moreover, Tropical countries like the one which has this god create a lot of ruckus since producing this King on an industrial scale becomes a pain in the neck. From an analysis performed on search engines shows more people are looking for other uses of aluminum such as in green technology which shows the growing relevance of its usage on eco-friendly projects. Observe how the trend introduces aluminum as an old solution to improvement, … resolving environmental conflicts without halting development.

Aluminum’s Position on the Periodic Table

Classification: Metal, Nonmetal, or Metalloid?

The periodic table categorizes aluminum as a metal which exists within the post-transition metals section based on its location in Group 13. The element has an atomic number of 13 which allows it to form cations through the loss of three electrons because it possesses distinctive metallic characteristics. Recent data from search engine results shows that people want to know about aluminum because it serves as crucial material for green technologies. The sustainable applications of aluminum together with its classification as a metal establish aluminum as an essential material which both supports traditional industrial practices and contemporary environmental efforts.

Periodic Trends and Aluminum

The periodic table shows aluminum in group 13 and period 3 which helps scientists understand its chemical and physical behavior. The metal exhibits its metallic properties through its low electronegativity value of 1.61 which enables the metal to lose three valence electrons and create Al³⁺ ions that display periodic trends between increased metallicity and decreased electronegativity to the left of the periodic table.

The latest data from search engine platforms reveal that both the general public and industrial companies increasingly seek information about aluminum because of its use in renewable energy systems and sustainable manufacturing practices. The queries “recyclable metals in EV production” and “lightweight materials for solar panels” demonstrate that the world is moving toward using materials which provide both operational efficiency and positive environmental impact. Aluminum serves as a reactive metal in traditional chemical environments while it also functions as a central element in developing strategies for sustainability.

Aluminum demonstrates how basic chemical elements create actual environmental benefits when both its periodic behaviors and its green technology applications work together in their relationship.

Comparison with Other Elements

Aluminum outperforms other metals used in industrial and technological purposes because it achieves optimal levels of availability and recyclability and operational efficiency. Although copper provides superior electrical conductivity advantages, power transmission lines benefit more from aluminum because of its lower density and decreased costs. The production of energy-efficient infrastructure depends on this particular characteristic.

Aluminum provides better operational benefits than steel because it resists corrosion at high levels which protects against saltwater and moisture damage while lowering maintenance expenses throughout its lifespan. Aluminum requires less energy and money to extract and process than titanium which offers better strength and corrosion resistance.

The search data shows that people want lightweight recyclable materials because they search for terms like sustainable alternatives to stainless steel and most recyclable industrial metal which show higher search volumes. The public now understands sustainability better while aluminum has become a main environmental solution. The aluminum industry uses recycled materials to create environmentally friendly metal solutions which enhance industrial operations.

Chemical Properties of Aluminum

Oxidation States of Aluminum

The oxidation number held by aluminum remains at +3 during its reactions from where we can infer that it is its most predominant oxidation number. The element aluminum, in particular, exhibits this character because the three outermost electrons for the element are very mobile in any chemical change it takes. These electrons are above the core and upon joining chemical bonds they are excited leading to Al³⁺ anions which are very stable due to the fully filled or octet principle of stability.

An increased number of users has been identified searching for the oxidation behaviour of aluminum with partly naive questions like, “Why is aluminum always +3?” or “Give examples of +3 charge of aluminum compounds”. There is general agreement already of the key part played by aluminum in industry processes. It is because when the compounds of aluminum such as aluminum oxide (Al₂O₃) and aluminum sulfate (Al₂(SO₄)₃) are popular in business’ s practice, it would be expected that aluminum should be in +3 oxidation state most of the time. In the same way, the reliable nature of aluminum with regard to chemical behavior has made it widely useful to scientists and ‘practical men as well’.

Reactivity with Other Elements

To start with, whether is aluminum a metal or nonmetal in nature it has a different structure that can easily form bonds with other elements. Aluminum is highly reactive because of its group number. The most interesting factor about its reactivity is that it can lose all its three electrons to form a +3 cation, which in turn results in relatively stable and complete octet. As mentioned earlier in the paper, this characteristic tends to activate reactive Al with O2 and in turn, it causes the formation of the aluminum oxide Al2O3 around the metal, therefore, protecting it from any further corrosion. This would be an example of a metal reacting with one of the halogens, in this case, chlorine gas which gives aluminum chloride AlCl3 which is used by sales engineers in industries to catalyze the means.

Does aluminum react with hydrochloric acid? Aluminum combines with this acid to form aluminum chloride (AlCl3) and hydrogen gas. 6HCl + 2AlCl₃ → H₂ + 3H₂. Understand that, similar to acids, aluminum makes such reactions with ‘In Chemistry, is aluminum a metal or nonmetal or should it maybe be a metalloids’ why the answer is similar. Such interactions result in the formation of sodium aluminate NaAlO2, along with the emission of hydrogen gas. Such reactions prove that even as an amphoteric element, aluminum would naturally react with numerous reactants either acidic or basic. Cutting edge developments affirm that aluminum-based plastics and other products support cells working in industry catalyses through a number of chemical interchanges.

Common Compounds of Aluminum

There is a variety of reactions in which aluminum participates due to presence of two opposite chemical tendencies in the element, including its high chemical activity and supposition of the element as an amphoteric. Aluminum exists in combustible forms that are most common as compounds of a dihydrate form, Al₂O₃, lime, AlCl₃, and gray sulfate of aluminum,? Al₂(SO₄)₃? Al₂O₃ that becomes known as alumina is of special utility in the smelting of aluminum through its recovery by the Hall-Héroult technique, and also in other protective uses such as, covering industrial refractory problems and making ceramics. Aluminum chloride works as an agent for water treatment in support of the Friedel-Crafts and Acylation reaction. At the same time, it also includes the use of aluminum sulfate, which is used for coagulation of water for treatment and also for the production of paper.

The latest research data shows that scientists continue to study aluminum compounds because of their potential to create sustainable development solutions. Researchers have developed recent innovations which demonstrate that alumina functions as a thermal stability enhancer for lithium-ion battery systems, which use alumina in energy storage applications. Researchers are now working to improve aluminum-based catalysts so they can support green chemical processes, which will help decrease waste and reduce their effect on the environment. The findings prove that aluminum has multiple scientific and industrial applications, which make it essential for developing contemporary technological advancements.

Physical Properties of Aluminum

Mechanical Properties

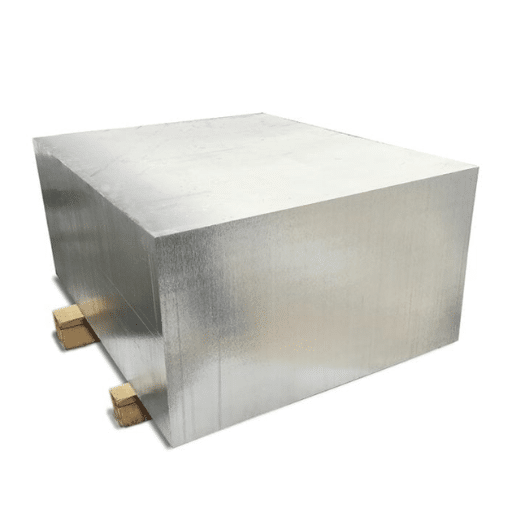

Aluminum displays outstanding mechanical attributes which allow it to be used in various industrial applications that require different material properties. The material has a density of 2.7 g/cm³ which makes it one-third as heavy as steel while still providing enough strength for construction purposes. The development of new aluminum alloys has resulted in better tensile strength since high-strength aluminum alloys can now reach strengths beyond 600 MPa. The material’s high ductility which enables it to sustain large deformations without breaking makes aluminum suitable for use in extrusion and rolling operations. The material demonstrates outstanding impact resistance together with fatigue resistance which increases the operational lifespan of components that undergo repeated loading cycles. Aluminum maintains its essential role in engineering needs because of its physical properties which combine strength with lightweight design and enduring performance together with continuous advancements in alloy development and treatment methods.

Conductivity and Thermal Properties

The material aluminum receives high regard because it possesses outstanding electrical and thermal conductivity which makes it one of the most efficient conductive substances. Aluminum serves as a conductor in electrical systems because it costs less than copper while weighing less than copper despite having electrical conductivity that reaches 61 percent of copper’s capacity. The material aluminum possesses a high thermal conductivity which ranges between 235 W/m·K and serves as an ideal material for heat exchangers, radiators, and thermal management systems found in electronic devices.

Material science has achieved progress which enables the creation of specialized aluminum alloys that feature better conductivity for particular industrial needs. The automotive and aerospace industries use alloys that combine improved strength properties with thermal performance characteristics to enhance energy efficiency and heat dissipation capabilities. The current developments demonstrate that aluminum can satisfy modern engineering requirements while preserving its traditional attributes of dependability and adaptability.

Corrosion Resistance

The natural oxide layer which develops on aluminum surfaces establishes an efficient protective shield which stops corrosion from damaging the metal. The passive oxide layer can regenerate itself after any damage which provides protection for extended periods under different environmental conditions. Recent progress in alloy development together with surface treatments like anodizing has improved aluminum’s resistance to corrosion which allows its use in extreme conditions found in marine environments and industrial facilities. Public records and technical documents which include search data reveal that aluminum alloys from the 5xxx and 6xxx series provide excellent corrosion protection, making them ideal for environments with high humidity and salt exposure. The system maintains its structural integrity through aluminum, which reduces maintenance costs while extending the useful life of components used in demanding engineering applications.

Applications of Aluminum in Various Industries

Construction and Architecture

Engineers and architects use aluminum in their work because the metal provides high strength properties while remaining lightweight and it can withstand corrosion and it allows for various design methods. According to the latest data insights from search engine, queries surrounding “sustainable building materials” and “lightweight structural solutions” have seen a significant surge, reflecting growing industry and consumer focus on sustainable construction practices. Aluminum serves as an essential element to fulfill these requirements because it combines recyclable materials with strong durability which meets present environmental requirements. The material serves multiple architectural functions because it can be used for curtain walls and window frames and roofing and facade systems. The material serves as an essential component for modern building projects because it works well with both energy-efficient architectural designs and modular construction methods that are currently used.

Aerospace and Transportation

Aluminum serves as an essential material for the aerospace and transportation industries because it provides high strength-to-weight performance together with corrosion resistance and malleability. The characteristics of the material make it essential for the creation of aircraft fuselages and wing structures and high-performance vehicle components. The aerospace industry currently employs aluminum-lithium alloys which use advanced metallurgy and alloying technology to achieve lighter weight while preserving structural strength because these materials improve fuel efficiency and performance.

The diesel and electric vehicle sectors achieve improved energy efficiency through the use of aluminum because its low weight properties benefit all types of vehicles including cars and trains and electric vehicles. Recent data highlights a growing trend in the adoption of aluminum for battery enclosures in EVs, addressing both thermal management and structural requirements. The industry uses this eco-friendly method to achieve its objectives of decreasing carbon emissions and fuel usage which establishes aluminum as a fundamental material for developing advanced transportation systems.

Consumer Electronics

The unique combination of lightweight aluminum strength and corrosion resistance and excellent thermal conductivity properties makes aluminum essential for manufacturing consumer electronics products. The current search data shows that people have increased their interest in premium durable products because of their searches for aluminum in smartphones and aluminum laptop frames. Devices like smartphones and laptops and wearables achieve better durability through aluminum integration which also supports essential heat dissipation for high-performance electronics. The company uses aluminum recycling processes to support its sustainability goals which meet current consumer preferences for environmentally sustainable technology products. Designers use aluminum as their main material for developing modern electronic devices because it enables them to design new features.

FAQ

Is aluminum a metal or nonmetal — is aluminium a metal?

The question asks whether aluminium exists as a metal or nonmetal. The question asks whether aluminium exists as a metal or nonmetal. The chemical element aluminum exists as a metal because it belongs to the post-transition metal category on the periodic table which includes elements with atomic number 13. The metal exists in physical form because its metallic bonds with outer electrons give it electrical power transmission capabilities and thermal energy transfer abilities. The lightweight properties of aluminum make it suitable for use in airplanes and beverage cans because its density is lower than that of other metals. A pure aluminum metal creates a protective oxide film which makes the material more resistant to rusting but its base form remains as solid metal. Aluminum exists as a metal because its physical properties and alloying behavior show that it displays metallic characteristics.

What causes aluminum to produce a protective oxide film and what impact does oxidation have on the metal?

Aluminum reacts with oxygen to create aluminum oxide which forms a protective oxide layer on the metal surface that prevents additional corrosion damage. The oxide layer enables aluminum products to maintain their original condition which allows easy recycling of aluminum foil and utensil products through multiple applications. The protective layer controls oxidation state changes at the material interface which normally displays Al3+ state during reactions with aluminum hydroxide and aluminum chloride. The addition of small silicon or magnesium quantities to alloys results in altered corrosion resistance and mechanical behavior, which differs from pure aluminum. Aluminum durability increases through oxidation which creates a protective surface layer instead of causing quick material destruction.

What particular physical characteristics of aluminum make it usable in various applications throughout the world?

Aluminum possesses physical properties that include low density and excellent electrical and thermal conductivity and high malleability and ductility and a melting point that is lower than most other metals. The physical characteristics of aluminum enable its application in various products which include foil and cookware and large aluminum structures such as airplanes and beverage cans. The metal can create alloys with magnesium and silicon and other elements that provide different mechanical characteristics which manufacturing processes can use. The combination of high conductivity and lightweight properties makes aluminum the preferred material for electrical and thermal applications that require lightweight components. According to the Aluminum Association, aluminium is used in a wide range of applications because it balances strength, corrosion resistance, and recyclability.

Which oxidation states can aluminum exist in, and what physical form does an aluminum atom take?

Aluminum most commonly exhibits a +3 oxidation state because it loses all three of its valence electrons which exist in its outermost electron shell. The aluminium cation in chemical compounds like aluminium oxide and aluminium chloride and aluminium hydroxide exists in its common form Al3+. Aluminum exhibits only one oxidation state which determines its chemical properties in both scientific research and industrial applications. The atomic structure and electron configuration explain why aluminum tends to form ionic bonds in salts and oxide layers on metal surfaces. The industrial processes for producing aluminium through bauxite ore extraction and for creating aluminium alloys used in industry both depend on the +3 oxidation state.

What are the mechanical property differences between aluminum and other metals which determine its industrial applications?

The combination of aluminum’s ductility and malleability together with its favorable strength-to-weight ratio make the metal suitable for airplane parts and utensils and structural components. Pure aluminum exists as a soft metal but the combination of magnesium and silicon or copper with aluminum creates alloys that provide increased strength and customized ductility. Aluminum exhibits lower density than steel but its strength-to-weight ratio matches that of steel which makes it essential for transportation applications. The combination of metal processing and heat treatment establishes mechanical properties of aluminum alloys which manufacturers develop for different performance requirements. Aluminum shows its ability to support both heavy-duty applications and lightweight applications because manufacturers can create it into thin sheets that maintain their strength.

Does aluminum function as an effective conductor while its metal properties determine this ability through its conductive capacity?

Aluminum functions as an effective electrical and thermal conductor because its metallic bonds and free electrons allow electricity and heat to pass through it and this property makes the metal suitable for use in power lines and electronic devices that require lightweight materials. Aluminum remains a suitable option for building large-scale conductors because its combination of electrical and thermal conductivity allows it to replace copper despite lower conductivity levels. The metallic nature of aluminum with delocalized electrons explains its ability to conduct. In some applications aluminum is preferred despite a higher resistivity because its cost, abundance, and ease of recycling balance performance. When engineers design with aluminum they evaluate its conductivity together with mechanical properties and corrosion resistance to determine appropriate applications for different aluminum types.

Reference Sources

-

Introduction to Aluminum and Aluminum Alloys

ASM International Handbooks

This chapter provides an overview of aluminum and its alloys, discussing their properties and applications. -

New Classification of Defects and Imperfections for Aluminum Alloy Castings

SpringerLink

This paper explores the classification of structural defects in aluminum alloys, offering insights into their properties and behavior. -

Identification and Classification of Aluminum Scrap Grades Based on the ResNet18 Model

MDPI Applied Sciences

This study focuses on the classification of aluminum scrap grades, highlighting the properties of pure and alloyed aluminum.