Designers employ heat exchangers to transport heat making uses of several manufacturing settings in the production of power, in the function of chemical reactors, in heating and ventilating equipment, in the food and beverage industries, etc. Factors such as the performance, corrosion resistance, as well as the cost factor considering the choice of materials are very important in determining the service life and effectiveness of the entire system.

There are so many materials available in the market such as stainless steel and associated exotic alloys, and choosing the best material for heat exchanger turns into a difficult task of tradeoffs. This article provides an overview of what to appreciate when choosing a heat exchanger material as well as the different categories of materials so that every one can make their choice as required. This guide is intended for industrial engineers, professionals in the purchasing department, or people who want to understand more about industrial activities.

Understanding Heat Exchangers

Heat exchangers are devices designed to transfer heat between two or more fluids without mixing them. They are widely used in industries such as power generation, chemical processing, HVAC, and food production. The primary purpose of a heat exchanger is to either cool or heat a fluid efficiently, depending on the system’s requirements.

What is a Heat Exchanger?

A heat exchanger comprises of a device that enables exchange of heat between multiple fluids i.e. two or more different fluids in contact without intermingling. The principle of a heat exchanger is rooted in such systems where the function of a thermal system is to either warm up or cool the diffusible fluids within the system for particular purposes for instance, in temperate control of industrial systems, power plant, air conditioning and day-to-day appliances like fridge and geyser.

Types of Heat Exchangers

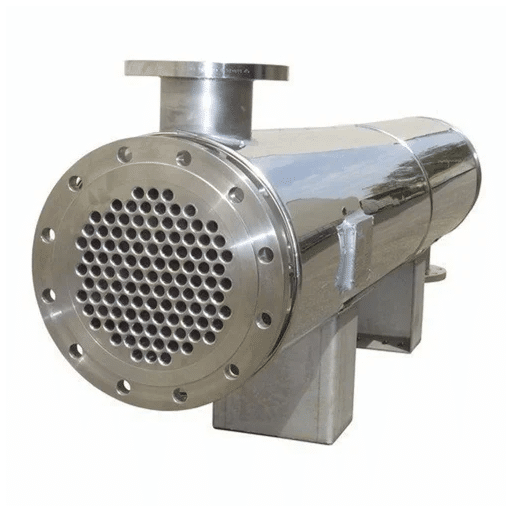

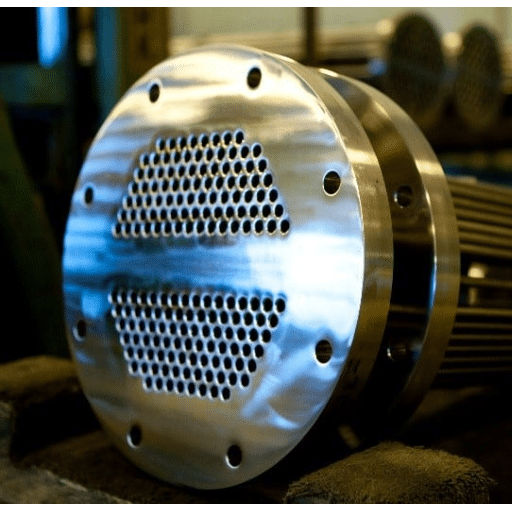

Shell and Tube Heat Exchanger

This the most widely used and the most universal heat exchanger construction. Where there is an enclosing outer shell containing a bundle of tubes. A fluid passes through the tubes while the other flows externally through the shell. These heat exchangers are quite effective and therefore employed in various industries including power plants, chemical industries, and petroleum industries as they are able to operate at extremely high pressures and temperatures.

Plate Heat Exchangers

These have several thin plates that increase the surface area considerably. These heat exchangers are very compact, as well as efficient which is why they are very popular in systems such as HVAC, process food manufacturing, and refrigeration. These heat exchangers are constructed in separate, easy to clean and maintain units.

Air Cooled Heat Exchangers

Air-cooling systems are systems that employ forced air in order to cool a fluid or liquid. They are cheaper and greener because there is no need for water in cooling them. Air cooled vaporizers are found in almost all remote locations or industries that do not have enough water resources, namely petrochemical and gas industries.

Double Pipe Heat Exchangers

The construction of the double pipe heat exchangers is such that there is a pipe within a pipe that the fluid flows in and the other fluid flows within the annular space of the two pipes. They are suitable for small scale heat exchangers where it is required to carry out uncomplicated operations.

Regenerative Heat Exchangers

This type of equipment helps store the heat from a hot fluid and then transfers it to a cold fluid. Also used in power stations and gas turbine engines, they are energy saving and assist in reducing energy wastage during operations.

Finned Heat Exchangers

These include the addition of fins or extraneous surfaces to the structural component in order to increase the effective area of heat exchange. Usually employed in the automotive, HVAC, and industrial drying buildings, where the enhancement of the heat exchange capability due to spatial limitations becomes an imperative necessity.

Compact Heat Exchangers

These types of heat exchangers are specifically manufactured for applications that require space and weight considerations and are usually very compact because they are electronic parts used in automobile blocks, aeronautical industries, and naval architecture.

Applications of Heat Exchangers

| Industry | Application | Key Benefits |

|---|---|---|

| Automotive Industry | Radiators, air intake systems | Engine temperature control, prevents failure (up to 90% heat transfer efficiency) |

| HVAC Systems | Air handling units, condensation devices | Energy efficiency, indoor air quality maintenance |

| Power Generation | Boilers, condensers, steam turbines | Maximum steam condensation, minimal energy loss |

| Chemical Production | Reactors, distillation sections | Temperature control, product quality, equipment protection |

| Food & Beverages | Pasteurization, sterilization, cooling | Product safety, extended shelf life, hygiene compliance |

Importance of Material Selection in Heat Exchangers

Key Point: Selecting the right materials is very crucial when it comes to the design and heat and mass transfer capability of the heat exchangers. The type of material selection is one of the main factors affecting the equipment’s efficiency, its expected life and the safety of its usage.

While designing a product it is vital to consider the operating conditions, i.e., temperature or pressure of the system. In most cases these are high temperature and/or high pressure, so materials used should be able to take that very kind of strain without getting damaged or deformed.

- Stainless steel is commonly used because it is resistant to corrosion and may be recommended for factors relating to thermoplastic materials in food processing practice

- Copper is considered the best material for heat exchanger in terms of thermal conductivity

- Titanium offers very high strength-to-weight ratio and high corrosion resistance, especially for chemical industry or sea vessels

Impact on Heat Exchanger Performance

The selection of heat exchanger materials and the working environment and medium also play a critical role in the efficiency of these systems. For example, corrosion, thermal expansion, and pressure variations are among the factors that high-performance stainless steel or titanium, which are considered the best in many applications, can effectively resist.

Industry Insight: Today’s statistics and practices show that various industries are found to pay considerable attention to the development of each material so as to promote energy conserving and cut down on the cost of their operations. Progress in material engineering such as composite and alloy science helps increase the durability of heat exchangers and design with lesser possibility of failure.

Factors Influencing Material Selection

Choosing appropriate materials for heat exchangers is a process that entails a number of factors. The main considerations include:

- Corrosion Resistance: Protection from aggressive mediums through passive film formation

- Thermal Conductivity: Ensuring efficient heat transfer, which is the primary purpose of the exchanger

- Mechanical Properties: Strength and structure for performance and stress containment

- Cost Effectiveness: Often the overriding factor in industrial applications

- Sustainability: Environmental safety and recyclability of materials

Common User Queries About Material Selection

The choice of material implementation of a heat exchanger is based on the working environment. If a corrosive environment is encountered, stainless steel will be the material of choice owing to its high chromium content as well as anti-rust and oxidation properties. For more aggressive conditions associated with chemical processing and marine products, however, titanium alloys are preferable since they can combat corrosion while still offering strength over an expanded range of temperatures.

The most operating temperature requirement is indeed a limiting factor in the selection of such materials. For high temperatures, the usage of such materials such as nickel-based or stainless steels for the structural purposes is implemented most often. While in low temperature regions, aluminum base materials which are highly conductive but also very cheap, are the most appropriate materials.

Yes, in many cases, cost is a major consideration when selecting materials. While higher-performing alternatives such as titanium or nickel-based alloys are available, they are often not used for many applications because of their expensiveness. Stainless steel is the most common material for its multiplicity in use and low cost in working within many environments.

There is now a drive towards finding sustainable substitutes for many materials. Aluminum and stainless steel, which can be easily recycled, can be used to meet such standards efficiently. Biodegradable or environmentally friendly usage coatings are the changes we can expect to see in the improvement of the best material for heat exchanger in the coming years.

Corrosion Resistance in Heat Exchanger Materials

Where heat exchanger materials are concerned, the resistance to corrosion is important for equipment functionality and durability reasons. Heat exchanger materials such as stainless steel, titanium, and certain nickel-based alloys are commonly employed today due to the fact that they are usable in corrosive environments that may involve high temperature, salt or acidic content.

Understanding Corrosion in Heat Exchangers

Metal surfaces in heat exchangers tend to get corroded as a result of the exposure of the exchanger material to the chemical activities of contaminating agents which could be water, air, or process fluids. High temperatures, high humidity and presence of chloride and sulfate types are known to aggravate the situation. As a result, it may lead to bad performance, instability of structures, and heavy finances for repairing the damage.

Materials with High Corrosion Resistance

| Material | Corrosion Resistance | Best Applications |

|---|---|---|

| Titanium & Alloys | Excellent – inert to chlorides and oxidation | Marine, chemical processing |

| Stainless Steel (316L) | Moderate to High – cost-effective | Food processing, general industrial |

| Nickel Alloys (Hastelloy) | Excellent – highly resistant to corrosive substances | Severe chemical environments |

| Advanced Ceramics | Excellent – chemically inert | Extreme chemical conditions |

| Engineering Plastics (PTFE, PEEK) | Excellent – non-reactive | Specific chemical applications |

Mitigating Corrosion Risks

Contemporary approaches to corrosion mitigation include:

- Use of protective coatings and advanced alloys

- Cathodic protection systems

- Sophisticated monitoring systems with sensors for early detection

- Scheduled maintenance programs

- Water-based treatments for operational environments

Best Materials for Shell and Tube Heat Exchangers

In order to select the best material for heat exchanger fabrication it is important to take into account the thermal conductivity, resistance to corrosion, resistance to pressure, and the types of fluids in use.

| Material | Advantages | Limitations | Cost |

|---|---|---|---|

| Stainless Steel | Excellent corrosion resistance, mechanical strength, versatile | Moderate thermal conductivity | Moderate |

| Copper Alloys | Superior heat transfer efficiency | Lower corrosion resistance than stainless steel | Moderate to High |

| Titanium | Exceptional corrosion resistance, excellent for marine/chemical use | Expensive | High |

| Carbon Steel | Cost-effective, fair mechanical properties | Requires coating for aggressive substances | Low |

Overview of Material Options

With the developments in material science, the best material for heat exchanger can involve composite materials or layered approaches:

- Composite Materials: Carbon fiber reinforced plastics with high specific strength and corrosion resistance

- Coatings: Ceramic coating and nanometric coating to enhance surface properties

- Hybrid Materials: Aluminum-coated steels for affordable and durable solutions

Comparing Tube Materials

When looking at how tube materials compare for heat exchanger use, factors such as thermal conductivity, corrosion resistance, strength, and cost-effectiveness all contribute to the resultant performance. Recent research has confirmed that:

- Stainless steel continues to be one of the most preferable options owing to enhanced corrosion resistance properties

- Copper tubes are appreciated due to their extraordinary heat conductivity

- Hybrid tube materials (aluminum-coated carbon steel) offer a good compromise between longevity and economics

Choosing the Right Material for Specific Operating Conditions

Critical Selection Factors:

- Operating temperature range

- Operating pressure levels

- Fluid characteristics (corrosive, acidic, saline)

- Environmental conditions

- Budget constraints

- Maintenance requirements

Influence of Temperature and Pressure

Temperature and pressure are significant factors which influence both the operation and durability of heat exchangers. Heat levels if high may cause cracking, corrosion and breakage of material and pressure levels is another factor that poses a risk of wear and even destruction of some aspects of a heat exchanger with time.

Engineers are able to design optimal heat exchangers for applications under these extreme conditions by analyzing the capability of the material and fluids for different parameters. Current advancements in materials science and computational techniques enable better predictions on temperature and pressure changes in heat exchangers.

Material Selection for Industrial Heat Exchangers

Several important things should be taken into consideration while choosing the best material for heat exchanger in order to improve its durability, heat transfer efficiency and performance. Based on newly conducted surveys, several materials like stainless steel, titanium, aluminum and copper alloys are known for different properties and high preference in many cases.

Case Studies: Successful Material Choices

Case Study 1: Titanium in Seawater Applications

The advances in technology have made titanium perhaps the best material for heat exchanger when it comes to seawater cooling systems. This has remained so for its excellent resistance to corrosion which is common in saline or seawater. The progress made with the development of better alloys and structures has facilitated in the use of different grades of titanium and even minimized the problem of biofouling and active corrosion.

Key Benefits: Prolonged immersion resistance, minimal biofouling, excellent cost-to-performance ratio over useful life.

Case Study 2: Stainless Steel (316L) in Food Processing

316L stainless steel is an example of a material that is commonly used in food-grade heat exchangers because it resists corrosion very well and is easy to clean. The material can withstand aggressive chemicals and is very easy to sanitize. Current modeling and optimization capabilities make it possible to evaluate conditions of use for a heat exchanger, such as high temperature acidic food processing, with substantial safety guarantees.

Key Benefits: Hygiene compliance, chemical resistance, ease of cleaning, regulatory approval.

References

-

A Review of Recent Advances in Additively Manufactured Heat Exchangers – Purdue University

Discusses the use of copper and other materials for heat exchangers, highlighting their thermal conductivity and suitability.

Visit the site -

A Review on Polymer Heat Exchangers for HVAC&R Applications – Miami University

Explores the use of polymer composites in heat exchangers, focusing on their thermal conductivity and density.

Visit the site -

Heat Exchanger Design Options and Tritium Transport Study – University of North Texas

Evaluates candidate materials like Alloy 617 and 230 for heat exchangers, considering their high-temperature performance.

Visit the site

Frequently Asked Questions (FAQ)

What type of heat exchanger works the best?

The best material for a heat exchanger is determined by two factors: operating conditions and the technology being used. Materials containing stainless steel are ideal due to their non-corrosive and copper is due to their excellent heat transferring abilities. For extremely corrosive systems, as seen in oil and gas industries, and other such examples, titanium or special alloys may be more favourable though expensive.

What is the ideal heat exchanger material?

One of the factors that is most important in heat exchangers and thereby has a bearing on performance is the selection of material for such devices. This is because materials of high thermal conductivity promise optimum process especially in realisation of heat exchanges. At the same time, corrosion resistant materials boost durability of the heat exchanger. A careful consideration in selecting the material may enhance the energy savings potential of the equipment and let it serve longer without repairs.

On what aspects does the material selection of heat exchangers depend and why?

There are numerous reasons for choosing a particular material for a heat exchanger. These factors include but are not limited to thermal conductivity, corrosion resistance, as well as ability to cope with high pressure and temperature conditions. And the role of the application in this case, is significant as well whether it is a chemical engineering or power engineering equipment. Specific material requirements may also appear for particular applications.

What are the common materials used in shell and tube heat exchangers?

Common materials used in shell and tube heat exchangers predominately include carbon steel, stainless steel and copper. The best material has its own merits – for example stainless steel is great when it comes to resistance against corrosion whereas copper is better for heating purposes because of its high thermal conductivity. And the suggestion is dictated in most cases by the processed fluid and operating conditions.

Why is importance placed on corrosion resistance in the designing of heat exchangers?

Corrosion resistance in heat exchangers is very significant as this equipment always contacts aggressive media which causes material destruction in heat exchanger parts. The use of these materials makes the component resistant to corrosion and therefore more reliable as there are few chances of failure f which might result to loss of production and incur additional repair costs.

What are the effects of selecting the wrong material for heat exchangers?

Thermal inefficiency may result from using unsuitable materials, excessive servicing and overuse of the component also cases of turbocharger failures. As a case in point, materials that readily burst under extreme pressure conditions cannot be used, neither can those with poor conductivity as heat exchange abroad will be rather problematic and hence spoil the system’s performance.

What are the effects of operating environment on choosing of materials for heat exchangers?

When it comes to building and operating heat exchange systems, it is evident that so many factors are taken into careful consideration. For example, what sort of materials the heat exchangers would be exposed to in operation, for instance high pressure or temperature; presence of chemicals that can corrode or deposit on surfaces (for example chloride containing environment) etc.

What is it about heat exchangers that make thermal conductivity materials important?

Thermal conductive materials are crucial in heat exchangers as they facilitate or rather conduct, the transfer of heat between the two fluids. On this, thermally conductive materials such as copper or aluminum are highly preferred in most situations due to their enhanced ability to improve the performance of the heat exchanger. Performance improvement also enhances the efficiency of energy usage in various applications.

Would it be possible to have renewable energy structures use built-for-purpose heat exchangers with particular materials?

Appropriate heat exchanger materials known for their durability and efficiency can improve the performance of renewable energy systems, for instance. Heat exchangers used in solar thermal systems or other renewable technologies should possess materials that show good thermal and corrosion-resistant properties.