To aid industries that rely on the integrity of materials and precision, the Heat Treatment of Stainless Steel is crucial for the performance and durability of the stainless steel components. Highlighting the methods which stand out as two essential processes that annealing techniques are solution annealing and bright annealing, each with the purpose of achieving a certain set of characteristics. In what ways do each process differ, and how can you know which one serves your purposes best? This blog covers everything you need to know, from the differences between the two techniques to the processes, advantages, and applications of each. This guide is helpful to you whether you are a curious engineering student, a veteran engineer, or a seasoned steel manufacturer.

What is the difference between bright annealing and solution annealing processes?

Both bright annealing and solution annealing refer to stainless steel heat treatment processes, differing in their purpose and manner of execution.

- Bright Annealing emphasizes surface finish and removes oxidation to provide the metal with a clean aesthetic appearance by restoring its reflective quality. This treatment is carried out in a vacuum or controlled atmosphere to avoid oxidation during the process.

-

However, Solution Annealing focuses on improving the metal’s mechanical properties by fracturing carbides; therefore, enhancing the material’s resistance to corrosion. This process typically requires heating a material to a specific temperature, then quenching it rapidly, and cooling it through controlled measures.

Whether appearance stands out or it is corrosion-resistance, while mechanical performance is a priority influences the choice between these processes.

Core Differences in the Annealing Process Methodology

The steps in the annealing process can be divided into categories based on the objective of the method, for example, relief of stress, enhancement of corrosion resistance, and improvement of mechanical properties. Each category uses a different method of heating and cooling. Presented below are the primary differences in approach:

- Stress Relief Annealing

This procedure seeks to eliminate internal stresses in metals while keeping their microstructure intact. It consists of slowly heating the material to a lower temperature, usually between 450°F and 750°F (232°C to 399°C), followed by controlled cooling. This technique is suited for parts that have been machined or welded, where the internal stresses may lead to distortion or cracking.

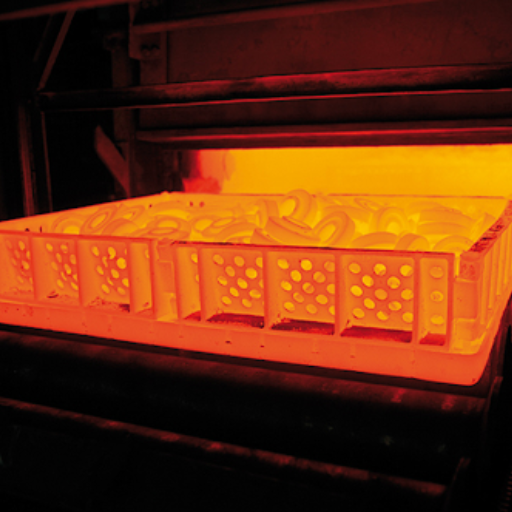

- Solution Annealing

Solution annealing is performed at higher temperatures, generally between 1850°F and 2100°F (1010°C to 1150°C), and involves rapid cooling, typically by water or air quenching. This method enhances corrosion resistance by dissolving carbides in stainless steels. It must be done to avoid carbide precipitation, which promotes intergranular corrosion in high-temperature applications.

- Full Annealing

Full annealing is designed for carbon steels; this technique involves heating the material to around 50°F (10°C) above its critical temperature. This ensures that the steel undergoes full recrystallization, which refines the grain structure and greatly improves machinability. After this, the material is placed in a furnace where it is slowly cooled to attain a soft, ductile state.

- Normalization

Even though normalization is not often included in annealing, it can be marked as heating to a temperature just above the critical transformation temperature of a material, and then cooling in air. This method improves grain structure, which increases strength and toughness, making it appropriate for structural and pressure vessel elements.

These processes serve different aims as far as metallurgy is concerned, and the result is determined by metal type, the time spent heating the metal, and the cooling rate. Knowing these definable distinctions helps achieve the structural, mechanical, or aesthetic targets intended through the correct annealing technique.

How Controlled Atmosphere Affects Bright Annealing vs. Open Air Solution Annealing

The selection of the atmosphere for an annealing procedure is vital for determining the final quality of the product. Bright annealing, also known as “BA,” is carried out in a controlled atmosphere consisting of inert gases such as hydrogen or a mixture of nitrogen and hydrogen. This environment stops oxidation from developing on the surface of the metal giving it a reflective, clean, and very appealing look . Bright annealing is particularly effective for stainless steels and alloys which require an oxide free surface.

Moreover, open-air solution annealing or “OASA” is performed in normal atmospheric conditions with no control over the environment. While it does dissolve metals and soften them, it has excessive surface oxidation. Oxide scales formed during open-air solution annealing will require extra post-treatment, such as pickling or grinding, to achieve a clean surface, which makes it a very costly and time-inefficient option. Research shows that bright annealing is more complex and intensive in terms of equipment; it reduces the amount of secondary treatment required and lowers the product’s resistance to corrosion due to unwanted surface impurities.

Factors like processes and their costs get greatly impacted by the selection of the atmosphere. The oxygen and gas balancing in controlled atmosphere annealing is set at optimal levels, which avoids resource wastage. Shifting to open-air annealing increases energy consumption because of the need to do much more to control the oxidation problems. Surfaces with extremely high quality and production optimization provide the manufacturer with the incentive to use bright annealing, which is done in controlled atmospheres in tempering furnaces.

Impact on stainless steel structure and properties

Stainless steel undergoes significant changes in internal structure and properties owing to the atmosphere condition dependent processes of annealing. Controlled atmosphere annealing reduces oxidation risk and preserves the stainless steel’s Chromium oxide layer, critical to its corrosion resistance. Research indicates that hydrogen or nitrogen-enriched atmospheres are better at enhancing ductility and mechanical strength by providing more uniform crystal grain structures.

As noted in the data, stainless steels with austenitic structure are usually subjected to annealing at temperatures between 1900°F to 2100°F (1038°C to 1149°C). This value yields near optimal softness and relieves internal stress as well. Annealing increases machinability, Trained staff on the steel can perform greater complex tasks as opposed to posed before. Achieving these structural improvements enables stainless steels to withstand extreme conditions while maintaining light weight, critical for the aerospace industry, in addition to other fields like medical and chemical engineering.

What are the specific benefits of bright annealing for stainless steel?

“Prime” or “Bright” annealing offers the following benefits for stainless steel:

- Enhanced Surface Finish: The process results in a smooth, reflective, and visually appealing surface that does not require any further polishing.

- Improved Corrosion Resistance: Bright annealing improves rust and corrosion resistance by preventing surface oxidation.

- Consistent Strength and Ductility: The heating and cooling cycles deliver uniform mechanical properties to the stainless steel, ensuring its strength and formability.

- Clean and Contaminant-Free Surface: Contaminants such as dirt and oil are removed during bright annealing, making the steel perfectly sterile for sterilized uses in the medical and food industries.

The advantages provided here make the bright annealing process particularly useful to optimize the performance and life cycle of various stainless steel components.

How bright annealing enhances surface finish and corrosion resistance

Bright annealing improves the surface finish of stainless steel pumps making it smooth, highly polished as well as free from any visible imperfections. Whilst the bright annealing process, stainless steel is heated to a designated temperature and is kept in a hydrogen or nitrogen-hydrogen gas atmosphere to avoid scaling or oxidation. No oxidation occurs which aesthetically improves the finish and also aids in decreasing surface roughness. This is important in preventing bacterial growth in the food and pharmaceutical industries.

More importantly, the protective chromium oxide layer, which improves the durability of stainless steel, is preserved. Hence, the bright annealing process improves the corrosion resistance of the stainless steel. Studies reveal that the pitting and crevice corrosion of stainless steel, which is bright annealed, is significantly lower in chloride-rich environments than when compared to conventionally and non-annealed stainless steel. Laboratory tests verify that the corrosion rate of steels processed through bright annealing is lower due to the removal of surface impurities and enhanced passivation, which is ideal in harsh, demanding conditions such as medical instruments, marine equipment, and chemical handling systems.

Applications for bright annealed stainless steel tube and pipe

Bright annealed stainless steel tubes and pipes are adaptable components widely used throughout different industries. The following is an outline of their common uses, along with additional information:

- Marine Equipment

-

-

- For construction of vessels, offshore drilling platforms and sub sea piping systems owing to high endurance against chlorides and seawater attack.

-

Ongoing corrosion rate testing indicates up to 50% better resistance in marine environments than non-annealed materials.

-

- Chemical Handling Systems

-

-

- There’s no better option for transporting strongly corrosive chemicals like acids and alkalis due to these chemicals’ smooth, impurity-free surfaces.

- Laboratory stress tests display an increased lifespan in highly acidic environments compared to conventional stainless steel pipes.

-

- Medical Instruments

-

-

- Hypodermic needles, diagnostic devices, and surgical tools are made from this material because of its exceptional cleanliness, biocompatibility, and ease of maintenance.

- Maintains stringent sterilization standards because surface smoothness ensures rapid cleaning, as is required in the medical industry.

-

- Food and Beverage Processing

-

-

- Significant in constructing pipelines for brewing, dairies, and food packaging machinery, as the smooth surface inhibits bacteria buildup and facilitates cleaning.

-

Certified FDA and EC compliant as materials intended for food contact are used.

-

- Pharmaceutical and Biotechnology Industries

-

-

- Opted for pharmaceutical-grade pipes and laboratories for drug manufacturing processes because of their remarkable chemical resistance as well as the precision of the polish.

- Test reports emphasize virtually no contamination risk in fluid transfer systems.

-

- Automotive and Aerospace Components

-

-

- Applied to areas such as exhaust systems, fuel lines, and structural components that require high temperature and corrosion resistance.

- Improves the performance durability under extreme mechanical stress and variable environments.

-

- Architectural Applications

-

-

- Employed in the production of furnishings such as railings and cladding because of aesthetic value, the mirror polish achieved through bright annealing is pleasing to the eye.

-

Very resistant and so they will retain their aesthetic value for many decades, even in harsh indoor and outdoor.

-

Functional and aesthetic requirements are met by bright-annealed stainless steel pipes and tubes which continue to outperform in industries where precision and performance are essential. This is because bright-annealed stainless steel pipes and tubes are tough, durable, and highly reliable.

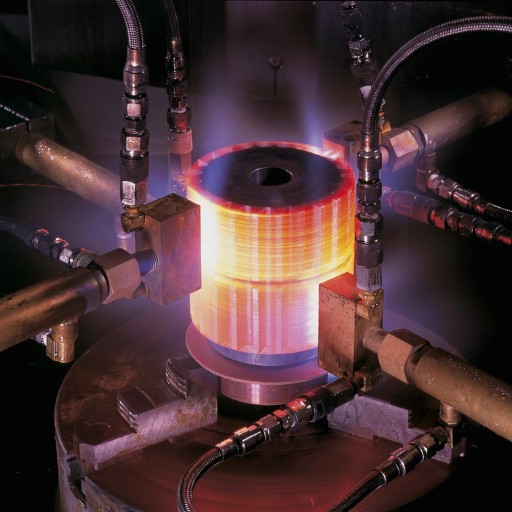

Temperature considerations in the bright annealing furnace

The bright annealing process optimally works with precise temperature control. In regard to bright annealing, the annealing temperature for stainless steel is around 1040 °C (1904 °F) to 1200 °C (2192 °F), depending on the alloy grade being processed. For complete recrystallization of the material, removal of internal stresses, and to achieve the desired results, the temperature across the furnace needs to be uniform.

Another important feature that needs to be controlled in the process is the dew point of the furnace atmosphere. For bright annealing, the dew point should be maintained at or below -40 °C (-40 °F) in order to eradicate steel surface oxidation and discoloration. This protective atmosphere is generally composed of high purity hydrogen or a mixture of nitrogen and hydrogen which aids in reduction throughout the oxidation phase while the work piece is undergoing heating and cooling.

Additional critical aspects include rapid cooling of the material which is often achieved by the use of controlled gas flows. Cooling rates need to be optimized to a certain point to avoid the precipitation of carbides since these can hinder the corrosion resistance of the material.

Bright annealing forms complete; modern furnaces have incorporated real-time monitoring systems, which ensure atmospheric control and temperature consistency. These systems aid in the reduction of production flaws, thus increasing efficiency and retaining the quality finish essential for pipes and tubes made of stainless steel.

When is solution annealing the preferred heat treatment method?

When a stainless steel part requires improved corrosion resistance and a uniform microstructure, solution annealing is the treatment of choice. It is also the treatment of choice for parts that operate in hostile and corrosive environment including chemical, marine, and food processing industries. This is done as well when the strength-properties like ductility and toughness are also very important.

Solution annealed austenitic stainless steel applications

Because of the annealed austenitic stainless steel’s incredible ability to resist corrosion, endure mechanically, and survive in extreme environments, it is solution processed and utilized across several industries. Here are some of the primary usages:

- Chemical Processing Equipment: The vessels, pipes, and heat exchangers that need to be fabricated to deal with corrosive chemicals are often made of solution annealed grades like 316L or 304L. These materials withstand pitting as well as stress corrosion cracking in very aggressive acidic or chloride environments.

- Marine Industry: Other components like propeller shafts, fasteners, and pump housings are made out of solution annealed stainless steel since they are submerged in seawater, or coastal regions and so require saltwater resistance. For example, 316 grade is a common choice for use in seawater or coastal conditions.

- Food Processing and Pharmaceuticals: Areas like food, and pharmaceuticals require hygienic surfaces. Solution annealed low carbon stainless steel has reduced carbide precipitation. this results in smooth surfaces which resist bacterial deposits, and cleans per strict FDA and European requirements.

- Energy and Power Generation: High-temperature resistant austenitic stainless steel is used to manufacture boiler tubes, nuclear reactor parts, and exhaust systems. Moreover, its oxidation resistance is essential in energy plants because of the structural integrity under thermal cycling conditions.

- Cryogenic Applications: Solution annealed 304 and 316 stainless steel is an austenitic cryogenic steel. They have high ductility and toughness at cryogenic temperatures. These properties make them perfect for liquid nitrogen tanks, cryostats, and other low-temperature systems.

The given excerpt showcases yet another application of solution annealed austenitic stainless steel, describing it’s significance in modern engineering in relation to its performance, safety, and harsh environmental conditions in addition to regulatory requirements.

How does solution annealing affect carbide precipitation and microstructure?

Solution annealing is essential for managing carbide precipitation and the microstructure refinement of austenitic stainless steels. In this process, the material undergoes heating at a designated temperature between 1,040°C and 1,120°C (1,900°F – 2,050°F) to facilitate the dissolution of chromium carbides into the austenite matrix. Following the achievement of the set temperature, the material undergoes rapid cooling, commonly quenching, to avert the re-precipitation of carbides and ensure microstructural uniformity.

Chromium carbide precipitation cannot be present within steel in order for the steel to have appropriate corrosion resistance capability, primarily in welded areas or those susceptible to attack via intergranular corrosion. Studies indicate that the existence of lesser carbide precipitation tends to increase chromium concentration at the grain boundaries, which increases the barrier to localized pitting and stress corrosion cracking.

From the microstructural standpoint, solution annealing yields the relief of internal stresses resulting from fabrication and the presence of unevenly distributed grains. This uniformity increases the mechanical properties of the alloy, such as toughness, strengthening ductility, permitting the steel to endure harsh environments like chemical processing, nuclear reactors, and even cryogenic applications. High-level methods like EBSD for electron backscatter diffraction demonstrate that solution annealed steels contain, with stronger structural stability, reduced martensitic deformation dominantly witnessed within the microstructure of annealed solution steels.

To get the best results for any particular alloy composition and application, the heating rate, holding time, and cooling method need to be very specific, ensuring a balance between structural durability and material endurance.

Solution treatment effects on hardness and ductility

Solution treatment affects the mechanical properties of stainless steels, especially their hardness and ductility. In solution annealing, steels undergo heating to high temperatures, normally between 1,040 and 1,120°C, followed by rapid cooling, usually via water quenching. Carbides are dissolved, and alloyed internal structures are homogenized—this restores ductility and reduces internal stresses from thermal or fabrication processes.

Enhancements in ductility are attributed to the uniform austenitic structure that solution treatment promotes. Some steel grades, like AISI 316L, have a significantly enhanced elongation at fracture, which makes them ideal for tough applications. The material simultaneously loses its strength due to the dissolution of carbide precipitates and internal stress relief. It is common to measure microhardness, and Vickers hardness tests indicate lower values post-solution treatment—this reduction is variable depending on the preceding deformation or heat treatment.

Also, custom processes for treatment can enhance strain hardening ability, which is important for high-stress applications. In specific cases like piping used in corrosive environments or high-strength structural components, engineers balance the heat holding times and the cooling rates to improve both hardness and ductility simultaneously. More recent developments in the modeling of thermodynamics have also improved prediction capabilities for the impact of solution treatment in more intricate alloy systems. This has increased the effectiveness of the thermodynamic model.

What equipment and conditions are required for each annealing method?

- Full Annealing

-

-

- Equipment: Furnace with precise temperature controls.

- Conditions: The material is heated to the Stress Relaxation temperature and is disabled from triggering any further thermal stresses by holding it for a period of 60 minutes, followed by controlled rate cooling (commonly within the furnace).

-

- Stress Relief Annealing

-

-

- Equipment: Furnace or oven exploitable for very low temperature holds.

- Conditions: Heating the material to above room temperature for a controlled period of time with lower than suggested energy input demonstrates heavy reduction in internal stresses.

-

- Solution Annealing

-

-

- Equipment: Furnace with the ability of near instantaneous heating and complete quenching of pre-heated water/air sprays.

- Conditions: The material in question is submersed in alloying liquid for a while and heated so that alloying elements are captured and left free to escape from the ligand.

-

- Spheroidizing Annealing

-

-

- Equipment: Any controlled furnace system can be used for this.

- Conditions: Spheroidization is done for longer periods at the set heating level that is kept below the critical temperature. Very slow cooling follows.

-

All techniques utilize precise heating and cooling cycles for property attainment. All techniques require temperature control and uniformity to be precise.

Bright annealing furnace requirements and inert gas environments

To achieve high surface finish, corrosion resistance, and veneer quality, materials undergo processing in a bright annealing furnace. Such furnaces play a crucial role in retaining the surface quality and preventing oxidation and tarnishing during work. Requirements for the bright annealing furnace include the following:

- Temperature Precision

For the precise heating of each metal grade, the furnace requires a temperature range of 1040еС to 1200еС for stainless steels. Even heating is critical for preventing microstructure distortion at thermally uniform structures.

- Protective Atmosphere

The gas should be hydrogen or nitrogen, resistant to heating surfaces in order to stop oxidation. Hydrogen works especially well because it will scrub residual surface oxide layers. The gas also does not need to be too clean, no higher than -60еС or more for less dew point gas, for shredding atmospheric surface layers.

- High Purity Gas Supply

If such gas is part nitrogen or hydrogen, then it needs to be very clean to advance validations for surface finishing standards. Adding these gases makes the surface develop faint stains or holes, also known as pitting.

- Efficient Cooling System

Materials should be pressed together and maintained in the oven under a protective atmosphere to preserve surface attributes such as roughness for aluminium parts, as the surface requires. Quenching in an inert atmosphere is the standard for re-oxidation control.

- Sealing Integrity

It is vital to seal the furnace tightly in order to guarantee that no air or contaminants are able to infiltrate the chamber, thereby protecting the inert gas atmosphere.

- Monitoring Systems

For constant supervision of temperature, gas flow rates, dew point, and the composition of the atmosphere, advanced monitoring devices are required. Such a degree of control guarantees constancy in the processes of annealing and the quality of the products.

Industries like aerospace, medical devices, and high-purity chemical equipment that value the performance and aesthetics of materials pay close attention to bright annealing processes done in controlled facilities.

Solution annealing temperature ranges and cooling considerations

The temperature range for performing solution annealing varies between 1,850°F to 2,100°F (1,010°C to 1,149°C) based on the alloy and its use. For instance, the 304 and 316 austenitic stainless steels require roughly 1,900°F to 2,000°F (1,038°C to 1,093°C) to ensure optimal homogeneity and stress relief permeate. These temperatures are vital to fully dissolving carbide precipitates and distributing alloying elements uniformly, providing high mechanical strength and exceptional corrosion resistance.

Changing the rates of cooling equally affects the process. After holding a specific temperature for solution annealing, it is common practice to quench rapidly in a bid to retain dissolved carbides (undercooling) and suppress the undesirable phases, particularly the sigma-phase in austenitic stainless steels. Quenching can be done with water or forced air, with water providing the quickest rate. For some alloys, however, where thermal shock or distortion due to rapid cooling is a problem, low-speed cooling using air or inert gas fans may be preferred.

Maintaining the correct temperature and cooling standards ensures the structural integrity of the material while guaranteeing its metallurgical structure corresponds to the requirements of the end-use application. This is especially important in the gas and oil, nuclear, and medical industries where reliability and performance are critical.

How do these heat treatments impact the mechanical properties of stainless steel?

Mechanical characteristics of stainless steel, such as hardness, strength, ductility, and even corrosion resistance, undergo change due to their heat treatment. For instance, annealing enhances ductility and ease of work by reducing internal stresses. Quenching, on the other hand, increases both hardness and strength while reducing ductility. Stress relieving helps retention of other properties while residual stress is effectively eliminated. These procedures have to be tailored to the particular functional needs of the stainless steel in question.

Effects on stress relief and work hardening

Work hardening and stress relieving are two critical procedures that directly influence the performance of stainless steel. Stress relief is mostly achieved by heating the stainless steel in a controlled manner to relieve internal stresses induced by welding, machining, or cold working. As with other types of stainless steel, the grade and intended results dictate how much stress relief heating is done. Typically, the ranges for stress relieving stainless steel are between 300°F to 750°F (150°C to 400°C). Stress relief minimizes the chance of detrimental distortion, cracking, or material failure under operational loads.

Unlike other processes, work hardening occurs due to the plastic deformation processes of rolling, bending, or drawing. These changes strengthen and harden the material’s crystal structure, though ductility may be lost. An example is the cold working of austenitic stainless steels like 304 or 316; their tensile strength spikes to almost 150% of their annealed state. However, excessive work hardening can become problematic as it makes the material difficult to machine or weld, creating the need for multiple annealing cycles to restore ductility.

These balancing acts need to be performed for all industries that use stainless steel parts. Adjusting stress relief temperatures or level of work hardening done ensures the best possible outcome, especially in medium to high demanding applications like medical devices, aerospace components, and construction materials that need both strength and durability.

Improvements to corrosion resistance from different annealing types

The type and parameters of annealing done on stainless steel during its processing impact stainless steel’s corrosion resistance. The standard steel annealing, done between 1000°F to 1200°F, enhances corrosion resistance as it dissolves chromium carbide and reestablishes the uniform microstructure of steel. This approach works particularly well with 300 series stainless steels, which are common in the chemical industry in processors that are sensitive to corrosion, as well as in marine applications.

Unlike bright annealing, which prevents surface oxidation by performing annealing under controlled inert or vacuum atmospheres. This also results in a magnificent surface finish due to the proliferation ofa smooth outer layer, thus enhancing the corrosion resistance. The enhanced smoothness of the outer surface makes the material more resistant to destructive corrosive agents actively acting in harsh conditions, thus enhancing the durability of the material.

Duplex stainless steels with annealing tailoring will set at roughly 1800°F notice a balance in dual phase microstructure, yielding better mechanical properties as well as stress corrosion cracking resistance. Some studies also show low-carbon stainless steels subjected to annealing at specific optimal temperature have better pitting corrosion resistance than untreated counterparts, by 15-20%.

Selecting the appropriate annealing type to maximize corrosion resistance based on the application and grade of stainless steel will extend the service life of critical systems in health care, desalination, and petrochemical industries.

What are the industry applications for each type of annealing?

- Full Annealing

Applied in the construction and automotive sectors, full annealing increases the ductility while reducing the hardness of some components like shafts, gears, and structural frameworks.

- Stress-Relief Annealing

Commonly used in aerospace and heavy machinery, this process helps remove residual stresses in parts such as forgings, welded structures, and castings.

- Bright Annealing

Serving the food processing and pharmaceutical industries, bright annealing polishes and removes corrosion from surfaces of equipment like tubing and storage containers ensuring a smooth finish.

- Solution Annealing

Used in healthcare and petrochemical industries, solution annealing tackles the need to restore the corrosion resistance and durability of stainless steel medical instruments, as well as pipelines and heat exchangers.

Industries that require bright annealed stainless steel components

Due to their long life span, sleek surface, and resistance to corrosion, Bright annealed stainless steel components are used in many industries. Below are key industries along with their related uses:

- Healthcare and Medical Industry

The healthcare industry uses bright annealed stainless steel because of its superior hygiene norms. Typical uses are surgical instruments, hypodermic needles, and cabinets. In addition, the corrosion resistance of annealed stainless steel adds a great degree of reliability on the stored equipment which undergoes extensive cleaning and sterilization.

- Food and Beverage Industry

This stainless steel material is very important for the food industry as it includes the structural components of food grade storage tanks, conveyor belts, and processing machinery. The polished and smooth surface allows for ease of cleaning and maintenance while also minimizing contamination and adhering to food class standards.

- Chemical Processing Industry

Bright annealed stainless steel is widely used in special chemical processing due to its ability to withstand aggressive or corrosive environments. Safety and efficiency relies on the strength of the materials and resistance to corrosion and includes pipework, reactors, and mixing tanks.

- Automotive Industry

The unique design features and the consistency of performance make this steel a go-to for the automotive industry. It is used for decorative elements, trim, structural parts, fuel lines, and exhaust systems that require a combination of durability and good-looking steel.

- Architecture and Construction

Due to its sleek appearance and resistance to wear, stainless steel that is brightly annealed is preferred in contemporary architectural designs for scaffolding, elevators, and decorative columns. Its durability, as well as maintenance-free requirements make it increasingly popular in green construction.

- Pharmaceutical Industry

For cleanliness and precision, bright annealed stainless steel supports high-end machinery such as tablet presses, sterile fluid transfer systems, and cleanroom fittings. Its corrosion-resistant traits also support its use in chemical formulation plants.

- Oil and Gas Industry

Bright annealed stainless steel is utilized in the critical components like offshore drilling platforms, pipelines, and storage tanks within the oil and gas industry. Its capability to endure harsh conditions decays with time and exposure, ensuring operational dependability and safety.

Wider Industries vary in their needs, yet use bright annealed stainless steel due to the performance capabilities it delivers through its inherent qualities.

Applications where solution-annealed materials are preferred

Solution-annealed materials are prominent in different sectors with high strength, durability, and corrosion resistance. This is achieved by heat treatment, which neutralizes specific alloying components. Such a process enables these components to undergo a uniform microstructural transformation that improves their mechanical properties.

- Chemical Processing Equipment

They use solution annealed materials for chemical reactors, heat exchangers and storage tanks. These materials can be used at high temperatures and can withstand aggressive chemical environments such as strongly acidic, alkaline, and chloride conditions. For instance, stainless steel grades 316L and Duplex are commonly used due to their outstanding resistance to intergranular corrosion.

- Power Generation Systems

Used in the nuclear and thermal power generation industries are turbines, boilers, and high-pressure steam systems. These items require the use of solution-annealed materials. They also provide adequate safety and efficiency when dealing with high-pressure or high-temperature environments. Some sources suggest that Alloy 600 and 625 are among the most popular materials used in these applications because they are easier to creep and fatigue resistant in high-stress conditions.

- Pharmaceutical and Food Processing

Hygienic surfaces are crucial in the pharmaceutical and food sectors. Solution annealed stainless steel is a material of choice in these applications owing to its very smooth and non-porous surface finish. Such properties eliminate the risk of contamination and support rigid requirements for cleanliness. In these industries, stainless steel grades 304 and 316L are a standard for pipes, valves, and storage vessels.

- Aerospace and Automotive Components

Certain high-performance components like engine parts, fasteners, and structural components are made from solution annealed alloys. These materials offer the appropriate strength-to-weight ratio required in the aerospace and automotive industries in addition to fatigue and oxidation resistance. Superalloys used in aerospace applications such as IN718 are processed by solution annealing to enhance performance in\/extreme operating conditions.

With the aid of solution-annealed materials, industries gain improved operational efficiency, lower maintenance expenditures, and longer equipment lifespans, all of which provide critical advantages for enduring success in challenging applications.

Heat exchanger and welding considerations

The basis of the choice of Heat exchangers is the experience of pre-heating, cooling, heating, and heat recovery in various Thermodynamic cycles. Exchangers function as a cornerstone in the majority of industrial systems. When it comes to heat exchangers, the materials in use must have high Thermal conductivity coupled with long-term corrosion resistance at high temperatures and considerable pressure. Common alloys employed in the making of heat exchangers include:

Stainless steels and Nickel-based alloys like IN718 because they resist thermal fatigue and retain structural integrity

Welding Methods for these materials have to be very specific to retain mechanical properties, such as GTAW, also known as Gas Tungsten Arc Welding, and more electron beam welding. They have both high precision and the lowest likelihood of imperfections. Managing HAZ is another frail area where much focus needs to go. Strength or corrosion resistance cannot be allowed to deteriorate further, and be on the protected side. A major consideration to be noted is the supplemental impact of post-weld treatment in raising and restoring uniformity through relieving residual stresses in the materials. When operational conditions are provided, satisfactory performance is ensured.

Real-time monitoring technologies and advanced modeling have redesigned processes for welds in heat exchangers. With the aid of these novel inventions, industries are able to trust in calmly and reliably on the efficiency and reliability of the production and use of heat exchangers even under extreme conditions like aerospace systems, power plants, chemical processing plants, or activities.

Reference Sources

- Corrosion Behavior in Duplex Stainless Steel (2021)4:

- Key Findings: Bright annealing in reducing atmospheres (e.g., H2 and N2) significantly impacts the surface and corrosion resistance of super duplex stainless steel (SDSS). N2 addition promotes phase transitions, leading to Cr2N precipitates, which reduce corrosion resistance. Annealing in 100% H2 at 1100°C caused hydrogen-induced cracking.

- Methodology: Experimental analysis included microstructural observations (SEM), phase characterization, and corrosion testing under varying gas compositions.

- Thermal Treatment Effects on AISI-304 (2023)2:

- Key Findings: Brine quenching after thermal treatment at 800°C altered mechanical properties and microstructure. Prolonged heating led to Cr depletion and carbide dissolution, increasing hardness but reducing tensile strength and toughness.

- Methodology: Tensile, hardness, and toughness tests were conducted alongside microstructural analysis using SEM and XRD.

- Creep Properties in Fe-Ni-Based Alloys (2021)3:

- Key Findings: Solution annealing improved creep rupture life by dissolving interdendritic phases and increasing Ti and Nb content in the matrix. However, excessive Ti led to coarse B2-NiAl phases, limiting the benefits.

- Methodology: Creep tests at 750°C, microstructural analysis (SEM, TEM), and thermodynamic phase stability calculations.

Frequently Asked Questions (FAQs)

Q: What is annealing, and why is it a critical heat treatment process for stainless steel?

A: Annealing is a heat treatment process used to alter the physical and sometimes chemical properties of a material to increase ductility and reduce hardness. For stainless steel specifically, annealing is a process where the metal is heated to a specific temperature and then cooled under controlled conditions to relieve internal stresses, soften the material, and improve machinability. The annealing of stainless steel is crucial as it restores the structure of the metal to its optimal condition, enhancing corrosion resistance and ensuring the material performs as required in various applications.

Q: What is the difference between bright annealing and solution annealing?

A: Bright annealing is a type of annealing process performed in a controlled atmosphere (typically hydrogen, nitrogen, or argon) to prevent oxidation, resulting in a clean, bright metal surface. Solution annealing, also known as solution heat treatment, involves heating the material to a higher temperature to dissolve precipitates into the metal’s solid solution, followed by rapid cooling to keep these elements in solution. While both processes enhance material properties, bright annealing focuses on surface appearance and preventing scale formation, whereas solution annealing aims to maximize corrosion resistance and mechanical properties by optimizing the microstructure.

Q: What happens inside the heat treatment furnace during bright annealing?

A: Inside the heat treatment furnace during bright annealing, several controlled processes occur. The metal is heated to temperatures typically between 1900-2100°F (1040-1150°C) in an oxygen-free environment, usually containing hydrogen, nitrogen, or another inert gas. This special atmosphere inside the furnace prevents oxidation that would otherwise discolor the metal surface. The absence of oxygen and water vapor ensures that no scale forms after annealing on the surface. Temperature is precisely regulated throughout the process, and cooling is managed carefully to achieve the desired metallurgical properties while maintaining the bright, clean surface finish.

Q: What are the primary applications of bright annealing for different metal materials?

A: Bright annealing is used across various metal materials with specific benefits for each. For stainless steel, it’s essential in producing medical equipment, food processing equipment, and decorative architectural elements where appearance matters. Copper and brass components undergo bright annealing for electrical applications requiring both conductivity and appearance. Nickel alloys benefit from this process for aerospace components. Titanium parts for medical implants and aerospace applications utilize bright annealing to maintain surface integrity. Even precious metals used in jewelry manufacturing rely on this process. In each case, bright annealing provides both the necessary mechanical properties and an oxide-free, lustrous finish.

Q: How does solution annealing impact the structure of the metal compared to other heat treatments?

A: Solution annealing fundamentally alters the structure of the metal by dissolving precipitates and carbides back into solid solution within the austenite matrix. Unlike subcritical annealing or stress relief treatments that primarily reduce hardness or internal stresses, solution annealing homogenizes the microstructure and optimizes corrosion resistance by preventing chromium depletion at grain boundaries. This process creates a supersaturated solid solution where alloying elements are uniformly distributed throughout the material. The rapid cooling that follows prevents these elements from re-precipitating, resulting in a material with optimal corrosion resistance, ductility, and mechanical properties that other heat treatments cannot achieve.

Q: What is the primary purpose of bright annealing, and how does it benefit stainless steel products?

A: The primary purpose of bright annealing is to create a clean, scale-free, and reflective surface while simultaneously achieving the metallurgical benefits of conventional annealing. This surface treatment provides significant benefits for stainless steel products, including enhanced corrosion resistance (by removing surface contaminants that could initiate corrosion), improved formability for further manufacturing processes, elimination of the need for post-annealing cleaning or pickling operations, superior aesthetic appearance for visible applications, and restoration of the material’s optimal microstructure. The process of bright annealing ensures stainless steel components maintain their intended functional properties while exhibiting the characteristic lustrous finish expected of high-quality stainless steel products.

Q: How do temperature settings in a heat treatment furnace differ for bright annealing versus solution annealing?

A: Temperature settings in a heat treatment furnace vary significantly between these processes. Bright annealing typically occurs at moderately high temperatures ranging from 1900-2100°F (1040-1150°C) for austenitic stainless steels, with the primary focus being surface finish. Solution annealing requires higher temperatures, typically 1900-2150°F (1040-1175°C) for 304 stainless steel and up to 2050-2250°F (1120-1230°C) for high-alloy grades like 316. These higher temperatures are necessary to fully dissolve carbides and other precipitates. Additionally, temperature uniformity is more critical in solution annealing to ensure complete dissolution throughout the material, while bright annealing places greater emphasis on atmosphere control to prevent surface oxidation.

Q: What are the alternatives to having materials annealed and pickled, and what advantages does bright annealing offer?

A: Alternatives to having materials annealed and pickled include mechanical finishing (grinding/polishing), electropolishing, or passivation treatments. However, bright annealing offers several distinct advantages: it eliminates the environmental concerns associated with pickling acids; provides superior surface finish in a single process step; reduces material handling and processing time; prevents material loss that occurs during pickling; ensures more uniform properties throughout the workpiece; and delivers better hydrogen embrittlement resistance since no acids are used. The bright annealing process is particularly valuable for thin materials where pickling might cause excessive metal removal or for complex shapes where uniform pickling would be difficult to achieve.

Q: How does the controlled atmosphere during bright annealing affect the final properties of stainless steel?

A: The controlled atmosphere during the bright annealing of stainless steel profoundly affects the final properties in several ways. By eliminating oxygen and water vapor, it prevents chromium oxidation, maintaining the full corrosion resistance of the alloy. The clean, oxide-free surface creates superior finish quality with increased reflectivity. The absence of surface scale preserves dimensional accuracy, particularly important for precision components. The controlled cooling in this protective atmosphere ensures optimal grain structure development without introducing unwanted phase transformations. Additionally, the elimination of surface defects that would otherwise form during oxidation leads to improved fatigue resistance and mechanical properties, making bright annealing particularly valuable for critical applications in aerospace, medical, and food processing industries.