Carbon steel is an extremely popular, flexible, and multipurpose material that is the backbone of many industries including construction and cookware. It is the favorite material in many applications due to its excellent tensile strength and low cost. But this brings one question that is frequently asked whenever carbon steel is involved – can it rust? If it can, what is the best way to care for it? The present article will delve into the characteristics of carbon steel, the reason why it is prone to rusting, and the measures one can take to keep it in good condition and to prolong its life. If you are a professional dealing with industrial-grade materials or a home cook who loves to have a quality carbon steel pan, then one thing is for sure: knowing the specific traits and care needs of carbon steel is of the utmost importance. So, keep reading to discover the most helpful hints and insights for maintaining your carbon steel in an excellent state.

What is Carbon Steel?

Definition and Composition

Carbon steel, basically, is an alloy of iron and carbon, with the weight of the latter usually varying from 0.05% to 2.0%. The combination of materials is that which imparts carbon steel the properties of strength, durability, and versatility. To add to that, carbon steel is usually considered to be poor in alloying elements compared to stainless steel, lacking almost always chromium or nickel in significant amounts which straight away rule out the corrosion resistance of this type of steel. However, the attributes of steel can be varied according to the carbon content—steels with low carbon are going to be more ductile and easier to form while being hard and strong comes with higher-carbon steels. This flexibility of carbon steel is the reason why it is a favorite material in many sectors like construction, automotive, and also to produce culinary tools and machinery.

Types of Carbon Steel

Based on carbon content and changing properties, carbon steel is usually separated into four primary types. They are:

- Low-Carbon Steel (Mild Steel): This steel is composed of about 0.3% carbon, is highly ductile, and therefore is easy to shape and weld. It is very much applied in buildings, where it is used for construction, cars, and pipes.

- Medium-Carbon Steel: The carbon content in this type ranges from 0.3% to 0.6%, and it provides a good combination of ductility and strength. The metal is therefore used in making gears, axles, and other parts needing stronger steel than mild steel can offer.

- High-Carbon Steel: The carbon content in this steel is between 0.6% and 1%, making it one of the hardest and most wear-resistant materials. Hence, it is suitable for the manufacture of cutting tools, springs, and high-strength wires.

- Ultra-High-Carbon Steel: This category of steel has carbon content above 1% it has remarkable strength and hardness but is also very brittle. It is only used in specialty applications like knives, punches, and other tools where long life is of utmost importance.

The awareness of these classifications does not only help but also challenges industries in their quest for the right type of carbon steel to be used across applications that require the balancing of performance, cost, and specific project requirements.

Comparison with Other Steels

The comparison of carbon steel with stainless steel or alloy steel shows that the main differences consist of the composition, properties, and applications. Steels like carbon are basically made up of iron and carbon. The other elements that are present are in tiny amounts. The mere fact that the composition is very simple makes carbon steel very cost-effective and thus, the most suitable when projects demand strength and durability but require less or no resistance against corrosion. On the other hand, stainless steel is composed in such a way as to include a big proportion of chromium which contributes to the steel’s corrosion resistance making it a good candidate for moisture or chemical environments. Similarly, Alloy steel which consists of manganese, nickel, and chromium, etc. has been developed, for instance, to have hardness, toughness, corrosion resistance, etc., thus providing a combination of these properties.

Informed by the latest statistics, the decision between carbon steel and its competitors is mostly based on the characteristics needed in the final product. For example, within the building industry, carbon steel continues to be the key option for structural reinforcements due to its high tensile strength and low cost. Meanwhile for the utensils in the kitchen or instruments in the medical field, stainless steel is the one that is picked because of the properties of being hygienic and resistance to corrosion. Knowing the differences allows industries to pick the most suitable type of steel for their specific needs and thus they get to make the most of both cost and performance.

How Does Rust Form on Carbon Steel?

The Science of Rusting

Rusting is a series of chemical reactions that take place when carbon steel is oxidized; iron reacts with oxygen from the air to form rust in the presence of water or moisture. Such a reaction produces iron oxide, which is also known as rust, and the metal gets covered with a reddish-brown flaky layer. Rusting is a characteristic that carbon steel possesses because of its high iron content and its being devoid of chromium, a corrosion-resistant element found in stainless steel.

Key Factors Accelerating Rust Formation:

- High humidity levels

- Saltwater exposure

- Air pollution with sulfur dioxide

- Continuous exposure to moisture and oxygen

Currently, it is asserted that various conditions such as high humidity, saltwater exposure, and air pollution with sulfur dioxide contribute to a quicker rusting rate. For instance, carbon steel structures in the vicinity of the sea get rusted faster because the atmosphere is rich in salt. Methods to prevent rusting include applying various protective coatings, using corrosion inhibitors, or galvanization, which is done by applying a zinc coating on iron to provide moisture and oxygen barriers. It is very important to have a good grasp of the conditions mentioned above, as this will assist in taking necessary measures against rust and maintaining carbon steel’s durability.

Factors Contributing to Carbon Steel Rust

Moisture and oxygen together constitute the main reason for carbon steel to rust because they start the oxidation reaction. Other environmental factors like humidity and fluctuations in temperature are very important in speeding up the corrosion process. The mentioned coastal regions are more prone to this as the high salt in the air makes it act as an electrolyte thus fastens the chemical reaction; also, continuous exposure to air and water can lead to the formation of acidic water solutions by connecting sulfur monoxide and dioxide to carbon through industrial processes which can be further be worsened by forming acidic compounds from the water.

Recent revelations show that the wrong way of storing carbon steel, such as letting it be in a humid or poorly ventilated area, can contribute to the increased formation of rust. Following the latest data, the industry is moving towards using advanced materials and coatings like nanotechnology-based inhibitors and green corrosion-resistant compounds that are less affected by these factors. Knowledge of these factors and taking the right measures makes it possible to use carbon steel for a longer time in various ways.

Common Misconceptions About Carbon Steel Rust

People generally think that if one uses protective coatings and inhibitors, then carbon steel will not rust at all. Though these methods greatly reduce the chance of rusting, they do not render carbon steel completely resistant to corrosion, especially in cases where the protective layer has been damaged or the environmental conditions are harsh. The thought that stainless steel is the only rusting-proof choice is another common fallacy. Moreover, advances in material science, such as the employment of nanotechnology-based inhibitors and eco-friendly compounds, have led to the effective preservation of carbon steel in many situations. The latest information suggests that a personalized strategy involving appropriate protective measures along with constant maintenance offers the best way to handle and reduce corrosion in carbon steel applications.

Does Carbon Steel Rust Easily?

Carbon Steel vs. Stainless Steel Comparison

To tell apart carbon steel and stainless steel, one should mainly look at the differences in the materials from which they are made, their resistance to corrosion, and their use areas. Carbon steel has mainly iron and carbon in it, thus it is hard and long-lasting but gets rusty when coming in contact with moisture and air unless the iron is protected. As for stainless steel, its major component is chromium—often at no less than 10.5%—which produces a very thin but highly effective oxide layer on the surface thus the material’s being very much resistant to rust and corrosion in general.

As per the most recent figures, carbon steel is generally used in applications where it is necessary to have strong and cheap materials, such as in the case of building and making cars. On the other hand, stainless steel is more appropriate for places with a lot of humidity, chemicals, or very high or very low temperatures, like in the case of the making of medical tools, food processing, and marines equipment. In addition to the aforementioned areas, despite stainless steel being the one with better anti-corrosion properties, carbon steel still overcomes it in terms of tensile strength and cost in many structural applications.

In the end, it is the matter of discerning specific demands of the application that decides which material to use, carbon steel or stainless steel. Properly assigning the maintenance routines according to the material used will thus ensure the best performance in the most challenging situations even.

Rusting and Environmental Factors

Rusting is one of the processes that are most sensitive to the conditions of the environment, and the factors that take part in this process, such as humidity, temperature, and salts or pollutants, act as accelerators of the oxidation process. High humidity is one of the causes that allow the moisture necessary for iron to combine with oxygen and produce iron oxide (rust). The warm temperature usually double the speed of the chemical reaction since it is a heat-dependent reaction, while the cold slows it down. The places at the seaside or with a lot of salt in the air, such as those next to oceans, increase the rusting process because salt acts as a conductor of the electrical reaction between iron and oxygen thus speeding it up.

On top of that, the industrial areas that have higher pollutant levels in the air due to sulfur dioxide or other substances suffer from the fast rusting of the metals as a result of the acidic compounds formed by the pollutants when they come into contact with water. The use of protective coatings, regular maintenance, and the selection of rust-resistant materials such as stainless steel can minimize these environmental effects significantly. Knowledge of these factors is crucial for developing methods to stop rust in both daily life and industrial activities.

The Role of Metal Alloys in Rust Protection

Different metal alloys have different levels of rust resistance mainly because of their different compositions as well as the specific elements that inhibit corrosion. For example, stainless steel which is made of iron, chromium, and usually nickel is not susceptible to rusting because the presence of chrome forms a protective oxide layer over the iron surface preventing its contact with water and air which are the two main components in the rusting process. The same goes for weathering steel and other such alloys; these develop a protective patina which further needs some time before starting to rust again. In contrast, carbon steel is widely regarded as the least resistant to rust when compared to all the types of steel due to its not containing protective components like stainless steel does. The most recent research points out the increased deployment of next-generation alloys such as aluminum-magnesium, among others, which impart amazing corrosion resistance in saltwater applications. Progress in alloy technology is always aiming to tailor materials to certain conditions, consequently, the costs related to maintenance are cut down, and the service life of opposition to rust-prone applications is prolonged.

How to Prevent Rust on Carbon Steel

Seasoning Techniques That Are Correct

Step-by-Step Seasoning Process:

- Clean the Surface: Remove all dirt, oils, and residues completely

- Heat the Steel: Apply even heat to open the steel’s pores

- Apply Oil: Use a thin layer of high-smoke-point oil (flaxseed or grapeseed)

- Bake the Oil: Heat at high temperature for about an hour

- Cool and Repeat: Allow to cool and repeat for multiple layers

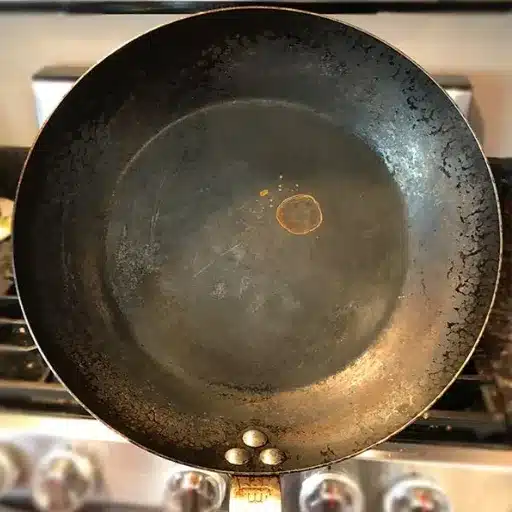

The proper seasoning of carbon steel is an absolute necessity for the prolongation of its life and the prohibition of rust. The whole procedure starts by giving a good cleaning to the surface, so that dirt, oils, and residues are completely removed. Heating the steel evenly after cleaning will open its pores, and this will help the seasoning layer to stick better. The next step is to oil with a very thin layer of high-smoke-point oil, e.g. flaxseed or grapeseed oil, and to spread it evenly on the surface. Then, the steel is put in the oven or heat source, and the oil is “baked” into the surface at a high temperature for an hour. The polymerization of the oil takes place during this step and a hard, protective layer that is resistant to moisture and oxidation forms.

The recent data underscore the necessity of re-seasoning at regular intervals, especially for those items that are subjected to frequent use or water. The search trends indicate the increasing popularity among the buyers of seasoning methods that use natural oils, mainly because of their eco-friendly and non-toxic qualities. Regular and proper maintenance together with storage in a dry place will further improve the amount of time that carbon steel will take to get rusted.

Practices in Storage That Are Rust-Proof

✓ Best Storage Practices:

- ✓ Use climate-controlled storage rooms

- ✓ Store in vacuum-packed bags

- ✓ Include silica gel packs with items

- ✓ Wrap in corrosion-resistant paper

- ✓ Ensure proper ventilation

Perfect storage practices are the key to preventing completely the formation of rust on carbon steel. The data obtained from search engine trends indicates an increasing number of people looking for climate-controlled storage rooms as a solution. These places will ensure that the temperatures are stable and that the amount of humidity is not too high, thus avoiding two of the main causes of rust. Moreover, keeping carbon steel pieces in vacuum-packed bags or putting silica gel packs together with them will additionally minimize their contact with moisture. Corrosion-resistant paper wrapping has also become a very popular option for users who prefer environmentally friendly methods over synthetic coatings. Intervals between inspections and maintenance can be reduced significantly when these methods are applied, and thus the life of carbon steel tools will be increased greatly.

Oils and Finishes That Are Used as Protection

The most effective method of preventing carbon steel surfaces from rust and corrosion is using oils and finishes. Natural oils such as linseed or mineral oil are recommended widely for their ability to trap moisture on the basis of the data from search engine. The oil not only prevents rust but also keeps the steel’s original look throughout the years. Besides, artificial products, for example, silicone-based sprays or specialized anti-corrosion finishes, are also durable and easy to apply. Frequent reapplication is critical to making sure that the protection layer does not break down, particularly in humid areas. The combination of these practices together with the proper cleaning will result in long-lasting protection for carbon steel items.

How to Remove Rust from Your Carbon Steel

Using Steel Wool and Other Tools

One of the most effective ways to get rid of rust on carbon steel surfaces is by using steel wool together with right methods and tools. Firstly, choose very fine-grit steel wool to prevent scratching the metal surface at all. With moderate force, slightly rub the area with rust around in circles. For the hardest rust spots, you can make the operation more effective by adding a rust-removing water-soluble chemical or white vinegar beforehand so that the oxidation will be easier to be removed. On the other hand, for rust removal on larger or more resistant places, wire brushes or sandpaper can also be helpful. As a matter of fact, after the rust has been removed, you must always wash the surface properly with warm, soapy water, then dry it to the last drop to avoid the risk of corrosion starting again. In fact, when these procedures are applied properly, the carbon steel will get back to its original look and a smoother and cleaner finish will be guaranteed. What is more, the application of a protective coating after cleaning can considerably prolong the life of your carbon steel items.

Natural Remedies for Rust Removal

Eco-Friendly Rust Removal Solutions:

• White Vinegar: Acetic acid dissolves rust effectively

• Baking Soda Paste: Mix with water for gentle abrasive scrubbing

• Lemon Juice + Salt: Citric acid loosens rust naturally

• Potato Juice: Oxalic acid helps dissolve rust

• Cream of Tartar Paste: Combine with baking soda and hydrogen peroxide

There are many natural solutions that can do a good job at fighting rust without any use of harsh chemicals. The most favorite of them are vinegar that has strong rust-dissolving properties when the items are soaked or wiped with it; this is due to its acetic acid content. Baking soda when mixed with water creates a gentle abrasive paste that is very effective in scrubbing rust off metal surfaces. Another good combination is lemon juice with salt; the citric acid in lemon reacts with rust, making it loose, thus, coming off with less effort.

Just like that, experts suggest that rusty pieces of metal be immersed in potato juice, as it is the oxalic acid in the potato that helps to dissolve rust. Meanwhile, large objects can be treated by the application of a paste made from cream of tartar, baking soda, and hydrogen peroxide, which is natural but quite a powerful method at the same time. All these remedies are inexpensive ones, friendly to the environment, and free of the toxic ingredients that are usually present in conventional rust removers. Using right and careful methods along with regular care of surfaces will bring back and keep the steel or metal objects in question their original condition.

When to Seek Professional Help

In most cases, Do it Yourself (DIY) methods can be applied on minor cases of rusting or corrosion, however, some situations do require professional intervention. If the corrosion has far gone and rusted through the metal or the connection of the parts has become feeble, or the rust is on delicate machines or valuable antiques, it is always a good idea to consult an expert. Professionals often work with advanced equipment and methods, such as sand-blasting, electrolysis, or chemical treatments, to make sure that the restoration is thorough yet without inflicting any damage at the same time. Recent search data indicates that a considerable number of people prefer taking their artifacts like car frames, industrial machines, or historical artifacts requiring more than just home remedies, to professional care. Professional help not only increases the longevity of the piece but also guarantees safe and proper handling.

Frequently Asked Questions

Will a pan made of carbon steel corrode?

Indeed, carbon steel pans are likely to corrode due to the fact that they are made of carbon steel, which when put in contact with moisture and air, starts to rust. In order to make the process of corrosion slower, a number of cooks perform the seasoning-related trick of coating the pan with a very thin layer of oil, so that in one way, the oil acts as a protective layer, and in another, an oxide layer that eliminates any immediate rusting. Moisture from air or direct contact with moisture can result in carbon steel losing its shiny luster and turning into a brownish-ruinous state of the ron-throw away kind.

Besides regular usage and proper drying post-washing, these practices help keep the metal free of rust and thus help prolong the life of the cooker. The rusty or chemically rusty spots can be dealt with by the scrub-technique employing coarse salt and oil, followed by re-seasoning to recreate the protective layer.

How do you prevent carbon steel from rusting on a frying pan?

To block carbon steel on a frying pan from rusting, always make sure you dry the pan completely and apply a very thin layer of oil or a protective layer of oil after cleaning creating a protective film. Regularly season the pan to generate a robust oxide layer that prevents the direct interaction of carbon and iron in steel with the oxygen and water. Do not leave the pan wet or allow the pan to rust if you allow it to air-dry in a humid environment, as carbon steel rusts more quickly in high moisture conditions. When rust has been removed after scrubbing the pan, reapply oil and heat to prevent rust from forming again. A careful and correct use of a paper towel or soft cloth to wipe off excess oil will ensure an even thin layer that will aid in the prevention of future rust.

What is the best way to remove rust from carbon steel and stop pan rust?

The first step is to take a coarse salt abrasive or a scrub pad and start to clean the rust until it has all been taken away; then, rinse with water and dry your pan completely. For difficult rust, you can either use gentle chemical rust remover or repeat dipping and scrubbing with oil and salt; then scrub the salt and oil away and re-season the surface of your pan. After the rust has been eliminated, heat the pan and apply a thin layer of oil to create a protective film which will aid in preventing rust from happening.

Regular maintenance including wiping with a paper towel or soft cloth and storing in a dry place will certainly be more effective in preventing rust than infrequent care. In case the layer of oxide that shields the metal from corrosion gets eroded, develop it back through seasoning so that the pan gets its protection back.

Can a high carbon steel product rust faster than medium carbon or low carbon steel and how to prevent rust from forming?

The higher carbon content might alter the way the surface behaves, however, all types of carbon steel will still rust since the carbon and iron in the steel will still react with the oxygen and water to create rust. Carbon steel products, regardless of whether they are of high carbon steel or medium carbon steel, require regular seasoning and an application of a thin layer of oil in order to mitigate the formation of rust. Always keep products away from moisture and make it a point to wipe them dry with a soft cloth or paper towel after cleaning in order to minimize the possibility of the carbon steel surface being exposed to water.

For industrial parts needing long-term protection, galvanizing or using other coatings is an option, but in the case of kitchenware, seasoning is still the most effective and commonly used method. When rust is spotted, the initial step is to remove it from the surface immediately, followed by the application of oil and heat to restore the barrier.

Is there any distinction between cast iron and carbon steel with respect to rust stain and maintenance of a frying pan?

Of course, but the distinctions are rather minimal and would be barely noticeable for the average user. Both cast iron and carbon steel, if left in moisture, can get a rust stain, and seasoning is an advantage for both. The cast iron is thick and may be more forgiving, on the other hand, the carbon steel is quick in heating and is lighter and the surface of the carbon steel requires the same care to prevent rust. The same treatment is applicable to both materials; use coarse salt to scrub the pan with and remove food and rust, dry it completely and season to restore the protective film. A soft cloth is to be used until the rust is removed and subsequently heated with oil to establish a long-lasting protective layer. Through regular maintenance, the pan is not ruined but its service life is prolonged.

What should I discuss with my steel supplier regarding carbon steel so that the chance of it rusting is minimized?

Raise with the steel supplier the issue of grade and surface finish because the latter can sometimes limit the initial access of oxygen and water and thus delay the onset of rust. Inquire if the supplier has the option of pre-treated or coated carbon steel for you to use in a project that requires longer corrosion resistance or if galvanizing options are available for industrial usage. For piping, check if the steel is high-carbon or medium-carbon, and whether any protective wrapping or oil coating was applied for transport.

Also, how about the maintenance of the equipment and whether any special devices or treatments are required for the removal of chemical or stubborn rust? When you know this information, you can consider how to scrub the rust, if necessary, and how to season or coat the surface to inhibit the formation of rust.

How can you tell if rust from carbon steel is removable and the pan is not ruined?

A little surface rust or a rust stain is generally removable and the pan is not ruined if the underlying metal has not been pitted very deeply. Scrub with coarse salt and a scrub pad until all the rust has gone, then dry and re-season the pan to restore the oxide layer that blocks the path of future corrosion. It is the case that if a pan’s surface area has been rusted and smoothed over, and the surface has been seasoned, the pan can be considered as having its normal service life.

Deep pitting or wide chemical rust that has eaten through the metal may be more difficult to fix without specially designed equipment. For the typical kitchen, a lot of rust can be dealt with simple methods like scrubbing it with salt and oil, using a soft cloth, and repeated seasoning.

What common habits could keep a frying pan from rusting and ensure that the rust stays away from the pan?

The frying pan should be dried right after washing and a thin layer of oil should be applied to form a protective film that will help stave off carbon steel rust. Carbon steel is vulnerable if the pan is left in contact with moisture or in a moist environment as it is exposed to oxygen and water easily and rust may form quickly. Excess oil should be wiped off with a paper towel or soft cloth and the pan stored in a dry place, and the pan should be re-seasoned periodically especially after heavy use or after rust removal.

If early rust appears, it should be scrubbed with coarse salt and then oil reapplied followed by heating until the oxide layer is rebuilt. These preventive measures not only keep the surface of carbon steel in good condition but also prolong the life of the cookware.

Reference Sources

- Harvard University – Atmospheric Corrosion Prediction of Carbon Steel:

This study examines the rust layer formation on Q235 carbon steel and compares it with weathering steel.

Atmospheric Corrosion Prediction – Harvard University - Ohio State University – Reducing Steel Corrosion to Combat Climate Change:

This article discusses the environmental and economic impacts of steel corrosion and strategies to reduce it.

Reducing Steel Corrosion – Ohio State University - National Academies Press – Corrosion of Buried Steel:

This chapter explores the corrosion rates of plain carbon steel in various environments and the factors influencing it.

Corrosion of Buried Steel – National Academies Press