Steel is a fundamental material in a variety of fields, ranging from construction to the production of goods, but have you ever thought about its magnetic properties? Out of all the steel types, carbon steel is the one that not only has high strength and versatility but also interacts with magnetism in a unique way. The present blog post takes you along the intriguing journey of the conjunction between carbon steel and magnetism, clarifying the reason that some steely types show magnetic behavior while others do not. Whether you are an engineer, a student, or just inquisitive, this journey through the magnetic properties of carbon steel will reveal to you the valuable insights into the science of steel and its applications in the real world. Get ready to discover the hidden powers inside this crucial material!

Introduction to Carbon Steel

What is Carbon Steel?

Carbon steel is an alloy that contains mainly iron and carbon and has very versatile and widespread use with the carbon content of 0.05% up to 2.1% by weight. In contrast to stainless steels, which usually have remarkable amounts of alloying elements like chromium or nickel, carbon steels do not belong to this category. The carbon content is a determining factor for the material’s properties such as hardness, strength, and ductility. More carbon leads to stronger but less ductile steel, while lower carbon gives larger ductility. Carbon steels are often used for the construction and manufacturing of tools and production because of their strength, cheapness, and versatility for use in different applications.

🔑 Key Characteristics of Carbon Steel

- Composition: Primarily iron with carbon content ranging from 0.05% to 2.1%

- Minimal alloying: Unlike stainless steel, lacks significant chromium or nickel

- Property variation: Carbon content directly affects hardness, strength, and ductility

- Cost-effective: Economical choice for diverse industrial applications

Types of Carbon Steel

Carbon steel is classified into three main categories according to its carbon content—low carbon steel, medium carbon steel, and high carbon steel:

Each variety of carbon steel corresponds to particular industrial and manufacturing requirements thus demonstrating this material’s versatility in different applications.

Common Uses of Carbon Steel

With strength, durability, and cost-effectiveness as its main characteristics, carbon steel is a highly adaptable material that can be easily used across many industries. The following are some common applications of carbon steel:

🏭 Industry Applications

- Construction: Used in buildings, bridges, infrastructure (pipes, railways). Its resilience under stress makes it ideal for structural components.

- Tools and Machinery: High carbon steel excels in making tools, cutting machines, and heavy-duty machinery parts due to its hardness and wear resistance.

- Automotive Industry: Medium carbon steel is commonly used for axles, gears, and engine components, offering an optimal combination of strength and malleability.

- Energy Sector: Critical for oil, gas, and water pipelines due to excellent tensile properties and pressure resistance.

- Household Applications: Everyday items like pots, knives, and garden tools benefit from carbon steel’s toughness and edge retention.

Carbon steel, due to its wide-ranging applications, continues to be a crucial support of modern manufacturing and engineering advances. For its excellent strength and durability, carbon steel is becoming more and more popular among industries, thanks to new technologies and increased demand.

Understanding Magnetic Properties

What Does Magnetic Mean?

Magnetism is a characteristic of some materials to generate a magnetic field, which can either pull or push other materials away. This phenomenon is the result of the movement of electric charges, especially the orientation of electrons in the material. Based on their reactions with magnetic fields, materials are generally categorized into magnetic (ferromagnetic), non-magnetic, or weakly magnetic (paramagnetic and diamagnetic). Among the most common magnetic substances are iron, nickel, and cobalt which are strongly attracted to magnets because of their internal structure and electron configuration. The comprehension of magnetism is very essential in fields such as electronics, data storage, construction, and medical imaging technologies, reflecting its extensive naturalness in modern science and industry.

📊 Material Classification by Magnetic Response

| Ferromagnetic | Strongly magnetic (iron, nickel, cobalt) |

| Paramagnetic | Weakly attracted to magnetic fields |

| Diamagnetic | Weakly repelled by magnetic fields |

How Magnetism Works

The mechanism of magnetism involves the motion of electrons and the ordering of magnetic domains. Electrons at the atomic level revolve around the nucleus and spin on their axes, thus producing minuscule magnetic fields. If the majority of these fields are pointing in the same direction within a material, then that material is said to be magnetized. The very thing that comes about from this aligning of the magnetic domains—that is, regions where the fields of the atoms are uniformly directed—is the strong magnetic effect. Materials such as iron, nickel, and cobalt are such that the alignment occurs naturally, and that is why they are so magnetic.

Technological advances, as shown by contemporary data, indicate that magnetism is a necessity in electric motors, hard drives, and MRI machines. Research is done to improve magnetic materials and to study quantum magnetic phenomena that will lead to great impacts on energy-saving and data-processing improvements. The interaction between electrons, domains, and electric currents as external factors reveals the intricate mechanisms controlling magnetism and emphasizes its significance in the technology of today.

⚡ The Science Behind Magnetism

- Electron Movement: Electrons revolve around the nucleus and spin on their axes, creating tiny magnetic fields

- Field Alignment: When these fields point in the same direction, the material becomes magnetized

- Magnetic Domains: Regions where atomic magnetic fields are uniformly directed create strong magnetic effects

- Natural Alignment: Materials like iron, nickel, and cobalt naturally align, making them highly magnetic

Difference Between Magnetic and Non-Magnetic Metals

Among the metals, if iron, cobalt, and nickel are mentioned, we will be referring to the ones with strong magnetic properties. The reason for such a behavior of metals is the presence of unpaired electrons and proper alignment of the magnetic domains. Such metals are classified as ferromagnetic since they can be magnetized and still retain their magnetism even when the external magnetic field has been removed. Magnetic metals are used in many applications such as electric motors, transformers, and storage devices due to their ability to produce and maintain magnetic fields.

On the other hand, there are non-magnetic metals such as aluminum, copper, and gold, which do not show having any magnetic properties at all. The essence of the atomic structure of such metals is that there are no unpaired electrons and the magnetic domains are not aligned, therefore they cannot be classified under magnetism conditions. It is a fact that these metals are not magnetic just like that, the scenario can be changed slightly when they are subjected to strong magnetic fields (like in the case of paramagnetism), the metals become weakly magnetic for as long as the fields last, but these effects are very much insignificant in practice.

Distinctive features between magnetic and non-magnetic metals mainly have to do with their atomic structure and electron configurations. Today’s innovative research in alloys and composite materials is opening new avenues where metals are made to possess specific magnetic properties for next-gen technologies such as quantum computing and eco-friendly energy solutions.

Is Carbon Steel Magnetic?

Factors Affecting Magnetism in Carbon Steel

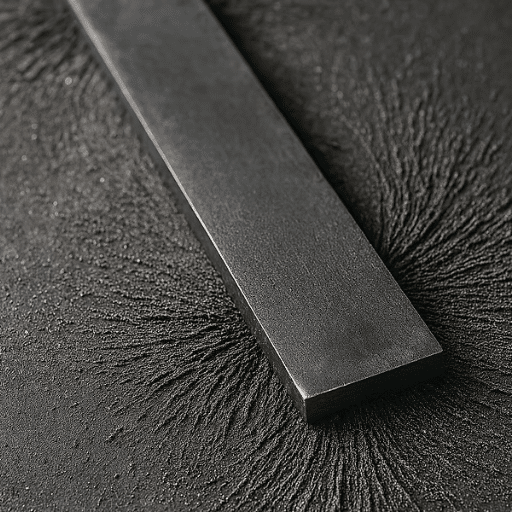

The magnetism of carbon steel is determined by a number of important factors among which are its composition, microstructure, and heat-treatment. The main component of carbon steel is iron with a certain percentage of carbon and other elements. The magnetic properties are mainly due to iron content as iron is a ferromagnetic material. The carbon content and the presence of other alloying elements such as manganese or silicon can however, affect the overall magnetic behavior of the steel.

The microstructure of carbon steel is another factor that plays a critical role in the magnetism of the steel. Depending on the processing and heat treatment that the material undergoes, different phases such as ferrite, which is highly magnetic, and austenite, which is non-magnetic can be present. Heat treatment methods like quenching, annealing, or tempering can change the ratio of these phases, which in turn influences the magnetism in carbon steel.

🔬 Factors Influencing Carbon Steel Magnetism

- Composition: Iron content provides ferromagnetic properties; carbon and alloying elements (manganese, silicon) modify magnetic behavior

- Microstructure: Ferrite phase is highly magnetic, while austenite phase is non-magnetic

- Heat Treatment: Methods like quenching, annealing, or tempering alter phase ratios and magnetic properties

- Temperature: High temperatures may cause loss of magnetic properties due to structural changes

Last but not least, temperature is one of the external factors that affect magnetism; at high temperatures the magnetic properties may be lost because of changes in the material structure. With the most recent data, carbon steel is usually magnetic as long as ferromagnetic phases are present in the microstructure, thus it is general-purpose and acceptable in scenarios where the magnetism-sensitive environment is present.

Comparison with Other Steel Types

A comparison of carbon steel with other types of steel like stainless steel and alloy steel brings out the magnetic property differences which are very much owing to the composition and microstructure modifications. Carbon steel which is characterized by metallic iron content and simple structure usually exists in the form of “ferromagnetic” phases, such as ferrite and martensite, thus is regarded as magnetic most of the time. On the contrary, stainless steel shows inconsistencies in its magnetic properties with different grades. For instance, austenitic stainless steel (like 304 or 316) is considered to be non-magnetic in nature for it has a high chromium and nickel content that stabilizes the austenitic phase. However, ferritic and martensitic stainless steels exhibit magnetism comparable to carbon steel.

On the contrary, alloy steels typically add various elements such as manganese, chromium, and molybdenum to get desirable mechanical properties. These additions can affect the magnetism of the steel, but still, many alloy steels are not completely non-magnetic. The latest data suggest that the final choice of the materials among these often goes by the application requirements regarding whether magnetic properties are to be avoided or considered advantages. Hence, carbon steel is used in applications that require maximum magnetic efficiency, while austenitic stainless steel is the best option for places where there is a need for magnetic interference resistance.

Common Misconceptions About Carbon Steel Magnetism

⚠️ Debunking Myths

- ❌ Myth: Carbon steel is always a very strong magnet

✓ Reality: While most carbon steels have strong ferromagnetic properties due to high iron content, the degree of magnetism varies based on alloy composition and heat treatment processes - ❌ Myth: Environmental factors have no influence on carbon steel magnetism

✓ Reality: Temperature significantly affects magnetic properties, with high temperatures potentially leading to magnetization reduction - ❌ Myth: All carbon steels behave identically with magnets

✓ Reality: Carbon content and alloying elements can alter magnetic permeability significantly

Recently, it has been suggested that one has to understand these subtleties in order to be able to choose the right material for applications where the magnetic field is of critical importance. This not only emphasizes the need for material specifications to be consulted in-depth but also the reliance on broad-oriented assumptions about carbon steel should be minimized.

Applications of Magnetic Carbon Steel

Magnetic Applications in Industry

Magnetic carbon steel, owing to its great magnetic characteristics and durability, finds extensive use in a variety of industries. The loudspeakers are one of the primary applications where the magnetic steel quality has to be conducted by magnetic fields very efficiently for the energy to be transmitted with minimum loss. The magnetized parts of the engine help to perform better and give the customer more reliable products.

Recent studies propose that magnetic carbon steel is also a must for the manufacture of electromagnetic shielding devices since it accounts for the reduction of electromagnetic interference in high-performing apparatus. It is thus indispensable for the electronics and telecom industries. Moreover, the breakthrough in material science mentioned in search data suggests that the development of superior carbon steel alloys with higher permeability and lower magnetic losses is still in progress, thereby making the adaptability of these materials even wider in the high-tech and renewable energy fields, for instance, wind turbine generators. Hence, it is very important to ensure that the right material is selected according to the specific industrial needs in order to make the most of these developments.

🏭 Industrial Applications Overview

| Loudspeakers | Efficient magnetic field conduction for minimal energy loss |

| Electric Motors | Magnetized parts enhance performance and reliability |

| Electromagnetic Shielding | Reduces interference in electronics and telecommunications |

| Wind Turbine Generators | Superior alloys with higher permeability for renewable energy |

Carbon Steel in Magnetic Devices

As per the most recent search engine data, carbon steel still greatly influences the field of magnetic devices because of its low cost, good availability, and positive magnetic characteristics. In fact, carbon-steel alloys with improved permeability and less magnetic loss are becoming increasingly common in such applications as the manufacturing of transformers, motors, and wind power generation. The control that these materials have among strength and magnetic performance can be regarded as their asset in both the classic and the new tech areas.

On the other hand, the case still remains that industrial applications face the issues of heat resistance, corrosion and specific use case material optimization. Material science has been making considerable progress in curing these defects by pushing the carbon steel technology in high-tech applications even further. The selection of the proper alloy composition and the incorporation of advanced manufacturing methods are the key steps to the full exploitation of the benefits of carbon steel in magnetic device technologies.

⚙️ Magnetic Device Applications

- Transformers: Carbon steel alloys provide improved permeability for efficient power transfer

- Electric Motors: Balance of strength and magnetic performance for industrial and consumer applications

- Wind Power Generation: Reduced magnetic loss enhances renewable energy efficiency

- Sensors: Reliable magnetic response for detection and measurement systems

Benefits of Using Magnetic Carbon Steel

In the battery of various industrial and technological applications, magnetic carbon steel is one of the preferences because of its number of merits. Its great magnetic properties have made it possible to transfer power and generate electricity, in such devices as transformers, electric motors, and sensors, very efficiently. Moreover, one of the important characteristics of carbon steel is its high durability, it possesses very good mechanical strength that guarantees a long life of the machine and its resistance to wear and tear. Besides, its price is very low compared to other high-performance magnetic materials, so it is more than an ever economically viable option for mass production. The progress that has been made in the areas of heat treatment and alloying to magnetic carbon steel performance have been since the materials have been upgraded with better magnetic permeability and lesser energy losses. Being a component of modern sustainable energy systems and smart tech, it is inseparable from the future.

✅ Key Benefits Comparison

| Benefit | Description | Impact |

|---|---|---|

| Excellent Magnetic Properties | Efficient power transfer and electricity generation | Enhanced device performance |

| High Durability | Superior mechanical strength and wear resistance | Extended machine lifespan |

| Cost-Effectiveness | Low price compared to other magnetic materials | Economical for mass production |

| Advanced Processing | Heat treatment and alloying improvements | Better permeability, lower energy losses |

| Sustainability | Essential for renewable energy systems | Critical for future smart technologies |

Frequently Asked Questions

Do metals have magnetic properties? Is carbon steel magnetic?

Carbon steel is magnetic due to its nature as an iron-carbon alloy because pure iron plus numerous iron-based steels have the property of being ferromagnetic so the piece of steel will interact with magnets and magnets will work on it. There are a lot of factors influencing the magnetic response including the amount of carbon and the crystal structure, thus high-carbon and low-carbon steels may have different magnetic characteristics and might show different responses to a magnetic field. Low-carbon and cold-rolled steel generally have prevailing magnetic domains on their surface thus they are very magnetic in comparison to some high-carbon or alloyed tool steels. When the amount of carbon is increased, especially in the high carbon content range, the magnetic strength may vary and in some heat-treated tool steels the output is less magnetic thus the steel is less magnetic. Hence, it is necessary to take into account that the right steel for magnetic applications is dependent on the amounts of carbon, whether it is cold-rolled, and whether there is a coating such as galvanized steel that does not change the underlying magnetic properties. Metals lose their magnetic properties only if they are non-magnetic or when the magnetic domains cannot align or move freely in the applied magnetic field.

How are magnetic strength and steel solutions connected?

Choosing the proper steel and steel solutions means that one has to consider the carbon content, the crystal structure, and the processing because these factors control the magnetic strength and the magnetic response of the final steel products. Carbon steel contains carbon in different amounts from the lowest to the highest grades, and the higher carbon content or the presence of carbides in the tool steel can reduce the steel’s magnetism in comparison to pure iron-based grades. Surface treatments like galvanizing improve corrosion resistance but typically do not make the surface more magnetic; they mainly protect the substrate while cold-rolled steel provides a better surface finish that may be desirable for some applications. If you are looking for steel that is very magnetic for sensors or motors, then low-carbon or pure iron alloys would be the best option, whereas, in the case of less magnetic steel, specialized steels with high strength or corrosion resistance might be more suitable. In many design scenarios, engineers balance the parameters of magnetic strength, high strength, and corrosion resistance to select the right steel solutions for the intended use.

Why are metals sometimes non-magnetic? Is it possible for carbon steel to be non-magnetic?

Even though lots of metals have ferromagnetic elements in their composition, some of these metals become non-magnetic due to the particular arrangements of their electrons, the presence of certain alloying elements or the fact that they do not allow the alignment of the domains with the field. Carbon steel and certain tool steels can be less magnetic if the heat treatment or alloying has changed their microstructure, or if phases are formed which disrupt the magnetic domain alignment. Additions of a few alloying elements like nickel, manganese, or chromium can either increase or decrease the magnetic properties of steel; while certain grades of stainless steel sometimes act as non-magnetic metals depending on their microstructure. The magnetic behavior also varies with the type of steel process which is either cold-rolled or annealed because the processing has an effect on the alignment of the magnetic domains and consequently on the strength of the magnets on the part.

Can carbon steel solutions and different types of carbon steel be made less magnetic or more magnetic?

Carbon steel magnetic properties can be manipulated as the materials and processing will decide whether steel is going to be magnetic or non-magnetic for a specific application. The addition of carbon or alloying elements can sometimes result in reduced magnetism, while the opposite—reduction of carbon and careful control of alloying—usually leads to the retention of the ferromagnetic behavior typically seen in pure iron and low-carbon steel. In soft, low-carbon steels, the magnetic domains can align more easily, therefore designers often choose low-carbon grades when they require a strong magnetic response, while high-carbon tool steels or high-carbon-content steel may become less magnetic after specific heat treatments. Techniques like stress-relief annealing, cold-rolling, and surface finishing have an effect on how strongly the material will interact with magnets and whether magnets will work effectively for sensors or actuators. In the end, the selection of the appropriate type of steel depends on balancing the magnetic response with the resistance to corrosion, the high strength requirement, and the function of the final steel products.

💡 Key Takeaways

- Carbon steel is generally magnetic due to its high iron content and ferromagnetic phases

- Magnetism varies based on carbon content, alloying elements, microstructure, and heat treatment

- Low-carbon steels typically exhibit stronger magnetic properties than high-carbon variants

- Temperature and processing methods significantly influence magnetic behavior

- Carbon steel’s cost-effectiveness and magnetic properties make it ideal for transformers, motors, and renewable energy applications

- Understanding material specifications is crucial for selecting the right steel for magnetic-sensitive applications

📚 Reference Sources

- The Effect of Changes in Total Carbon – APS Journals: This study explores the variation in magnetic properties of carbon steel and chrome steel based on carbon content and treatment methods.

- Magnetic Properties of Metals and Alloys – Carnegie Mellon University: This academic resource examines the magnetic characteristics of various metals and alloys, including medium and high-carbon steels.

- Magnetic Properties of Solids – HyperPhysics: This educational resource provides a detailed overview of magnetic susceptibilities of various materials, including carbon-based substances.