Whenever selecting the correct material for cutting tools and industrial applications, the decision usually comes down to two widely known competitors: Carbon Steel and High-Speed Steel (HSS). Each material has its own unique qualities, plus points, and downsides, so the decision is very important not only for manufacturers but also for engineers and hobbyists. The current post is going to be an extensive examination of the basic distinctions between Carbon Steel and High-Speed Steel by looking into their make-up, efficiency, life-span, and overall use in different tasks etc. If you are trying to make a cost-saving choice or if you are looking for the best material for high-precision job, this in-depth comparison will be able to guide you in making a wise choice. So, keep watching as we reveal the properties and major differences that divide these two materials.

Understanding Steel Types

🔧 Carbon Steel Introduction

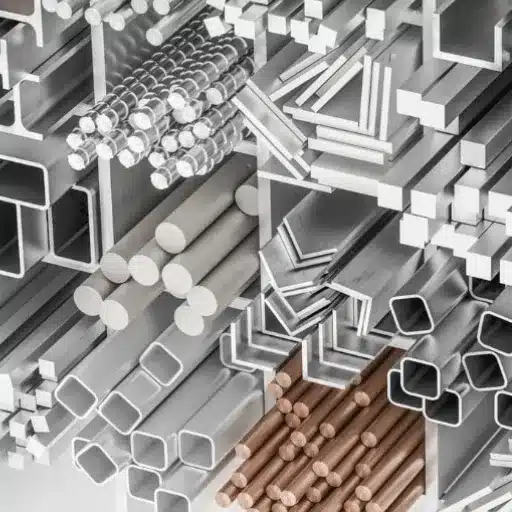

Carbon steel is often the first material that comes to mind when considering steel for a specific application due to its wide range of applications and low price. It is mainly made of iron and carbon with a carbon content that determines its hardness, strength, and ductility. The low price and the properties of carbon steel allow it to be widely used in construction, piping, automobiles, and general industrial applications.

Depending on the carbon content, it is known as low, medium, and high-carbon steel and each gives different characteristics that are good for certain uses. Latest reports indicate that carbon steel is still the preferred material for projects that need one mechanical performance that is good but without the high price of the specialty alloys. Its machinability and high load bearing ability make it fit for use in structural framing, bridges, and machine part manufacturing.

⚙️ HSS Overview

High-Speed Steel (HSS) is a tool steel that has been classified into a group due to its very high hardness, wear resistance, and high-temperatures strength retention. Its major cut-off is HSS tools, drills, taps, and milling cutters where the need for tools under very extreme working conditions is critical.

As per the latest data, HSS has its superior properties due to the addition of tungsten, molybdenum, chromium, and vanadium, which increase the life and the capacity to withstand high temperatures. HSS, more over, has a sharp cutting edge that remains even at the high temperatures produced by high-speed machining. Although carbide and ceramics are the competitors to HSS, they are more expensive and less versatile. The performance of HSS is further advanced through coating technologies like titanium nitride (TiN) or titanium aluminum nitride (TiAlN), thus it becomes a good option for not only manufacturing but also machining needs in modern times.

📊 Main Differences Between Carbon Steel and HSS

By their makeup, characteristics, and utilization, carbon steel and high-speed steel (HSS) differ strongly. The major component of carbon steel is iron and carbon, which provide reasonable strength, and hardness, yet it cannot sustain its properties at the high, hot end of the spectrum. This is the reason carbon steel is mainly reserved for construction, pipelines, and basic tools which do not demand extreme heat characteristics. Conversely HSS is a specialized steel that is made particularly for cutting-tools that are subject to high speeds. The steel comprises tungsten, molybdenum, cobalt, and vanadium among others all of which give the steel higher hardness, toughness, and resistance to heat. This has enabled HSS tools to keep their edges sharp and work efficiently even with the considerable heat involved in machining processes.

Composition and Properties

Chemical Composition of Carbon Steel

Iron and carbon are the main constituents of carbon steel, with the percentage of carbon usually between 0.05% and 2%, depending upon the grade and the use. Besides, carbon it also sometimes has a little quantity of other elements like manganese, silicon, and sulfur.

Carbon in greater amount leads to hardness and strength, but at the same time, it cuts down ductility which makes the decision of composition very crucial for meeting specific needs of application. The recent data accentuates the necessity of proper balancing of these elements for getting the best in terms of performance in these sectors: construction, cars, and manufacturing.

Chemical Composition of High-Speed Steel

Carbon, tungsten, molybdenum, chromium, vanadium, and cobalt are the primary constituents of high-speed steel (HSS) with iron as the base metal. Besides, according to the most current data, the normal composition percentages are 0.7-1.5% carbon, 18-20% tungsten or a mixture of tungsten and molybdenum, 3-4% chromium, and 1-5% vanadium with 5-10% cobalt for some grades.

Key Alloying Elements in HSS:

Carbon (0.7-1.5%)

Provides base hardness

Tungsten (18-20%)

Enhances cutting performance

Chromium (3-4%)

Improves corrosion resistance

Vanadium (1-5%)

Increases wear resistance

Cobalt (5-10%)

Boosts heat resistance

Molybdenum

Enhances durability

The interactive collaboration of these elements gives HSS its rare properties such as great resistance to wear, superb retention of hardness, and thus the capacity to withstand high-temperature operations in the course of machining. Recent breakthroughs stress the need to fine-tune these proportions in light of the particular application. To illustrate, an increase in cobalt content results in a rise in heat resistance, on the other hand, tungsten and molybdenum give a remarkable boost to the cutting performance and durability. Keeping chemical compositions within strict limits, it becomes possible for the manufacturer to customize HSS for the sectors like manufacturing, aerospace, and automobiles with the customer being guaranteed higher performance and the product still working under the toughest conditions longer.

Physical Properties Comparison

High-speed steel (HSS) is a material that has several key physical properties which are responsible for its use in demanding applications. HSS stands out for its remarkable hardness, which usually is in the range of 62 to 67 HRC depending on the composition and heat treatment used. Such hardness enables HSS to endure cutting edges at high temperatures without wear or deformation substantially occurring. HSS’ already mentioned property of toughness greets supporting high-stress operations along with other advantages of resistance to chipping and cracking.

When looking at carbide, for example, as a tool material, HSS has the great advantage of being flexible and resilient, thus not so easily getting brittle and failing. However, coating advancements such as titanium nitride (TiN) and aluminum titanium nitride (AlTiN) have taken the performance of HSS to another level by giving it extra heat resistance and making it less friction-y during the cutting operations. HSS technology is taking a very interesting path as evidenced by the latest search engine data. Everywhere, questions are being asked about its quality delivery in the industries that need high-performance materials all the time, e.g, for making precision tools, drills, and machine parts. Hence, modern engineering techniques help high-speed steel retain its versatility and extensive utilization as a raw material for a diverse array of applications.

Performance in Applications

Applications of Carbon Steel

Carbon steel is a heavy-duty and multifunctional material that is a major factor in the industrial sector. It’s high strength, durability, and economical price are the three main reasons for its widespread use.

Common Carbon Steel Applications:

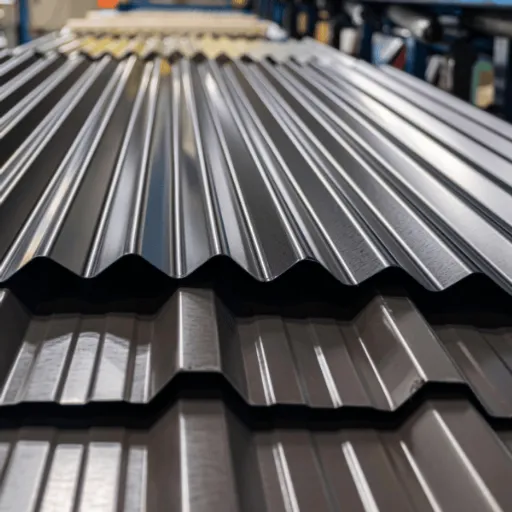

🏗️ Construction

Beams, bridges, reinforcement bars

🚗 Automotive

Car frames, engine parts

🔧 Cutting Tools

Basic cutting and machining tools

⚡ Oil & Gas

Tanks, pressure vessels

🏭 Infrastructure

Structural components, piping

⚙️ Manufacturing

Machine parts, general industrial use

In spite of its ability to endure very high-stress environments and being a candidate for heat treatments, carbon steel is still one of the most important materials for the modern engineering and industrial fields. A growing trend in global industrial sectors is displayed where the interest for carbon steel applications is shown to be increasing steadily.

Applications of High-Speed Steel

High-speed steel (HSS) is often considered a household name when it comes to maintaining its hardness and resistance to wear under high-temperature conditions thus its need in tools for cutting and machining operations is inevitable.

Primary HSS Applications:

- Drill Bits: Precision drilling in metal and hard materials

- Milling Cutters: High-speed material removal operations

- Saw Blades: Cutting through tough materials

- Taps: Thread cutting in demanding applications

- Turning Tools: Metal lathe operations

Recent data from search trends indicates that there is a marked rise in the interest of high-speed steel regarding advanced machining processes and specialized industries. Queries often focus on its inclusion in precision tools and modern coatings compatibility, which, like titanium nitride, enhance its performance and longevity. This increased attention not only confirms the necessity of HSS in fields where long-lasting and reliable tools are a must but also reasserts its position as the backbone of contemporary manufacturing and engineering.

HSS vs Carbon Steel: Suitability for Drill Bits

Carbon Steel Drill Bits

Best For: Softer materials like wood or plastic

Limitation: Less durable, may overheat when used intensively

Heat Resistance: Poor compared to HSS

HSS Drill Bits

Best For: Metal, alloys, and tough materials

Advantage: Exceptional durability and wear resistance

Heat Resistance: Excellent, maintains sharpness at high temperatures

🏆 Winner: HSS generally comes out on top regarding drill bits compared to carbon steel though for most applications HSS is the superior choice. High-speed steel can be exposed to high temperatures during cutting and thus it is necessary to use it in high-speed and high-friction operations. Recent data points to searches done on “HSS vs carbon steel drill bits” as users highlighting the main issues of longevity and efficiency where HSS has gotten the upper hand in industrial and high-demand settings. In most cases of modern drilling operations, especially in metalworking and manufacturing, HSS is the best choice because of its reliability and increased performance potential.

Advantages and Limitations

✅ Advantages of Carbon Steel

💰 Cost-Effective

Carbon steel being the cheapest steel type, thus making the metal the main option for those who conduct easy and soft payment tasks like devoting their time and effort to wood or plastics.

🔄 Easy to Grind

Carbon steel is a very good material for grinding, hence re-grinding or conditioning the cutting edges will not be too hard on the user and this will allow for the application of many purposes still to come.

👥 DIY Friendly

Perfect for amateur or DIY users who are running short of money and working in the non-industrial area where the less infrequency of use and budget become the main factors.

✅ Advantages of High-Speed Steel

🔥 Superior Heat Resistance

HSS can endure high temperatures for a long time without losing the edge of its cutting tools, making it reliable for machining with high speeds and repetitive processes in factories.

⏱️ Extended Tool Life

The service life of the tools will be longer and their performance will be uniform even when the conditions are very tough, since HSS can easily take off the wear during the process.

🎯 Precision & Versatility

HSS’s adaptability encompasses a wide range of uses, such as drilling, milling, and heading. The pros have chosen HSS for longevity and accuracy demanding tasks.

⚠️ Limitations of Carbon Steel vs High-Speed Steel

High-speed steel (HSS) limitations are particularly evident in tough industrial environments when carbon steel is compared with HSS. Search engine statistics reveal that users often criticize carbon steel for not being able to take on the high heat i.e. excessive heat during very aggressive cutting/machining. As a result, there is a limitation on the application of carbon steel in high-speed processing where great heat and, thus, very high resistance are needed to keep tool characteristics and durability. Besides that, carbon steel has lower tensile strength and is less resistant to wear, which makes it unsuitable for long and harsh use. In contrast, HSS provides unparalleled heat treatment, which yields high hardness and toughness, thus staying on the forefront of precision tooling industry. This comparative analysis rests assured that HSS is the only choice for the cutting tool as well as the rest of the high-performance application sectors.

Frequently Asked Questions (FAQ)

❓ When it comes to cutting tools, how do high speed steel and carbon steel measure up against one another?

High speed steel (HSS) comes with a very positive quality that is hardiness and resistance to wear, besides being better than most carbon steel tool grades, which is why it is for high-speed cutting and power tool and grinder applications. On the other hand, carbon steel which mainly consists of high carbon steel and medium carbon steel can be easier to sharpen and is thus preferred for hand tools such as chisels, scrapers, and lathe tools where extreme cutting and edge holding require more than heat resistance. The addition of alloying elements such as tungsten and molybdenum in prevalent high-speed steel (e.g., M2) elevates steel hardness and improves hardness and toughness after heat-treated quench and temper cycles. Low carbon steel and mild steel are two soft steel types so as to not meet the hardness and abrasion resistance needed for demanding cutting ability. In conclusion, HSS is the one you want when the hardness of high-speed steel and good wear resistance under heat are required, while carbon steel tool designs balance cost, ease of sharpening, and toughness.

❓ When is it more convenient to use high carbon steel rather than HSS for hand tools?

High carbon steel is a wonderful alternative for hand tools such as chisels, scrapers, and drill rods which need an edge that can be easily re-sharpened and will also hold an edge under shop conditions. HCS, in comparison with HSS and carbon materials used in the cutting industry, possess better toughness and are also easier to anneal and temper at home to adjust hardness and toughness. The HCS blades can be treated in such a way that they will have good hardness and abrasion resistance but will not be able to match the HSS hardness after the treatment cycles. If your cutting involves wood and power tools are not used, then high carbon steel or even medium carbon steel may be of good performance and less maintenance. However, for metal turning tools/lathes, alloy steel or HSS is usually preferred because of its excellent wear resistance at the cutting speeds.

❓ What are the factors that separate tool steels from high speed steel in terms of alloying elements and treatment?

The primary distinctions between steel and high-speed steels are the alloying elements and the heat treatment methods: HSS has a mixture of metals such as tungsten, vanadium, cobalt, and molybdenum, which gives the steel a higher melting point, hardness, and makes it resistant to wear. The ordinary carbon steels and low carbon steels (high carbon steel, medium carbon steel) rely mostly on carbon content and less complicated tempering and anneal cycles to reach the desired properties. Also, they respond differently to quench and temper steps. M2, a common high-speed steel grade, is designed to maintain its hardness at high temperatures (over 1000F), which is necessary for cutting at high speeds, while soft steels may deform due to the heat. When it comes to tools like drill rods, turning tools, and metal lathe tools, the heat-treated HSS will outlast carbon tool steel in wear resistance and cutting capability. Simply put, alloy tool steel and HSS are made to perform at an unbeatable level due to both their alloying elements and accurate heat treatment, while carbon steels continue to be a choice due to their cost and sharpening advantages.

❓ Is it possible to interchange HCS (high carbon steel) with high speed steel for the making of lathe tools and drills?

HCS can be applied for some tools and drills, particularly in low-speed or manual operations where easier sharpened material and toughness are more highly appreciated, but it cannot completely replace high-speed steel when high hardness and wear resistance at high cutting speeds are required. The high-speed steel and M2 or other high-quality HSS grades have a higher hardness of high-speed steel and better hardness and abrasion resistance after the heat-treated quench and temper processes. For heavy-duty or production turning tools the alloying elements in HSS help to maintain cutting ability and prevent rapid wear making them preferable for power tools and grinders. If you decide to use HCS for a tool, you should expect to anneal and temper it properly and accept more frequent resharpening compared with HSS. Ultimately, matching the steel used to the application—soft steel or mild steel for patterns and fixtures, HCS for hand tools, and HSS for high-speed machining—gives the best results.

❓ What are the effects of heat treatment steps like quench and anneal on the performance of carbon steel and high speed steel?

Heat treatment steps like quenching, annealing, and tempering are crucial for releasing the desired steel properties in both carbon steel and high-speed steel, but the processes and effects vary depending on the composition. Carbon steels (low, medium, high carbon steel) go through quench and temper cycles to reach a combination of hardness and toughness suitable for chisels, scrapers, and hand tools; they are also generally more difficult to anneal and manipulate at a workshop level. High-speed steel needs very accurate heat-treated sequences and sometimes even special cooling to get to the high hardness and wear resistance that allows HSS to cut at high temperatures. The presence of alloying elements like tungsten and vanadium in HSS has a significant impact on the tempering behavior and final hardness of the steel, often enabling the hardness of high-speed steel to surpass that of standard carbon steels. Properly heat-treated materials regardless of whether they are alloy tool steel, M2 or HCS will ensure that the tool keeps an edge and provides excellent cutting performance while at the same time reducing the likelihood of premature failure.

Reference Sources

- Common Tools for Working with Ferrous Metals – University of Florida

This document discusses the use of high-speed steel and carbon steel in machining, highlighting their strengths and limitations in threading and other applications.

- The Optimal Carbon Content of High-Speed Steels – Harvard University

This study explores the relationship between carbon content and the hardness of high-speed steels, providing insights into their performance in high-temperature applications.

- Steels for High-Speed and High-Stress Applications – Purdue University

This resource focuses on the properties of steels used in demanding applications, emphasizing wear resistance, fracture toughness, and thermal treatment.