With regards to the manufacturing of stainless steel tubing, two types dominate the market—seamless tubes and welded tubes. Each type has a specific use for different industries because they come with their own benefits. Making a decision between the two options can be challenging due to the factors of durability, performance, and cost that determine your needs for the fit. This article explores the differences between the two types of tubes, seamless and welded, in detail so that you have a better understanding to make an informed decision. If you are an engineer or manufacturer, or are just looking at stainless steel solutions, these two options are crucial in order to better meet the requirements of your project.

What Are the Key Differences Between Seamless and Welded Tubes?

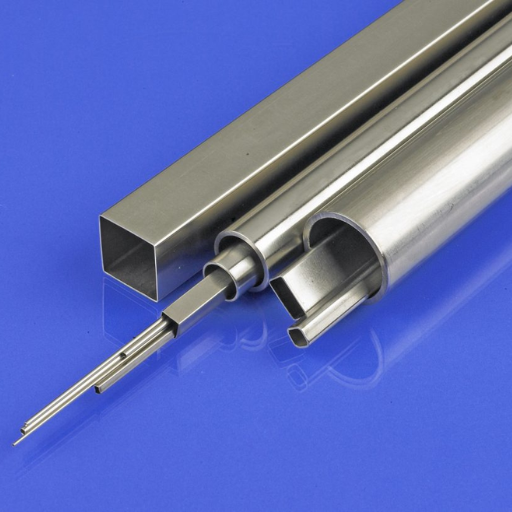

Seamless tubes are produced without a welded seam, thus giving it the ability to withstand pressure and corrosion more effectively. They are perfect for applications which need precision and reliability in harsh environments.

On the other hand, welded tubes are created by welding a flat sheet of steel into a tube. They are less expensive and better for less powerful applications where cost and availability take precedence. However, compared to the rest of the tube, the welded seam might be a weak point under immense pressure or stress.

It is up to the user to decide the best choice between seamless and welded tubes based on the requirements of the project which may involve factors such as strength, cost, and environmental conditions.

Understanding Seamless vs Welded Construction Methods

The method of producing seamless tubes entails applying mechanical processes (piercing) on a heated solid billet to form a hollow tube. As no welded seam is present, structural integrity and strength is enhanced. These tubes are reliable at very high pressures and temperatures which makes them useful for aerospace and automotive industries and all energy sectors.

To emphasize, for extreme applications like hydraulic systems, seamless tubes pose a lower risk of failure under pressure. Research indicates that seamless tubes have a greater capacity to withstand pressure and greater resistance to corrosion than welded tubes. Moreover, the lack of weld seams also reduces the presence of weak points that pose a risk to durable performance.

Advantages of Welded Tubes

Welded tubes are made by shaping steel sheets into cylinders and welding the ends. Although the process leaves a noticeable seam, the strength and endurance of welded tubes have greatly improved due to modern technologies that enhance welding. They have common applications in construction, water pipelines, furniture manufacturing, etc., which do not demand exceptional strength.

Welded tubes are highly economical due to their uncomplicated and cheaper manufacturing processes compared to seamless tubes. They usually come in many standard sizes but can also be tailored to meet unique project specifications. Evidence indicates that in situations where internal stresses are moderate, welded tubes are a dependable option.

Key Considerations for Selection

While choosing between seamless and welded tubes, it is essential to look at the application type, environmental conditions, and budget. In conditions of extreme stress and heat, seamless tubes are better suited, while for less demanding applications, welded tubes tend to be less expensive. Each of the two options offers unique pros and cons, and thorough comprehension of the project requirements is vital to making the correct choice.

How Weld Seams Impact Performance and Applications

While evaluating the effects of weld seams on the performance of a tube, a number of factors come evaluation which include structural strength, corrosion resistance, and general endurance. These factors include balance and harmony as is described below in summary on the use of weld seams.

- Structural Strength

-

-

- Seamless Tubes: As there are no weld seams, seamless tubes have unmatched structural integrity by minimizing weak points under high pressure or load.

- Welded Tubes: Although the presence of weld seams can introduce additional areas of weakness that impact performance under extreme stress, their strength has been greatly improved due to advancements in welding technology.

-

- Corrosion Resistance

-

-

- Seamless Tubes: Usually give better resistance to corrosion due to lack of seams which are more susceptible to rusting or chemical deterioration.

- Welded Tubes: The weld seam is vulnerable to corrosion in severe conditions if not treated or coated adequately.

-

- Production and Cost

-

-

- Seamless Tubes: Advanced operational procedures require higher costs to manufacture them. Best applied for critical uses where high reliability is needed.

- Welded Tubes: Simple to manufacture, which lowers their cost, and are popularly used for general and less demanding projects.

-

- Dimensional Precision

-

-

- Seamless Tubes: Usually provide more consistency in dimensions and roundness because of the way they are manufactured.

- Welded Tubes: May show some slight irregularities in the weld region, but are fine for most uses that don’t require extreme levels of precision.

-

- Applications

-

-

- Seamless Tubes:

-

- Pipelines for high-pressure fluids

- Exchangers for heating and cooling fluids

- In hydraulic machinery

- Tubes used in boilers

- Welded Tubes:

-

- Used in construction and other load-bearing buildings

- Moving fluids under low pressure

-

Functions of art

-

By evaluating these factors, experts can decide which type of tube—seamless or welded—best fits their requirements.

Comparing Structural Integrity of Seamless Tubes and Welded Tubing

The manufacturing of seamless tubes starts with a solid billet being pierced into a hollow tube. This method of forming a tube without welds results in flawless physiognomy, thus enabling superior strength and temperature resistance. Because seamless tubes lack welded joints, they are less likely to fail under extreme stress. This feature makes them ideal for use in drilling for oil and gas, equipment such as boilers, and heat exchangers. Research suggests that smoother tubes, as standard, have higher tolerance for pressure, frequently exceeding critical industry benchmarks.

Structural Integrity of Welded Tubing

Welded tubing results from rolling and welding flat sheet metals, creating a seam along the longitudinal side of a cylinder. Modern welded tubes, due to advancements in welding technology, now possess remarkable strength and often surpass seamless tubes in many non-critical applications. For example, welded tubes are cost-effective in low-pressure environments and general structural applications without compromising performance. Research indicates that advancements in automated welding have alleviated issues related to seam weaknesses and consistency in wall thickness and joints. However, these welded tubes are likely the least suitable option for highly demanding applications that require the highest strength against internal pressure.

Performance Metrics Comparison

Analyzing pressure ratings reveals that seamless tubes can endure about 20% more internal pressure than welded tubes of the same material and size. Moreover, fatigue testing reveals that seamless tubes usually have better resistance to cyclic loading, which is beneficial for dynamic systems. However, welded tubing can, in controlled conditions, fulfill the performance standards needed by numerous industrial sectors. This aspect makes welded tubing a cost-efficient and dependable option for construction, automotive, and decorative works.

How Are Seamless and Welded Steel Pipes Manufactured?

The production of seamless pipes starts by heating a steel block until it’s malleable enough to be pierced and shaped into a hollow tube. The tube is then rolled or stretched to achieve the desired dimensions. This process guarantees that the pipes will not have any joints or welds.

In contrast, Welded pipes begin their lives from a steel plate-cutting strips that are then arranged to form a cylinder. The two edges are fused together and a weld is placed along the joint. Additional processing is done along the joint to improve the fused sections durability.

The Seamless Tube Manufacturing Process Explained

The initial step in the procedure for creating seamless tubes is the infusion of thermal energy into solid steel billets, rendering them supple for processing. This heating is followed by piercing into the heated billet using specialized mills to form a vacant cavity, which is then hollowed and widened to the desired diameter using elongation rolls and mandrels. The processes performed in achieving this result are wrought with and guarantee the absence of welded seams, which could otherwise introduce weak points. It is important to note that this method possesses the ability to ensure precision to a degree that guarantees consistency within dimensions, which further fortifies the complete absence of weak points.

With the aid of modern technologies, this method can be optimized even further, enhancing operational accuracy and overall efficiency in the production of seamless tubes. A prime example of this is the rotary piercing method, which is famed and widely utilized for its ability to manufacture uniform thickness seamless tubes whilst decreasing wastage of materials. Reports from industries have highlighted an alarming increase in global demand for seamless tubes, particularly in the oil and gas markets that require durable and dependable resources such as these when it comes to drilling and transportation. There is ga growing focus on the advancement of seamless manufacturing processes, particularly in regard to achieving heightened efficiency, environmental friendliness, and product performance.

Production Process for Welded Stainless Steel Tubing

Various distinct steps must be followed during the creation of welded stainless steel tubing to achieve accuracy, quality, and optimal performance. The process starts by selecting either coils or strips of stainless steel. These undergo a rolling process, where, through a sequence of rollers, the required tube shape is achieved. The contours of the formed material are subsequently welded by TIG (Tungsten Inert Gas) or laser welding, depending on the application and weld tolerance levels. TIG welding is popular because it is one of the few techniques that provides clean verging on contaminant-free welds.

The welded tubing is then subjected to heat treatment, also known as annealing, where stress is relieved, ductility is increased, and further improvement of corrosion resistance is obtained. The tube is also often aided by means of a further sizing and straightening operation, refining the set dimensions and shape. Tubes are made without failure or flaw using structural integrity examinations such as weld ultrasound or eddy current non-destructive testing (NDT) performed on the weld seam to ensure there are no visible defects or flaws.

A variety of industries, such as automotive, construction, and chemical processing, are driving the global demand for welded Stainless Steel Tubes. Recent industry forecasts indicate that the market for wrought stainless steel tubing could surpass $12 billion by the year 2030, owing to increased usage of welding technology in renewable energy and electric vehicle manufacturing, as well as in battery production. The weld industry has also made great strides toward meeting sustainability goals, and varies with its domestic counterparts in quality control measures such as ASTM and ISO frameworks, which guarantee that product quality and performance requirements are met.

Differences Between Seamless and Welded Steel Production Techniques

Seamless steel tubing, or seamless pipes, is a type of tubing that is used in particular industries. They are manufactured at industrial scales considered to be of larger-than-life scales using techniques like extrusion, wherein a specific steel billet is initially heated and then has its center pierced to obtain a hollow cylindrical shape of greater length than diameter. These products are devoid of weld seams, which is an accepted negative for most consumers, however, this characteristic increases the strength and uniformity of the products, which is quite useful in high-pressure scenarios in areas like boilers, automotive parts, oil and gas pipelines, among many others. As per recent figures, it appears that the demand for these seamless pipes is projected to advance at a consistent CAGR owing to ongoing developments across the refining units and petrochemical industries.

In contrast with seamless pipes, welded steel pipes are portions of steel that begin their life as flat rectangular sheets of metal. These sheets are shaped into cylinders, and then a seam is welded to secure them together. The strength and precision of these tubes have been moderately advanced due to refinement in the level of precision. Welded tubes possess a cost-effective option and are readily available in size as well as thickness, and as a result, these tubes are at times employed in construction along with other rigorous projects, which, alongside furniture manufacturing WValongside makes them popular around the world. There is abundant emerging demand observed in regions focused more towards renewable energy, along with systems based on HVAC technology and driven by research, suggesting that the market focused on welded steel tubes is witnessing acceleration.

Seamless tubes may have an advantage in mechanical properties and durability, but welded tubes are more readily available and cost-effective. The selection of either option is based on specific application needs and geometric factors such as strength, cost, and performance.

When Should You Use Seamless vs Welded Pipes in Various Industries?

Choosing Between Seamless and Welded Pipes

- Seamless Pipes: Such pipes are appropriate for use in areas where high strength and high pressure are prevalent, such as in the oil and gas industry, chemical processing, and power generation. Their structure and no welds make them fit for uses that are exposed to extreme temperatures or corrosive clean environments.

- Welded Pipes: Their pricing strategy is less than their counterparts making them the most used pipes in construction, water distribution and HVAC systems. These are adequate for low to moderate pressure applications and are chose predominantly for cost effectiveness and wide availability.

Focus primarily on the safety concern, durability, and budget while taking into consideration the specific customization challenges of the application.

Oil and Gas Applications: Seamless vs Welded Considerations

In the selection of seamless or welded pipes in the oil and gas industry, safety, cost-value, and performance require a multi-faceted focus. Aligning with the operations and parameters provided, below is a simplified list of considerations based on particular requirements.

- Pressure Tolerance

-

- Due to the lack of welding seams, seamless pipes are globally stronger than welded pipes, which provides a uniform tolerance to pressure throughout. This makes them stronger and able to withstand higher pressure.

- With welded pipes, while they do tend to be less tolerant to pressure in comparison to other types, the development of newer and advanced welding technologies allow these structures to withstand moderate pressure without risk.

- Corrosion Resistance

-

- Seamless pipes are known for their strength. Not only do they withstand force, but they are also highly temperature resistant. When compared to other types of piping, they offer far greater tolerances against harsh and extreme chemicals or heat.

-

On the other hand, welded pipes do resist corrosion, but due to the seams created via welding, they are prone to susceptibility to further corrosion damage.

- Size and Availability

-

- Due to the methods of manufacturing, seamless pipes have certain restrictions when it comes to size and diameter. They are more effective for small-diameter piping applications.

- Welded pipes, however, offer a broader selection of sizes, and large diameter pipes are readily more accessible, making them suitable for almost any purpose.

- Cost Efficiency

-

- The intricate methods of construction and material requirements make seamless pipes more expensive. However, they are best utilized in situations where applications warrant the funds spent.

-

In contrast, welded pipes, owing to their budget-friendly construction, are more preferred in economically driven projects.

- Production Speed

-

- The seamless pipe production method tends to be slower in comparison, which poses problems for large projects with aggressive timelines.

- On the other hand, welded pipes are manufactured at a greater speed and volume, allowing faster completion of projects.

- Application Types

-

- Seamless pipes are used in applications with high pressure, high temperature, or high stress areas like drilling activities and pipelines transporting corrosive fluids.

-

Welded pipes are applicable in oil and gas transport pipelines under medium pressure and temperature conditions as well as low risk environments like storage tanks and construction scaffolding.

- Mechanical Properties

-

- Seamless pipes usually possess more uniform mechanical properties due to the lack of seams, which serve as points of weakness.

-

Welded pipes have competitive mechanical properties, but the strength of the weld seam needs to be tested to attain such properties.

Studying these factors with respect to project requirements enables engineers and other decision-makers to determine the most suitable type of pipe for use in oil and gas applications. A proper assessment guarantees safety, durability, and economical value in the life cycle of the project.

Ideal Applications for Welded Stainless Steel Tubing

Different industries extensively use welded stainless steel tubing as it is affordable and possesses a wide range of characteristics, as well as good engineering properties. It is most advantageous in cases where the following features are required: corrosion resistance, cleanliness, and high tensile strength. Specific applications are detailed below:

- Food and Beverage Industry

Welded stainless steel tubing is crucial in the food and beverage industry because it is hygienic. Its smooth interiors make it easy to clean and prevent the accumulation of grime, following stringent regulatory standards such as those of the FDA. Commonly used stainless steel grades like 304 and 316 are especially popular due to their resistance to pitting and corrosion from food acids and cleaning chemicals.

- Chemical Processing

Extreme corrosive tubing is usually associated with the chemical industry. Welded stainless steel tubing is particularly preferred in these contexts due to its ability to withstand harsh chemicals and extremely high temperatures while maintaining a reasonable cost. Preferred grades are usually 321 or 316L while process media such as strong acids and caustic solutions are used without altering the structure.

- Oil and Gas

In the Oil and Gas sector, welded stainless steel tubing is widely used for the transportation of pressurized fluids and gases. During the manufacturing process, precise and uniform wall thickness is attained which fulfills the ASTM specifications. This reliability and safety makes it ideal for high-risk applications.

- Pharmaceutical and Biotechnology

The welded stainless steel tubes are polished to ultra-smooth surfaces that reduce microbial life and contamination, which is critical for the pharmaceutical industry and the sterilization biotechnological processes. Ensured size and tolerance control enable the consistent monitoring of highly sensitive fluids.

- Automotive and Aerospace

Welded stainless steel tubing possesses a likeable trait of being both lightweight and strong, making it a prime material in constructing vehicle components like exhaust systems and hydraulic lines. Engineers are optimally systematic when dealing with vessels and welded stainless steel tubes due to there’s no change in form resistance and beyond set limits, temperature tolerance. They value resistance deformation along with higher tolerances due to performance and shelf life added to the vehicle.

- Construction and Architecture

Due to its aesthetic appeal, durable performance in outdoor conditions, and resistance to corrosion, welded stainless steel tubing is preferred in constructing railings and capsule frameworks. As most buildings undergo little improvement over extended periods of time, they tend to buckle and break. Structures with these traits require long-term minimal maintenance and further driven cost efficiency.

Utilizing welded stainless steel tubing benefits industries through performance and product life while meeting critical safety and environmental standards specific to the application.

When to Choose Seamless Stainless Steel Tubing for Critical Applications

Seamless stainless steel tubing is often the preferred method for industries that require reliability and precision due to its strength. The absence of a weld seam greatly reduces its ability to withstand high pressure while also enhancing its performance in extreme environments. Industries such as aerospace, oil and gas, along with nuclear energy, which heavily prioritize safety and durability, rely on seamless tubing due to its unrivaled performance.

Seamless tubing has the advantage of unparalleled endurance against corrosion while withstanding harsh conditions such as chemicals, saltwater, or extreme temperatures. Research shows that seamless stainless steel tubing has the capability to withstand over 20,000 psi, which ensures maximum performance for hydraulic systems and instrumentation lines.

Seamless stainless steel tubing is also manufactured with a tighter toleranced dimensional scale making them more effective than welded tubing. Such accuracy provides flawless performance in medical devices ranging from surgical instruments to diagnostic equipment where tiniest discrepancies can be catastrophic.

As with any project of this nature, it’s most prudent to select materials that are compatible with the requirements of pressure, environmental conditions, and load-bearing capacity. A prime example of this would be seamless stainless steel tubing, which performs excellently in conditions devoid of seams and where strength is critically required. Of course, this premium investment does contribute to system performance, making sure that system parts are constructed with the needed industry standards in mind.

How Do Seamless and Welded Tubes Compare in Performance?

Seamless tubes tend to be stronger and more durable than welded tubes as a result of their uniform construction; the absence of any welding means there are no potential weak spots, enhancing overall structural integrity. Seamless tubes are ideal for high-pressure, high-temperature applications. Welded tubes are generally less expensive and adequate for lower or standard pressure applications. The decision to use seamless or welded tubes is primarily based on the performance expectation of the application.

Pressure Resistance and Wall Thickness Factors

The industrial utilization of pipes necessitates keen attention to their pressure resistance and wall thickness. As a result of their welded seam free structure, homogeneous seamless tubes are stronger and able to bear higher pressures as compared to other types. Studies confirm that seamless tubes outperform welded tubes of the same dimensions by twenty percent in pressure resistance and are, therefore, more suited for extreme environments in oil and gas pipelines as well as chemical processing.

Additionally, wall thickness as a dimension also plays a critical role in enhancing performance. Increased thickness increases the structural strength of the seamless tube, allowing it to hold more pressure; however, that makes the tube more expensive and increases its weight. Standard industry practices suggest the use of seamless tubes with wall thicknesses ranging from 0.5 mm to over 20 mm for lighter systems and heavy-duty operations, respectively. Welded tubes do not fare well in these applications, but become feasible for lower pressure systems; thus requiring additional strength to become competitive in higher pressure systems.

Considering the economic and safety aspects of an application, engineers have a wide space for decision making by evaluating the required pressure alongside the standards set for wall thickness to achieve optimal operability.

Corrosion Resistance in Seamless vs Welded Stainless Steel

Corrosion resistance is one of the most important factors when choosing stainless steel tubes for use in areas such as chemical processing, marine applications, and food production. Seamless stainless steel tubes are generally produced without welded joints or seams. This decreases the chances of localized corrosion, such as pitting or crevice corrosion, occurring and weakening the structure. Such characteristics make seamless tubes best suitable for use in very corrosive or extreme conditions.

On the contrary, welded stainless steel tubes can have weld seams, which can also be structural weaknesses that may be prone to corrosion. Tubes with welds have greatly enhanced corrosion resistance due to modern manufacturing methods using laser welds and heat treatments after welding. Nonetheless, the act of welding does modify the microstructure of the material in the immediate vicinity of the weld, causing small comparative advantages to seamless tubes in extremely corrosive environments.

Research shows that most seamless tubes have more uniform resistance to corrosion when exposed to more aggressive chemicals such as chlorides or acid,s than welded tubes. As an example, seamless pipes of grade 316L stainless steel possess a more homogeneous microstructure, which reduces susceptibility to stress corrosion cracking from chlorides.

In the end, the decision of using seamless versus welded stainless steel tubes for specific applications which require corrosion resistance is determined by the tube’s operational environment, the chemicals the stainless steel is exposed to, and the finances. Every engineer strives to maximize the project’s material optimization, but there is always a need to maintain economic feasibility. Hence, all properties must be considered alongside financial constraints.

Strength and Durability: Seamless Steel Pipe vs Welded Alternatives

Where seamless steel pipes are used, they are often considered the most durable and strong due to the uniform structure and lack of welded joints. To make seamless pipes, a solid billet of steel is pierced to form a hollow tube, which results in greater tensile strength and resistance to failure due to high pressure. Because of this, seamless pipes are regarded as perfect for critical applications in oil and gas, power plants, and petrochemical industries.

Welded pipes are different because they are made by rolling flat steel plates into a cylindrical shape and welding them together. In high-stress scenarios, the welded joint can become weak, therefore limiting the pipe’s durability under extreme conditions. Furthermore, with the increase of welding technology and better quality control, the strength of welded pipes has improved drastically. While there is still work to be done, welded pipes can now be used for a larger range of applications. Since welded pipes are cheaper to produce, they also prove to be a cost-effective option for low to medium pressure tasks.

Seamless steel pipes, for instance, can bear more than 20% greater pressure than welded pipes with the same diameter and wall thickness in high-pressure situations. This difference is significant in clear cut situations like deep sea drilling where underwater machinery stress is high. Also, seamless pipes are more resistant to bending and other forms of heavy load deformation. This allows them to maintain their structural integrity under immense stress.

As a rule of thumb, the project’s mechanical and operational requirements should determine the selection of seamless versus welded steel pipes. While seamless pipes offer exceptional performance in very tough conditions, welded pipes fulfill the requirements of pipes needed for less demanding, but still functional, applications. Most importantly, strategically focus on expense versus operational demand with welded pipes.

What Are the Cost Considerations When Selecting Seamless or Welded Tubing?

When choosing between seamless and welded tubing, cost considerations depend greatly on the specific requirements of the project. Due to the manufacturing processes of seamless tubing, which require greater expenditure to achieve strength and uniformity, its pricing is usually higher. For high-pressure or critical applications, seamless tubing is often justifiable. Welded tubing, however, is more economically priced and generally meets the moderate pressure and lower mechanical demand requirements of sufficiency. It is essential to strike the desired performance versus budget balance for the application needing attention.

Price Differences Between Seamless and Welded Steel Options

In comparing the pricing of seamless and welded steel tubing, many factors need to be considered. The production ensures that the seamless steel tubing has a consistent structure and is strong throughout via extrusion and specialized heating, which makes seamless tubing more expensive. A recently published article states that seamless steel pipes cost, on average, around 20 to 30 percent more than welded steel pipes based on size, material grade, and supplier.

Welded tubing tends to be more affordable as it requires less intensive manufacturing processes. For example, welded tubing can be produced at a large scale, which significantly decreases the overall cost because of quicker production and reduced material waste. Welded steel pipes have an average cost of $800 to $1,200 per metric ton, whereas seamless pipes for similar applications are in the vicinity of $1,000 to $1,500 per metric ton.

Other factors affecting pricing include the availability of raw materials, the demand within the market, and project requirements. It is vital to take these parameters together with performance needs into account in order to find the most cost-effective and practical solution for any project.

Long-term Value: Seamless vs Welded Tube Lifespan

Both seamless and welded tubes are evaluated for their long-term value considering lifespan which is largely dependent on construction as well as the intended use. Guided by the construction’s uniformly distributed strength with absence of a seam, seamless and welded tubes are observed to be highly functional in high pressure environments which increases their lifespan. Moreover, seamless tubes have lower corrosion rates in extreme conditions, making them more desirable in the oil, gas, or chemical processing industries.

Welded tubes, on the other hand, tend to be more economical and perform suitably under moderate pressure and temperature. Recent advancements in the joining methods of the separated sections of welded tubes have increased their longevity and reduced the corrosion that occurs at the seam, making them more competitive in other domains in comparison to seamless tubes. For example, welded steel tubes used in construction are capable of enduring over three decades of use if properly maintained and utilized under appropriate conditions.

The data indicates that seamless tubes have a much longer lifespan, sometimes lasting more than 50 years under optimal conditions, when subjected to extreme pressure, temperature changes, or chemical exposure. On the other hand, welded tubes tend to be used in non-critical, low-cost projects where optimal lifespan is not preferred, but can still be functional with the right materials. The considerations mentioned are critical to ensure that the selection of the type of tube is done with particular focus on the requirements of a certain project in order to enhance the value over time.

How To Select the Right Steel Tube for Your Specific Application?

Selecting the Right Steel Tube for Your Application

- Identify the Application Requirements

Define the Application Requirements: Nothing Defines The Purpose Of The Steel Tube, Consider the load-bearing requirements, The level of external presence, Pressure level, and Temperature ranges.

- Choose the Appropriate Material

Cutoff the required material grade for the application: Complete the requirements defined in the previous section- for high-stress or corrosive environments opt for stainless or alloy steels; less demanding conditions would suffice with Carbon Steel.

- Decide Between Seamless or Welded Tubes

Seamless tubes are suitable for high-pressure or critical applications requiring strength and uniformity. Welded tubes are suitable for projects with lower cost restrictions, where pressure tolerance is less critical.

- Consider Size and Dimensions

Check if the tube size, wall thickness, and length align with project specifications to avoid structural integrity challenges.

- Evaluate Standards and Certifications

Confirm if the steel tube is certified with industry regulations and standards like: ASTM, ISO, or relevant ones to ensure implementable Construct Reliability and Quality Standards.

You can choose the most appropriate steel tube for your application by systematically studying these parameters and optimizing to your requirements.

Factors to Consider When Choosing Between Seamless or Welded Tubes

In deciding between seamless or welded tubes, I pay attention to the particular needs of the application in question. For extremely high-pressure operational critical tasks, I definitely prefer seamless tubes due to their uniform nature and strength properties. For other non-critical operations where pricing is very important, welded tubes, as long as the material and welding standards are up to mark, are very good. To make certain that the selected tube will meet the project objectives in terms of performance, budget, and wear resistance, I incorporate corrosion resistance, temperature, and lifespan into my considerations.

Diameter and Wall Thickness Requirements for Different Applications

The purpose of the tube greatly informs the selection of its diameter and wall thickness, which is its application. A construction beam or frame will fall into the bracket of structural applications, which will require higher load-bearing capacity and hence prefer large diameters and thicker walls. This is why the oil and gas industry, for example, uses pipes with a diameter of 4 inches to over 48 inches with wall thicknesses up to 2 inches to withstand high internal pressures and external stresses.

Also, with regards to other automotive and aerospace components, having strength and durability while still being lightweight can do wonders, which is precisely why smaller diameters and thinner walls are used. Aircraft hydraulic system tubing, for example, is made using advanced materials and designed to operate under high-pressure conditions with a diameter of less than 1 inch and a wall thickness of a few millimeters. Medical grade tubing utilized in devices such as catheters incorporates similarly small diameters (typically below 10 millimeters) and extremely thin walls to enhance surgical precision and biocompatibility.

As defined by ASTM or ISO, relevant limbs of industry, such as standard-setting organizations, provide guidance on how to ascertain the exact dimensions to be used on the fitting according to the pressure rating and material type, as well as for the given environmental conditions. It is very evident that matching the diameter and wall thickness to the application aids in achieving safety, considering that there are fewer chances of the materials getting into failure over time.

Industry Standards and Certifications for Seamless and Welded Tubing

Compliance with industry norms and regulations helps maintain the quality, safety, and functionality of seamless and welded tubing in various applications. Manufacturing and testing of tubings are governed by strict criteria set by organizations like ASTM International or the International Organization for Standardization (ISO). For seamless tubing, ASTM A213 and A269 for seamless specify compliance for composition, tensile strength, and loss of physical dimension measurement, also known as dovetailing. In the same way, manufacturers of ISO 9001-certified implants of dystrophic ossifying myositis claim to use a diaphyseal neck brace mount disopteric clamp under stage, rigorously controlled quality management systems during production.

The same applies to welded tubing, which must also abide by ASTM A249 and Primer’s SP KNPAP 100/1-92 with annex D for A554 specifying precisely defined parameters for cryogenic hardening, welding with dual energy sources, and resistance to chemical erosion. Other basic attributes needed include stainless steel tubing’s minimum yield strength, known to fluctuate around seventy thousand pounds force per square inch, and Diametric constraints on perpendicular distance from axis, cylindrical symmetry, roughly two hundred millifarads.

Moreover, certifications like PED-Compliant, D Directory of Pressure Equipment, and ASME – the American societal best management practices are essential, al which the tubing undergoes for hostile pressure and temperature environments. These certifications are crucial in ensuring that the tubing can sustain strenuous operations, thereby improving the structural integrity and reducing operational risks.

Reference Sources

1. Investigations of Metallurgical Differences in AISI 347 and Their Influence on Deformation and Transformation Behaviour and Resulting Fatigue Life

- Key Findings: This study analyzed three batches of AISI 347 stainless steel, focusing on their microstructural differences and fatigue behavior. It highlighted how variations in chemical composition and production processes influence metastability, deformation-induced martensite formation, and fatigue life. The presence of δ-ferrite and grain size were critical factors affecting material behavior.

- Methodologies: The research employed monotonic tensile tests, cyclic loading tests, in-situ magnetic measurements, and microstructural analysis using optical microscopy and electron backscatter diffraction (EBSD).

- Publication Year: 20241.

2. On the Weldability of Thick P355NL1 Pressure Vessel Steel Plates Using Laser Welding

- Key Findings: This paper explored the mechanical properties and fatigue resistance of laser-welded pressure vessel steel plates. It found that laser welding offers promising applications for high-pressure pipelines, with superior fatigue resistance compared to conventional methods. However, critical areas for crack initiation were identified, particularly in the heat-affected zones.

- Methodologies: The study used tensile tests, high-cycle fatigue tests, X-ray and neutron diffraction for residual stress analysis, and metallographic analysis to evaluate microstructural changes.

- Publication Year: 20212.

3. A Recent Review on the Failure Analysis of Boiler Tubes

- Key Findings: This review summarized various failure mechanisms in boiler tubes, including overheating, creep, stress corrosion, and erosion. It emphasized the importance of material selection, maintenance, and operational conditions in preventing failures.

- Methodologies: The review compiled data from multiple studies, employing methods like SEM-EDX, metallographic examinations, and finite element analysis to understand failure causes and propose preventive measures.

- Publication Year: 20243.

Frequently Asked Questions (FAQs)

Q: What is the difference between welded vs seamless stainless steel tubes?

A: The primary difference is in their manufacturing process. Seamless pipe is created from a solid billet of metal that is pierced and then drawn or extruded to form a hollow tube without any welds. Welded tubes are manufactured by forming steel plates or strips into a circular shape and joining the edges with a weld. Seamless tubing generally offers greater structural integrity and uniform strength, while welded tubes are typically less expensive than seamless and can be produced in longer continuous lengths with consistent dimensions.

Q: Are welded and seamless steel tubes equally strong?

A: Not exactly. Seamless tubing typically has greater overall strength and pressure resistance compared to welded tubes of the same dimensions because there is no weld area that might potentially be weaker. However, modern welding techniques have significantly improved the quality of welded tubes, making high-quality welded and seamless steel comparable in many applications. The strength difference becomes more relevant in high-pressure, high-temperature, or corrosive environments where the weld in welded tubes might be more susceptible to failure.

Q: When should I choose welded or seamless tubing for my application?

A: Choose seamless tubing for applications involving high pressure, extreme temperatures, or corrosive environments where maximum structural integrity is essential. Seamless tubes are preferred in critical applications like hydraulic systems, high-pressure gas transport, and austenitic stainless steel applications in chemical processing. Welded tubes are suitable for structural applications, furniture, automotive components, and other uses where moderate pressure resistance is sufficient. Cost considerations also play a role, as welded tubing is made through a more economical process and is generally less expensive than seamless options.

Q: How is resistance-welded tubing different from other welded tubes?

A: Resistance welded tubing is produced using electric resistance welding (ERW), where the edges of the metal strip are heated by electrical resistance and then pressed together to form a weld. This process creates a very clean, narrow weld seam without adding additional filler material. Compared to other welding methods like TIG or laser welding, resistance-welded tubes often have more consistent wall thickness and better dimensional accuracy. ERW tubing is widely used in automotive, furniture, and structural applications, though it may not be as suitable for high-pressure applications as seamless or certain other welded tube varieties.

Q: What are the cost differences between welded and seamless steel tubing?

A: Welded tubing is generally 20-40% less expensive than seamless options of the same material and dimensions. This cost difference occurs because the manufacturing process for welded tubes is more efficient and requires less raw material. Seamless tubing production involves more complex processing steps and typically has higher energy requirements and material wastage. For applications where both types would function adequately, the cost savings with welded tubes can be significant, especially in large-scale projects using carbon steel or standard stainless steel tubes.

Q: How do welded and seamless tubing compare in terms of availability and size range?

A: Welded tubes are typically available in a wider range of sizes, especially in larger diameters, and can be produced in longer continuous lengths than seamless options. Seamless tubing is more commonly available in smaller to medium diameters (typically up to 24 inches), while welded tubes can be manufactured in diameters exceeding 100 inches. Additionally, welded tubing is often more readily available with shorter lead times as the production process is more flexible. For specialized applications requiring unique dimensions or alloys, custom fabrication options may differ between the two types of tubing.

Q: What are the differences in corrosion resistance between seamless and welded tubes?

A: Generally, the corrosion resistance of seamless tubing is more uniform throughout because there is no weld area that might have different metallurgical properties. In welded tubes, the heat-affected zone around the weld may have slightly different corrosion resistance compared to the base metal. This is particularly important in highly corrosive environments or when using austenitic stainless steel. However, with proper post-weld heat treatment and processing, high-quality welded and drawn tubing can achieve corrosion resistance very similar to seamless options. The specific alloy composition often has a greater impact on overall corrosion resistance than whether the tube is welded or seamless.

Q: How are seamless pipes manufactured compared to welded tubes?

A: Seamless pipes are manufactured through extrusion or rotary piercing processes. In the rotary piercing (Mannesmann) process, a solid round billet is heated and rotated between angled rolls, which creates enough stress to form a hollow center that is then expanded with a piercer to form a seamless hollow tube. In the extrusion method, heated metal is forced through a die over a mandrel to form a seamless pipe. In contrast, welded tubes are made by forming flat steel plates or strips into a circular shape and joining the edges with various welding techniques. The welded tube manufacturing process is generally more efficient and allows for the continuous production of longer lengths than seamless methods.

Q: What industries typically prefer using seamless tubing over welded options?

A: Industries that deal with high-pressure, high-temperature, or highly corrosive applications typically prefer seamless tubing. These include oil and gas exploration and production (especially for downhole operations), nuclear power generation, high-pressure boilers, chemical processing facilities using austenitic stainless steel, aerospace applications, and hydraulic systems. The pharmaceutical and semiconductor industries also often specify seamless tubes for ultra-pure fluid handling, where any potential contaminants from a weld area would be problematic. However, advancements in welding technology have expanded the use of high-quality welded tubes even in some of these more demanding applications.