Copper, a metal that is always in fashion and very adaptable, has not really withstood time and nature at all. Throughout the years, copper undergoes a slow but drastic change via a process known as corrosion, and eventually, the greenish layer, popularly referred to as “copper rust,” is formed. But what actually is the reason for this occurring and what are the consequences in terms of the longevity and visual appeal of copper? In this post, the writer will guide the reader through the process of corrosion, then assess the impact on the metal and finally, offer the reader some simple ways of prevention and upkeep. This guide will help to decode the complicated interplay between copper and its environment regardless if you are just a curious viewer or a person searching for handy information.

What is Copper Rust?

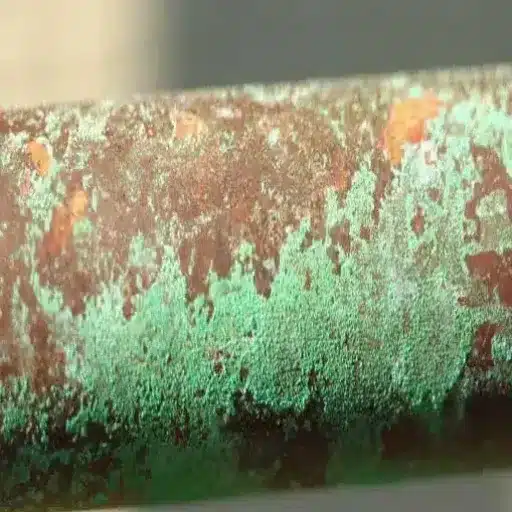

Definition of Copper Rust

Copper rust, commonly known as patina, is the result of the corrosion process that takes place when the metal is exposed for a long time to oxygen, water, and other elements in the environment. The greenish-blue color that develops on the surface of the metal consists of various compounds, such as copper carbonate, copper sulfate, and copper chloride. The most important distinction between the two processes is that while iron rust causes complete destruction of the metallic part, patina works in the reverse way by actually giving the metal more life. Patina has gradually been recognized as one of the very few things—if not the only thing—along with durability that is specially linked to copper’s strength. The strength of copper when adequately passed down or maintained is dependent on modern research and insights.

The Patina Process Explained

The gradual exposure of copper to elements is the first phase of the patina formation process. Oxidation is the very first stage of such natural phenomena, where the metal reacts with oxygen in the air and forms copper oxide. The surface reaction has been further extended by the interaction with moisture, carbon dioxide, and street pollution which in turn results in the production of the compounds such as copper carbonate, copper sulfate, and copper chloride. The presence of water and other solvents is not at all necessary as the various layers of compounds formed will be the unmistakable greenish-blue layer which is the hallmark of patina. Newer research points out that the rate of patina development is a result of ambient conditions such as humidity, pollution, and exposure to ocean air. The whole process is long but very beneficial for the copper hidden under patina by providing a strong and protective barrier against corrosion. Therefore, patina, with its twofold function of a natural show and a protective layer, is undoubtedly a wonder.

Differences Between Rust and Patina

Rust and patina, while they are both manifestations of surface oxidation, differ greatly in their composition, visual aspects, methods of production, and impacts. Rust is primarily caused by the oxidation of iron or steel during their exposure to air and moisture, which results in the formation of a thick flaky layer of reddish-brown color. This process weakens the metal, ultimately leading to its removal in layers because of almost complete disintegration. However, the oxidation of copper, bronze, and brass is the cause of patina; it gives a thin greenish-blue layer which is non-reactive to the metal thus preventing corrosion rather than allowing it to go deeper.

Newer findings point out that the climate where rust and patina develop has a significant impact on their formation. For example, rust is more likely to occur in hot, humid places, especially with the use of road salts, while patina may develop concurrently in such areas, provided the copper is supplied with more salt and sulfur compounds. Furthermore, the common belief is that rust brings about damage and ugliness, whereas patina is frequently associated with beauty and history, thus being connected to, for instance, architectural treasures or vintage items.

Key Insight: What a remarkable difference it is between patina and rust to the point of the latter being relegated to the position of mere decay.

Causes of Copper Corrosion

Environmental Factors Affecting Corrosion

The corrosion of copper is very much influenced by the environmental conditions. The oxidation of copper, which is the main reaction occurring, is highly dependent on the rate of humidity as it greatly affects the speed and availability of the reactions between copper and oxygen. Moreover, urban or coastal environments with the presence of the aforementioned substances (sulfur dioxide and chloride ions) not only promote the oxidation of copper by creating a coating (i.e. patina) on the metal but also speed up the process. Numerous reactions occur with temperature fluctuations, and the metal surfaces become more reactive due to the harsh conditions. Recent findings suggest that urban and coastal areas with high levels of pollution and salt are more aggressive towards copper and thus, there is a much higher rate of corrosion than in rural or dry areas. This, in fact, makes it necessary to consider the local environmental factors when copper materials are used in construction or other applications.

The Part That Moisture Plays In Copper Oxidation

Moisture is indispensable to the Copper Oxidation process since it is the sole medium for the chemical reactions involved. The residents of copper and moisture are such that they can interpenetrate and thus coalesce into oxide layers. Oxidation will be expedited to a large extent or to the extent where further oxidation conditions will be created due to water. The most recent studies reveal that the countries where there is heavy annual rainfall or extremely humid conditions are considered to be copper-wise losers, i.e., they experience faster rusting rates as compared to areas that are dry. Besides, moisture is a factor that contributes to the development of patinas or the greenish layers that appear on the copper. These patinas form as a result of the interplay between gases and oxidation products of copper, hence, keeping the copper underneath uncoated from corroding further. When one considers the influence of moisture on copper, one cannot overlook the aspect of copper being protected and remaining useful in different situations depending on the climate, particularly in the case of climate-sensitive areas.

The Effects of Pollutants on Copper Alloys

The pollutants that are present in the environment cause damage to copper alloys primarily in the aspect of corrosion and degradation. The rates of corrosion are increased by such pollutants as SO₂, NOx, and Cl ions. For instance, SO₂ combines with moisture in the atmosphere and forms sulfuric acid, which very powerfully attacks the surfaces of copper alloys. On the contrary, copper material is being weakened because of the high concentration of chlorides in coastal and industrial areas which are causing pitting.

According to the latest statistics, industrial emissions are the major contributor to copper alloy corrosion through the action of pollutants. Nevertheless, there are ways to protect these alloys like applying anti-corrosive coatings or adding tin to copper, which makes the alloy less prone to corrosion and hence extends its life. Furthermore, continuous environmental monitoring and the reduction of pollutant release from factories are the two primary measures that could guarantee the durability and longevity of these materials in both industrial and architectural applications.

Chemical Process of Copper Oxidation

How Copper Corrodes: A Chemical Overview

The corrosion of copper is mainly due to the combined action of these elements—oxygen, water, and industrial pollutants that are the metals’ natural environment. When copper gets in contact with the water and oxygen, it gets oxidized and a layer of copper(I) oxide (Cu2O) forms on its surface. This layer acts somewhat like a shield but, at the same time, it allows the copper to react further with water and air’s carbon dioxide, thus, producing copper carbonate (CuCO3) which is the primary component of the beautiful green patina that all of us admire and notice on the old copper architecture. Moreover, the presence of sulfide compounds in the air might facilitate the already air-pollution-caused corrosion through the copper sulfide production.

According to a recent review research study, the industrial development and urban pollution are the two most significant reasons that accelerate the copper corrosion process in cities, especially the ones with high sulfur dioxide emission. If the atmospheric pollutants are reduced and at the same time microcrystalline seals or special alloy compositions are used as preventive treatments, the corrosion rates can be lowered. Furthermore, the real-time environmental monitoring systems that are becoming more sophisticated will be able to improve the prediction and mitigation methods. The various chemical reactions together with the latest preventive techniques are all very essential in maintaining the copper’s structural and aesthetic integrity in all types of applications.

Oxidation Reactions in Copper

The oxidation of copper is essentially the reaction of copper with oxygen and the presence of water which eventually leads to copper oxide covering the metal surface. Initially, this reaction of copper oxidation and patina production might take a long time ending in a very thin layer of greenish copper carbonate, which is highly effective in preventing further corrosion of the metal. Recent findings have revealed that humidity, temperature, and pollution are the three primary factors of the environment which influence the rate and manner of oxidation. In other words, during the times of falling sulfur dioxide and other pollutants, it is the urban places where oxidation will probably occur very quickly. After deciphering the complete chemistry behind these reactions, the environmental modeling and advanced coatings can be used as the perfect tools by the industries to predict and manage the rate of copper oxidation such that the looks and functionality of the metal are not affected.

Understanding the Formation of Green Patina

The beautiful green patina on copper is nature’s way of saying that the metal has undergone a long process of oxidation due to oxygen, moisture, and air pollutants. This greenish surface that can be considered as nature’s artwork is just one of the many products of copper oxidation which is followed by different oxide species such as copper carbonate, copper sulfate, and copper chloride forming the color range of typical green. Recent environmental research data have revealed that humidity and air pollution, for instance, are the major factors that make urban or coastal areas prone to patina formation quicker than dry environments.

Conservationists now point out that the green patina on metal surfaces not only acts as a protective shield but also lowers the frequency of maintenance and, in addition, it is looked upon as a distinctive feature of historical artifacts. Interestingly, architects and restorers who are concerned about the wondrous visual and functional aspects sometimes ask how to control or accelerate this process. In this connection, to facilitate the decision, the contemporary solutions are the use of controlled environments, application of chemical accelerators, or protective sealants that either enhance or inhibit the development of patina based on certain design goals or industrial requirements. This thin line of demarcation between beauty and toughness is the reason why copper can be used in various applications while still maintaining its regal appearance.

Preventing Copper Rust

Effective Coatings for Copper Surfaces

The application of good coatings is a must if one wants to prevent copper from the corrosion process or from acquiring an unsightly patina. The main factors that inhibit moisture and other pollutants present in the environment from accessing the copper surface are protective sealants, which can be clear lacquers, polyurethane coatings, or wax-based solutions. The pioneering nanotech coatings that are getting prominence for their longevity and invisibility have been offering excellent protection and at the same time letting the occasion of copper natural brilliance. Moreover, eco-friendly coatings are not the only ones to be used; bio-based ones are gaining ground too in the marketplace as sustainable alternatives. The coating has to be the right one, whereby exposure conditions and appearance should be considered along with the functional requirements thus both aesthetic and long-term preservation would be achieved.

Best Practices for Copper Maintenance

The copper will be in perfect condition only if proper care methods are followed. If the surface is cleaned periodically with a soft cloth and a mild detergent, it will remain free of dirt and debris that would otherwise lead to tarnishing. For external copper that is to be weathered, the use of a protective coating from the very beginning will ultimately ensure that the copper will not be affected by corrosion and oxidation. It is very important to reapply the coatings at intervals that correspond to the longevity of the product and the exposure to the environment.

✓ Copper Maintenance Checklist

- ✓ Clean regularly with mild detergent and soft cloth

- ✓ Apply protective coating to external copper

- ✓ Reapply coatings at appropriate intervals

- ✓ Ensure proper ventilation around installations

- ✓ Avoid abrasive materials that could scratch surfaces

- ✓ Use copper-specific cleaning agents only

Controlling the moisture level, the main contributor to patina and degradation, can be achieved by having good ventilation around the copper installations. In case patina is meant to be done for aesthetic reasons, it will be a lot better to practice the controlled methods that will lead to an even and lasting effect. Do not use any abrasive materials that could scratch or otherwise damage the copper surfaces, and allow only cleaning agents that are specifically formulated for copper to maintain its integrity and appearance.

These best practices combined with the latest knowledge imply that long-term preservation can not be accomplished without regular maintenance and protective measures that are specifically adapted to the exposure conditions, which together will create a balance.

Use of Corrosion Inhibitors on Copper Alloys

Copper alloys, although they are widely regarded as the best materials due to their excellent resistance to corrosion and beautiful appearance, can still corrode under the right conditions. The primary role of corrosion inhibitors is to form a protective layer over the metal surface that resists corrosion. This barrier not only prevents the alloy from coming into contact with the environmental elements like moisture, oxygen and contaminants but also keeps the surface free from corrosion. The most effective corrosion inhibitors for copper alloys as per the latest data are benzotriazole (BTA) and tolyltriazole (TTA), which are highly appreciated for their capability to stop oxidation and tarnishing. In addition, researchers highlight the importance of pairing inhibitors with proper environmental controls like constant humidity and pH levels, for maximum protection. These findings highlight that there is a need for tailored strategies based on the specific applications and conditions in which the copper alloy is exposed.

Removing Copper Rust

A Stepwise Approach to Copper Cleansing

If you want to keep the copper’s integrity, you will have to adopt a cautious method along with cleaning to avoid losing its shine. Take these measures one after another:

- Materials Collection

White vinegar, salt, a soft cloth, non-abrasive sponge, and warm water are the materials that one will require. Tougher stains can be treated with baking soda or lemon juice, which can be used as extra cleansing agents. - Prepare a Cleaning Solution

Mix white vinegar and salt in equal proportions in a bowl to get a gentle abrasive paste. Or, in case of your preference for a natural solution, squeeze the juice of a lemon and mix it with baking soda. - The Solution’s Application

Soak the soft cloth or sponge in the mixture and delicately spread it over the tarnished area of the copper item. To get rid of stains and oxidation patches, use a circular motion. - Rinse Thoroughly

When the cleaning is done, the copper item is to be rinsed with warm water to get rid of the residual cleaning solution and impurities. - Dry and Polish

Take a clean, soft cloth to completely dry the surface and avoid water stains. Then gently rub the copper to highlight its natural shine. - Curtailing Future Tarnishing

To further copper’s beautification, the application of a protective layer of beeswax or the use of a specialized copper polish is recommended. This is in addition to keeping the storage in a dry environment at a controlled temperature which can also lessen the chances of oxidation.

By using the old cleaning ways along with these preventive measures, the copper utensils can last for decades in great condition.

Homemade Treatments for Copper Oxidation

Copper corrosion, primarily caused by moisture and air, can be healed through eco-friendly methods. One of the most popular methods is the combination of lemon juice and table salt. The acid of the lemon juice neutralizes the rust, while the salt’s grain wipes the surface clean. Just apply the mixture prepared to the corroded area, allow a few minutes for the reaction, and then gently rub it off with a cloth or sponge.

Then again, another solution is a mixture of white vinegar, flour, and salt that is claimed to be an effective remedy. Gradually combine the three ingredients in equal proportions to get a thick paste and then apply it onto the affected area. Leave it for about thirty minutes, then remove with warm water and finish with a dry cloth.

Baking soda is also described as one of the gentlest and most effective methods according to the recent expert sources. Its mild abrasiveness really fits the situation of buildup removal without any damage at all. The formation of a paste using baking soda and water and applying it with great care to the rust areas have always yielded good outcomes.

If you combine these natural approaches with regular cleaning and maintenance, it will be a cost-effective and eco-friendly way of restoring and protecting your copper items without resorting to harsh chemical cleaners or specialized products.

Professional Ways For Serious Oxidation

In cases of drastic corrosion, it is only normal to seek after professional solutions and specialized treatments in order to have your copper items completely restored. Amongst the common ways of restoration is the process of electrolysis, wherein an electric current is passed through the metal and corrosion is being removed at the same time the metal is kept intact. Another technique is the use of industrial-grade chemical cleaners specifically manufactured for copper restoration. These cleaners are extremely gentle and their ingredients work by dissolving the corrosion without even touching the copper surface.

In case the piece is of very high value or the damage is very extensive, it is advisable to contact a metal restoration expert. Moreover, the professionals may opt for micro-abrasion, a method that utilizes very fine particles to clean with high accuracy. When these methods are used, your copper items can be as bright as the day they were made and the risk of damage is at the same time reduced to a minimum.

Frequently Asked Questions

Does copper made of copper rust like iron and other metal alloys?

The word “rust” is often used in reference to iron and its alloys, but it does not mean the same for pure copper, as it does not undergo the oxidation process of ferrous metals. The reason for this is that rust is solely iron oxide and therefore pure copper does not contain any iron that could result in the formation of iron oxide. Quite the opposite, copper will get tarnished and possibly oxidated with the resulting green or blue-green compounds like copper oxide and verdigris instead of dark brown or black colors which are characteristic of rust. In the presence of electrolytes or acidic water, copper and its alloys can corrode very fast, for instance, copper pipes or sheets in turbulent water can have pitting. The use of copper in various areas like electrical wires and etc., depends on the metal’s conductivity and the resistance to corrosion, but sometimes coatings are applied to increase the life of the metal. The oxidation process forms a patina which gets thicker over time until it reaches the copper carbonate stage in outdoor environments at which the patina provides the metal with some protection against further corrosion.

How do the effects of corrosion on copper differ from corrosion on copper alloy like an alloy of copper and zinc?

Corrosion reactions of copper alloys such as brass (which is basically an alloy of copper and zinc) might not be the same as those of the pure metal; this is due to the presence of zinc, which changes the chemical and electrochemical conditions. The phenomenon known as galvanic corrosion might occur when the combination of copper and zinc is immersed in an electrolyte, and the less noble metal (usually zinc) is corroded quickly; this is especially true for the case of copper and zinc fittings or used metal parts that are in contact with each other. Copper will not corrode in the same manner as zinc and will rather create regions of oxide that are rather uniform, while the alloy may suffer localized corrosion or dezincification. Furthermore, the transfer of electrons during the oxidation process from either copper or the alloy to the oxidizing agent is affected by the electrical conductivity and mechanical properties of the metal or the alloy. Resistance to corrosion is among the most important characteristics that the designers consider when selecting a particular application of copper or its alloy, along with the use of coatings and sacrificial anodes.

Can copper corrode when exposed to water and oxygen, and what are the effects of corrosion on copper in plumbing?

The interaction of water and oxygen on copper results in oxidation; in the end, the rusty process will bring through the greenish verdigris or other copper compounds in case an electrolyte like seawater is present. For the plumbing case, copper pipes are less likely to corrode but still might get pinholes, where bubbling water erodes the pipe or dezincification if the water chemistry is not well controlled; treating water with low pH and high oxygen content can mitigate these risks. It is claimed that copper atoms, through this ionic dissolution and oxidation process, are joining forces with water’s oxygen atoms and ions, forming a corrosion layer that might have an impact on the quality and conductivity of the water. Copper corrosion is more rapid in some environments, especially in the presence of chlorides or sulfates, and this has necessitated the adoption of preventive measures in copper applications such as coatings or cathodic protection. The system’s long-term performance greatly depends on regular monitoring and a good understanding of the physical and chemical properties of the feed water.

Why does copper not rust like ferrous metals do, and over what time do oxidations differ, creating rust or patina on copper items?

Iron and its alloys are the main components that undergo the mineral and chemical process of rusting. The reaction between iron and oxygen along with water leads to the creation of iron oxide, which is the final product of these processes. On the other hand, copper does not contain iron, thus it does not undergo the rusting process. Rather, it undergoes oxidation which at times produces layers, like that of copper oxide or, for example, over very long periods of time, copper carbonate (verdigris). The patina that people have already acoiated with statues and roofs turns out to be a very slow oxidation process. The greenish patina can actually serve as a shield to the copper bycorrosion process, whereas rust will often lose its grip on the substrate and thus more iron will be exposed to the corrosive environment. The factors that determine the deterioration rate of copper include the presence of pollutants, electrolytes, and humidity, while in the case of the marine or industrial environment, its resistance to corrosion may be diminished. Understanding these differences can assist in material selection, for instance, the durability of copper and tin alloys (bronze) or copper and zinc alloys (brass) will be different in the same conditions.

What is the role of copper and its alloys in galvanic corrosion, can this affect copper wires and plates?

Electric current passing through dissimilar metal pairs causes galvanic corrosion; the less noble metal dies and gets the more active one (usually it is copper) which gets more corroded. Plates and wires made of copper are very stable, generally, but if they get connected electrically to other metals like steel, iron, or alloys, the iron-containing metal might lose its integrity (corrode) while copper remains safe, though it might experience localized corrosion at the junctions. When copper and its alloys are intermixed with zinc, the zinc part may get corroded (de-zincification) and consequently lose its strength to keep the assembly intact. To mitigate the effects of galvanic corrosion, engineers would use various techniques such as installation of insulating barriers, use of sacrificial anodes, or material selection based on compatibility considering factors like electrical conductivity and chemical properties of the environment. Proper material selection and fitting maintenance schedules along with the application area will suffice in reducing the adverse effects of corrosion.

What are the typical indicators of copper corrosion and what kinds of copper applications need special protection?

Copper corrosion is characterized by several indicators such as changes in the visual appearance of the copper, dark brown or black oxide formations, green or blue copper carbonate areas (also known as verdigris), little pits formed on the surface of the metal, and the reduction in electrical conductivity when copper wires or contacts are used. The major uses of copper in harsh environments that need special protection are marine hardware, outdoor architectural components, and electrical systems where conductivity is very important; thus coatings, cathodic protection, or alloy selection are the techniques used (i.e., preventing the use of metals that easily corrode). It should be emphasized that copper-tin bronzes, copper-zinc brass, and other copper-alloys exhibit different corrosion mechanisms; therefore, the alloy content determines the service life. In plumbing, the combination of aggressive water chemistry and turbulent flow can accelerate the corrosion of copper pipes, so the designers are always monitoring the electrolyte and oxygen levels to make sure that no damage occurs. Regular maintenance and understanding of the environmental conditions (both physical and chemical) will provide an opportunity for early problem detection and will greatly extend the equipment lifespan.

Reference Sources

- ThinkIR – The Study of Copper Corrosion Mechanisms

This study explores the corrosion mechanisms of copper in various water environments, including saltwater, tap water, and deionized water.

- Nature – Effects of Environmental Factors on Copper Corrosion

This research investigates the corrosion behavior of copper in an aerobic deep geological repository environment, focusing on factors like pH and chloride.

Effects of Environmental Factors on Copper Corrosion – Nature

- PubMed Central (PMC) – Study on Corrosion Behavior of Porous Pure Copper

This study examines the corrosion behavior of porous copper samples using advanced electrochemical techniques.