For choosing the right materials in regards to heat transfer operations, understanding thermal conductivity is fundamental. Because of its strength, resistance to corrosion, and deceptive beauty, stainless steel is usually the centerpiece in such conversations. But how does steel conduct heat in comparison to other metals like copper, aluminum, or brass? In this article, we will cover the essentials of stainless steel’s thermal conductivity; its performance on heat transfer phenomena, and its impact on industries like cookware, construction, and others. Engineers and designers, or any curious minds interested in the materials used on day-to-day items, will find this guide helpful in comprehending the steel’s range of conductivity compared to other metals.

What is the thermal conductivity of stainless steel, and how does it work?

Stainless steel does not conduct heat as well as other metals do, like aluminum or copper. Depending on the grade and composition, its thermal conductivity lies between 10 and 30 W/m·K. This is low in comparison to other metals. This is due to the alloyed structure of stainless steel, which contains chromium and nickel. These elements make the flow of heat more difficult and therefore make stainless steel less effective at transferring heat. He, very similar to cast iron, steel’s properties permit its use in industrial and military applications in which strong materials are needed, which also have the ability to withstand high temperatures. The components of stainless steel make it useful for thermal insulation or cookware.

Defining thermal conductivity and heat transfer properties of stainless steel

The thermal conductivity of stainless steel typically lies between 10 and 30 W/m·K at room temperature, which is affected by the alloy composition and structure. For example, austenitic stainless steels 304 and 316 grades have lower thermal conductivity compared to ferritic or martensitic grades cited earlier. The reason for this is the crystal structure of austenitic stainless steel, which hinders heat flow.

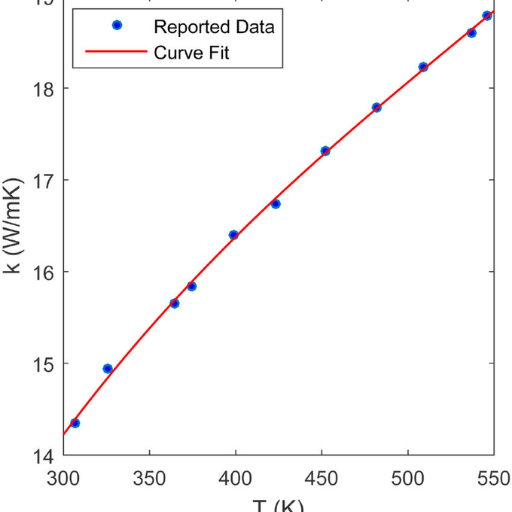

Thermal conductivity is heavily dependent on temperature. In some grades of stainless steel, conductivity increases with temperature, but it remains much lower than aluminum or copper. Copper, for example, has a conductivity of about 400 W/m·K, while stainless steel is far behind, making it ideal for applications that need thermal resistance.

The addition of alloying components such as chromium and nickel also helps lower conductivity. These elements block the continuity of the metallic bonds, reducing the material’s ability to transfer heat. Stainless steel’s specific heat capacity is about 500 J/kg·K, adding to its low thermal conductivity. This helps retain controlled heat more effectively.

Due to these features, other systems such as industrial ovens, cryogenic systems, heat exchangers, and insulated piping also benefit from them. In these circumstances, engineers use stainless steel since it provides durability without excess thermal energy transfer.

How the microstructure of stainless steel affects its ability to conduct heat

It’s Stainless Steel’s unique microstructure, which changes with different grades and compositions of the alloy, that determines its thermal conductivity. Stainless steel is typically divided into three main categories of microstructure: austenitic, ferritic, and martensitic. The presence of nickel and chromium in austenitic stainless steels yields the lowest thermal conductivity of 15 – 25 W/m·K. This is due to their face-centered cubic (FCC) crystal structure, which impedes heat vibrations, phonons, from moving freely.

In comparison, ferritic stainless steels have a body-centered cubic (BCC) structure. This allows them to generally display higher thermal conductivity at 25 – 30 W/m·K. Thanks to their microstructure, ferritic stainless steels can bound corrosion. Martensitic stainless steels, with crystal body-centered tetragonal (BCT) crystal structure, have a specific amount of alloy content and processing that allows them to have adaptable thermal conductivity, generally lying between austenitic and ferritic steels.

Moreover, the thermal conductivity of stainless steel can be influenced by microstructural features, such as grain size and the presence of impurities or secondary phases. Generally, larger grains decrease thermal resistivity, while the presence of impurities and carbide precipitates disrupt heat flow. These relationships help the engineering and material science communities to choose the correct grade of stainless steel for applications that require efficient thermal performance, such as in heat exchangers or thermally insulating materials.

Measuring the thermal conductivity of stainless steel compared to other metals

Every material or substance has the ability to conduct heat to some extent. This is known as thermal conductivity. A good example would be stainless steel is significantly valued for its strength as well as corrosion resistance. It does, however, demonstrate lower thermal conductivity in comparison to other metals. As an example, the thermal conductivity of stainless steel ranges from anywhere between 15 to 25 W/m·K, which is considerably lower than that of aluminum and copper, which have measurements of 235 W/m·K and 400 W/m· K, respectively. Other factors like the specific alloy and its microstructure,e also determine the thermal conductivity of stainless steel.

Stainless steel has significant strength, durability and resistance to corrosion, which makes it ideal for use in chemical processing equipment or food-grade piping. These applications do not demand high thermal conductivity. Aluminum is widely favored in a lot of industries while copper is the most sought after material for use in transferring heat through electrical wiring, heat exchangers, and cooling devices.

The lesser heat conductivity of stainless steel enables it to preserve temperature differences better, which makes it ideal for use in applications requiring insulation. Adjusting stainless steel’s other properties includes optimizing thermal conductivity, which helps engineers improve the efficiency of many systems.

How does stainless steel’s heat conductivity compare to other metals?

Compared to other common industrial metals like aluminum and copper, stainless steel has lower heat conductivity. For instance, copper is far more thermally conductive and thus very effective at transferring heat. Aluminum does conduct heat better than stainless steel, though not as efficiently as copper. While low thermal conductivity is less efficient for applications that demand quick heat transfer, it is helpful in applications that require heat retention or insulation.

Stainless steel vs. carbon steel: Differences in thermal conductivity

Because of their distinct compositions and structures, both stainless steel and carbon steel showcase marked differences in thermal conductivity. For example, due to the composition of chromium and nickel, stainless steel contains lower thermal conductivity as compared to carbon steel. On average, stainless steel’s thermal conductivity is around 16 W/m·K, depending on the grade. This value is significantly lower compared to carbon steel, which has thermal conductivity between 45-60 W/m·K.

Stainless steel, due to its lower thermal conductivity, is best suited in cookware that evenly retains heat or in industrial tanks that are insulated and protected from extreme temperature changes. Due to its high thermal conductivity range, carbon steel is preferable in automotive parts, heat exchangers, or any high temperature tools that require rapid heat transfer.

The different structures of these materials affect the transfer of energy in other contexts and enhance overall energy efficiency. These distinct properties show the importance of material selection for engineering decisions and how crucial performance requirements are operationally.

Why metals like aluminum and copper have higher thermal conductivity than stainless steel

Steel and aluminum have different thermal conductivities because of their atomic structures and the way they bond: race metals such as copper and aluminum have greater thermal conductivity compared to stainless steel. The amount of free-moving electrons in metals mostly dictates their thermal conductivity, and free electrons greatly move heat energy. Copper with a value of 400 W/m·K and aluminum with 235 W/m·K both have abundant amounts of free-flowing electrons, meaning energy is easy to transfer. In comparison, though, stainless steel has an alloying composition of chromium and nickel, which results in it having a complex atomic structure. This results in stainless steel having a thermal conductivity of 15-30 W/m·K, which is considered weak. The reason is that these alloying constituents, while great for improving strength and corrosion resistance, create internal obstructions to the flow of free electrons and disrupt, making the thermal conductivity weak.

Metals like copper and aluminum can serve as better examples for the distinction in difference in thermal conductivity because of how they are omnipresent in heat sinks, making sure that power output from electronic parts is cooled quickly. With stainless steel, the versatility of the material can be observed, but because of its low thermal conductivity, it is best applied in places that need strength and withstand oxidation. The sets of examples presented clearly delineate the manner in which materials can be utilized to help manage temperature outputs, with the intrinsic structure of the material being utilized.

Understanding the relatively low thermal conductivity of stainless steel in context

The relatively lower range of thermal conductivity of stainless steel alloys, having a value between 15 and 30 W/m·K, is attributed to its internal structure and composition. Unlike metals like copper and aluminum, which loosely bond electrons responsible for rapid heat transfer, stainless steel has a lattice structure that offers resistance to electron mobility. Its alloying elements, like chromium and nickel, will also influence this property as they strengthen and resist corrosion, but weaken thermal conductivity.

Putting this into context, copper, a thermal conductor, exhibits conductivity values of approximately 400 W/m·K, with aluminum around 205 W/m·K. The stark differences between the two highlight why copper and aluminum are preferred in applications like electrical wiring and heat exchangers, where heat dissipation is the priority. Conversely, stainless steel is an outstanding performer when requiring resistance to corrosion, durability, or appeal, even if thermal efficiency is sacrificed.

Along with other factors, temperature influences how a material’s thermal conductivity is exhibited. For instance, with stainless steel, while conductivity may fluctuate with temperature, it does not approach the levels of more highly conductive metals. Such observations reveal that one must be keen on the distinctive characteristics of stainless steel regarding its thermal properties when making material selections for industrial processes, especially in cases that involve precise thermal control.

Which grades of stainless steel conduct heat best?

With regards to thermal conductivity, the best performing grades of stainless steel are usually ferritic stainless steels, for example, grade 430. These steels have better thermal conductivity relative to austenitic grades like 304 or 316 due to their metallurgical structure. It is noteworthy, however, that even the most thermally conductive grades of stainless steel do not compare to other materials such as copper and aluminum, which are highly conductive.

Thermal conductivity of 304 stainless steel and other common grades

Thermal conductivity, as a material property, is the ability of a material to conduct heat energy and is one of the most important properties of a material. The thermal conductivity for stainless steel grade 304 is about 16.2 W/m·K at room temperature, approximately 20°C. Compared to other materials, the conductivity of stainless steel is low when we consider copper, standing at 400 W/m·K and aluminum, measuring 237 W/m·K.

Grade 316 stainless steel used for its superior anti-corrosion properties has approximately 14.6 W/m·K, therefore lower thermal conductivity than grade 316 due to higher molybdenum content. A ferritic grade 430 stainless steel shows thermal conductivity higher than both 304 and 316 measuring approximately, 23 W/m·K. This is due to simpler alloy composition and metallurgical structure which causes this change.

Grasping these thermal conductivity values is important for the proper selection of materials in processes involving effective heat transfer or thermal management. Stainless steels, such as 304 and 316, do provide impressive durability and versatility, but their lower thermal conductivity makes them less ideal for applications where thermal efficiency is paramount. In other cases, designers might prefer copper or aluminum for applications where high conductivity is essential.

How austenitic stainless steel differs from ferritic stainless steel in heat conduction

Austenitic stainless steels, such as 304 and 316, show lower thermal conductivity in comparison to other ferritic stainless steels. The thermal conductivity of ferritic stainless steels, like 430, is around 25 W/m·K, depending on their specific composition and temperature. In comparison, for austenitic stainless steels, it is more common for their thermal conductivity to be between 14 to 16 W/m·K. This remarkable difference is due to the differences in crystal structure between the two types of steels.

Ferritic stainless steels have a body-centered cubic (BCC) crystal structure, which allows thermal energy to be transferred more efficiently. On the other hand, austenitic stainless steels contain a face-centered cubic (FCC) crystal structure. While the FCC addition allows for improved ductility and toughness in materials, it also limits the ability to conduct heat.

Thermal conductivity in austenitic grades is also lowered due to increased amounts of alloying elements like nickel and molybdenum. These elements, though beneficial in corrosive environments and in increasing mechanical strength, have lower capabilities in thermal transfer. Thus, for the case where thermal conduction is essential, ferritic stainless steels are preferred. This is observed in the automotive industry, where ferritic stainless steels are used in exhaust systems or in heat exchangers.

Selecting the right stainless steel grade for efficient heat transfer applications

If you want to achieve optimal performance with a stainless steel grade in a heat transfer application, maximum efficiency can be achieved when thermal conductivity, corrosion resistance, and operating temperature are taken into account. Along these lines, conductivity and corrosion protection influence grade selection.

As an example, ferritic stainless steels like 409 and 439 have relatively high thermal conductivity compared to austenitic counterparts. As a case in point, automotive exhaust manifolds require effective heat sinks, and thermal conductivity values of ferritic grades which range from 24 to 30 W/m·K make them suitable for such applications. In contrast, austenitic stainless steels like 304 and 316 offer superior corrosion resistance but lower thermal conductivity (~16 to 21 W/m·K).

How different materials behave under temperature change is also an important factor to consider. In this regard, ferritic stainless steels have the upper hand. With linear expansion coefficients of around 10.2 µm/m·K, they exhibit less thermal expansion than austenitic counterparts, which generally lie between 16-18 µm/m·K. For components subjected to warm/cool cyclic conditions, for example heat exchangers or furnace fixtures, thermal fatigue poses a severe risk which is reduced with these properties.

Finally, the cost and long-term durability of the materials in particular environments must be taken into account. After considering all of these issues alongside the application-focused ones, it is possible to identify a grade of stainless steel that allows for effective heat transfer while providing reliability during operation.

What are the practical implications of stainless steel’s heat transfer properties?

Stainless steel’s transfer of heat has numerous real-world applications, particularly in an industry that requires management and control of thermal budgets. The ability of stainless steel to conduct heat justifies its use in heat exchangers, industrial ovens, and stainless steel cookware, all of which require energy efficiency and even heat distribution. In addition, the durability of stainless steel allows it to maintain its corrosion resistance and withstand thermal cycling, which is essential for changing temperatures or exposure to harsh substances. The durability, together with the thermal conductivity of the material, provides dependability, low maintenance, and cost-effective solutions for diverse operational environments.

Benefits of lower thermal conductivity in stainless steel components

The reduced thermal conductivity of stainless steel parts provides several advantages. It maintains better thermal insulation, reduces heat loss, increases energy efficiency, and improves the functionality of cookware or industrial machinery. Furthermore, delimiting temperature variations allows for greater control over processes, improves the safety of high-temperature systems, and makes the systems easier to manage.

Applications where stainless steel is widely used despite its thermal conductivity limitations

- Cookware and Kitchen Equipment

Because of its resistance to corrosion, aesthetics, and durability, stainless steel is a preferred material for pots, pans, and other kitchen utensils. Its thermal conductivity may be lower than that of copper or aluminum, but the use of clad or layered designs compensates for that. For instance, stainless steel cookware is commonly made with an aluminum or copper core to aid in proper heat distribution.

- Building and Construction

Facial and structural stainless steels are widely used for architectural facades, roofing systems, and building constructions. Destructive corrosion and anti-buildup of extreme temperatures add to its life expectancy. Using steel in such durable conditions removes the remaining concern over thermal conductivity.

- Medical and Pharmaceutical Equipment

Medical grade stainless steel is the primary metal for surgical instruments and medical implants due to its sterility strength. Besides thermal conductivity limitations, properties such as biocompatibility and sterilizability take higher priority.

- Aerospace and Automotive Components

Automotive and aerospace use stainless steel for fuel tanks, exhaust systems, and structural reinforcements. Stainless steel is essential due to it’s high tensile strength and oxidation resistance. Elevated temperatures deteriorate thermal conductivity which is not an issue for protecting equipment.

- Industrial Processing and Petrochemicals

The stainless steel industry harnesses the metal in constructing tanks, piping, heat exchangin units and even reactors. Its relatively lower thermal conductivity is offset by its ability to survive corrosive mediums, high temperature places, and also places where hygiene must be observed.

- Food and Beverage Industry

Fermenters, storage tanks, and even certain types of processing equipment utilize stainless steels because of their resistance to contamination and pure hygienic features. In these scenarios, the thermal conductivity constraints are tolerable because the material’s strength, ease of cleaning, and protection of food from harm are critical.

- Energy and Power Generation

Other branches of industry were relatively more advanced in using this alloy, these include power plants and renewable plants like solar-powered equipment, and also in nuclear reactors. The stainless steel alloy suffers a lot when being used in places with high temperatures, pressure, and even corrosive media, but its thermal conductivity is a benefit. Its utilization is clear in places like steam turbines, stainless steel is utilized in the boiler system too.

Supporting Data:

- In 2022, the worldwide market for stainless steel reached 56.3 million tons, revealing the material’s extensive adoption across industries.

- Stainless steel cookware’s reliability and durability allow it to capture 35% of the global kitchenware market.

- More than 70% of surgical instruments used worldwide are made of stainless steel, underscoring the profound impact of the material on health care.

These applications showcase why stainless steel is so valuable, especially considering the limitations in thermal conductivity.

Balancing corrosion resistance and thermal properties in stainless steel selection

Choosing the correct grade of stainless steel entails a careful consideration of its thermal properties and corrosion resistance, particularly in cases where precision and longevity are imperatives. Stainless steel grades 304 and 316 are particularly advantageous in cases where outstanding corrosion resistance is required; 316 is superior due to its greater molybdenum content, making it more applicable for marine or chemical exposure. However, grades like 430, belonging to the ferritic family, lose some resistance to corrosion in exchange for better thermal conductivity,y which is useful in heat transfer applications such as automotive exhaust systems or industrial heat exchangers.

Duplex stainless steels combine traits from different categories, which is useful for industries needing both. It is because these steels have both the austenitic and ferritic structure, meaning corrosion resistance is balanced with strength and thermal performance. Also, expansion rate matters. For example, lower thermal expansion grades like martensitic stainless steels tend to get selected for high temperature applications to reduce deformation. Since stainless steel makes up around $112 billion of the global steel market (according to recent industry data), it reflects how important balancing stainless steel performance characteristics is for engineers and designers from all fields. Knowing how to balance these properties leads to the right choice of materials for the best efficiency and durability.

How can stainless steel be optimized for heat transfer applications?

When using stainless steel for heating purposes, it is critical for the material’s corrosion resistance to soften in conjunction with its thermal conductivity. The modification of alloys and refined fabrication methods can improve the thermal conductivity of stainless steel, which is relatively low in comparison to other metals like copper or aluminum.

Stainless steel contains metals such as copper and aluminum, which possess greater thermal conductivity. Research indicated that aluminum could be used to augment stainless steel and enhance its thermal conductivity by as much as 10-15% while preserving its corrosion resistance. Moreover, advanced heat treatment processes can mold the microstructure of stainless steel, improving its thermal performance.

Optimization of complicated components of stainless steel can also prove useful. Techniques like manufacturing thinner walls or adding surface textures like grooves or fins can increase the heat transfer efficiency by providing greater exposure to the coolant and warmer surfaces.

Coating technologies have developed remarkably and now provide great attempts to improve thermal conductivity on stainless steel. Thin layers that increase thermal conductance, such as metallic nitrides or carbides, provide great improvement on heat transfer functioning while maintaining strength and resistance to oxidation.

The emerging technologies enable stainless steel to conform with the increasing requirements of many industries such as power generation, chemical processing, and modern manufacturing which need high efficiency materials with excellent performance, especially in heat transfer and durability.

Design considerations to improve heat transfer with stainless steel

When optimizing stainless steel for better heat transfer, surface end issues need special attention. Advances in material science and engineering provide the essential groundwork for these considerations. One of these issues is the surface finish of the stainless steel. A smoother surface results in less thermal resistance. For example, polished surfaces of stainless steel are known to do much better than rough surfaces in heat exchangers because of lower fouling and better thermal efficiency.

Also equally important is the selection of the Grade of Stainless Steel. The metallurgical grade of the stainless steel is equally important. The higher grade ferritic stainless steels are preferred where efficient heat transfer is required because they have higher thermal conductivity. Certain Ferritic alloys, like Type 43,0, can have thermal conductivities that can be 25% more than the austenitic counterparts like Type 304. Thus, ferritic alloys are preferable in some domains.

Polished surfaces of stainless steel are known to do far better than rough surfaces in heat exchangers because of lower fouling and better thermal efficiency.

Applying advanced geometries onto stainless steel structures like microchannels and ribbed or corrugated designs remarkably improves heat transfer. Heat exchange is further enhanced when adding these designs to promote turbulence.

Thermal interface materials and some coatings can be applied to the stainless steel surface to increase its heat transfer properties. These thin materials lower thermal contact resistance, allowing for better conductivity.

Optimized design is paying off for some industries and is being readily adopted. One case incorporates the modified performance of stainless steel surfaces in the heat exchangers, which can lead to efficiency improvements of 10-20%, directly translating to energy savings and operational value.

With the proper surface finishing, selection of appropriate materials, structural configuration, and creative coatings, the level of interfacial heat transfer with stainless steel can be remarkably enhanced, which can withstand the stresses posed by contemporary industrial requirements.

Combining stainless steel with materials with high thermal conductivity

Stainless steel’s strength, durability, and high resistance to rust make it a widely used metal in industrial businesses. Its low thermal conductivity compared to other metals does reduce its usefulness in some heat transfer systems. Partnerships with other metals like aluminum, copper, or even carbon composites, which have high thermal conductivity, can greatly enhance the performance of stainless steel and solve many difficulties.

For example, the fusion of copper and stainless steel can increase conductivity by 30% to 50%, depending on the thermal use. This alloy offers higher mechanical strength than stainless steel while also allowing great heat conduction of copper, making it useful in devices such as exchangers and electronic cooling systems. Moreover, aluminum-stainless steel composites are quite common in the automotive industry because of their lightweight properties and good thermal management, which helps save energy in the system.

Also, integrating these materials is easy using more sophisticated manufacturing processes like thermal spraying and diffusion bonding, which guarantees a low thermal resistance at the boundary. These advancements maintain the required strength in highly stressed conditions while improving the ease with which heat is transferred. Efforts in research and development are still aimed at maximizing these combinations to yield better performance indicators while ensuring ease in their economic cost and sustainability.

Innovations in stainless steel for better thermal performance

The development of new alloys with high mechanical strength and thermal conductivity is one of the remarkable improvements in stainless steel. For example, high grades like ferritic stainless steels are being developed with lower levels of impurities to enhance the heat cooling capabilities. Some studies suggest that certain ferritic stainless steels can reach thermal conductivities of about 25 W/mK, which makes them fit for demanding tasks such as in heat exchangers and cooling systems for electronics.

Moreover, other compositions of stainless steel now include exact proportions of aluminum and copper to further improve the conduction of heat. Even at high temperatures, these materials retain their corrosion resistance and structural integrity, guaranteeing dependability over a long period of time. For example, a recently conducted study showed that these new alloys are capable of sustaining maximum thermal efficiency at over 700°F (370°C), which is much higher than the other standard stainless steel grades’ endurance in industrial use.

Besides the material structure, surface treatments and modification processes are of great importance too. The use of laser structuring and surface texturing methods has been implemented to improve the thermal interaction and the rate of heat transfer by enhancing the surface area. Specific configurations subjected to these processes can, in some cases, achieve as much as 15% improvement in heat dissipation, which is critically valuable for power generation and automotive industries.

Reference Sources

- Influence of Processing and Microstructure on Thermal Conductivity of Selective Laser Melted 316L Stainless Steel4:

- Key Findings: The study explored how processing conditions and build orientation affect the thermal conductivity of 316L stainless steel produced via selective laser melting (SLM). A critical energy density of 44.4 J/mm³ was identified, below which porosity increased and thermal conductivity decreased. The average thermal conductivity was measured at 14.3 W/m-K for low-porosity samples.

- Methodology: Thermal conductivity was measured using frequency domain thermoreflectance and bulk thermal conductivity methods. The study also used transmission electron microscopy to identify amorphous regions affecting conductivity.

- Experimental Study of Effective Thermal Conductivity of Stainless Steel Fiber Felt5:

- Key Findings: This research analyzed the effective thermal conductivity of porous stainless steel fiber felt under varying pressures. It found that matrix conduction, air convection, and thermal radiation contributed approximately 40%, 37.9%, and 22.1%, respectively, to the total thermal conductivity.

- Methodology: An experimental apparatus was designed to measure thermal conductivity under different pressures, and the contributions of various heat transfer mechanisms were quantified.

- Thermal Conductivity and Electrical Resistivity of Eight Selected AISI Stainless Steels3:

- Key Findings: The study provided a comprehensive evaluation of thermal conductivity and electrical resistivity for eight AISI stainless steels, including 304 and 316. It highlighted the influence of alloying elements, heat treatment, and cold working on these properties.

- Methodology: Data was systematically compiled and critically evaluated, with experimental measurements covering a wide temperature range.

Frequently Asked Questions (FAQs)

Q: What is the thermal conductivity of stainless steel compared to other metals?

A: Stainless steel has a thermal conductivity that is significantly lower than many other common metals. For example, while stainless steel has a thermal conductivity value of approximately 14-16 W/m-K, aluminum has a thermal conductivity of about 205-250 W/m-K, and copper reaches 385-400 W/m-K. This means stainless steel conducts heat much less efficiently than these alternatives. Steel generally has better thermal conductivity than stainless steel (about 3-4 times higher), with values around 45-60 W/m-K, making regular steel a better heat conductor while still not matching aluminum or copper.

Q: Why is stainless steel preferred in applications despite its lower thermal conductivity?

A: Stainless steel is preferred in many applications because it offers an excellent balance of properties. While stainless steel has a lower thermal conductivity than aluminum or copper, it provides superior corrosion resistance, strength, and durability. This makes it ideal for environments where exposure to moisture, chemicals, or harsh conditions is a concern. Additionally, stainless steel’s ability to maintain its structural integrity at high temperatures, combined with its hygienic properties, makes it invaluable in food processing equipment, medical devices, and architectural applications where longevity and cleanliness are more important than the ability to conduct heat efficiently.

Q: How do different grades of stainless steel vary in their thermal conductivity?

A: Different grades of stainless steel show variation in their thermal conductivity based on their composition. Austenitic stainless steels (300 series) like 304 and 316 typically have thermal conductivity values of 14-16 W/m-K. Ferritic stainless steels (400 series) generally exhibit slightly higher thermal conductivity, around 20-28 W/m-K. Martensitic stainless steels can range from 20-30 W/m-K. The variation occurs because thermal conductivity is influenced by the alloying elements – higher nickel and chromium content (which make stainless steel more corrosion resistant) typically reduces thermal conductivity, while higher iron content improves it.

Q: Is stainless steel considered to have good thermal conductivity for industrial applications?

A: In absolute terms, stainless steel does not have good thermal conductivity compared to metals like aluminum or copper. However, its thermal properties are often adequate for many industrial applications where moderate heat transfer is sufficient. In situations where corrosion resistance is crucial, such as chemical processing or marine environments, stainless steel’s modest thermal conductivity is an acceptable trade-off for its exceptional corrosion resistance and durability. For applications where rapid heat dissipation is critical, engineers often use stainless steel with heat-enhancing designs (like fins) or in composite structures with better thermal conductors.

Q: How does stainless steel’s thermal conductivity affect its use in food processing equipment?

A: In food processing equipment, stainless steel’s relatively low thermal conductivity can be both a limitation and an advantage. For cooking or cooling applications, the lower conductivity means more energy may be required to heat or cool products. However, this same property helps prevent hot spots and promotes more even heating. More importantly, stainless steel’s unparalleled combination of corrosion resistance, ease of cleaning, and resistance to bacterial growth makes it the preferred material for food processing equipment despite its thermal limitations. Where necessary, designers compensate for stainless steel’s thermal properties by increasing surface area or incorporating other materials for heat transfer while using stainless steel for food contact surfaces.

Q: How does copper’s high thermal conductivity make it different from stainless steel in applications?

A: Copper’s high thermal conductivity makes it drastically different from stainless steel in thermal applications. With a thermal conductivity approximately 25 times higher than stainless steel, copper excels in heat exchangers, cooling systems, and electrical applications where rapid heat dissipation is crucial. While stainless steel trades thermal efficiency for corrosion resistance and strength, copper prioritizes thermal performance. This makes copper the preferred choice for radiators, heat sinks, and cookware bases where heat transfer is paramount. However, copper lacks stainless steel’s corrosion resistance, strength, and durability, making it unsuitable for structural applications or environments where it would degrade. Often, the best designs incorporate both metals: copper for heat transfer components and stainless steel for structural and corrosion-resistant elements.

Q: In architectural applications, how does the thermal conductivity of stainless steel compare to architecturally exposed structural steel?

A: In architectural applications, stainless steel has a thermal conductivity approximately 3-4 times lower than architecturally exposed structural steel. Regular structural steel conducts heat more efficiently (around 45-60 W/m-K) compared to stainless steel (14-16 W/m-K). This difference affects building energy performance – stainless steel creates less thermal bridging, potentially reducing heat transfer through building envelopes. While structural steel is more economical and provides better heat conductivity for some applications, stainless steel offers superior corrosion resistance and longevity for exterior architectural elements. The choice between them often depends on whether thermal conductivity is desired (for heat dissipation) or undesired (for thermal insulation), along with aesthetic considerations and exposure conditions.

Q: How does aluminum’s thermal conductivity compare to stainless steel, and when would each be preferred?

A: Aluminum has a thermal conductivity approximately 14-16 times higher than stainless steel (205-250 W/m-K versus 14-16 W/m-K). This dramatic difference means aluminum transfers heat much more efficiently, making it preferred for heat sinks, radiators, and cooking vessels where rapid, even heating is crucial. Aluminum would be chosen when lightweight thermal efficiency is the priority, such as in automotive radiators, electronics cooling, and HVAC components. Stainless steel is preferred when corrosion resistance, durability, and strength are more important than thermal performance, particularly in chemical processing, food handling, medical equipment, and exterior architectural applications. Often, designers create hybrid solutions, using aluminum for thermal components while protecting it with more corrosion-resistant stainless steel elements in exposed areas.

Q: What factors influence the thermal conductivity of the material in both stainless steel and other metals?

A: Several key factors influence the thermal conductivity of stainless steel and other metals. Composition is critical – pure metals generally conduct heat better than alloys, which is why stainless steel (an alloy) conducts heat less efficiently than pure copper or aluminum. The crystalline structure significantly impacts thermal conductivity, with more organized structures typically conducting better. Temperature affects conductivity, with most metals showing decreased conductivity at higher temperatures. For stainless steel specifically, the proportion of chromium, nickel, and other alloying elements reduces thermal conductivity as they disrupt the iron lattice structure. Manufacturing processes also play a role – cold working, heat treatment, and forming methods can all modify the microstructure of metals, subtly affecting their thermal conductivity properties.