The selection of the most suitable material for construction, manufacturing, or even DIY projects often leads to two popular options: galvanized steel and aluminum. Each of these materials has its peculiar properties and advantages, making them suitable for different applications. However, the question remains whether one is better than the other for your needs. This ultimate guide will take you through the major differences between galvanized steel and aluminum in the areas of durability, cost, environmental impact, and versatility. Whether you are a professional in the industry or a curious DIY enthusiast, the purpose of this article is to give you the necessary insights to make a wise choice.

Composition and Properties

Understanding Galvanized Steel

Galvanization is a process that coats steel with zinc, which becomes the distinguishing feature of galvanized steel. The protective barrier created by the zinc coating not only prevents the steel from rusting but also keeps it working for a longer time even in very challenging places. Steel that is galvanized is highly appreciated because it can last for a long time and is strong, thus it is commonly used in different fields: from construction and automotive manufacturing to outdoor structures like fences and handrails.

Key Insight: Galvanized steel is an economically and environmentally friendly material for many projects. The zinc-coated steel possesses very good resistance to corrosion and is highly effective in humid areas where it rains frequently. Moreover, recycling galvanized steel is completely sustainable since it can be reused without losing its strength.

Characteristics of Aluminum Metal

Aluminum is a metal that is lightweight, durable, and versatile, possessing all these properties simultaneously. One of the main characteristics is its resistance to corrosion, as it creates its own protective layer when exposed to air. Aluminum is also very malleable and can be shaped easily, making it useful in various applications, including construction and automobile manufacturing.

Additionally, aluminum demonstrates remarkable strength despite being lightweight, especially when combined with other metals like magnesium or silicon. Its excellent conductivity, both thermal and electrical, makes aluminum the most suitable material for heat sinks, cables, and electronic parts. Moreover, aluminum has the property of being 100% recyclable, indicating its sustainability and alignment with green initiatives around the globe.

Notable Properties of Aluminum:

- Lightweight yet strong structure

- Natural corrosion resistance through oxide layer formation

- Excellent thermal and electrical conductivity

- 100% recyclable without quality loss

- High malleability for easy shaping

Resistance to Corrosion in Both Metals

Aluminum and steel both demonstrate strength against corrosion, though they achieve this through different mechanisms. When an aluminum surface is exposed to air, an oxide layer forms instantly and acts as a shield against further oxidation or corrosion. This inherent nature of aluminum makes it quite resistant to rust, even in places where humidity is very high and salt is present.

Steel, conversely, needs certain treatments or alloying to improve its resistance to corrosion. For example, stainless steel is chemically mixed with chromium, producing a passive layer of chromium oxide on the surface that inhibits the rusting process completely. Nevertheless, plain carbon steel may be more prone to rusting unless protected through coating with zinc (as in galvanized steel) or employing other protective methods.

| Material | Corrosion Protection Method | Best Environment |

|---|---|---|

| Aluminum | Natural oxide layer formation | High humidity, salt presence, marine environments |

| Galvanized Steel | Zinc coating (sacrificial protection) | Outdoor structures, moderate moisture exposure |

| Stainless Steel | Chromium oxide passive layer | Chemical exposure, high strength requirements |

Advantages and Disadvantages

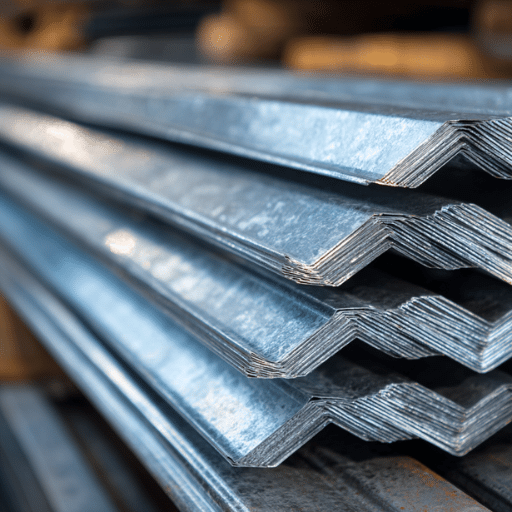

Durability of Galvanized Steel

The usage of galvanized steel is widely accepted due to its remarkable durability, which it achieves through the zinc coating that acts as a shield against corrosion and rust for the underlying steel. This quality makes it highly attractive for outdoor and industrial applications where conditions of moisture and adverse weather are routine.

Galvanized steel is extensively used in construction, automotive, and energy sectors because of its long life and low maintenance requirements. Nevertheless, although it is very effective in preventing rust formation, it is not as resistant to highly acidic or chloride-rich environments. In such cases, materials like stainless steel can provide better solutions. Therefore, it is essential to carefully weigh factors of cost, environment, and purpose to determine if galvanized steel is suitable for a particular project.

Lightweight Nature of Aluminum

Aluminum is renowned for its lightness, a characteristic that raises its demand in industries such as aerospace, automotive, and construction. It weighs only about one-third of steel, bringing major benefits in terms of reducing overall weight in structures or vehicles, which leads to better fuel efficiency and lower energy consumption.

Sustainability Advantage:

The recycling of aluminum and its resistance to corrosion contribute significantly to its value, aligning perfectly with global sustainability goals. This versatility and adaptability ensure aluminum remains indispensable across a broad spectrum of applications.

Maintenance Requirements

The remarkable maintenance properties of aluminum are largely attributed to its natural resistance to corrosion and its durability. For outdoor structures or applications, simple cleaning with mild soap and water on a regular basis is usually sufficient to keep dirt and debris from accumulating.

Maintenance Checklist:

- Conduct periodic surface inspections for cuts or scratches that may damage the protective oxide layer

- Clean regularly with mild soap and water to prevent debris accumulation

- In tough conditions (coastal or industrial areas), apply occasional protective coating to improve lifespan

- Check for signs of galvanic corrosion if aluminum is in contact with dissimilar metals

Common Applications

Use in Construction and Roofing

Aluminum has become the most preferred material in the construction and roofing industries due to its numerous advantages, including lightness, strength, resistance to corrosion, and flexibility of use. There is increasing acceptance of eco-friendly building materials, where aluminum is frequently highlighted for being recyclable and energy-efficient.

The natural oxide layer provides aluminum with immunity against rust and breakdown even in extremely unfavorable conditions. Additionally, modern manufacturing practices ensure aluminum roofing panels last longer and offer more variation, making it possible to withstand the roughest weather without increasing heating costs through the use of solar-reflective coatings.

Automotive Industry Applications

Aluminum is indispensable for the automotive sector owing to its lightness and remarkable strength-to-weight ratio. These features help manufacturers produce vehicles that consume less fuel while ensuring overall safety. There is increased interest in environmentally friendly automotive innovations, and aluminum naturally emerges as a key material in realizing this demand.

Manufacturers use aluminum for various vehicle components, from engine blocks to body frames, all with the objective of making vehicles less polluting and more powerful. Additionally, aluminum’s recyclability aligns with the automotive industry’s sustainable practices, making it a vital factor in the future of vehicular innovation.

Manufacturing and Industrial Uses

Aluminum’s versatility has made it dominant in various manufacturing and industrial applications. Its merits, especially in eco-conscious industries, have gained increasing recognition. The material is often chosen for sustainable manufacturing due to its outstanding characteristics, including lightweight, corrosion resistance, and extraordinary strength-to-weight ratio.

These qualities make aluminum highly sought-after in industries such as construction, aerospace, and electronics, where efficiency and dependability are paramount. Moreover, being fully recyclable, aluminum perfectly coincides with the global movement toward reducing adverse environmental effects, bolstering its role in the shift toward greener industrial practices.

Cost Comparison

Initial Costs of Galvanized Steel vs Aluminum

The initial costs of galvanized steel and aluminum differ through several factors, such as material accessibility, market demand, and production costs. Generally, galvanized steel is less expensive initially than aluminum due to the less intensive production process and the availability of raw materials such as iron.

| Material | Average Price Per Pound | Initial Cost Advantage |

|---|---|---|

| Galvanized Steel | $0.50 – $1.50 | More economical upfront |

| Aluminum | $2.00 – $3.00 | Higher initial investment |

Note: Aluminum’s stronger corrosion resistance and greater strength-to-weight ratio might eventually turn its higher initial cost into a favorable factor in the long run, depending on the application where durability and weight savings are primary concerns.

Long-term Value Considerations

When comparing the long-term value of galvanized steel and aluminum, you need to consider many factors beyond initial cost. Consumers and industry actors are rapidly choosing materials that score high on sustainability and lifecycle performance.

Aluminum has much lower environmental impact and is highly eco-friendly as it is recyclable, eliminating production costs in the long run. Galvanized steel may be less expensive initially, but its durability against rust and wear may lead to higher maintenance costs over time. Hence, if environmental considerations are a concern, aluminum is the right choice, even though it is pricier upfront.

Financial Implications of Choosing Between Materials

Financially speaking, material choice has significant implications, and recent data reveal that more attention is being given to life-cycle costs rather than just initial expenses. Aluminum, even though its first cost might be high, eventually proves to be an economical choice because it requires less frequent replacements and offers longer usage time.

Cost Analysis Summary:

- Galvanized Steel: Lower upfront costs but potential for higher maintenance expenses over time

- Aluminum: Higher initial investment with lower long-term maintenance and replacement costs

- Trend: Industry prioritizing total cost of ownership over short-term savings

Durability Under Stress

Case Studies of Galvanized Steel Performance

Galvanized steel has repeatedly shown remarkable durability and effectiveness in various applications, especially in industries where materials are subjected to extreme environments.

Real-World Examples:

- Clifton Suspension Bridge (UK): Galvanized components have withstood elements and traffic weight for over a century with minimal corrosion noted

- Midwest United States Agriculture: Galvanized steel fencing outlasted extreme weather including heavy rains and snow, remaining functional for over 30 years with minimal maintenance

- Infrastructure Lifespan: In corrosive environments, galvanized steel can add 50 years or more to infrastructure life, outperforming untreated or coated steel options

Aluminum Performance in Challenging Environments

Aluminum has proven to be a highly adaptable material in the toughest environments where mechanical strength, light weight, and corrosion resistance are needed most. The natural oxide layer on aluminum makes it excellent at fighting against rust and degradation even in rigorous places such as marine environments and industrial settings with high humidity and pollution.

Recent studies indicate that properly treated aluminum alloys can not only resist but thrive under large temperature differences in aerospace and automotive fields, making it the ideal material for those applications. Aluminum processing requires less energy and time compared to steel, leading to a smaller environmental impact. The prerequisites of aluminum for projects involving weight reduction without loss of durability—particularly in transportation sectors trying to enhance efficiency and lower emissions—are at the forefront.

Comparative Analysis of Stress Resistance

When considering stress resistance in lightweight applications, aluminum stands out compared to materials like steel and titanium. Recent engineering data supports that aluminum alloys show excellent stress resistance due to their natural flexibility and ability to bear cyclic loading without fatiguing.

The 7075-T6 alloy is a prime example, with extensive applications in the aerospace sector where high strength-to-weight ratio and endurance under high stress conditions are both critical. When force is applied beyond what a material can withstand, steel will eventually deform permanently, while aluminum’s elastic limit ensures efficient recovery, making it more reliable in dynamic environments. This flexibility proves valuable for construction and automotive sectors, revealing that material science continues innovating to maximize usefulness in challenging cases.

Frequently Asked Questions

Can both galvanized steel and aluminum handle outdoor roof applications?

Both galvanized steel and aluminum function well in roofs exposed to the elements but with varied performances depending on conditions. While the zinc coating on galvanized steel protects against rust and corrosion, aluminum creates a protective oxide layer that prevents further corrosion. Aluminum is typically lighter, making it preferred where weight is an issue, while galvanized steel is most suitable where tensile strength and impact resistance are crucial. For coastal roofing, although aluminum has better resistance against saltwater corrosion, it can experience galvanic corrosion if in contact with other metals. Selection should consider alloys, local climate, and sustainability goals.

How do the differences between galvanized steel and aluminum affect corrosion resistance?

The corrosion resistance differences stem from their protective mechanisms and environmental interactions. Galvanized steel features a zinc layer that provides sacrificial corrosion protection, degrading before the underlying carbon steel. Aluminum forms a natural oxide layer that bonds and prevents further oxidation. In highly acidic or polluted environments, zinc coating may degrade rapidly, while properly chosen aluminum alloys may offer better long-term stability. Steel is generally stronger and heavier, helping in conditions with abrasiveness. For impact-resistant applications, choose steel; for superior corrosion resistance, choose aluminum.

Considering metal properties, which would one select for building components?

Choosing between galvanized steel and aluminum for construction components requires careful consideration of strength, weight, and corrosion resistance. Galvanized steel provides more tensile strength and is preferred for heavy-duty parts, while aluminum excels in lightweight applications. Different aluminum alloy grades offer varying properties, with pure aluminum being softer than most steels. Consider surface treatment and whether zinc can protect steel during fabrication where cuts or welding occur. Also factor in lifecycle and recyclability: aluminum being recyclable is less harmful to the environment, though steel recycling processes are more established.

Is aluminum superior to galvanized steel in corroding environments?

Aluminum may be the better choice over galvanized steel in many corroding environments, but it depends on the specific case. Aluminum’s involuntary oxide layer formation provides protection that prevents corrosion development throughout the material’s life, performing similarly to galvanized steel in marine and humid conditions. In galvanic environments where contact with other metals occurs, aluminum corrosion could occur unless proper isolation is implemented. Generally, steel sustains less damage due to protective zinc coating when physical damage occurs. Aluminum alloys specially designed for high salt and acid resistance typically prevail over standard galvanization. Material choice depends on specific chemical exposure, required tensile strength, and whether maintenance repainting is acceptable.

What are the most frequent usages of galvanized steel and aluminum in construction?

Zinc-coated steel and aluminum applications differ based on their unique properties. Galvanized steel excels in resisting mechanical damage and physical wear, making it ideal for structural supports, beams, railings, and areas requiring high tensile strength and impact resistance. Aluminum, being lightweight yet pliable, is extensively used for door and window frames, building facades, roofs, and soffits where less dead load and superior corrosion resistance are priorities. Many projects feature collaboration between aluminum and galvanized metal components, leveraging aluminum’s natural protective layer and galvanized steel’s mechanical strength for optimal performance.

What factors distinguish between galvanized steel and aluminum for outdoor furniture and fixtures?

Weight, corrosion resistance, and maintenance should be main factors when deciding between galvanized steel or aluminum for outdoor furniture and fixtures. Aluminum is generally preferred for lightweight furniture as frames are easily moved, and the aluminum oxide layer protects against rusting, making maintenance minimal. Galvanized steel has superior strength, making it common for heavy-duty fixtures like benches and railings, with zinc coating protecting against rust and corrosion. Consider the finish: painted or powder-coated galvanized metal can extend lifespan, while anodized aluminum enhances surface hardness and corrosion resistance. Also assess cost, recyclability (recycled aluminum is commonly used), and whether fixtures will be exposed to dissimilar metals that may trigger galvanic corrosion.

Conclusion

The choice between galvanized steel and aluminum ultimately depends on your specific project requirements, environmental conditions, and budget considerations. Both materials offer distinct advantages that make them valuable in different contexts.

Key Takeaways:

- ✓

Choose Galvanized Steel when you need maximum strength, impact resistance, and cost-effectiveness for heavy-duty applications, structural supports, and projects where weight is not a primary concern. - ✓

Choose Aluminum when lightweight construction, superior corrosion resistance, minimal maintenance, and environmental sustainability are priorities, particularly in marine environments, aerospace, and automotive applications. - ✓

Consider Long-term Value rather than just initial costs—aluminum’s recyclability and lower maintenance requirements often offset higher upfront expenses over the material’s lifecycle. - ✓

Evaluate Environmental Conditions carefully—coastal areas favor aluminum’s saltwater resistance, while inland industrial applications may benefit from galvanized steel’s mechanical durability.

Reference Sources

- International Journal of Automotive and Mechanical Engineering (IJAME) – Corrosion Comparison of Galvanized Steel and Aluminum: This paper highlights the corrosion resistance of aluminum compared to galvanized steel under various conditions. Corrosion Comparison of Galvanized Steel and Aluminum – IJAME

- Academia.edu – A Detailed Comparison of Various Steel Types: This paper compares stainless steel, structural steel, and aluminum in terms of their chemical and mechanical properties and applications. A Detailed Comparison of Various Steel Types – Academia.edu

- Defense Acquisition University – Experimental and Modeling Studies of Atmospheric Corrosion of Steel and Aluminum Alloys: This study explores the atmospheric corrosion rates of galvanized steel and aluminum alloys under different conditions. Atmospheric Corrosion of Steel and Aluminum Alloys – DAU