Steel is widely recognized as the most versatile and broadly used material in engineering and industrial applications. Its thermal conductivity is a critical factor that influences steel’s performance under different conditions, sometimes serving as a decisive element in mission-critical applications.

Understanding steel’s heat conductivity is essential for designing systems heavily dependent on thermal management—from construction and manufacturing to cutting-edge technologies like aerospace and energy systems. This comprehensive guide explores the principal thermal properties of steel, factors affecting conductivity, and ways to optimize these properties in real-world applications.

Introduction to Thermal Conductivity

Thermal conductivity refers to the ability of a substance to transfer heat. It is quantifiably represented in watts per meter-kelvin (W/m·K) and determined as the rate of heat flow through a material at a temperature difference.

The thermal conductivity of steel is influenced by its composition, microstructure, and temperature among other factors. Generally, low-carbon steels conduct heat better than alloyed steels because the latter have more impurities that hinder heat flow.

This characteristic is vital in operations where proper heat dispersing is needed—such as heat exchangers or structural components subject to changing thermal loads. Understanding and controlling thermal conductivity are critical for material performance and reliability.

Definition of Thermal Conductivity

Thermal conductivity, often represented by the symbols k or λ, is a material characteristic that describes the process of heat flow through the material. It is measured in watts per meter-kelvin (W/m·K), representing the amount of energy passing through a material segment per unit of time in the presence of a certain temperature gradient.

Fourier’s Law of Heat Conduction:

q = -k · ∇T

where q = heat flow per unit area

k = thermal conductivity

∇T = temperature gradient

This equation demonstrates that the rate of heat transfer is a linear function of the thermal conductivity of the substance with the constant of proportionality being the conduction rate.

Common Thermal Conductivity Values:

- Copper: 398 W/m·K – Excellent thermal conductor

- Aluminum: 237 W/m·K – High thermal efficiency

- Steel: 15-60 W/m·K – Varies by composition

- Glass: 1 W/m·K – Significant insulating properties

Importance of Thermal Conductivity in Metals

The thermal conductivity properties of metals like copper and aluminum make them indispensable in industries requiring efficient heat transfer. These materials are commonly used in applications where their ability to dissipate heat quickly is essential:

| Metal | Thermal Conductivity | Primary Applications | Key Advantages |

|---|---|---|---|

| Copper | 398 W/m·K | Heat exchangers, electrical wiring, electronic cooling components | Rapid heat dissipation; excellent electrical conductivity |

| Aluminum | 237 W/m·K | Heat sinks, aerospace thermal management, automotive systems | Lightweight; good thermal efficiency; cost-effective |

| Steel | 15-60 W/m·K | Construction, manufacturing, pressure vessels | Excellent mechanical strength; versatile; durable |

🔬 Recent Advancements: Nanotechnology developments are focused on enhancing thermal properties of metals through coatings and modifications. These innovations are particularly important for processors, circuit boards, and other electronic components where efficient heat removal prevents overheating and contributes to reliability and lifespan.

Overview of Steel as a Metal

Steel is a multifaceted alloy composed mainly of iron and carbon, with other elements such as chromium, nickel, manganese, and vanadium added in different proportions depending on the application. Material characteristics such as excellent tensile strength, toughness, and ductility have made steel a primary choice for various industries.

📊 Global Steel Usage: Worldwide, steel comprises approximately 75% of total modern building materials, demonstrating its profound role in the infrastructure sector. Through techniques like nanotechnology and thermal property manipulation, steel continues to improve and is increasingly used in innovative engineering solutions such as eco-friendly buildings and high-performance machinery.

Thermal Conductivity of Steel

The thermal conductivity of steel is a key property responsible for its performance in various applications like construction, manufacturing, and thermal systems. This value typically ranges between 15 to 60 W/m·K depending on composition and alloy type.

Carbon Steel vs. Stainless Steel

Carbon Steel: Generally has higher thermal conductivity due to simpler composition

Stainless Steel: Lower thermal conductivity due to alloying elements like chromium and nickel, which influence heat transfer characteristics

Recent analysis shows that incorporation of nanostructures in material science has improved thermal management of steel. Energy efficiency has been maximized in applications such as heat exchangers, pipelines, and structural components in high-temperature areas. Steel’s ability to conduct heat excellently while retaining good mechanical strength allows engineers to develop materials appropriate for the most challenging scenarios, including aerospace and renewable energy sectors.

Factors Affecting Thermal Conductivity of Steel

Composition and Alloying Elements

Steel’s thermal conductivity varies significantly with composition and alloying elements. Pure iron has relatively high conductivity, but thermal properties change as carbon, chromium, and nickel are added.

- High-carbon steel: Lower conductivity due to carbon affecting lattice structure

- Stainless steel: Chromium and nickel disrupt heat flow, resulting in lower conductivity

- Advanced variants: Compositions optimized for specific thermal demands

Material Density and Microstructure

Density and microstructure are critical factors affecting thermal conductivity. Variations in grain size, phase distribution, and dislocation density can greatly impact performance.

- Denser materials: Fewer voids allow more uniform heat transfer

- Complex microstructures: Austenitic or martensitic phases may have lower conductivity due to increased scattering

- Processing methods: Heat treatment and forging control microstructure and thermal performance

Temperature

Temperature significantly influences thermal conductivity. Most steels show decreased thermal conductivity with increasing temperature, though the degree varies with composition.

- High temperatures: Increased atomic vibrations cause greater phonon scattering

- Critical applications: Turbines and industrial furnaces require careful material selection

- Performance considerations: Material choice must ensure longevity and efficiency

Comparison of Steel with Other Metals

Steel is an alloy consisting mainly of iron and carbon, known for its high tensile strength and low cost. Comparison with aluminum, titanium, and copper reveals that each metal has specific physical and chemical properties depending on intended applications.

| Comparison | Key Differences | Advantages | Best Applications |

|---|---|---|---|

| Aluminum vs. Steel | Steel is 2-3x heavier than aluminum | Aluminum: Lightweight, natural oxide layer for corrosion resistance Steel: Greater strength and longevity, superior wear resistance |

Aluminum: Aircraft, automotive Steel: Construction, heavy industry |

| Titanium vs. Steel | Titanium has highest strength-to-weight ratio | Titanium: Best corrosion resistance, excellent for marine/chemical environments Steel: Most economical, most workable |

Titanium: Aerospace, biomedical, military Steel: General industrial applications |

| Copper vs. Steel | Copper is best thermal/electrical conductor but softer | Copper: Superior conductivity, high ductility Steel: Better for structural loads, more economical |

Copper: Electrical wiring, heat exchangers Steel: Load-bearing structures |

Industry Insight: Steel continues to be the most popular material in numerous areas due to its excellent strength-to-weight ratio, versatility, and scalability of production. However, material science has opened new avenues for alternative metals in markets specifically targeted for certain performance characteristics like weight reduction or excellent corrosion resistance.

Applications of Steel Based on Thermal Properties

Heat Exchangers and Boilers

Steel is the material of choice due to high-temperature resistance and good thermal conductivity. Stainless steel is particularly used as it resists scaling and maintains integrity at high temperatures, supporting efficiency in power plants and chemical processes.

Furnace Components

High-chromium and nickel steel alloys are main materials in furnace construction. These materials withstand extreme heat with no thermal cycling and gradual structural degradation, essential for forgers and metallurgists.

Automotive Exhaust Systems

Modern exhaust systems depend on steel’s capacity to handle combustion heat without losing resistance to oxidation and corrosion, guaranteeing long life and high performance under thermal stress.

Pressure Vessels

Industrial pressure vessels require materials withstanding both high pressures and temperatures. Carbon steels and low-alloy steels with thermal properties designed for oil and gas are common choices in processing units.

Cookware and Kitchen Equipment

Stainless steel cookware offers outstanding thermal stability, uniform heat distribution, and resistance to thermal shock. Its durability under repeated heating makes it preferred in both professional and household kitchenware.

Wiedemann-Franz Law and Its Relevance

The Wiedemann-Franz Law establishes a straightforward relationship between the electrical and thermal conductivity of metals, stating that the ratio of these characteristics is directly proportional to temperature.

Wiedemann-Franz Law:

L = κ / (σ × T)

L = Lorenz number (~2.45 × 10⁻⁸ WΩK⁻² for most metals)

κ = thermal conductivity

σ = electrical conductivity

T = absolute temperature

Principle Foundation: This law is based on the nature of free electrons in metals, which are the common factor for both heat and electricity conduction. This principle significantly impacts designing systems requiring high thermal and electrical efficiency.

Practical Applications:

- Microelectronics: Copper and aluminum usage reduces energy loss and implements good heat dissipation

- Heat Exchangers: Material selection for optimal thermal and electrical control

- Power Generation: Technologies where controlling heat and electricity is crucial

- Thermoelectric Materials: Renewable energy systems optimization

Understanding the Wiedemann-Franz Law

The Wiedemann-Franz Law is a core principle in solid-state physics connecting thermal conductivity and electrical conductivity with temperature as a proportional constant. Its mathematical formulation appears as κ/σ = L·T, with validity assumed primarily for metallic conductors.

⚠️ Important Research Development: Recent studies point out the significance of investigating nonconformity with the Wiedemann-Franz Law in nanostructured and composite materials, challenging traditional views. Research on quantum materials and unusual conductors indicates that factors like electron-electron interactions and lattice vibrations (phonons) can produce considerable anomalies.

Breakthrough Materials: Materials showing low thermal conductivity but moderate electrical conductivity—such as certain complex oxides and organic polymers—are highly researched and approaching breakthroughs in renewable energy resource transfer.

📈 Search Trend Analysis: Rising demand for high-performance thermoelectric materials research reflects global prioritization of energy efficiency and sustainability. Queries like “breaking the Wiedemann-Franz ratio,” “quantum thermal properties of materials,” and “low thermal conductivity innovations” indicate strong interest in understanding the limits and extensions of this law.

Application of the Law to Different Alloys

Copper-Aluminum Alloy

Acknowledged for excellent conductivity, this alloy nearly ideally follows the Wiedemann-Franz Law under standard conditions. However, at cryogenic temperatures, electron scattering mechanisms drastically change the ratio of thermal to electrical conductivity.

Nickel-Chromium Alloy (Nichrome)

Extensively used in high-resistance applications, Nichrome displays lower thermal conductivity compared to its electrical conductivity, revealing deviation attributed to peculiar electron scattering models and presence of localized electronic states.

Iron-Silicon Alloy

With average electrical conductivity, this alloy suffers thermal conductivity loss caused by its crystalline nature and phonon scattering. Controlled doping can render thermal and electrical transport properties even more separated.

Titanium-Aluminum-Vanadium Alloy (Ti-6Al-4V)

Celebrated for high strength-to-weight ratio, this alloy shows striking differences from classical law predictions. The chief reason is the composite microstructure and thermal resistance dominated by phonons.

Zinc-Copper Alloy (Brass)

Frequently used for industrial and decorative applications, brass aligns closely with the Wiedemann-Franz Law at room temperature. However, exceptions occur at higher temperatures due to thermally activated electron-phonon interactions affecting conductivity dynamics.

Implications for Engineering and Design

Conductivity—both thermal and electrical—of materials such as silicon and brass has significant impact on engineering and design decisions. Discrepancies between observed and predicted values by the Wiedemann-Franz Law assist in creating modern semiconductors where heat dissipation management is critical.

Engineering Applications:

- Deploy resistance materials in specific areas to minimize unwanted heat transfer

- Use conductive materials like brass to assure product lifetime

- Leverage computational tools and data insights for material innovations

- Modify designs according to technological and industry needs

Heat Conductivity in Certain Metals

Heat conductivity in metals such as copper, aluminum, and brass is crucial in electronics, building, and manufacturing industries. Engineers and researchers utilize search trend data to discover hot topics, questions, and innovations in heat conductivity.

Data-Driven Material Selection: Considerable searches about “efficient heat-conducting alloys” or “thermal management for electronics” indicate increased interest in material optimization for specific applications. By integrating this data with advanced material science research, engineers can meet real-world industry needs and manufacture products that are both efficient and long-lasting.

Comparison of Heat Conductivity in Various Alloys

| Alloy/Metal | Thermal Conductivity Range | Cost Consideration | Primary Use Cases |

|---|---|---|---|

| Copper | ~400 W/m·K | Higher price; targeted for superior performance | High-performance electrical and thermal applications |

| Aluminum Alloys | 200-250 W/m·K | Low price; adaptable to different industries | Lightweight structures requiring efficient heat dissipation |

| Stainless Steel | ~15 W/m·K | Moderate cost; excellent for heat retention | Applications demanding heat retention and corrosion resistance |

Recent trend analysis reveals that user inquiries normally reflect a trade-off between material performance and cost-efficiency. Engineers must make decisions about alloys matching application requirements by considering both technical and economical factors.

Case Studies: High Conductivity Alloys

Example 1: Copper Alloys in Electric Systems

Copper alloys with their fantastic conductivity remain the preferred choice for electrical applications. Among them, C11000 electrolytic tough pitch (ETP) copper is most commonly used for electrical wiring owing to its high conductivity—close to 100% International Annealed Copper Standard (IACS).

Industry Impact: Recent statistics show telecommunications and power distribution sectors are main adopters of such alloys to make energizing processes more efficient and reduce energy loss—a critical concern for renewable energy grids.

Example 2: Aluminum Alloys as Light Conductors

Aluminum alloys can be considered the best material choice for many applications due to being less expensive and, to some extent, less conductive than copper. For absolute least weight, alloy grades such as 1350, which have aluminum purity over 99.5%, are used in overhead power lines and aerospace applications.

Market Trends: Growing trend for materials with high conductivity, lightweight properties, and good price point. Latest developments show aluminum alloys are widely used in industries where weight reduction is essential, offering optimal performance at low cost.

Future Trends in Metal Heat Conductivity Research

The research on metal heat conductivity has a promising future inclined towards materials that are both high-conductivity and lightweight, such as advanced composites and alloys currently in development.

🔬 Emerging Technologies

- Graphene-Infused Metals: Attracting attention due to amazing thermal and electrical properties, offering great prospects in electronics and energy systems

- Nanotechnology: Manipulating materials at atomic level to create thermally efficient yet structurally strong materials

- Advanced Composites: Combining materials to achieve superior performance characteristics

🌍 Sustainability Focus

Sustainability is the overriding factor as industries clamor for materials with least possible environmental impact. Key approaches include:

- Preference for recyclable and eco-friendly alloys

- Recycling of binders and materials integrated into production processes

- Active research in academic and industrial sectors

🤖 Data-Driven Development

Conventional data-driven methods have proven highly effective in recent years:

- Machine Learning: Predicting and modeling thermal behavior in metals

- Artificial Intelligence: Accelerating development of new materials

- Predictive Analytics: Speeding up material innovation processes

These developments, combined with requirements for multifunctional materials, indicate this field will not only change rapidly but also keep pace with challenges of modern technology and industry.

Resources and Properties Database

The use of advanced data sources, including newest search engine insights, has transformed the process of classifying materials according to their properties and resources. Resources and Properties Database utilization of real-time data supports precise and exhaustive material information including thermal, mechanical, and chemical behaviors.

Accessing Thermal Properties Databases

To properly and precisely access databases containing thermal properties, leverage several online platforms and tools offering extensive material information:

- MatWeb: Comprehensive material property database

- Specialized Repositories: Industry-specific material information sources

- Search Engine Technology: Simplifies process of finding curated thermal data

- Comparative Tools: Enable efficient material comparisons

Example Queries: Typing “thermal conductivity of aluminum” or “specific heat capacity of polymers” usually leads to reliable sources with trustworthy data.

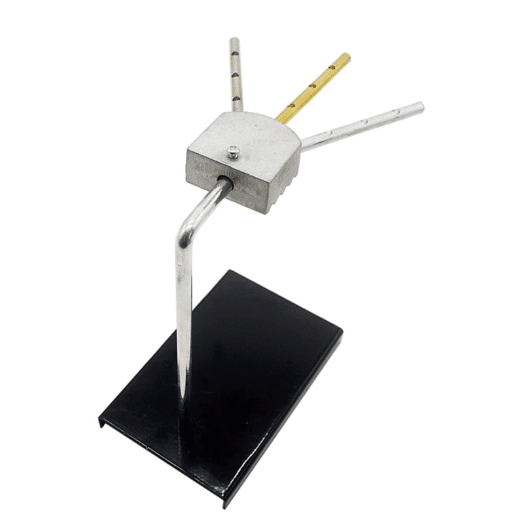

Tools for Measuring Thermal Conductivity

Determination of thermal conductivity involves specialized equipment producing accurate readings and usable data for both research and practical applications.

| Instrument | Method Type | Best For | Key Features |

|---|---|---|---|

| Hot Disk Thermal Constants Analyzer | Transient method | Wide range of materials | Fast measurements; versatile application |

| Laser Flash Analysis | Flash method | Thin samples; high-temperature materials | Non-contact; high accuracy |

| Guarded Hot Plate | Steady-state method | Insulation materials; low-conductivity substances | High precision; reference standard |

Modern Capabilities: These instruments are designed to provide consistent measurements for different materials ranging from metals and ceramics to polymers and composites. Blending advanced measurement tools with search engine technology remarkably boosts material property studies, enabling rapid access to comparative analyses, operational guides, and material-specific benchmarks.

References

- Thermal Conductivity – HyperPhysics – A resource from Georgia State University providing thermal conductivity data for various materials, including steel.

- Thermal Conductivity Data – AIP Handbook – A detailed reference from MIT with data on the thermal conductivity of metals, including steel, at various temperatures.

- Is Stainless Steel a Good Conductor of Heat? – A blog from Butler University exploring the thermal conductivity of stainless steel compared to other metals.

Frequently Asked Questions (FAQ)

What is the thermal conductivity of steel?

Steel’s thermal conductivity is a property that greatly varies depending on its type, but in general, it falls within the range of 45 to 60 watts per kelvin per meter. This property is the one that defines thermal conducting ability and that is one of the reasons why steel is still considered as the material of choice for such diverse industries as construction and manufacturing.

How does the thermal conductivity of stainless steel compare to carbon steel?

Stainless steel has lesser thermal conductivity than carbon steel which makes it a soft conductor of heat. On the other hand, this characteristic is one of the reasons why stainless steel is preferred over other materials in such critical applications as food processing where heat resistance is a primary concern, for instance, in ovens.

Why is thermal conductivity important in metals?

The thermal conductivity of a metal is the main determining factor for how efficiently it can transfer thermal energy, thus it is important in metals. Applications where heat has to be dissipated quickly, such as in heat exchangers and cooling systems, demand high thermal conductivities.

What role do metallic elements play in the ability to conduct heat?

The presence of free electrons in metallic elements is the main reason for their heat conduction effectiveness. The valence electrons present in these metals are the main contributors to high density and thermal conductivity, thus enabling the metals to transport heat perfectly through their structure.

How does thermal expansion affect the thermal conductivity of steel?

Thermal expansion is one of the factors that can influence thermal properties of steel. The reason is that when steel is heated up, it expands, which may lead to changes in density, hence thermal conductivity. Thus, in applications where precision of dimensions is crucial, the understanding of thermal expansion becomes important as in the case of structural shapes.

What are poor thermal conductors and how do they differ from metals?

Poor thermal conductors, such as nonmetals like silica aerogel, are materials that do not transfer heat efficiently. The difference between metals and nonmetals lies primarily in their structures; metals, rich in electrons, have high thermal conductivities while poor conductors have tightly bound electrons whose movements are restricted, thus limiting the transfer of heat.

How is thermal conductivity measured in materials?

Thermal conductivity is a measure of how many watts of heat can be conducted through one meter of a material using a one kelvin temperature difference and is expressed in watts per kelvin per meter (W/m·K). Knowing this is very important because the materials’ thermal behavior in application will be determined.

What is the significance of the Wiedemann-Franz Law in thermal conductivity?

The Wiedemann-Franz Law states the relationship between the thermal and electrical conductivity of metals. The law proclaims that the opposite is also the case, in that good conductors of heat are also good conductors of electricity, and this is one reason why metals like copper and aluminum are commonly and widely used in heat transfer applications.

How does temperature affect the heat conductivity of iron and steel?

Heat conductivity of iron and steel is temperature-dependent. Their thermal conductivity at low temperatures increases, while at high temperatures various factors like thermal energy transport and expansion may cause a change in their conductivity properties, which in turn affects their performance in different applications.