Aluminum foil is one of the most common household items that can be found in kitchens all over the world due to its various uses and convenience. However, have you considered its thickness and how it affects the way it is used? The thickness of aluminum foil is essential from the moment you wrap food, or until you finish grilling and even during your home DIY project the effectiveness will depend on thickness. In this blog post, we will take a closer look at the foil world, explaining how thickness is measured, what kinds are available, and how to pick the right one for your purpose. You will not only have a better grasp of the essential product but also be able to make wiser choices whenever you get a roll next time. We will unveil the aluminum foil mystery and reveal the intricacies!

Introduction to Aluminum Foil Thickness

What Is Aluminum Foil?

Aluminum foil is the product of aluminum metal used in its thinnest and lightest form. The process of making it involves rolling slabs of aluminum into thicknesses which generally vary between 0.00017 and 0.0059 inches. It is often referred as a foil with many uses that can be seen both at home and in factories. Besides cooking food, it is widely used for food preservation, insulation and the like due to its good heat conduction, long-lasting nature and resistance against moisture and light. Besides, the shining side of the foil plays a crucial part in thermal properties thus making it indispensable for the kitchen and different fields of production as well. Recent data reveals that searches for aluminum foil often emphasize its capability of keeping food fresh and are thus recommended by almost everyone as a necessity in their lives.

Significance of Foil Thickness

Foil thickness is one of the most important factors that determine its efficiency in performing different tasks. To illustrate, if grilling or storing in a freezer, it would be safer to use thick foil since tearing and puncturing resistance is of the utmost importance in such cases. On the other hand, wrapping sandwiches or lining baking trays with thinner foil would be more appropriate for light duty. Recent statistics from search engines show that the majority of users seek the optimum thickness of foil that would keep food fresh a long time. Moreover, the general agreement is that heavy-duty foil, usually around 0.024mm thick, offers the best barrier against moisture and light, thus prolonging the shelf life of food and avoiding spoilage. It is very important to know the right thickness for particular applications as this ensures both effectiveness and cost savings, thus contributing to sustainability through less waste.

Key Point:

Understanding the right thickness for particular applications ensures both effectiveness and cost savings, contributing to sustainability through less waste.

Aluminum Foil’s Common Applications

Aluminum foil is a very good material that is used in many different ways, from food preservation to industrial use. As per the latest information from search engines, one of the most frequent inquiries is about the reasons for using aluminum foil in cooking and storage. The main factors are its remarkable heat conduction, the possibility of attaining a perfect seal for the food items, and its property of being a barrier against light, moisture, and air. The use of heavy-duty aluminum foil is very common in grilling and baking as it protects food from dehydration and at the same time allows the cooking process to be uniform. Moreover, its down-to-earth nature makes it perfect for securing the food wraps, hence minimizing the chances of the food being infected or going bad. Not only food-related uses, but also insulation and electrical engineering which require lightweight and durable materials, find aluminum foil as an excellent choice due to its lightweight and durable characteristics. These multifunctional attributes make it an indispensable tool in both households and industries around the globe.

Standard Aluminum Foil Thickness Measurements

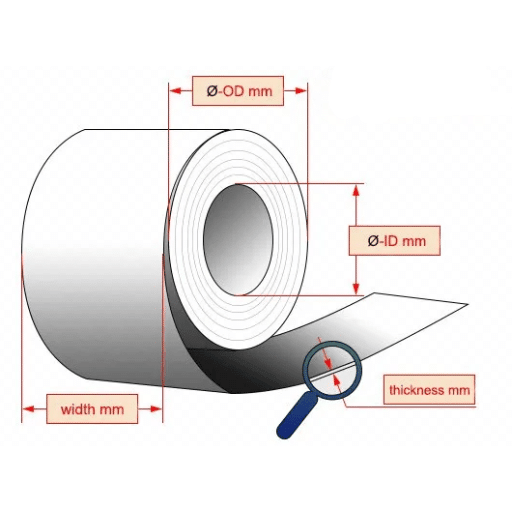

Measurement Units: Mils and Micrometers

Aluminum foil thickness is usually measured in mils and micrometers. A mil is a unit of measurement which is equal to 0.001 inches, or one-thousandth of an inch while a micrometer (or micron for short) is one-millionth of a meter, i.e., 0.000001 meters. As for the conversion, 1 mil is about 25.4 micrometers. The thickness of standard household aluminum foil ranges from 0.63 mils (16 micrometers) up to 1 mil (25 micrometers), depending on the area of application, with heavy-duty foil being thicker than the standard type. All these thicknesses imply that the foil is able to zoom in and out very well, and besides, it is quite strong and flexible, so it can serve different applications.

| Measurement Unit | Definition | Conversion |

|---|---|---|

| Mil | 0.001 inches (one-thousandth of an inch) | 1 mil = 25.4 micrometers |

| Micrometer (Micron) | 0.000001 meters (one-millionth of a meter) | 25.4 micrometers = 1 mil |

Typical Thickness of Household Aluminum Foil

Foil for domestic purposes offers a wide range of thicknesses to meet various requirements, the two most common types being standard-duty and heavy-duty. The most recent data suggests that regular household foil is about 0.63 mils (16 micrometers) thick, which is just enough for light tasks like sandwich wrapping and covering dishes. The thickness of heavy-duty foil is about 1 mil (25 micrometers) which is suitable for grilling and lining baking pans among other demanding applications. The indicated thicknesses of the foil give us a good idea of how the material can be both flexible and strong for everyday use thus accommodating various cooking and storage needs effectively.

| Foil Type | Thickness (Mils) | Thickness (Micrometers) | Common Uses |

|---|---|---|---|

| Standard-Duty | 0.63 mils | 16 micrometers | Sandwich wrapping, covering dishes |

| Heavy-Duty | 1.0 mil | 25 micrometers | Grilling, baking, freezer storage |

Variations in Standard Foil Thickness

The thickness of standard aluminum foil can be grouped into distinct categories by application. One such category is lightweight or regular-duty foil (about 0.63 mils) which is commonly used for storage and covering food to keep it fresh. The other category is heavy-duty foil (around 1 mil thick), which is mainly used for grilling, freezing, or baking dishes, and these applications are all due to the foil’s high resistance to tearing and punctures.

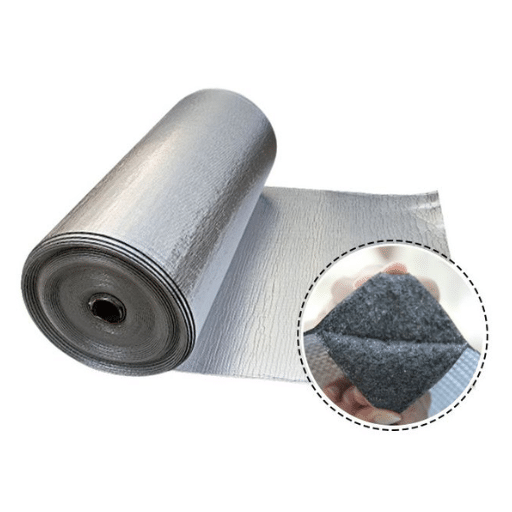

Moreover, some industrial and commercial uses may require even thicker grades of foil, for example, extra heavy-duty foil (up to 1.5 mils or more), which is standard in settings demanding more insulation or durability. Noting these variations helps consumers to choose the best type of foil that meets their specific needs, whether cooking, storing, or in industry.

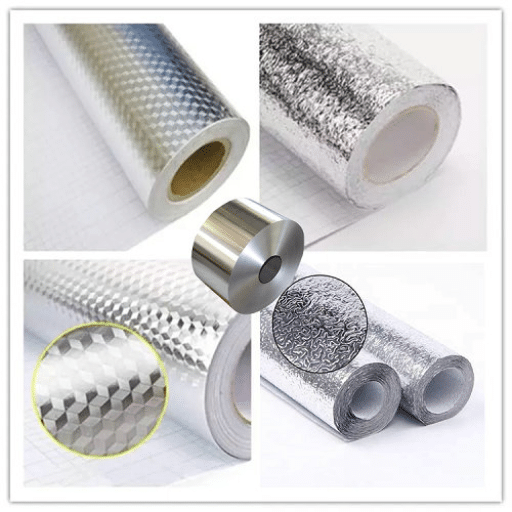

Different Types of Aluminum Foil and Their Thickness

Heavy-Duty Aluminum Foil

Heavy-duty aluminum foil usually is between 0.8 and 1.0 mils thick making it more tear-resistant and heavier than regular aluminum foil. This foil type is commonly used in many residential and commercial areas since it can tolerate higher heat and pressure. One of the most frequently asked questions according to the recent statistics of the search engine is, “What is heavy-duty aluminum foil used for?” The answer is in the numerous uses of heavy-duty aluminum foil.

Heavy-Duty Foil Applications:

- Perfect for grilling since it can endure high-temperature cooking without disintegrating

- Ideal for storage, preventing leaks or spills

- Strong enough to wrap items with sharp edges or unequal shapes

- Excellent for lining pans to make cleaning easy

Standard Aluminum Foil

While standard aluminum foil may be thinner and less durable than heavy-duty foil, it still remains to be a very versatile and popular kitchen material. According to the latest search data, the question, “What is standard aluminum foil best used for?” is one of the top queries. The answer is found in the combination of its strength and its flexibility.

The most common application of standard aluminum foil is everyday tasks like covering dishes, wrapping food for short-term storage, and keeping moisture while cooking. Its lightweight feature makes it very convenient and fun to work with whether you are molding it to cover a bowl or crimping it around food items. Also, it’s a practical option for baking, steaming, and preventing food in the oven from drying out. These attributes indicate why standard foil keeps being chosen by so many households.

Ultra-Thin Aluminum Foil

Ultra-thin aluminum foil marks a new milestone in the foil production technology, granting consumers with high functionality and varied usefulness. The major characteristics of this kind of foil are its extreme lightness and thinness, thus making it the right material for quite a few precision applications, such as delicate item packaging or use in the technical fields of electronics and pharmaceuticals.

In contrast to standard aluminum foil, ultra-thin foil is mostly used in high-tech environments where it can perform as a perfect moisture, air, and light barrier. Keeping track of the recent search data, queries related to ultra-thin aluminum foil often pinpoint its advantages in cutting down material waste while the latter is still high functionality at the same time. This rising awareness signals the material’s role in both consumer and industrial sectors, emphasizing the eco-conscious usages and innovations.

| Foil Type | Thickness Range | Key Features | Best For |

|---|---|---|---|

| Ultra-Thin | Less than 0.63 mils | Extremely lightweight, precision barrier | Electronics, pharmaceuticals, delicate packaging |

| Standard | 0.63 mils (16 micrometers) | Flexible, lightweight, versatile | Everyday cooking, covering, wrapping |

| Heavy-Duty | 0.8-1.0 mils (20-25 micrometers) | Tear-resistant, durable, heat-tolerant | Grilling, freezing, roasting |

| Extra Heavy-Duty | 1.5+ mils | Maximum durability, insulation | Industrial, commercial applications |

Common Misconceptions About Aluminum Foil Thickness

Debunking Myths

A commonly accepted myth surrounding aluminum foil states that it gets weaker or less efficient as it gets thinner, but this is not completely true. Ultra-thin aluminum foil might not look very strong, however, it carries most of the properties that are the key to the product, like durability, flexibility, and light as well as moisture-resistance.

People are getting increasingly curious about this issue of thinner foils and protection as recent data indicates. Trials and labelling confirm that no matter how thin foils are, they are made for specific usages such as food preservation or electronic shielding. Consequently, one can see how far the ultras-thin aluminum foil technology has come, and the promising fact that its functionality is still unbroken despite the lesser thickness.

Understanding Actual Performance

The public’s worries indicated in recent search trends must be taken into account while performing a scientific analysis of ultra-thin aluminum foil’s performance. One recurring question is whether the or reduced thickness has any negative impact on the functionalities that are of most significant kind like durability and effectiveness in real-world settings. However, given the recent test results and technological advancements, the answer is a loud and clear: “ultra-thin foil retains robust performance”.

The innovative engineering guarantees that the foil, even at its given minimal thickness, works as a good barrier against the moisture, air, and light, all of which are the very elements that playing significant role in food getting spoiled and losing its freshness. Moreover, in the case of electronics, the thin foil does the magical trick of providing both excellent conductivity and shielding as well as these being the functionalities that need to be very precise. The spotlight is on not the material but its microscopic structure and the precision of manufacture, as if to say thinner does not mean weaker if being engineered properly. Hence, the thin foil’s actual performance happens to be at least as good as expected, if not exceeding, in industries.

Important Note:

Thinner does not mean weaker when engineered properly. The microscopic structure and precision of manufacture determine actual performance, not just thickness.

Consumer Confusion Explained

Consumer confusion is mostly the result of lack of clear statement, too many options, or misleading information about the products and services. A recent search engine’s data reveals that one of the most common queries is comparing similar products and identifying their differences—that is, what makes one better than the other or which is the right one depending on the consumer’s situation.

To be specific, in the case of thin foil, often time consumers are looking for differences between aluminum and tin foil, their applications, and safety issues. This shows a necessity for clearer labeling and easier access to information. The whole confusion issue takes a turn only through the use of accurate and simple language that portrays the products in such a way that consumers are able to take their decisions, founded on the right information rather than on hearsay or false claims.

Choosing the Right Aluminum Foil for Your Needs

Factors to Consider When Selecting Foil Thickness

Primarily, intended use and the toughness required should influence your choice of aluminum foil thickness. Thicker foil is going to be more dependable for the heavy duty storage or cooking tasks as it can take in more heat. The standard type is sufficient for non-protecting tasks like covering dishes or wrapping light foods. Heaviest type or reinforced type is an excellent choice for special uses, for example, grilling delicate items or freezing food for long periods.

Search trend data points to the fact that consumers frequently turn to the internet for tips on the appropriate thickness in foil. Among the most popular of these questions are whether thicker foil performs better in heat retention and whether thin foil is safe for cooking at high temperatures. The functionality of the balance cost-effective comes into play here. Heavy-duty foil is suitable for the different baking, grilling, and freezer storage processes while standard foil is adequate for just food covering or transporting items for a short period of time. Thus, being aware of these differences will enable the consumers to choose confidently, by being well-informed.

Checklist: Factors to Consider

- ✓

Intended Use: What task will the foil perform (cooking, storage, freezing)? - ✓

Durability Requirements: Will it face sharp edges, high heat, or puncture risks? - ✓

Heat Exposure: High-temperature cooking requires heavier foil - ✓

Food Type: Delicate items may need non-stick or ultra-thin options - ✓

Storage Duration: Long-term freezer storage benefits from heavy-duty foil - ✓

Cost-Effectiveness: Balance performance needs with budget constraints

Practical Tips for Selecting Aluminum Foil

The first question that comes to mind when asking about aluminum foil is what its use is going to be. Many people are still wondering whether the thickness of aluminum foil affects its efficiency, as search engine data shows. The answer to this is “yes”; heavy-duty foil is thicker, more robust, and less likely to tear making use of such foil in grilling, roasting, and storage of food in freezers situations where strength is a must. On the other hand, the standard foil is perfectly suitable for such day-to-day tasks as sandwich wrapping or covering leftovers.

Furthermore, when using difficult or soft items, such as fish and cheese, non-stick foil would be the right choice as it will make cleaning easier. If you want to be eco-friendly, please consider switching to recycled aluminum foil, which will be the same in terms of functionality but with a smaller footprint. All in all, matching the foil type with your cooking or storage requirements can lead to saving time, reducing waste, and getting guaranteed performance.

Expert Tips:

- For Grilling: Always choose heavy-duty foil to withstand high temperatures and prevent tearing

- For Everyday Wrapping: Standard foil is sufficient and more economical for sandwiches and covering bowls

- For Delicate Foods: Opt for non-stick foil when working with fish, cheese, or sticky items

- For Eco-Conscious Users: Choose recycled aluminum foil without compromising functionality

- For Freezer Storage: Use heavy-duty foil to protect against freezer burn and maintain food quality

Aluminum Foil in Different Application Areas

Aluminum foil is one of the products used in different areas because of its versatility and efficacy. Food in the household is usually kept fresh by using it as a staple of keeping food fresh for later use without famishing other odors. Packaging for restaurants and catering services consists of the foil that keeps the quality of portions during the transport. Moreover, the material in baking, grilling, and steaming has become synonymous with heat distribution regulation and preventing burning.

Increased interest in the sustainable cooking solutions is evident from the search engine’s latest data, where “eco-friendly aluminum foil alternatives” was the most searched. This trend points towards a bigger demand for both recycled aluminum foil and reusable ones, which by the way are ideal for environmentally friendly chefs. So whether it is a matter of convenience or sustainability, aluminum foil has now become an indispensable tool across different settings by constantly meeting the specific need.

| Application Area | Recommended Thickness | Key Benefits |

|---|---|---|

| Household Food Storage | Standard (0.63 mils) | Keeps food fresh, prevents odor transfer |

| Grilling & Baking | Heavy-Duty (1.0 mil) | Heat distribution, prevents dehydration |

| Restaurant Packaging | Heavy-Duty (1.0 mil) | Maintains quality during transport |

| Freezer Storage | Heavy-Duty (1.0+ mil) | Prevents freezer burn, long-term protection |

| Industrial Applications | Extra Heavy-Duty (1.5+ mils) | Maximum insulation and durability |

| Electronics & Pharmaceuticals | Ultra-Thin (< 0.63 mils) | Precision barrier, lightweight packaging |

Frequently Asked Questions (FAQ)

What thickness does regular household foil have?

Regular household aluminum foil is usually between 0.016 mm and 0.024 mm in thickness, which is approximately 16 to 24 microns. In terms of gauge, it is about 0.63 to 0.95 mil (thousandths of an inch), but the manufacturers may define the thickness in different ways. The foil that is commonly used is also known as “household foil” and it is meant for cooking and wrapping. It has a good amount of flexibility along with strength so that it can easily be folded or molded around food. For the heavier tasks, you can opt for heavy-duty aluminum foil that will be thicker and more durable.

What gauge is heavy-duty aluminum foil compared to regular foil?

Heavy-duty aluminum foil is usually around 0.024 mm to 0.040 mm thick (24–40 microns), which makes it considerably stronger than the standard household foil. In terms of gauges, heavy-duty foil is often around 1.0 to 1.6 mil, which helps in preventing the foil from tearing and penetrating when used for grilling or wrapping sharp-edged foods. This type of foil is known as “heavy-duty foil” or “industrial foil” as it is used for tougher jobs like lining roasting pans. The thickness of the foil gives better heat retention and durability for repeated use or high-heat cooking. If you are looking for something in between then you can go for “extra-strength” or “strong” variants that would be between standard and heavy-duty thickness.

Which units are used to measure aluminum foil thickness—microns, mils, or gauge?

Aluminum foil thickness is usually reported in microns (µm) or mils (thousandths of an inch), and sometimes gauge is mentioned, although gauge is not standardized for foil. Micron measurements are very precise and are the most commonly used in manufacturing; normal household foil is about 16-24 microns. A mil equals 25.4 microns, so the conversion between microns and mils is straightforward when comparing products. The term “gauge” can be misleading because different materials have different gauge scales; in the case of foil, it is always better to go with microns or mils. Product labels might also use terms like “standard,” “extra strength,” or “heavy-duty” to show the relative thicknesses.

Can you distinguish thickness differences through touch or sight?

Thickness differences can mostly be sensed through touch: the stiffer and heavier or thick foil is less likely to tear if crumbled while thin foil on the other hand is delicate and easily tears. On the visual aspect, heavy-duty foil will probably be a little bit more matte or very slightly translucent than the standard one but the visual cues can be really subtle. For precise comparison use product specifications listing microns or mils instead of subjective inspection. In case you often need the stronger material, look for the labels that say “heavy-duty” or tell the higher micron value. Keep in mind that coatings or laminations can change the feel of the surface without indicating the thickness of the base foil.

What thickness of aluminum foil is used in industrial or packaging applications?

Aluminum foils for the industrial and packaging purposes vary greatly in thickness from about 6 microns to several hundred microns depending on the application, with common packaging foils usually in the range of 6 to 50 microns. Ultra-thin foils (less than 10 microns) are used for flexible packaging and insulation, where it is critical to keep barrier properties, while thick foils are for structural liners or heat shields. Manufacturers may refer to these products as “industrial foil,” “packaging foil,” or they may specify the ratings in microns. The selection depends on the required barrier performance, mechanical strength and cost. If exact specifications are important, ask for datasheets that include microns, tensile strength and temper.

What impact does foil thickness have on cooking and grilling performance?

The use of thick foil enables excellent puncture resistance and heat holding capacity, which makes heavy-duty foil the best choice for grilling, wrapping of bone-in meats or lining of pans that meet sharp edges. Utilizing thinner household foil is ideal for covering of dishes, steaming and low-risk wrapping tasks where flexibility and conformability are more important than durability. Thicker foil can also diffuse heat better which will result in no hot spots when being used as a shield or reflector. However, very thick foil might be harder to wrap tightly around food and can be a source of unnecessary weight for simple uses. It is advisable to choose the foil thickness according to the task: standard for light kitchen use, heavy-duty for grilling and tough jobs.

Quick Reference Guide: Choosing Your Foil

Light Tasks

Use: Standard Foil (0.63 mils)

Covering bowls, wrapping sandwiches, light baking

Medium Tasks

Use: Heavy-Duty Foil (1.0 mil)

Grilling, roasting, freezer storage, lining pans

Heavy-Duty Tasks

Use: Extra Heavy-Duty (1.5+ mils)

Industrial use, commercial packaging, maximum insulation

Reference Sources

- ScienceDirect – Aluminum Foil Overview: This resource provides an overview of aluminum foil, including its typical thickness range of 7–30 μm and its applications, such as container lids.

Aluminum Foil Overview – ScienceDirect - Springer – Thickness and Uniformity of Commercial Aluminum Foils: This study examines the thickness and uniformity of various commercial aluminum foils, with an average thickness of approximately 11 μm.

Thickness and Uniformity of Commercial Aluminum Foils – Springer - PubMed Central – Quantification of Aluminum Content Leached into Food: This study discusses the thickness of aluminum foil in relation to its leaching properties, highlighting the use of thinner foils in food applications.

Quantification of Aluminum Content Leached into Food – PubMed Central - HTMM Aluminum Foil Industry News: This article explains the reasons behind the thinness of aluminum foil, with thicknesses ranging from 6 to 200 microns, and its benefits in food packaging.

Why Aluminum Foil is So Thin – HTMM