Steel and stainless steel have become the go-to materials in many fields such as technology and construction due to their remarkable properties of strength, durability, and versatility. Nevertheless, thermal conductivity is the property that people mostly doubt. Is steel a good heat conductor after all? How does the thermal conductivity of steel compare with that of other metals, and what about the stainless steel composition; how does it eventually influence the thermal conductivity? This paper explores in detail the thermal conductivity of both steel and stainless steel, bringing out their heat transfer characteristics and the science behind them. This is a guide that will be very useful whether you are a curious DIY enthusiast, an engineer, or just a person who is fascinated by the properties of materials.

Introduction to Steel and Heat Conductivity

The thermal conductivity of steel means its capacity to conduct heat. Its composition has a big impact on that property, especially the amount of carbon and other alloying metals. For instance, simple carbon steel usually has better thermal conductivity than stainless steel, which has chromium and other metals added for its properties. These metals make the structure harder thus less heat can be transferred. Steel is not that much of a conductor compared to copper or aluminum, but still its mechanical properties along with durability, make it a viable choice for the application where strength along with moderate heat transfer and resilienc,e is needed. It is very important to understand these differences when it comes to selecting the right materials for thermal management in sectors like construction, manufacturing, and engineering.

What is Thermal Conductivity?

Thermal conductivity is the capacity of a material to transfer heat. It quantifies the speed at which heat energy flows through a material because of the temperature difference. The unit of measurement for thermal conductivity is generally in watts per meter-kelvin (W/m·K), which indicates how well the transfer of heat happens in a substance.

🔥 High Conductivity Materials

Materials with high thermal conductivity, like metals such as copper and aluminum, are heat conductors which render them very useful in applications like heat exchangers and electronic cooling systems.

❄️ Low Conductivity Materials

Low thermal conductivity materials, like wood, rubber and thermal insulation foams, are good heat insulators as they minimize heat transfer significantly.

Key Point: The factors affecting thermal conductivity are the composition of the material, temperature and the structural properties of the material, thus making it an essential feature to consider in different sectors like industrial engineering, sustainable building design, among others.

Importance of Conductors in Everyday Applications

In the contemporary world, conductors are a necessary part of life as they open the way for many practical applications that not only support technological advancements but also make daily living easier. Here are five important examples that highlight the significance of conductors in daily usage:

- 1

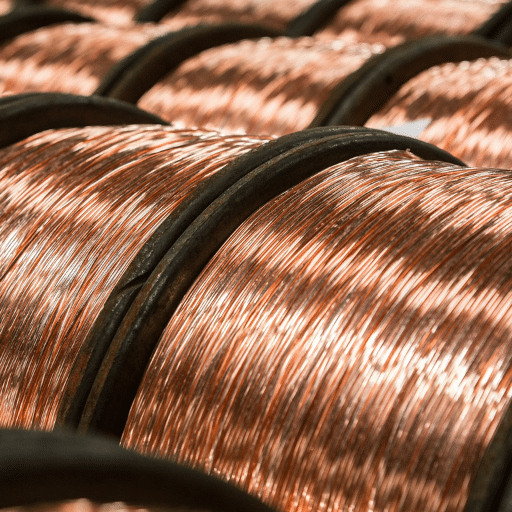

Electrical Wiring

Conductors such as copper and aluminum are the very materials that make electrical wiring in houses, buildings, and infrastructure possible. The choice for the majority of electrical systems goes to copper because of its great conductivity, which guarantees that electricity is transmitted satisfactorily with scarcely any energy loss.

- 2

Electronics and Devices

Circuit boards and components of smartphones and computers have gold and silver as the conductors assuring the transmission of signals. Their high conductivity and resistance to corrosion are reasons why they are used in electronic gadget production.

- 3

Power Transmission

The large-scale electricity transmission is made possible by the use of conductors. Due to its light weight and excellent electrical conductivity, aluminum is used in power lines with a steel core for added strength, hence, making it possible for energy to be distributed efficiently over long distances.

- 4

Heating Systems

Heating elements made from nichrome (a conductor alloy) are present in appliances such as toasters, irons, and water heaters. The conducting materials are in these systems that change the electric energy into heat thus providing a controlled and efficient heat source.

- 5

Automotive and Transportation

In vehicles, conductors are indispensable for such systems as batteries, electrical circuits, and spark plugs. The use of copper and other conductive materials guarantees that the performance of all electrical components like lights and sensors is without any interruption.

Industry Insight: These illustrations affirm that conductors are profoundly interwoven with daily life, infrastructure, technology, and the comfort of modern society being the backbone. It has been found through industry studies that copper alone makes up more than 60% of the total global industrial conductive material used, thus underlining its importance.

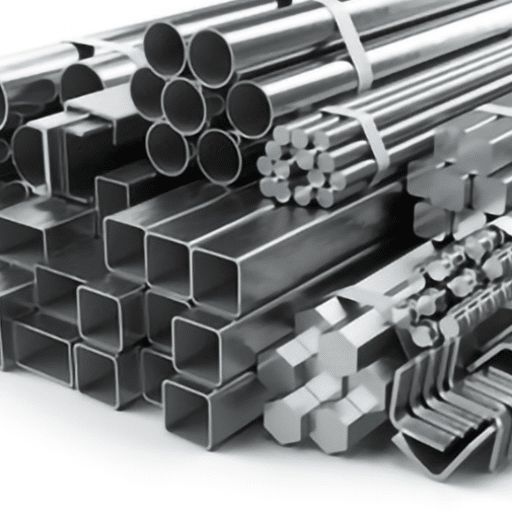

Overview of Steel and Its Properties

The steel material is among the most adaptable and widely utilized in the world today, being the choice for its spectacular strength, durability, and recyclability. This is a metal mixture formed by iron and a small amount of carbon plus the other elements such as manganese, chromium, nickel, and vanadium that are added to the alloy in order to improve the properties. The versatility of steel is the major reason why it is the primary material in many industries including construction and automotive manufacturing.

Below are the five important characteristics of steel:

💪 Strength

The steel has high tensile strength and thus is able to bear heavy weights without being deformed or broken. This quality makes it very useful in the construction of huge infrastructures like skyscrapers, bridges, and so on.

🛡️ Durability

The steel’s strength and resistance to damage are the reasons why it is considered a durable choice for long-term use, even in harsh environments.

🔒 Corrosion Resistance

Stainless steel, more specifically, is made to be resistant to rust due to the addition of chromium that creates a protective layer of oxide around the metal, thus it being perfect for use in the medical, food, and ocean-going industries.

♻️ Recyclability

Steel can be recycled completely with no reduction of quality. Hence, this is why it is one of the most eco-friendly materials with more than 85% of the produced steel being recycled all over the world.

🔧 Versatility

The various grades and compositions of steel allow it to be designed for any particular application, ranging from lightweight steel for car frames to super strong ones for industrial use.

Key Takeaway: These characteristics reveal how steel is a major factor in the development of modern day infrastructure and technology while at the same time being a driving force behind innovation and sustainability.

Thermal Conductivity of Steel

Thermal conductivity is a term that describes how well a material conducts heat. Steel, being a material of choice, shows different thermal conductivity levels according to its alloying constituents and grade. Here are the prominent features and numbers related to the thermal conductivity of steel:

📊 Thermal Conductivity Range

Steel’s thermal conductivity is mostly found in the range of 15-55 W/(m·K). Carbon and alloying elements are the biggest contributors to this variation.

🔬 Influence of Composition

Carbon Steel: Generally, low-carbon steels have better thermal conductivity than high-carbon ones because of their simpler structure.

Stainless Steel: Steels with high chromium and nickel content usually fall in the low thermal conductivity category around 15-25 W/(m·K).

🌡️ Temperature Dependency

Steel’s thermal conductivity is a function of temperature. The general trend is when the temperature goes up thermal conductivity of most steels goes down slightly.

🎯 Application-Specific Properties

Thermal conductivity of steel is an important property for the selection of type of steel in applications like heat exchangers and thermal interface where such efficient heat transfer is crucial.

⚖️ Comparison with Other Materials

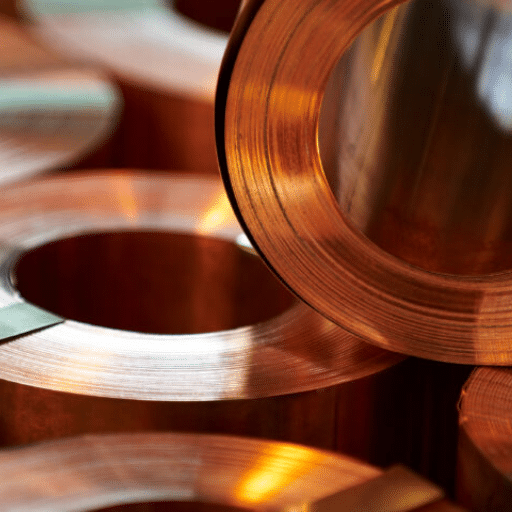

Steel’s thermal conductivity is about 40 times lower than that of copper (~400 W/(m·K)) and more than 3 times lower than that of aluminum (~205 W/(m·K)). This must be taken into consideration when designing heat-sensitive constructions.

Important Note: These characteristics render thermal conductivity as a key factor in determining the suitable kind of steel that will meet the requirements of particular temperature and heat transfer processes.

Understanding How Steel Conducts Heat

The thermal conductivity of steel is greatly influenced by various parameters. Each parameter holds the potential to affect the thermal performance of steel to a large extent that makes it crucial for specific applications to take them into account in the most precise way possible. Here are five comprehensive aspects that play a role in steel’s thermal conductivity:

1️⃣ Composition and Alloying Elements

Thermal conductivity of steel is one of the effects of alloying elements like chromium, nickel, and molybdenum among others. A case in point is that stainless steel which comprises a high content of chromium and nickel generally has lower thermal conductivity in comparison to carbon steel.

2️⃣ Temperature

Thermal conductivity varies in steel depending on the temperature. At increased temperatures, the thermal conductivity might undergo a slight rise or fall depending on the steel type thus this property is classified as temperature dependent.

3️⃣ Microstructure

The microstructure of steel which includes grain size, phase distribution, and inclusions among others is a major determinant of the heat conduction capability of steel. One of the examples is fine-grained steel which usually has more uniform thermal conductivity.

4️⃣ Density and Porosity

The steel with higher density is usually the one that conducts heat more efficiently. On the other hand, porosity or voids in the structure of the steel can serve as an insulating barrier hence decreasing the steel’s capability of heat transfer.

5️⃣ Surface Finish and Coatings

Conductivity of steel can be changed by the surface being coated with a special coating or by the surface being polished to a certain extent. Conductivity is reduced by the thermal insulation coatings and on the other hand efficiency in heat transfer might be given a boost by smoother and cleaner surfaces.

Comparison of Steel’s Thermal Conductivity with Other Metals

Steel’s thermal conductivity is a topic often examined through comparison with other metals to emphasize its performance in heat transfer applications. The thermal conductivity of a certain material is usually in units of watts per meter-kelvin (W/m·K). The table below shows steel’s thermal conductivity alongside five other metals that are mostly used:

Comparative Analysis: This comparison shows that steel’s thermal conductivity can compete with that of silver, copper, and aluminum among the metals, while, at the same time, being inferior to that of titanium. Based on the transfer of heat through the material, each of these metals is selected for different applications depending on their mechanical property combination.

Factors Affecting the Conductivity of Steel

Thermal conductivity of steel is affected by multiple factors and therefore it becomes very important to take such variables into account while choosing the steel for targeted uses. Here is a complete rundown of five main factors:

-

Composition of Alloying Elements

The impact on thermal conductivity isvery significant for the steel when certain elements like carbon, manganese, chromium, or nickel are added. For instance, the case with carbon content is that the higher it gets, the lower the thermal conductivity is since the metallic lattice of steel gets disrupted.

-

Temperature

Thermal conductivity in steel is temperature dependent and varies accordingly. Generally, with increase in temperature the thermal conductivity of steel gets to a slight decrease owing to changes in lattice vibrations and electron configurations at high temperature.

-

Grain Structure

Grain size and structure are crucial determinants of conductivity and are affected by steel’s processing like annealing or cold working. Finer grain structure increases the opposite of thermal conductivity that is development of boundaries, whereas the coarser grain structure promotes heat transfer.

-

Impurities

The presence of impurities can significantly change the heat transfer even if the amount is very small. For example, the presence of sulphur or phosphorus as impurities will hinder the movement of electrons and thus the conductivity will reduce.

-

Processing Methods

Different processing methods like quenching, tempering, or rolling can modify the microstructure of steel. These processes change the distribution and arrangement of atoms thus altering thermal conductivity.

Expert Insight: Knowing these factors aids not only in the choice of materials but also in the selection of proper processing methods to get the expected result in applications related to heat transfer.

Stainless Steel and Its Thermal Properties

Stainless steel is an adaptable alloy with good characteristics such as oxidation resistance and sturdiness, but the thermal properties of steel are such that they are involved in many applications as well. The following are the detailed features of the thermal properties of stainless steel, along with significant data:

🌡️ Thermal Conductivity

Stainless steel has lower thermal conductivity in general than carbon steel and aluminum. For instance, Type 304 stainless steel’s thermal conductivity at room temperature is about 16.2 W/m·K.

🔥 Specific Heat Capacity

It is a gesture of high thermal capacity that can efficiently absorb energy in the form of heat before increasing the temperature of the given mass. The specific heat capacity for Type 304 is roughly 500 J/kg·K.

📏 Thermal Expansion

Stainless steel gets bigger with the heat. Its typical coefficient of thermal expansion is about 17.2 μm/m·K for Type 304, which affects its use in high-temperature application areas.

🔴 Melting Point

The melting point of stainless steels is quite high, with a range of approximately 1370°C to 1450°C depending on the material grade and alloying elements used. Thus it can be applied in very high temperature areas.

🛡️ Oxidation Resistance at High Temperatures

Stainless steel in hot atmospheres is one of the materials that can resist oxidation and scaling very well, maintaining its properties even under thermal cycling where there are large temperature variations.

Conclusion: To sum up, the use of stainless steel in different sectors such as heat exchangers, cookware, automotive parts, and industrial equipment, is strongly supported by its properties and durability.

What Makes Stainless Steel Different?

Stainless steel is distinctly different from other materials by its brilliant composition and properties. It consists of iron, carbon, and at least 10.5 percent chromium, which gives it tremendous resistance against rust. The main reason for this is the presence of chromium, which creates a barrier by making an oxide layer over the metal that stops rust and decay from happening even in very tough conditions.

Apart from being rust proof stainless steel also possesses the highest strength, the longest lifespan, and the best recycling properties making it the most eco-friendly material in the long run. Besides, it can cater to different grades and finishes that are specially designed for industrial, architectural, and consumer use due to its being versatile. The wide range of these attributes has made stainless steel a very economical and dependable option in many industries.

Thermal Conductivity of Stainless Steel Compared to Carbon Steel

Thermal conductivity is a significant characteristic of materials intended for heat transfer applications. The difference in thermal conductivity between stainless steel and carbon steel results in their respective power and suitability for different purposes. Here is a comprehensive comparison of their thermal conductivity per grade, shape and condition:

Thermal Conductivity of Stainless Steel:

- ▸

Austenitic Stainless Steel (e.g. 304, 316): About 16 W/m·K at ambient temperature. - ▸

Ferritic Stainless Steel (e.g., 409, 430): Usually, it has values between 23 and 26 W/m·K. - ▸

Duplex Stainless Steel (e.g., 2205): Roughly 14 W/m·K at room temperature. - ▸

Martensitic Stainless Steel (e.g., 410, 420): Estimated to be in the range of 24-30 W/m·K.

Increasing the temperature enhances the conductivity in the case of less heat resistant grades, while it leads to reduced conductivity in other cases.

Thermal Conductivity of Carbon Steel:

- ▸

Low-Carbon Steel (e.g., 1010, 1020): Approximately 43-54 W/m·K at room temperature. - ▸

Medium and High-Carbon Steels (e.g., 1040, 1095): Different cases give a range from 40 to 50 W/m·K, depending upon the carbon content. - ▸

Heat-treated carbon steel grades: More or less similar in their thermal conductivity and can be said to be in the range of untreated grades.

Material Efficiency in Heat Transfer:

Carbon steel has the highest conductivity among the materials and stainless steel is the least conductive. Thus, heating and cooling process of carbon steel’s materials can be easily controlled directly by the material’s conductivity. Stainless steel is less conductive and thus, has lesser thermal resistance in heat sinking. However, it can still act as a reducer due to its low conductivity, making it useful as insulation in certain applications.

Impact of Alloying Elements:

Thermal conductivity in stainless steel goes down because of alloying elements such as chromium, nickel, and molybdenum which are otherwise responsible for the higher thermal conductivity of carbon steels. The iron of the purest grade will still have a thermal conductivity of around 80 W/m·K, and that goes down substantially in stainless steel because of the alloying.

Practical Applications Based on Thermal Conductivity:

Among the different areas of application, the most common ones for stainless steel are those which require excellent temperature control such as kitchen appliances, cryogenic applications, and chemical processing, plus it has the advantage of being in touch with the products. On the other hand, carbon steel is the material of choice for applications where heat conduction is extremely strong, for instance, with boilers, power plants, and automotive parts.

Key Takeaway: This comparison highlights again and again how profoundly different thermal features of stainless and carbon steels affect their use and position in various industries. It is through comprehension of these differences the right material for heat-related application is chosen.

Benefits of Stainless Steel in Heat Applications

Stainless steel has wonderful material properties that give it several great advantages in heat-related applications. The benefits of stainless steel not only make it a dependable option but they also guarantee longevity and efficiency in harsh conditions. Below is a list of five main advantages:

🔥 High-Temperature Resistance

Stainless steel resists high temperatures and does not lose its structural strength or functional performance. The heat-resisting grades such as 304 and 316 stainless steel are widely used in the applications where the prevention of heat is the main requirement such as in heat exchangers and parts of furnaces.

🛡️ Corrosion Resistance in High Heat

Stainless steel, unlike carbon steel, still has a strong corrosion resistance under high-temperature conditions. This quality is very important in places with wet or chemically aggressive atmospheres.

⚡ Thermal Conductivity

Stainless steel conductivity is not as high as carbon steel but it is still sufficient for heating and cooking applications, where even heat distribution and efficiency are ensured.

✨ Oxidation Resistance

When the temperature is raised, stainless steel creates the protective layer of chromium oxide, which stops oxidation and scaling. This is a big help in creating the longevity of the material in applications like the exhaust manifolds and the turbochargers.

🔧 Ease of Fabrication and Maintenance

Stainless steel is the least complicated material to be manufactured into the most intricate shapes for the heat-resisting applications and its surface is so smooth that it is easy to clean and maintain, thus, downtime and expenses are reduced.

Comparative Analysis: Steel vs. Other Metals

Steel conducts heat less efficiently than metals like copper and aluminum but more effectively than materials like lead and non-metals.

Heat Conductivity: Steel vs. Aluminum

Aluminum conducts heat significantly better than steel, making it more suitable for applications requiring high thermal conductivity.

Heat Conductivity: Steel vs. Copper

Copper conducts heat much more efficiently than steel, making it ideal for applications requiring superior thermal conductivity.

When to Choose Steel Over Other Conductive Metals

Steel is a great option in case strength, durability, and low price are important factors. Although it has lower thermal conductivity than copper, continuing with the structural integrity give steel a place in those applications which require mechanical stability, for example, in construction beams, automotive frames, and tool manufacturing. Furthermore, steel is generally more economical than metals with high conductivity like copper, especially in the case of big projects. Its anticorrosive property (when properly alloyed) and its being available in different grades and forms are the factors that make it even more versatile.

According to the most up-to-date information provided by Google, steel is still a preferred material in places where thermal conductivity is not the major factor, for instance, in high-stress structural applications. The right combination of strength-to-weight ratio and the capability of bearing big forces without causing deformation assures steel’s eternal rule in the fetching sectors like construction, engineering, and transportation. For the situations where high thermal efficiency is not important but strength and price are the deciding factors, steel still holds the position of being the most suitable choice.

Practical Implications of Steel’s Heat Conductivity

The relatively low heat conductivity of steel is a turning point in the application of steel in crafts and industries. The five main implications of thermal properties of steel are as follows:

Construction and Building Materials

Steel, by the middle of the road in heat conduction, serves well in heat conduction. For instance, if steel is used in roofs and walls, it will be able to transfer heat to the outer surroundings and there will be no loss in the steel’s quality ensuring fire resistance and safety in buildings.

Industrial Equipment and Machinery

Steel is a material of choice for industrial machines because it can undergo heat cycles and not deform in the least. For example, in a factory, steel is used for making gears and bearings where periodic heating may occur during the operation.

Cookware and Kitchen Appliances

Steel is less conductive than copper and aluminum, which have excellent heat conduction properties. Nonetheless, steel is still one of the most prominent materials used for cookware. The reason for this is it not only distributes the heat evenly but also the strength and wear resistance of steel are maintained. Take for instance, stainless-steel pots and pans which are less prone to scratching and for the same reason more affordable since they will last longer.

Energy Production and Power Plants

Steel is a key material in power generation systems where it not only needs to withstand very high temperatures, such as steam turbines, and heat exchangers, but it also needs to maintain its structural integrity. The ability of the material to conduct and withstand heat opens up the road for efficient energy transfer.

Transportation and Automotive Components

Importantly, the main use of steel in transportation and components of cars is through its application in exhaust systems, brake discs, and engine parts. Its good thermal performance and mechanical strength keep the parts durable and reliable even in highly stressed conditions.

The above implications are illustrative of the different uses of steel in different areas according to its thermal properties.

Applications in Construction and Engineering

Steel remains the backbone of construction and engineering with its profound strength and versatility, being indispensable for many applications. Along with their details and significance, below are five of the most important applications highlighted:

Structural Frameworks

Steel is so prevalent that whole buildings, bridges, and even towers are made up of their structural frameworks. Very skyscrapers and large scale projects can be built thanks to its high tensile strength and durability. For instance, the massive steel structures of modern skyscrapers make sure that these urban giants not only bear up and do not collapse under their own weight but also fight against the forces of nature trying to push them sideways.

Reinforced Concrete

The combination of concrete and steel bars, or rebar, results in a more tensile and flexible structure, which is the downside of pure concrete structures. This mix is widely used in the construction of foundations, columns, and beams of buildings thus increasing their resilience.

Bridges and Infrastructure

The same properties that make steel so advantageous for bridges and highways, amongst other infrastructure projects, include its capacity to carry heavy loads and resistance to deterioration due to environmental factors. For instance, construction companies use steel bridge decks because they are light and therefore, the total cost of construction is lower and stress on the supporting structures is also less.

Roofing and Cladding Systems

Steel sheets are widely used for roofing and cladding because they are weather-proof and can last for a long time. In addition to that, the fact that they can be coated with corrosion-resistant layers such as zinc (galvanization) makes them even more durable.

Heavy Machinery and Industrial Equipment

Heavy machinery made with steel will be one of the sources for construction and engineering projects because of its strength and wear resistance. bulldozers, derricks, and excavators, for example, have steel parts that are strong enough to tolerate heavy use and make the equipment work efficiently over a longer period.

These different applications illustrate how critical steel has become for the development of construction and engineering technologies while at the same time complying with the requirements of today’s modern development.

Use in Kitchenware and Cookware

The manufacturing of kitchenware and cookware, without steel, would not be the same because of its long-lasting nature, no rust at all, and soon-to-be excellent heat conductor. These features are the reason why steel is the first choice for many kitchenware products. Five of the most common steel applications are listed below:

Stainless Steel Pots and Pans

Stainless steel is the first choice for pots, pans, and frying pans because it does not react with the food, conserves heat, and is easy to clean, making it suitable for all types of cooking and the like.

Kitchen Knives

High-carbon stainless steel is the top pick for making extremely sharp and long-lasting kitchen knives. It can do so with its ability to maintain a sharp cutting point and prevent corrosion, thus the best choice for very accurate cutting.

Cutlery

Stainless steel is the main material for forks, spoons, and knives because of its strength and the fact that it can last long with just a little polishing, therefore, being both useful and good-looking.

Mixing Bowls

Stainless steel mixing bowls are practical for food prep as they are lightweight, durable, and their resistant to staining and odors.

Baking Sheets

Steel baking sheets and pans have the ability to hold and distribute heat evenly so that they can be used for baking not only cookies and pastries but also all other kinds of baked goods evenly.

All these usages are factors confirming the versatility of steel in the kitchen, meeting both professional and home cooking needs.

Challenges of Using Steel in Heat Transfer Applications

I have met one challenge when working with steel in heat transfer applications and that is its thermal conductivity being relatively lower compared to copper or aluminum. Consequently, it may take a longer time for the heat to be distributed, which in some cases, might lead to an inefficiency. Furthermore, in the case of steel, it is likely to experience thermal expansion, thus causing an increase in stresses and even distortions in high temperature surroundings. Although steel has the feature of being strong and applicable in many contexts, these factors can still act as a barrier in certain heat transfer situations.

References

- The Conduction of Heat in Solids

JSTOR

Explores the factors influencing heat conduction in solids, with insights into metal properties like steel. - Prediction of Thermal Conductivity of Steel

ScienceDirect

Analyzes the thermal conductivity of steel across various temperatures and its implications in engineering. - The Theory of Moving Sources of Heat and Its Application to Metal Treatments

ASME Digital Collection

Examines heat conduction and temperature distribution in metals, including steel, during thermal treatments.

Frequently Asked Questions (FAQ)

Is steel a good conductor of heat?

Steel is considered a poor conductor of heat compared to other metals like copper and aluminum. While it can transfer heat, its thermal conductivity is lower than that of these metals, which makes it less effective for applications requiring efficient heat transfer.

How does the thermal conductivity of stainless steel compare to other metals?

Stainless steel has a lower thermal conductivity compared to metals like copper and aluminum. This means that while stainless steel can conduct heat, it does so at a much slower rate, making it less suitable for applications that require rapid heat transfer.

What are the benefits of stainless steel in heat transfer applications?

Despite its lower thermal conductivity, stainless steel offers benefits such as corrosion resistance and durability. These properties make it an excellent choice for heat exchangers and environments where resistance to thermal expansion and corrosion is crucial.

Can steel alloys conduct heat effectively?

Steel alloys can vary in their ability to conduct heat. Some alloy steels are designed to improve thermal conductivity, but generally, they still fall short compared to metals with high thermal conductivity like copper and aluminum.

How does the thermal conductivity of structural steel affect its use?

The thermal conductivity of structural steel influences its application in construction. While it can conduct heat, its lower thermal conductivity compared to other materials may lead to heat loss in structures, requiring additional insulation to maintain energy efficiency.

Is stainless steel a good conductor of electricity?

Stainless steel is not a good conductor of electricity compared to metals like copper. Its lower electrical conductivity means it is often used in applications where electrical insulation is required alongside its structural properties.

What is the specific heat capacity of steel?

The specific heat capacity of steel is relatively low compared to other materials, which means it can heat up quickly but also loses heat rapidly. This property can affect its performance in thermal management applications.

How does stainless steel conduct heat compared to aluminum?

Stainless steel conducts heat at a lower rate than aluminum. While aluminum is known for its high thermal conductivity, making it a great conductor of heat, stainless steel’s properties make it less effective for applications requiring efficient heat transfer.

What are poor thermal conductors, and how does steel fit in?

Poor thermal conductors are materials that do not transfer heat efficiently. Steel is considered a poor conductor of heat, especially when compared to metals with high thermal conductivity like copper or aluminum, making it less ideal for certain thermal applications.