Your Complete Guide to Industrial-Grade Stainless Steel Piping Solutions

In the case of industrial and commercial projects, the use of large diameter stainless steel pipes is essential for providing durability, corrosion resistance, and structural integrity as the main features. Besides the oil and gas industry, construction, and water treatment, these pipes with superior performance are already or will be the backbone of many applications. But what differentiates them? The following blog covers all the aspects of large diameter stainless steel pipes that you need to know including their main features, different uses, and tips on how to manage inventories. If you want to be well-informed for your next big project, you are in the right place. Let us look at the main reasons why these pipes are an integral part of the present-day industry.

Understanding Large Diameter Stainless Steel Pipes

The large diameter stainless steel pipes are famous for their long lastingness, resistance to corrosion and ability to endure high pressures, thus making them indispensable in many sectors. They find a place in processes like transportation of oil and gas, water supply and construction works. The pipes have been accepted for their prolonged life, no/minimal maintenance requirements and superb operation in harsh conditions. Their multifunctionality and dependability have turned them into a major part of the contemporary infrastructure and industrial functioning.

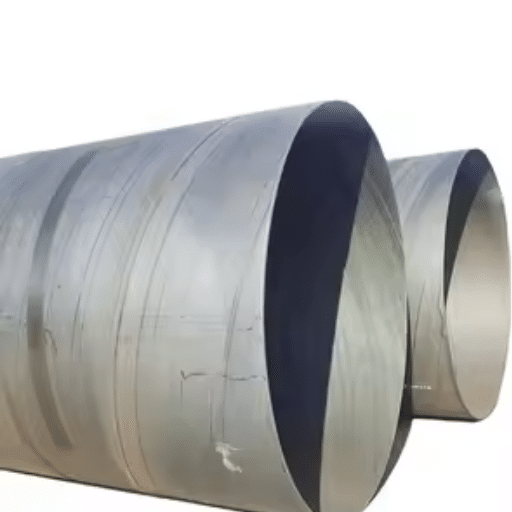

What is Large Diameter Stainless Steel Pipe?

Historically, a large diameter stainless steel pipe has been and is still considered to be a specialized pipe for applications requiring huge volume flow or large structural support. Basically, this kind of pipe is made out of stainless steel, which produces an alloy that is resistant to corrosion, thus ensuring its durability and reliability, even in the most extreme environments.

Key Industries Using Large Diameter Stainless Steel Pipes:

- Oil and Gas

- Chemical Processing

- Wastewater Treatment

- Construction and Infrastructure

- Renewable Energy Projects

Being the outcome of modern manufacturing techniques, the large diameter stainless steel pipes of today offer more precision, enhanced strength, and better customization options, thus becoming the very basis of modern industrial and infrastructural advancements.

Types of Large Diameter Stainless Steel Tubing

Seamless Stainless Steel Tubing

Seamless tubing is the perfect material for high-pressure applications as it is made without welding or seams. Its properties of strength and homogeneity make it the best pick for industries like oil and gas, aerospace, and chemical processing.

Welded Stainless Steel Tubing

Welded tubing is the result of welding together rolled steel strips to form a pipe. Although it is more affordable than seamless tubing, welded tubing is still very durable and, therefore, widely used in structural applications, water pipelines, and low-pressure situations.

Heat-Exchanger Tubing

Heat-exchanger tubing is made especially for heat transfer systems and is, therefore, extensively applied in power plants, chemical refineries, and HVAC systems. It guarantees great protection against corrosion and extremely high-temperature conditions.

Instrumentation Tubing

Instrumentation stainless steel tubing is high-precision, has near-impeccable-engineering characteristics, and is used in the most critical industries, e.g. pharmaceuticals and petrochemicals. It is manufactured for stringent tolerances and thus affords great purity for delicate applications.

Duplex and Super Duplex Tubing

The stainless steel tubing of duplex and super duplex types, on the other hand, provide the best of both worlds, i.e. very high tensile strength and superior resistance to corrosion. They are often found in marine applications, petrochemical plants, and desalination processes as they can last longer than the competition in tough conditions.

Key Specifications and Standards (ASTM)

In the case of stainless steel tubing, adherence to ASTM standards guarantees reliability, quality, and compatibility for different applications. The ASTM (American Society for Testing and Materials) offers globally accepted standards that cover material properties, dimensions, and performance.

Important ASTM Standards:

- ASTM A789/A789M: Criteria for production of both seamless and welded duplex stainless steel tubing with focus on corrosion resistance, mechanical properties, and quality control

- ASTM A790/A790M: Requirements for high-pressure and extreme environment seamless and welded super duplex steel pipes

Materials and Grades

| Grade | Type | Key Properties | Common Applications |

|---|---|---|---|

| UNS S32750 | Super Duplex | Exceptional corrosion resistance, high strength, excellent toughness | Offshore oil rigs, chemical processing |

| UNS S32760 | Super Duplex | High chloride exposure resistance, superior strength | Water desalination plants, marine environments |

| UNS S31803 (Duplex 2205) | Duplex | Cost-effective, good performance in moderate environments | General industrial applications, moderate corrosion resistance needs |

The material choice is usually made considering the factors such as temperature, pressure, and the presence of corrosive agents, in order to guarantee that the production of components with the desired properties lasts over time in the extreme operating conditions.

304 vs. 316 Stainless Steel

Stainless steels 304 and 316 are widely used in both industrial and consumer applications, however their differences are significant enough to have them classified as different groups. The main point of difference between the two is their chemical composition. Both are chromium-nickel alloys, but 316 stainless steel has the addition of molybdenum which provides it with superior corrosion resistance especially in the case of chlorides and other chemicals commonly found in very harsh environments and thus 316 is the most appropriate of the two.

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Composition | Chromium-nickel alloy | Chromium-nickel alloy + Molybdenum |

| Corrosion Resistance | Excellent for general applications | Superior, especially against chlorides |

| Cost | More affordable | Higher initial investment |

| Best Applications | Kitchen equipment, piping, tanks | Marine environments, pharmaceutical, chemical industry |

| Environmental Suitability | General purpose, mild environments | Harsh environments, saltwater, acidic conditions |

Corrosion Resistance of Alloy Grades

In terms of corrosion resistance, both 304 and 316 stainless steel grades are practically the same but the difference lies in their environmental surroundings. Corrosion resistant abilities of grade 304 can’t be questioned as it is able to resist general-purpose applications very well; however, susceptibility to corrosion in chloride-exposed places, like coastal regions, and exposures that involve pretty large amounts of saltwater is what happens with it most of the times.

Conversely, 316 stainless steel possesses excellent corrosion resistance owing mainly to the molybdenum inclusion that adds to its toughness against temperatures and corrosive conditions in general. Thus, the outstanding property of 316 in this respect makes it the number one choice for marine habitats, chemical plants, and places with a high saline or acidic atmosphere.

304L and 316L Stainless Steel Tubing

When one is faced with the choice of the two stainless steel tubing 304L and 316L, the main factors that will push the decision to one side or the other are the application needs and environmental conditions. The most recent research suggests that 304L stainless steel is the preferred option for those applications where cost, good corrosion resistance in mild environments, and so on are the main priorities.

In contrast, the 316L stainless steel shows excellent resistance to chlorides and acidic conditions and thus becomes the material of choice for nasty areas like marine, chemical plants, and water with a very high salt content or corrosion-prone areas. The presence of molybdenum in the 316L alloy is what gives it the ability to resist both pitting and crevice corrosion; this is very important for long lasting durability in harsh environments.

Key Decision Factors:

- Environmental conditions and exposure levels

- Expected service life requirements

- Budget constraints and long-term cost analysis

- Specific performance requirements

Manufacturing Process

The production of 304L and 316L stainless steel through manufacturing process is carried out in many stages:

- Melting: Raw materials including iron, chromium, nickel, and molybdenum are melted under very high temperatures

- Casting: The molten mixture is cast into slabs or billets that are solid forms

- Hot Rolling: Process to shape the material and improve its properties

- Annealing: Heat treatment to soften the material and relieve internal stresses

- Pickling: Chemical treatment to remove impurities and enhance corrosion resistance

Sustainable Manufacturing Innovation: The use of electric arc furnaces in stainless steel production effectively recycles scrap metal, lowering energy use and greenhouse gas emissions. This innovation aligns with the industry’s increasing demand for eco-friendly solutions.

Seamless vs. Welded Stainless Steel Pipes

| Aspect | Seamless Pipes | Welded Pipes |

|---|---|---|

| Manufacturing Method | Extrusion and drawing from solid billet | Welding steel strips or plates together |

| Structure | Uniform, no welded seam | Contains welded seam |

| Strength | Superior toughness and stress resistance | Good strength with modern welding technologies |

| Cost | More expensive | More affordable and versatile |

| Best Applications | High-pressure, high-temperature, oil and gas | Plumbing, construction, fluid transportation |

Pipe Cutting Techniques for Large Diameter Tubes

Selecting the right way to cut large diameter tubes is influenced by the type of material, precision requirements, time and budget limits. Current trends indicate that among the most popular ways to get high precision and efficiency are laser cutting and water jet cutting.

Laser Cutting

- Advantages: High accuracy, reduced material waste, smooth edges, less post-process finishing

- Ideal For: Stainless steel and alloy pipes requiring precision

- Consideration: High equipment cost makes it suitable for high-budget projects

Water Jet Cutting

- Advantages: Extremely adaptable, works with wide range of materials, no heat generation, eliminates material distortion

- Ideal For: Metals, composites, ceramics, and critical manufacturing applications

- Consideration: Increasingly sought after for precision work

Traditional Methods

- Plasma Cutting

- Saw Cutting

- Flame Cutting

These methods provide cost-effective options for projects where precision is not a major concern.

Polishing and Finishing Options

Polishing and finishing selections are crucial for obtaining the materials’ surface quality, durability, and aesthetic attractiveness as desired. Industries are adopting advanced polishing methods to achieve precise results:

Electropolishing

Removes surface defects, enhances corrosion resilience, and provides a shiny finish. Widely used for stainless steel applications.

Vibratory Finishing

Technique used in high-volume production for maintaining consistent quality across large quantities of items.

Mechanical Polishing

Traditional method for achieving desired surface finish and aesthetic appeal.

Modern Innovation: Automated polishing systems integrating AI and robotics ensure increased productivity and standardization in finishing processes.

Applications of Large Diameter Stainless Steel Pipes

Oil and Gas Industry

The use of large diameter pipes for the transportation of crude oil, natural gas, and petrochemical products is very common. Their capacity to endure high pressure and corrosive conditions makes them the best option for offshore drilling facilities and pipelines that stretch across continents. Offshore drilling rigs entirely depend on these pipes to withstand exposure to very salty water and extreme conditions.

Water Supply and Treatment

These pipes are indispensable in water supply and treatment systems, desalination plants and wastewater treatment plants. Because of their being anti-corrosive and ability to handle high flow rates, they are sure to last long and operate reliably. In desalination plants, stainless steel pipes can work effectively for decades without any degradation.

Construction and Infrastructure

Large diameter stainless steel pipes have been used in the structural support of large buildings, the construction of bridges, and they’ve even provided strength and resistance to environmental wear, thus prolonging the life of infrastructure projects. The use of stainless steel in construction has more than doubled as it can resist the severest of weather conditions and still maintain its structural integrity for many years.

Power Generation

Nuclear, thermal, and hydroelectric plants are some of the facilities that power generation plants use these pipes for the movement of steam, heating water, and other fluids. The power industry uses stainless steel pipes in different systems like boilers, heat exchangers, and turbines. Their heat resistance and structural integrity are very important for safe and efficient operations to take place.

Chemical and Pharmaceutical Industries

Large diameter stainless steel pipes are in use in chemical processing units and pharmaceutical production facilities. Their proficiency in maintaining product purity and resisting chemical corrosion is a major factor in these highly sensitive applications.

Food and Beverage Industry

In food processing and beverage production lines, large diameter stainless steel pipes are a must-have. Their non-reactive surface keeps contamination at bay, thus preserving product integrity and satisfying even the strictest hygiene standards. The most common applications are dairy processing, brewing, and soft drink manufacturing.

Automotive and Aerospace Industries

In exhaust systems of cars and fuel lines of airplanes, stainless steel pipes are indispensable where strength, lightness, resistance to heat, and corrosion are the main factors. All these qualities are the reason for the performance and safety of cars and planes in the harshest conditions.

Custom Applications and Specialty Uses

Stainless steel has been a very useful material for many custom applications and special areas:

- Medical Field: Surgical instruments, orthopedic implants, medical-grade surfaces

- Aerospace: Aircraft components, rocket engine parts

- Renewable Energy: Solar panel mounts, wind turbines

- Other Applications: Food processing equipment, luxury watches, modern art installations

Inventory and Sourcing

Large Inventory of Stainless Steel Pipe Products

A large selection of stainless steel pipe products guarantees that firms can resolve different customer needs, and do so quickly and efficiently. The manufacturing, construction, and petrochemical industries are all major consumers of pipes made of stainless steel because of their long-lasting nature, resistance to corrosion, and adaptability.

Key Consumer Questions:

- “Where can I buy good quality stainless steel pipes?”

- “Which company provides stainless steel products with a minimum environmental impact?”

Companies that hold large quantities of stocks, are ethically sourcing their products, and are very eco-conscious are in the best position to fulfill these consumer expectations.

How to Source 304 Stainless Steel and Other Grades

When it comes to sourcing 304 stainless steel and other grades, it is necessary to consider suppliers according to their quality, sustainability, and availability:

- Find Reputed Suppliers: Look for suppliers that comply with industry standards like ISO 9001 certification

- Prioritize Sustainability: Choose suppliers operating energy-efficient facilities or recycling materials in production

- Research Thoroughly: Use search engines to find leading global suppliers, review customer feedback, and explore industry discussions

- Utilize Business Directories: Platforms like ThomasNet and Alibaba for vendor comparisons

- Request Documentation: Obtain detailed technical specifications and material certifications

- Maintain Close Relationships: Work with suppliers who have large stocks for fast lead times and minimal delays

Considerations for Custom Steel Tube Orders

When ordering custom steel tubes, it is very important to consider the specific requirements of your application:

- Material Specifications: Clearly specify the required grade of steel (strength, corrosion resistance, heat tolerance)

- Dimensional Requirements: Precise specification of length, diameter, and wall thickness

- Certifications: Ensure supplier can meet necessary certifications and compliance standards (ASTM, ISO)

- Sustainability Considerations: Inquire about recycled materials and eco-friendly production practices

- Customization Capabilities: Look for suppliers with high-tech capabilities such as laser cutting or CNC machining

References

- Federal Register: Documentation on large diameter welded pipes, including specifications and trade details.

Link to source - CROSS Ruling (U.S. Customs and Border Protection): Tariff classification of stainless steel pipes manufactured to ASTM and ASME standards.

Link to source

Frequently Asked Questions (FAQ)

What are the advantages of using large diameter stainless steel pipe?

Large diameter stainless steel pipe has extremely high corrosion resistance, great durability, high strength-to-weight ratio, excellent aesthetic properties among other advantages. It is the most suitable option for a wide range of applications such as structural support, fluid transport, and decorative uses. Also, stainless steel gives an attractive look which makes it fit for both commercial and residential projects.

What sizes are available for stainless steel tubing?

Stainless steel tubing comes in a broad selection of sizes which include both outside diameter (OD) and inside diameter (ID) dimensions. Diameter sizes range from very small ones for delicate applications to very large ones for heavy-duty use. Moreover, custom cut service is available to satisfy your project requirement.

How does the specification of ASTM A554 apply to stainless steel pipe?

ASTM A554 is a standard specification that dictates the quality and requirements of welded stainless steel tubing for structural use. By following this specification, the pipe is made to garner those specific strength and corrosion resistance qualities, hence, making the pipe appropriate for a wide range of industrial and architectural applications.

What is the difference between seamless and welded stainless steel tubing?

Seamless and welded stainless steel tubing differ primarily in how they are made. The seamless tubing is made from a solid round steel billet that is heated and then canned by using a process that results in no seams, thus a homogeneous structure. The welded tubing, on the other hand, is made by taking a metal strip and welding its two edges. Seamless tubing is more often than not used in high-pressure applications because of their strength and reliability.

Can I get custom cuts for large diameter stainless steel pipe?

Definitely, most suppliers extend their custom cutting facilities for large diameter stainless steel pipe. This makes it possible for you to acquire pipe lengths specifically designed to meet the requirements set by your project, thereby, ensuring that you have the size and fit needed for your purpose. Custom cuts can be done not only for round but also for rectangular tubing.

What types of stainless steel fittings are available for large diameter pipes?

Several categories of stainless steel fittings are offered for large diameter pipes, which consist of elbows, tees, reducers, and flanges. These fittings serve to connect pipe sections, alter flow direction, or reduce the size of the piping system, and provide plumbing or structural applications with proper and secure assembly.

What is the corrosion resistance of 304 and 316 stainless steel?

The two, 304 and 316 stainless steel, exhibit superb corrosion resistance, however, 316 gives more of a safeguard against chlorides and the marine environment. 304 is quite general-purpose; it does fit application-wise many times but 316 is always there in heavy duty domains like in chemical processing or coastal regions where its properties are put to the test, hence, more demanding conditions.

What services and delivery options are available for stainless steel tube products?

A plethora of suppliers offer various services and delivery options for stainless steel tubes, which include fast shipping, same-day delivery, and stocking on demand. Apart from these, they could also provide services like cutting, polishing, and custom fabrication of tubes that are specifically requested by the customer.