Annealed and pickled stainless steel pipes Manufacturer in China

Engineered with precision technology for exceptional corrosion resistance, structural integrity, and long-term reliability in demanding industrial environments.

Annealed and pickled stainless steel pipes

- Premium Quality

- Customizable Sizes

- Industrial Grade

Overview :

Description :

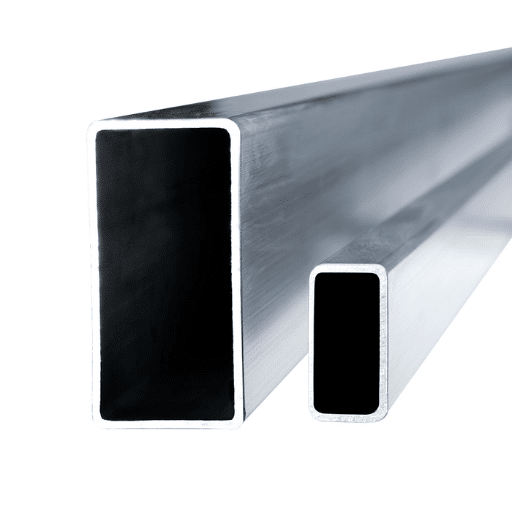

Annealed and Pickled Stainless Steel Pipes are premium piping solutions crafted to meet the rigorous demands of industrial, construction, and manufacturing applications. Produced using advanced techniques, these pipes undergo annealing—a heat treatment process—and pickling, which removes scale and enhances corrosion resistance, ensuring exceptional strength, durability, and longevity. Ideal for structural support and fluid transportation, they excel in harsh environments.

Available in various diameters, thicknesses, and lengths, these pipes offer customization flexibility while conforming to international standards like GB/T, ASTM, and ANSI. The annealed and pickled finish provides a clean, smooth surface, improving both functionality and corrosion resistance, making them suitable for high-pressure systems, food processing, and medical equipment manufacturing. With precise engineering and stringent quality controls, these pipes guarantee reliable, consistent performance for long-term use.

Get a Quote

Explore Our Annealed and pickled stainless steel pipes

304 Stainless Steel Pipe

Annealed and pickled 304 stainless steel pipes are a premium variant of the widely used 304 stainless steel pipe, engineered for enhanced performance in demanding applications. Renowned for their superior corrosion resistance, improved surface quality, and increased durability, these pipes undergo annealing to relieve internal stresses and enhance ductility, followed by pickling to remove surface impurities, resulting in a smooth, clean finish. Ideal for industries such as chemical processing, food and beverage, and pharmaceuticals, they excel in environments requiring hygiene and resistance to harsh conditions. Manufactured to rigorous international standards, annealed and pickled 304 stainless steel pipes ensure consistent quality, excellent weldability, and reliable, long-term performance for critical systems.

316L Stainless Steel Pipe

Annealed and pickled 316L stainless steel pipes are a high-quality variant of the 316L stainless steel pipe, designed for exceptional performance in corrosive and demanding environments. Celebrated for their enhanced corrosion resistance, superior surface finish, and excellent durability, these pipes undergo annealing to improve ductility and reduce internal stresses, followed by pickling to eliminate surface oxides and impurities, yielding a smooth, pristine appearance. With their low carbon content, they offer outstanding weldability and resistance to intergranular corrosion, making them ideal for applications in chemical processing, marine environments, pharmaceuticals, and food production. Manufactured to stringent international standards, annealed and pickled 316L stainless steel pipes deliver consistent quality, reliability, and long-lasting performance in critical and hygienic systems.

Get More Information

Feel free to reach out to us for ap stainless steel pipes price, availability, or any additional information. Let us help you find the perfect stainless steel piping solution for your industry needs.

Why Choose Us

- Expert Craftsmanship: Increases ductility with annealing, removes oxides with pickling, ensures a smooth surface with no corrosion, and the process is mature and efficient.

- Customizable Solutions : Satisfying global requirements, as in ASTM and ISO, with quality validation by ABS and DNV guarantees trustworthy performance.

- Certified Quality: Compliant with ASTM、ISO, ABS, 、DNV standards for global reliability.

- Dedicated Support: Provides technical consultation, material selection suggestions and fast delivery to ensure smooth project progress.

Tailored Solutions for Diverse Industries

Unlock the potential of Annealed and pickled stainless steel pipes with customized solutions for your unique applications

Growth in Sustainable Construction

As eco-friendly building practices rise, these pipes will see increased use in green infrastructure projects, leveraging their corrosion resistance, durability, and recyclability for water supply and structural applications in climate-resilient designs.

Expansion in Food and Beverage Processing

Due to the enhanced requirements for hygiene, Annealed and Pickled Stainless Steel Pipes will become increasingly popular with advanced food production systems because of their smooth, cleanable surfaces and corrosion resistance which meet sanitary standards in fully automated food processing plants.

Advancement in Renewable Energy Systems

Their application in solar thermal and geothermal energy plants is expected to grow, utilizing their enhanced ductility and resistance to thermal stress for efficient heat transfer and fluid transport in sustainable energy infrastructure.

Support for Water Treatment Innovations

These pipes will be pivotal for desalination and wastewater treatment facilities due to the increasing global demand for clean water. Their cost-efficient longevity and corrosion resistance improves functionality in mildly hostile settings.

Integration in Modular Manufacturing

The trend toward modular and prefabricated construction will drive demand for these pipes, where their improved weldability and uniform finish support rapid assembly of piping systems for industrial and residential applications.

Development in Pharmaceutical Automation

The transition to automated drug manufacturing processes will require high-purity fluid transport Annealed and Pickled Stainless Steel Pipes which will ensure smooth delivery with minimum contamination in modern production facilities.

Advantages of Ap stainless steel pipes

- The pickling process removes surface scale, oxides, and impurities, while annealing optimizes the microstructure of the stainless steel. This form of dual treatment increases the pipes' resistance to rust and chemical corrosion, making the pipes suitable for hostile environments.

- Annealing is the process of controlled heating and cooling to unlock internal stresses and refine the grain structure. This helps in improving the material’s ductility so that the pipes can be easily bent, shaped, or welded without cracking which is crucial during custom fabrication for complex piping systems.

- The pickling process is accomplished with the use of acidic solutions to eliminate surface blunders. As a result this raises the aesthetic appeal for visible applications while lowering the likelihood of contamination or bacterial adhesion in food, beverage, and pharmaceutical industries.

- Pipes undergo prolonged exposure to severe conditions such as high pressure, extreme temperatures, or corrosive fluids. The combination of these factors expands service lifetime while decreasing maintenance costs, these pipes are stronger due to the annealing and pickling processes that are combined.

- With excellent weld integrity and corrosion resistance, stainless steel welded pipes deliver long-lasting performance in challenging environments. They are particularly effective in industries requiring hygienic and durable systems.

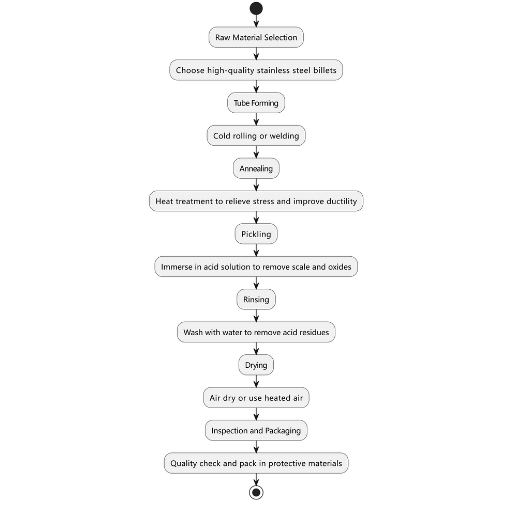

Manufacturing Process

- We take great care to select high-grade, stainless steel which contains the appropriate raw materials with the specific desired chemical and mechanical properties. The steps taken within this stage allows the end product to be durable, corrosion resistant, and provide excellent performance.

- We utilize automated welding machines such as TIG(Tungsten Inert Gas) and Laser welders to form seamless and strong pipes. Welding is done with great care so that constituents do not deviate from the conditions set and welded structures achieve the required precise measurements uniformly to the get the desired quality consistently.

- Heating treatment processes such as controlled heating and slow cooling is referred to as annealing. This is done post-welding on pipes to relieve internal stresses due to welding, refine ductility, toughness, and overall improve mechanical properties. Change grain structure to further enhance ductility.

- The smooth, scale and oxide free annealed pipes undergo pickling with chemical solutions such as nitric or hydrofluoric acid. With this finishing treatment, the pipe gains even more protection against rust and improves their visual impressiveness.

- Surface smoothing may be applied after pickling to achieve a finer finish. This step makes the pipes more hygienically appropriate for food or pharmaceutical processing by further reducing surface roughness and increasing cleanliness.

Annealed and pickled stainless steel pipes Pressure Rating Specification Chart

| Grade | Type | Corrosion Resistance | Strength | Applications |

|---|---|---|---|---|

| 304/304L | Austenitic | Good resistance to general corrosion, moderate in chloride environments | Yield: ~210-250 MPa, Tensile: ~505-620 MPa | Food processing, chemical industries, architectural structures |

| 316/316L | Austenitic | Excellent, especially in chloride and acidic environments due to molybdenum | Yield: ~220-290 MPa, Tensile: ~520-680 MPa | Marine, pharmaceutical, oil & gas, heat exchangers |

| 321 | Austenitic | Good, with resistance to intergranular corrosion at high temperatures | Yield: ~205-240 MPa, Tensile: ~515-650 MPa | Aerospace, exhaust systems, high-temperature piping |

| 410 | Martensitic | Moderate, better in mild environments, less than austenitic grades | Yield: ~260-450 MPa, Tensile: ~500-700 MPa | Structural supports, automotive components, fasteners |

| 2205 (Duplex) | Duplex (Ferritic-Austenitic) | Excellent, high resistance to pitting and crevice corrosion | Yield: ~450-620 MPa, Tensile: ~650-880 MPa | Oil & gas pipelines, chemical processing, seawater systems |

| 17-4 PH | Precipitation Hardening | Good, improved by heat treatment, less than 316 in harsh conditions | Yield: ~1000-1200 MPa (aged), Tensile: ~1100-1400 MPa | Aerospace, nuclear, high-strength structural uses |

Expert Guide to Annealed and pickled stainless steel pipes

What does pickled and annealed mean?

“Pickled” means treating stainless steel with acid to remove oxides and impurities, enhancing corrosion resistance. “Annealed” refers to heat treatment followed by slow cooling to relieve stresses and improve ductility, resulting in stronger, more durable pipe

What are the benefits of pickling stainless steel?

Pickling stainless steel removes oxides, scale, and impurities, enhancing corrosion resistance, improving surface smoothness, and ensuring hygiene. It boosts durability, aesthetic appeal, and suitability for applications like food processing and chemical industries.

What is the pickling curing method?

The pickling curing procedure includes dipping stainless steel in acid mixtures for oxide and scale removal which may contain nitric or hydrofluoric acid. This step enhances the passivation of the steel, as well as removes surface contaminants.

What does annealing do to stainless steel?

Relieving internal stresses, refining grain structure, and enhancing ductility in stainless steel is achieved by heating and slowly cooling it through a process known as annealing. This helps improve resistance to cracking and increases formability, thus providing better performance.

What is the process of pickling stainless steel pipes?

Removing the oxide scale and discoloration by means of pickling stainless steel pipes consists of dipping them into either nitric or hydrofluoric acid solutions. This is done to clean and polish piping for better feature visibility and corrosion removal.

Resources on Ap stainless steel pipes

✷ Applications of Ap stainless steel pipes✷

Annealed and pickled stainless steel pipes offer versatile solutions across industries, combining durability, corrosion resistance, and precision for a wide range of applications.

Oil and Gas Industry Pipes

Chemical Fluid Transport

Food Processing Equipment

Pharmaceutical Aseptic Systems

Marine Engineering Structures

Heat Exchanger Manufacturing

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Frequently Ask Questions

Q: What distinguishes annealed and pickled stainless steel pipes from other stainless steel pipes?

A: AP stainless steel pipes undergo annealing to enhance strength and ductility, followed by pickling to remove scale and improve corrosion resistance, resulting in superior durability and a clean, smooth surface compared to untreated pipes.

Q: How does the annealing process benefit AP stainless steel pipes in high-pressure applications?

A: Annealing relieves internal stresses and refines the microstructure, increasing the tensile strength and toughness of AP stainless steel pipes, making them ideal for withstanding high-pressure conditions in industries like oil and gas.

Q: Why is pickling critical for the performance of annealed and pickled stainless steel pipes?

A: Pickling removes oxides and surface impurities formed during annealing, enhancing corrosion resistance and ensuring a uniform, hygienic finish critical for applications such as chemical processing and food production.

Q: What industries most commonly utilize AP stainless steel pipes, and why?

A: Industries like petrochemical, pharmaceutical, and marine engineering prefer AP stainless steel pipes for their exceptional corrosion resistance, high strength, and clean surface, which meet stringent operational and sanitary requirements.

Q: How do AP stainless steel pipes comply with international quality standards?

A: AP stainless steel pipes are manufactured to standards such as ASTM A312, A790, and EN 10216-5, undergoing rigorous testing (e.g., hydrostatic and non-destructive) to ensure dimensional accuracy, mechanical properties, and surface quality.

Q: What role does the surface finish of annealed and pickled stainless steel pipes play in their functionality?

A: The smooth, oxide-free surface of AP stainless steel pipes, achieved through pickling, minimizes friction, prevents contamination, and enhances corrosion resistance, making them suitable for fluid transport and aesthetic structural uses.