Copper Pipe & Tube Machinery - A Comprehensive Guide to Copper Tube Manufacturing

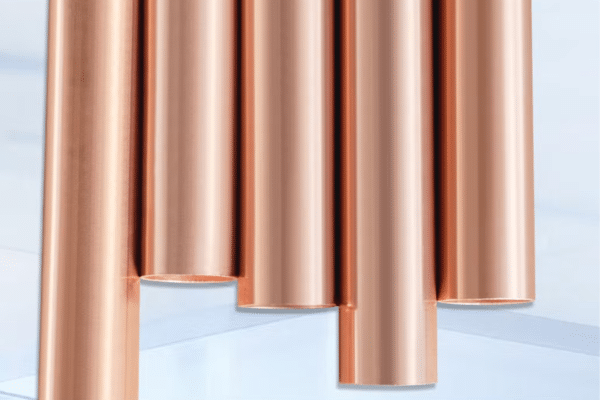

The demand for copper tubing is ever-increasing across various industries due to its remarkable properties. From refrigeration systems to plumbing and air conditioning units, copper tubes are integral components. We delve into the intricacies of copper tube manufacturing, offering insights into the processes and materials that make copper tubing an industry staple.

Overview of Tube Production

The copper tube production process begins with raw materials, primarily copper and copper alloys, which undergo stringent quality checks. The production line employs advanced machinery to ensure the precision and uniformity of the tubes. From extrusion to the final forming techniques, each step in the manufacturing process is meticulously controlled to produce superior copper products.

Features and advantages of the Machinery Manufacturing Copper Tube

Our copper tubes deliver exceptional thermal conductivity and corrosion resistance for demanding industrial applications. Manufactured to the highest international standards with state-of-the-art technology.

Precision Engineering

Designed and manufactured with tight tolerances, these tubes deliver consistent performance and reliability in machinery applications.

Superior Thermal Conductivity

Copper’s excellent heat transfer properties make it ideal for applications requiring efficient cooling or heating, such as HVAC systems and industrial machinery.

Versatile Applications

Available in various sizes and specifications, copper tubes can be used in a wide range of industries, including manufacturing, construction, and energy.

Aesthetic Appeal

The natural metallic finish of copper adds a professional and polished look to machinery and systems.

Detailed Specifications of Machinery Manufacturing Copper Tube

| Specification | Value/Standard | Certification |

|---|---|---|

| Material Grade | C12200 (Cu-DHP), C10200, C10800 | ASTM B88, ASTM B280 |

| Copper Purity | ≥99.90% Cu + Ag | EN 1057, EN 12735 |

| Phosphorus Content | 0.015% - 0.040% | Deoxidized High Phosphorus |

| Thermal Conductivity | 330-401 W/m·K @ 20°C | Laboratory Tested |

| Tensile Strength | 220-380 MPa (Annealed: 220 MPa, Hard: 380 MPa) | ASTM Standards |

| Yield Strength | 120-275 MPa (depending on temper) | ISO 9001:2015 |

| Elongation | 30-45% (Annealed), 5-12% (Hard) | Mechanical Testing |

Why choose to use our Machinery Manufacturing Copper Tube?

- Rigorous Quality Control: 100% eddy current testing detects microscopic defects. Dimensional inspection with ±0.05mm tolerance. Hydrostatic testing to 1.5x working pressure. Every batch includes material certification and chemical analysis reports.

- Industry Certifications: ISO 9001:2015 certified manufacturing. ASTM B88, B280, B75 compliant. NSF/ANSI 61 certified for potable water. UL listed for fire protection. EN 1057 and EN 12735 European standards approved.

- Extensive Inventory: Stock over 200 size combinations for immediate delivery. Standard lengths from 10ft to 20ft hard drawn tubes. Coil weights up to 1,000kg for continuous applications. Custom configurations within 2-3 weeks.

- Reliable Delivery: 99.2% on-time delivery record. Strategic warehouse locations across North America. Expedited shipping available for urgent orders. Secure packaging prevents damage during transport.

Applications of Machinery Manufacturing Copper Tube

HVAC & Refrigeration Systems

Industrial & Manufacturing

Machinery Manufacturing Copper Tube

Automotive & Transportation

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

Ready to Experience Superior Performance?

Our copper tubing solutions stand out due to our commitment to excellence and customer satisfaction. With state-of-the-art manufacturing processes and a focus on quality, our copper tubes are made of copper alloys that ensure superior performance in industrial applications.Reach out to us today to learn more about our product offerings.

Frequently Ask Questions

Q: What types of fittings are available for copper tubing?

A: Various types of fittings are available for copper tubing, including elbows, tees, and couplings. These fittings are essential for connecting copper pipes in plumbing and refrigeration systems, ensuring a tight and leak-proof seal.

Q: How is the wall thickness of copper tubes important?

A: The wall thickness of copper tubes is crucial as it affects the tube’s strength, pressure rating, and overall durability. A suitable wall thickness ensures that the tubing can withstand the pressures of various applications, including hydraulic and refrigeration systems.

Q: What are the benefits of using welded copper in manufacturing?

A: Welded copper offers several benefits, including enhanced strength and the ability to create seamless joints. This is particularly advantageous in applications where high pressure is involved, such as in automotive and hydraulic systems.

Q: What role does extrusion play in copper tube production?

A: Extrusion is a vital part of copper tube production as it allows for the continuous shaping of copper into tubes of various diameters and wall thicknesses. This process is essential for maintaining consistent quality and meeting the specifications required for different applications.

Q: How does copper tubing contribute to refrigeration systems?

A: Copper tubing is widely used in refrigeration systems due to its high thermal conductivity and corrosion resistance. It efficiently transfers heat, making it ideal for cooling systems and ensuring optimal performance in both residential and commercial applications.

Q: What are the specifications for high-quality copper pipe?

A: High-quality copper pipe specifications generally include a certain wall thickness to ensure durability and resistance to pressure. Additionally, the copper used should have excellent thermal and electrical conductivity, making it suitable for various industrial applications.