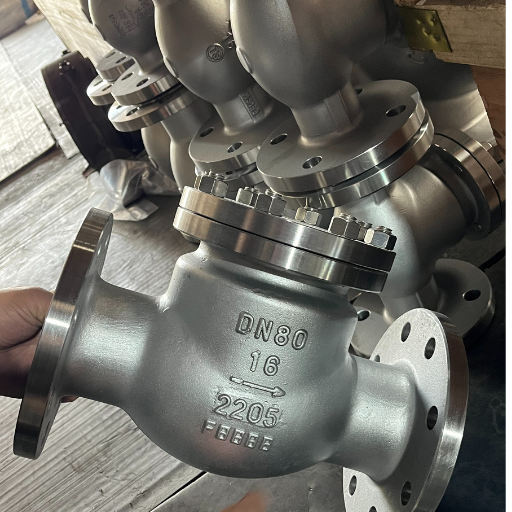

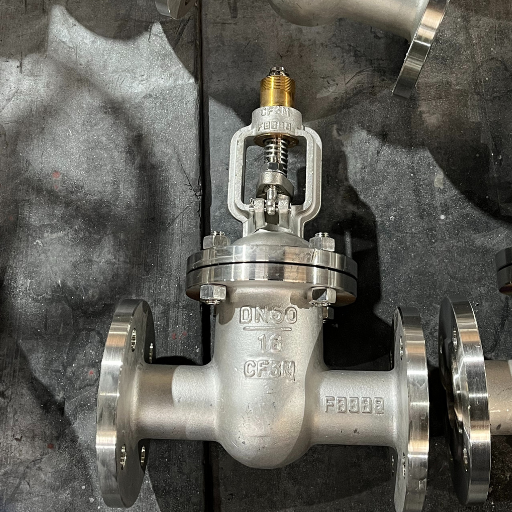

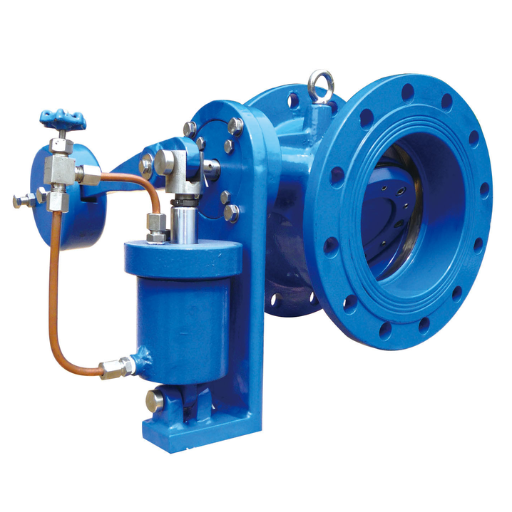

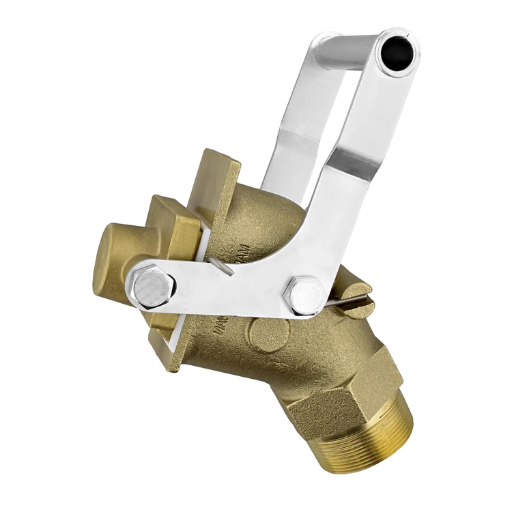

Industrial ball valves offer quick 90-degree operation, excellent shut-off performance, and durability in extreme conditions. Ideal for oil & gas, chemical processing, and water management, these versatile valves ensure precise flow control, minimal maintenance, and reliable performance across critical industrial applications.