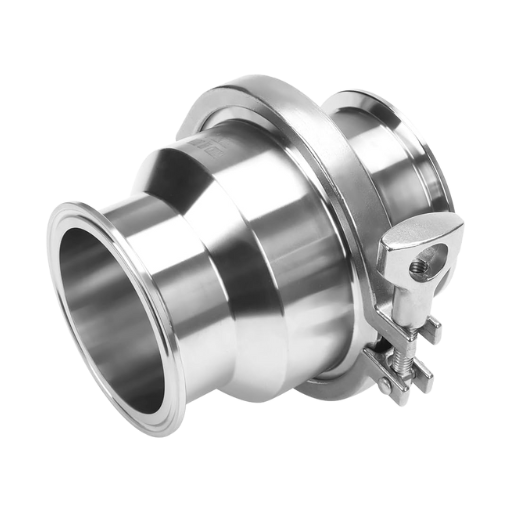

Top Sanitary Check Valves Manufacturer in China

Sanitary Check Valves are specialized, non-return valves designed to maintain unidirectional flow in hygienic systems, preventing backflow and contamination. These valves operate automatically, using a disc, ball, or spring-loaded mechanism, ensuring reliable performance with minimal maintenance. Ideal for food and beverage, pharmaceutical, and biotech applications, sanitary check valves comply with standards like 3-A and FDA, offering corrosion resistance and compatibility with clean-in-place (CIP) and steam-in-place (SIP) processes.

Sanitary Check Valves Technical Specifications

| Category | Details |

|---|---|

| Characteristics | 316/316L stainless; non-return, crevice-free; spring-loaded/disc; CIP/SIP compatible; low cracking pressure. |

| Surface Treatment | Polished internals (15-32 Ra); electropolished/passivated; external polished (240-600 grit) or brushed. |

| Dimensions and Specs | Sizes: ½”–4”; tri-clamp, weld; 145 psig max; -10°C to 150°C; inline vertical/horizontal. |

| Corrosion Resistance | Excellent vs. chlorides, CIP agents, food acids; limited in strong oxidizing acids; seals fluid-compatible. |

| Mechanical Properties | Yield: ≥205 MPa; Tensile: ≥515 MPa; Elongation: ≥35%; Hardness: ≤95 HRB; durable (~50,000 cycles). |

| Processability | Precision-machined; tool-free disassembly; CIP/SIP-ready; automatic operation; easy seal replacement. |

| Applications | Food & beverage, pharma, biotech, cosmetics, sanitary chemical systems. |

| Standards | ASTM A351, ASME BPE, 3-A, FDA 21 CFR 177, ISO 2852, API 598, EHEDG, ISO 9001. |

our latest news

Request Sanitary Check Valves Quote

Designed for precision and cleanliness, Sanitary Check Valves are ideal for the food, pharmaceutical, and biotech industries. Contact us today to customize your 3-A and FDA-compliant valves—ensure efficient, sanitary flow control now!