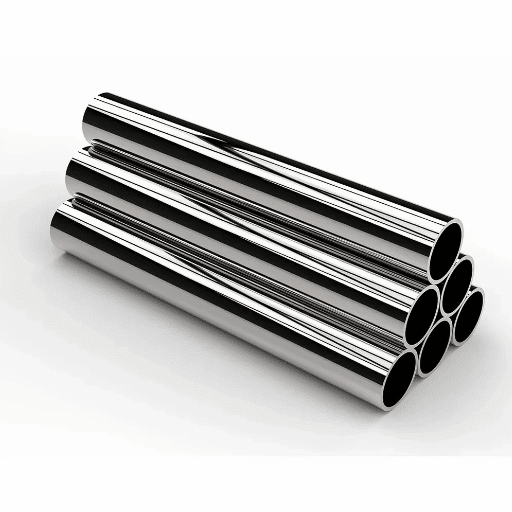

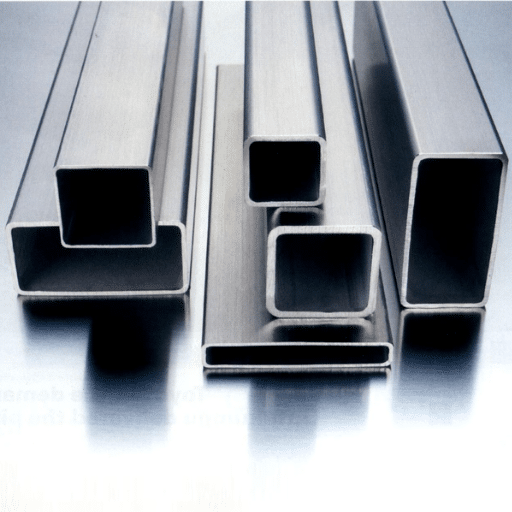

N08800 / 1.4876 Stainless Steel Heat Exchanger Tube

Engineered for high-temperature and corrosive environments, N08800 / 1.4876 stainless steel heat exchanger tubes deliver unmatched durability, thermal efficiency, and reliability for industrial applications, ensuring optimal performance in the most demanding conditions.

N08800 / 1.4876 Stainless Steel Heat Exchanger Tube - Detailed Specifications

| Parameter | Specification | Unit |

|---|---|---|

| Outer Diameter (OD) | 6.0 - 50.8 | mm |

| Wall Thickness | 0.5 - 3.0 | mm |

| Length | Up to 12 | meters |

| Temperature Range | -196 to 600 | °C |

| Pressure Rating | Up to 25 | MPa |

| Material Grade | N08800 / 1.4876 | - |

| Surface Finish | Polished or Pickled | - |

| Tolerance (OD) | ±0.1 | mm |

| Tolerance (Thickness) | ±0.05 | mm |

Understanding N08800 / 1.4876

What It Is:

Discover the unique composition and capabilities of N08800 / 1.4876 tubes, specifically designed for high-performance industrial environments.

- A nickel-iron-chromium alloy engineered to resist oxidation and carburization at elevated temperatures.

- Commonly used in heat exchangers due to its excellent thermal stability and strength.

- Designed to withstand harsh corrosive conditions, including chloride-induced stress corrosion cracking.

- Non-magnetic properties make it ideal for highly specialized industrial processes.

- Highly durable, ensuring longer service life compared to standard stainless steels.

Why It Is Your Core Focus:

Learn why N08800 / 1.4876 is the ultimate solution, enabling reliability and efficiency across challenging industrial applications.

- Guarantees efficient operation in power plants, petrochemicals, and chemical processing industries.

- Minimizes downtime with its corrosion-resistant capabilities, even under extreme temperatures.

- Enhances process reliability, reducing costs from maintenance and replacements.

- Preferred choice for complying with stringent industrial standards.

- Provides long-lasting, fail-safe performance critical for demanding environments.

N08800 / 1.4876 Stainless Steel Material Properties

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 30.0 - 35.0 |

| Chromium (Cr) | 19.0 - 23.0 |

| Iron (Fe) | Balance |

| Carbon (C) | 0.10 max |

| Manganese (Mn) | 1.50 max |

| Silicon (Si) | 1.0 max |

| Sulfur (S) | 0.015 max |

| Copper (Cu) | 0.75 max |

| Aluminum (Al) | 0.15 - 0.60 |

| Titanium (Ti) | 0.15 - 0.60 |

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 550 - 700 | MPa |

| Yield Strength | 240 min | MPa |

| Elongation | 30 min | % (in 2 in.) |

| Hardness (Rockwell B) | 85 max | HRB |

Versatile Applications of N08800 / 1.4876 Stainless Steel Heat Exchanger Tube

-

Petrochemical Industry: Heat exchangers in refineries.

-

Power Generation: Boiler tubes in power plants.

-

Chemical Processing: Corrosive fluid transfer systems.

-

Aerospace: High-temperature exhaust systems.

-

Marine Engineering: Seawater cooling systems.

-

Pharmaceuticals: Sterilization and heating equipment.

our latest news

Get a Quote for N08800 / 1.4876 Stainless Steel Heat Exchanger Tube

Whenever the operation requires higher thermal performance and resistance to high-temperature corrosion, trust in our N08800 / 1.4876 Stainless Steel Heat Exchanger Tubes. Designed for industrial strength and serviceability, these tubes assure a higher durability in rigorous conditions. Please call our experts today for more details and a customized quotation!