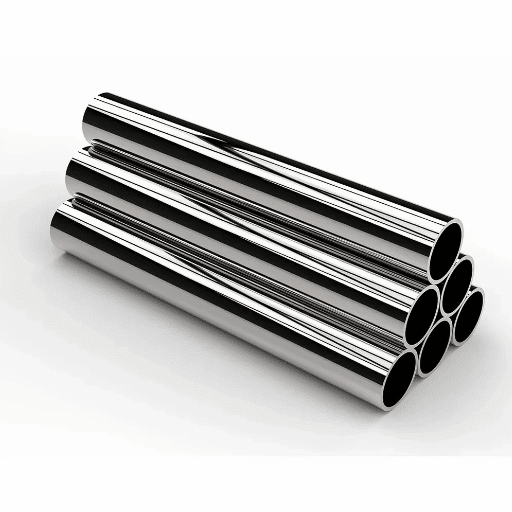

Trusted N08825 / 2.4858 Stainless Steel Heat Exchanger Tube Supplier in China

The N08825 / 2.4858 Stainless Steel Heat Exchanger Tube is engineered to deliver exceptional performance in the most challenging conditions. Its superior corrosion resistance and ability to withstand high temperatures make it an ideal solution for industries where reliability is non-negotiable.

N08825 / 2.4858 Stainless Steel Heat Exchanger Tube - Detailed Specifications

| Parameter | Specification |

|---|---|

| Material Grade | N08825 / 2.4858 |

| Standard | ASTM B163 / ASTM B423 / ASME SB163 |

| Outer Diameter (OD) | 6 mm - 50.8 mm |

| Wall Thickness | 0.5 mm - 5 mm |

| Length | Up to 12 meters |

| Corrosion Resistance | Outstanding in acidic and chloride environments |

| Max Operating Temperature | Up to 540°C |

| Applications | Chemical Processing, Marine, Power Generation |

| Tensile Strength | ≥ 550 MPa |

| Yield Strength | ≥ 220 MPa |

| Elongation | ≥ 30% |

Understanding the Standard: ASTM A240 / ASME SA-240

What It Is:

N08825/2.4858 stainless steel heat exchanger tube, durable alloy for extreme environments.

- High chromium, molybdenum, and nitrogen content.

- PREN over 40 for pitting resistance.

- Tight heat treatment and processing control.

- Optimizes austenite-ferrite balance for strength.

- Ensures exact microstructure for extreme durability.

Why It Is Your Core Focus:

N08825 / 2.4858 ensures superior defense and reliability in challenging applications.

- Guarantees exceptional performance in hot seawater.

- Resists aggressive chemical streams and high-chloride environments.

- Provides ultra-high mechanical strength for deep-sea use.

- Enables safer, efficient high-pressure systems.

- Offers certified proof of compliance for peace of mind.

N08825 / 2.4858 Stainless Steel Material Properties

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.02 |

| Silicon (Si) | ≤ 1.00 |

| Manganese (Mn) | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.035 |

| Nickel (Ni) | 24.0 - 26.0 |

| Chromium (Cr) | 19.0 - 21.0 |

| Molybdenum (Mo) | 4.0 - 5.0 |

| Copper (Cu) | 1.0 - 2.0 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 490 MPa |

| Yield Strength | ≥ 215 MPa |

| Elongation | ≥ 35% |

| Hardness (Rockwell B) | ≤ 90 |

| Density | 8.0 g/cm³ |

| Maximum Operating Temp | Up to 400°C |

Applications of N08825 / 2.4858 Stainless Steel Heat Exchanger Tube

-

Chemical Processing: Acid condensers and alkalis resistant systems

-

Marine Industry: Seawater cooling and desalination systems

-

Power Generation: Heat exchangers in steam & nuclear plants

-

Oil & Gas: Sour gas extraction and offshore processing platforms

-

Pharmaceuticals: Sterile production & cleanroom heat exchange systems

-

Food & Beverage: Hygienic heat management for processing equipment

our latest news

Get a Quote for N08825 / 2.4858 Stainless Steel Heat Exchanger Tube

Defend your operations against extreme corrosion and intense heat with N08825 / 2.4858 Stainless Steel Heat Exchanger Tube. Crafted for unparalleled performance and long-term reliability in challenging environments, it’s the ideal solution for critical industries. Contact us for your custom quote today!