Get in touch with us

Leave a message

+8615057563345

+8615057563345

Engineered with precision technology for exceptional corrosion resistance, structural integrity, and long-term reliability in demanding industrial environments.

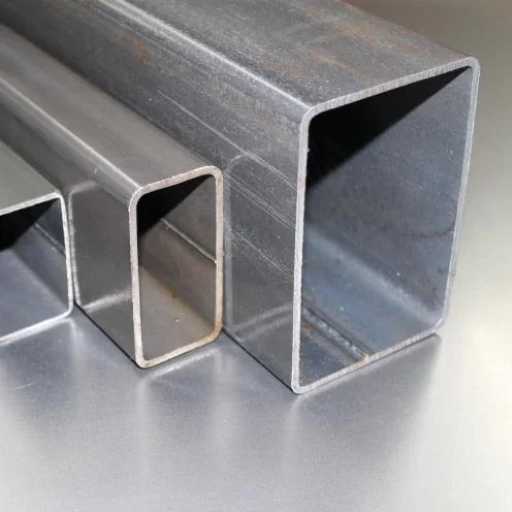

Stainless Steel Rectangular Tube, a premium-grade product designed for durability, versatility, and sleek aesthetics. Crafted from high-quality 304 stainless steel, this tubing meets the rigorous ASTM A554 standards, ensuring exceptional corrosion resistance and structural integrity. Available in a variety of rectangular steel tubing sizes, from small-scale dimensions to larger profiles, our stainless square tube caters to diverse applications—whether you’re working on architectural frameworks, industrial machinery, or custom furniture. Its polished or brushed finish not only enhances its visual appeal but also guarantees long-lasting performance in even the most demanding environments.

Priced competitively, the stainless steel rectangular tube offers excellent value without compromising on quality. Whether you’re searching for an affordable stainless steel rectangular tube price or a reliable solution for heavy-duty projects, this product delivers unmatched consistency and precision. Explore our range today and elevate your next project with a tubing solution engineered to exceed expectations.

316 stainless steel rectangular tubes are a highly adaptable and popular choice for a wide range of industrial applications. Renowned for their superior corrosion resistance, exceptional durability, and cost-effectiveness, these tubes excel in environments requiring the transport of liquids and gases, particularly where resistance to harsh conditions is essential. Featuring a polished surface finish and robust structural integrity, they are well-suited for use in marine applications, chemical processing, and architectural frameworks. Produced in accordance with international standards, 316 stainless steel rectangular tubes deliver consistent performance and long-lasting reliability.

304 stainless steel rectangular tubes are a versatile and widely used solution for various industrial and structural applications. Renowned for their excellent corrosion resistance, durability, and cost-effectiveness, these tubes are perfect for environments requiring strength and aesthetic appeal. Featuring a smooth surface finish and robust construction, they are well-suited for architectural frameworks, furniture manufacturing, and automotive components. Produced in accordance with international standards, 304 stainless steel rectangular tubes offer consistent quality and dependable performance for long-term use.

Seamless Stainless Steel tubing is arguably one of the most dynamic and reliable forms of stainless steel tubing because it can be used for structural, industrial or even decorative purposes. This kind of tubing is perfect for delicate and demanding environments where precision is vital due to its unparalleled strength, corrosion resistance, and seamless construction. Moreover, this tubing can also be used in high-performance automotive systems, architectural projects, and machinery fabrication due to its homogeneous design and polish finish. This form of stainless steel is also manufactured under strict regulations which ensures that it has consistent quality and pressure resistance.

Build Industries provides you with welded rectangualar steel tubing which is nuerous in ergonomic and economic benefits. As strong as it is corrosion resistive, stainless steel is also very adaptable which means that it can be used where both structural durability and beauty are essential. Since it is made with clear weld lines and cut with precision it can be used in architectural frameworks, furniture production and even heavy duty equipment production. Well polished rust and corrossion resistant steel can help guarantee efficiency when used in highly demanding projects due to the low operational cost. Outstanding performance does not have to mean paying through your nose when using steel welded rectangular tubing. When welded into closed structures, rectangular tubing does not have any sharp edges, which makes them much safer to use without the fear of cutting yourself.

Feel free to reach out to us for stainless steel rectangular tube price, availability, or any additional information. Let us help you find the perfect stainless steel piping solution for your industry needs.

Discover the versatility of Stainless Steel Rectangular Tube with tailored solutions, and explore which industries benefit from rectangular stainless steel tubing for their unique applications.

Stainless steel rectangular tubes are resistant to rust due to chromium forming a protective oxide layer, fully enduring rusting in harsh places such as moist environments and salt water, while requiring little upkeep.

These tubes are polished yielding a smooth finish which does not tarnish, so can be used architecturally as handrails or furniture, as they are easy to maintain and look stylish.

Stainless steel does not contain pores so no bacteria can thrive, allowing for the hygiene standards required in food processing as well as in medical and pharmaceutical equipment.

The strength and load-bearing capabilities of these tubes is very high, making them useful in construction and heavy machinery, allowing them to endure mechanical stress long-term.

Changeable measurements and ease of being welded or formed make these tubes useful in construction, automotive and industrial equipment.

These tough tubes are fully recyclable without any loss to quality which makes them replacing items less often needed and supporting the use of sustainable materials.

| Property | 316 Stainless Steel Rectangular Tube | 304 Stainless Steel Rectangular Tube |

|---|---|---|

| Characteristics | Austenitic stainless steel with molybdenum (2-3%), enhancing corrosion resistance. | Austenitic stainless steel, most common grade, good overall properties. |

| Surface Treatment | Typically available in mill finish, polished, brushed, or satin finishes. | Similar options: mill finish, polished, brushed, or satin finishes. |

| Dimensions/Specs | Common sizes: 1/2" x 1" to 4" x 6", wall thickness 0.065" to 0.5". | Similar range: 1/2" x 1" to 4" x 6", wall thickness 0.065" to 0.5". Weight charts also available, with similar weight range. |

| Corrosion Resistance | Excellent, especially in chloride environments (e.g., marine, chemical exposure). | Good, but less resistant to chlorides and pitting than 316. |

| Mechanical Properties | Yield Strength: ~30 ksi, Tensile Strength: ~75 ksi, Elongation: ~40%. | Yield Strength: ~31 ksi, Tensile Strength: ~75 ksi, Elongation: ~40%. |

| Processability | Good weldability and formability; slightly harder to machine due to molybdenum. | Excellent weldability and formability; easier to machine than 316. |

| Applications | Marine equipment, chemical processing, pharmaceutical, coastal architecture. Industries benefiting include oil & gas, wastewater treatment, and pulp & paper (due to corrosion resistance). | Food processing, architectural trim, automotive, general fabrication. Industries benefiting include construction, furniture, and HVAC (due to versatility and cost-effectiveness). |

| Standards | ASTM A554, A269, A312 (common for tubing); ASME SA240 (general). | ASTM A554, A269, A312; ASME SA240 (general). |

304 stainless steel rectangular tubing is chosen for its excellent corrosion resistance, durability, and versatility. It’s cost-effective, easy to fabricate, and ideal for structural, architectural, and industrial uses.

The 304 alloy (18% chromium, 8% nickel) provides corrosion resistance and strength. ASTM standards (e.g., A554 for welded tubing) ensure consistent quality, dimensional accuracy, and performance reliability.

Not inherently—strength depends on wall thickness and load direction. Rectangular tubing resists bending better along its wider face, while square tubing offers uniform strength in all directions.

Circular tubing is generally the strongest shape due to its uniform stress distribution, though rectangular and square tubing can be stronger in specific load scenarios with proper design.

I-beams are better for heavy, vertical loads (e.g., building supports), while rectangular tubing excels in lighter, multi-directional applications (e.g., frames) and offers a sleeker look.

Yes, square tubing can be bent using tools like a tube bender or press brake, though it may require heat or thicker walls to avoid cracking.

Strength varies by wall thickness and steel type. For 1-inch 14-gauge (0.083″) mild steel tubing, it can support roughly 300-500 lbs under static load, depending on span and support.

No universal answer—square tubing resists bending better in flat orientations, but round tubing is stronger against torsion and multi-axis loads due to its shape.

14-gauge steel square tubing has a wall thickness of approximately 0.083 inches (2.11 mm), based on standard steel gauge charts.

Material: Stainless steel grades 304/304L, 316/316L, 310/310S.

Industry Standards: ASTM A403, ANSI B16.9 compliant.

Sizes: ½ inch to 24 inches nominal pipe sizes.

Radius: Available in short radius (SR) and long radius (LR).

Wall Thickness: Schedules 5S, 10S, 40S, and 80S.

Temperature Resistance: Suitable for high-temperature applications.

Premium 304/316 stainless steel rectangular tubes offer various grades and finishes while providing aforementioned industrial and structural strength, as well as corrosion resistance, while meeting the requisite ASTM standards.

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.

A: Stainless steel rectangular tubes are hollow metal products in the form of a rectangle, used in construction, furniture, and other industries because of their durability and application flexibility.

A: These tubes are used in making handrails, as well as structural and decorative elements of architecture and design, automobile frames, and more.

A: ASTM A554 is a standard specification covering welded stainless steel mechanical tubing which maintains certain standards of precision welds, measurements, and polishing for the rectangular tubes.

A:304 stainless steel tubing sizes for rectangular tubes vary widely, typically ranging from 1/2″ x 1″ to 4″ x 8″ in width and height, with wall thicknesses from 0.065″ to 0.250″. Specific sizes depend on the supplier and compliance with ASTM A554 standards.

A: Available surface finishes include: Mill finish, brushed, polished, or satin. or. The type of finish depends on whether the tube is going to be a structural part or ornamental.

A: Consult with suppliers and take into consideration these factors: load requirements, the surrounding environment, and the desired aesthetic.

Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd., specializes in high-quality stainless steel pipes and fittings, offering reliable solutions for industrial applications worldwide.