Premium Stainless Steel Seamless Pipe Manufacturers

Discover top-quality stainless steel seamless pipes – durable, corrosion-resistant, and precision-engineered for excellence.

Stainless Steel Seamless Pipe

- Premium Quality

- Customizable Sizes

- Sanitary Grade

Overview :

Description :

Stainless steel seamless pipes deliver exceptional durability and corrosion resistance for diverse industrial needs. Made from grades like 304 or 316, these pipes feature a seamless design, ensuring superior strength and a smooth finish per ASTM A312 standards. Ideal for chemical processing, oil refineries, and water systems, they offer reliable performance in demanding conditions. Stainless steel seamless pipe manufacturers in India are renowned for producing high-quality options, meeting global demands with precision.

The stainless steel seamless pipe price varies based on grade, size, and market trends, yet remains competitive, especially from Indian suppliers. Manufactured through extrusion and rigorous testing, these pipes provide long-term value, with lifespans exceeding 50 years. Stainless steel seamless pipe manufacturers in India leverage advanced techniques to balance cost and quality, making them a top choice for industries worldwide seeking robust piping solutions.

Get a Quote

Explore Our Stainless Steel Tube Types

304 Stainless Steel Seamless Pipe

A foundational austenitic grade, 304 stainless steel seamless pipes offer a reliable and cost-effective solution across numerous industries. Renowned for excellent corrosion resistance in non-aggressive settings, combined with good formability and weldability, these pipes are widely chosen for general service applications. Providing a smooth bore and robust structural integrity, they are suitable for various piping systems, equipment fabrication, and moderate chemical environments. Produced adhering to stringent quality standards, 304 seamless pipes deliver consistent performance and trusted longevity for essential infrastructure needs.

316 Stainless Steel Seamless Pipe

The 316 grade stainless steel seamless pipe is specifically developed for enhanced performance in more aggressive conditions, particularly those involving chlorides. Benefiting from the addition of molybdenum, this alloy demonstrates superior resistance to pitting and crevice corrosion compared to 304. Offering excellent strength and durability at elevated temperatures, it is an optimal choice for marine environments, chemical processing plants, and applications exposed to corrosive substances. Manufactured with precision to meet diverse requirements, 316 seamless pipes ensure critical systems function reliably.

304l Stainless Steel Seamless Pipe

Representing a low-carbon modification of the 304 alloy, 304L stainless steel seamless pipes are designed for improved weldability. The reduced carbon content minimizes carbide precipitation during welding, significantly enhancing resistance to intergranular corrosion in the heat-affected zone. While maintaining the general corrosion resistance and mechanical properties of 304, the 'L' variant is particularly suited for applications requiring extensive welding, such as process piping in chemical, food, and pharmaceutical industries, providing dependable performance after fabrication.

Duplex Stainless Steel Seamless Pipe

Duplex stainless steel seamless pipes combine the benefits of both austenitic and ferritic stainless steels, characterized by their unique microstructure. These pipes deliver exceptional strength, often twice that of standard austenitic grades like 304 or 316. Furthermore, they offer outstanding resistance to various forms of corrosion, including stress corrosion cracking, pitting, and crevice corrosion. This high-performance combination makes them ideal for demanding applications in oil and gas, petrochemical, desalination, and structural engineering where both strength and durability in harsh environments are critical.

Large Diameter Stainless Steel Pipe

Designed for substantial volume transport and heavy-duty structural purposes, Large Diameter Stainless Steel Pipes are essential components in large-scale industrial projects. Available in various stainless steel grades, including 304, 316, and Duplex alloys, their specific properties are selected based on the intended application's corrosive conditions, temperature, and pressure requirements. Used in major pipelines, wastewater treatment facilities, and as structural supports, these pipes are manufactured to rigorous specifications to ensure maximum capacity, integrity, and longevity in demanding large-scale systems.

317 Stainless Steel Pipe

An enhanced version of 316 stainless steel, 317 stainless steel pipes feature a higher content of molybdenum and sometimes nickel, resulting in superior corrosion resistance. This alloy is particularly effective against pitting and crevice corrosion, especially in highly corrosive environments like pulp and paper mills, chemical processing using acids, and other harsh industrial settings. Offering excellent tensile and creep-rupture strength at elevated temperatures, 317 pipes provide a more robust solution than 316 for the most aggressive corrosive conditions, ensuring prolonged service life and reliability.

Get More Information

Feel free to reach out to us for pricing, availability, or any additional information. Let us help you find the perfect stainless steel piping solution for your industry needs.

Why Choose Us

- Expert Craftsmanship : Precision-engineered for unmatched durability and performance.

- Customizable Solutions : Tailored to your needs with flexible customization.

- Certified Quality : Meets global standards for quality and reliability.

- Dedicated Support : Expert support ensures seamless project success.

Tailored Solutions for Diverse Industries

Tailor-made seamless stainless steel pipe solutions to meet the unique needs of different industries with precision and reliability.

Sustainable Manufacturing

Environmentally friendly production processes reduce environmental impact while providing high-quality, durable seamless stainless steel pipe.

Customized pipe solutions

Customized to your specifications to ensure pipes are perfectly matched to industry needs and improve performance.

Advanced technical support

Experts provide comprehensive guidance from selection to installation to ensure efficient and successful projects.

Industry-specific designs

Precise and reliable pipe solutions are designed to meet the unique challenges of industries such as oil and gas, pharmaceuticals, etc.

Long-term cost benefits

Durable, low-maintenance pipes reduce operating costs and are a sustainable smart investment.

Innovative material technology

Use cutting-edge materials and processes to ensure pipes meet the highest quality and safety standards.

Advantages of Stainless steel seamless pipe

- Stainless steel seamless pipes excel in chemical plants due to their corrosion resistance, handling harsh substances reliably. Stainless steel seamless pipe manufacturers in India ensure quality for these demanding environments.

- These pipes withstand extreme pressure in oil and gas systems, offering seamless strength and safety for efficient transport.

- With a smooth, non-porous surface, they’re ideal for hygienic food and beverage processing, resisting contamination effectively.

- Their resistance to saltwater corrosion makes them perfect for marine applications, ensuring longevity in tough conditions.

- Despite varying stainless steel seamless pipe price, their durability and low maintenance provide long-term value across industries.

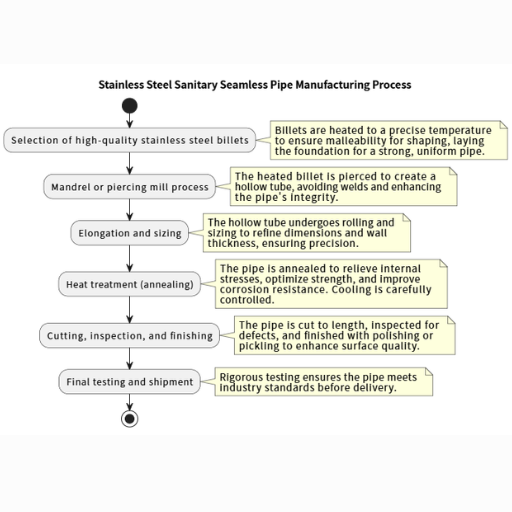

Stainless Steel Seamless Pipe Manufacturing Process

- The manufacturing process begins with the selection of high-quality stainless steel billets, which are heated to a precise temperature to ensure malleability for shaping. This step lays the foundation for a strong, uniform pipe.

- The heated billet is then pierced using a mandrel or piercing mill to create a hollow tube, forming the initial seamless structure. This seamless method avoids welds, enhancing the pipe’s integrity.

- The hollow tube undergoes elongation and sizing through a series of rolling mills, refining its dimensions and wall thickness to meet exact specifications. This ensures consistency and precision in the final product.

- Heat treatment follows, where the pipe is annealed to relieve internal stresses and optimize its mechanical properties, such as strength and corrosion resistance. Cooling is carefully controlled to maintain quality.

- Finally, the seamless pipe is cut to length, inspected for defects, and finished with processes like polishing or pickling to enhance its surface and performance. Rigorous testing ensures it meets industry standards before shipment.

Stainless Steel Seamless Pipe Size Chart

| Attribute | 304 Seamless Pipe | 316 Seamless Pipe | 304L Seamless Pipe | Duplex Seamless Pipe | Large Diameter Pipe | 317 Seamless Pipe |

|---|---|---|---|---|---|---|

| Type | Austenitic stainless steel | Austenitic stainless steel | Austenitic stainless steel | Duplex stainless steel | Varies (e.g., austenitic) | Austenitic stainless steel |

| Features | Durable, seamless, cost-effective | High strength, seamless, Mo-enhanced | Low carbon, seamless, weld-friendly | High strength, seamless, dual-phase | Seamless, robust for large-scale use | Seamless, high Mo for extreme durability |

| Surface Treatment | Pickling, polishing, annealing | Pickling, polishing, annealing | Pickling, polishing, annealing | Pickling, passivation | Polishing, passivation | Pickling, polishing, passivation |

| Weight | ~2 kg/m (1" pipe) | ~2.1 kg/m (1" pipe) | ~2 kg/m (1" pipe) | ~2.3 kg/m (1" pipe) | ~50 kg/m (24" pipe) | ~2.2 kg/m (1" pipe) |

| Dimensions & Specs | 1/8" to 24"; ASTM A312; length up to 12m | 1/8" to 24"; ASTM A312; length up to 12m | 1/8" to 24"; ASTM A312; length up to 12m | 1/8" to 24"; ASTM A790; length up to 12m | 24" to 80"; ASTM A312; length up to 12m | 1/8" to 24"; ASTM A312; length up to 12m |

| Corrosion Resistance | Good for non-aggressive environments | Superior, resists chlorides (marine use) | Good, similar to 304, better weldability | Excellent, resists pitting and stress cracks | Varies by grade, generally high | Outstanding, ideal for acidic environments |

| Mechanical Properties | Tensile: 515 MPa; Yield: 205 MPa; Elong: 40% | Tensile: 515 MPa; Yield: 205 MPa; Elong: 40% | Tensile: 485 MPa; Yield: 170 MPa; Elong: 40% | Tensile: 620 MPa; Yield: 450 MPa; Elong: 25% | Varies (e.g., 304: 515 MPa tensile) | Tensile: 515 MPa; Yield: 205 MPa; Elong: 35% |

| Processability | Easily welded, formed, machined | Weldable, formable, slightly harder | Excellent for welding, forming, machining | Weldable, formable, requires care | Weldable, formable, suited for heavy use | Weldable, formable, good machinability |

| Applications | Water systems, chemical processing | Marine, pharmaceuticals, chemical plants | Food industry, welded structures | Oil & gas, desalination, chemical tanks | Pipelines, structural supports, refineries | Pulp mills, marine, chemical processing |

| Standards | ASTM A312, ASME B36.19, EN 10216-5 | ASTM A312, ASME B36.19, EN 10216-5 | ASTM A312, ASME B36.19, EN 10216-5 | ASTM A790, ASME B36.19, EN 10216-5 | ASTM A312, ASME B36.19 | ASTM A312, ASME B36.19, EN 10216-5 |

Expert Guide to Stainless Steel Seamless Pipe

Why isn't stainless steel used for plumbing?

Stainless steel is used in plumbing but less in homes due to higher costs. It’s durable and corrosion-resistant, unlike cheaper copper or PVC options.

What is the difference between seamless pipe and normal pipe?

Seamless pipe is made from solid steel without seams. Normal (welded) pipe has a seam, making it less uniform and strong.

How long do stainless steel pipes last?

Stainless steel pipes last 50-100 years, depending on conditions. Their corrosion resistance ensures long-term durability.

What grade is seamless pipe?

Seamless pipes are often 304 or 316 stainless steel. Grade 316 resists corrosion better due to molybdenum.

Is seamless pipe stronger than welded?

Yes, seamless pipe is stronger, with no weak seam. Stainless steel seamless pipe manufacturers in India highlight its high-pressure suitability.

What does ERW stand for?

ERW means Electric Resistance Welded. It’s a cost-effective welding method using electric current for strong seams.

Why can't you use galvanized pipe for water?

Galvanized pipe corrodes, releasing zinc into water and clogging flow. Stainless steel is safer for drinking water.

What is the HS code for seamless steel pipe?

HS code for seamless stainless steel pipes is usually 7304.11 or 7304.19, varying by type and region.

What is the difference between PSL1 and PSL2 pipes?

PSL1 meets basic standards; PSL2 has stricter quality and testing, impacting stainless steel seamless pipe price.

Resources on Stainless Steel Seamless Pipe

✷ Applications of Stainless steel seamless Tubes✷

Stainless steel seamless tubes deliver unmatched performance across diverse applications, from transporting corrosive fluids to ensuring purity and durability in demanding industrial environments.

Oil and Gas Industry

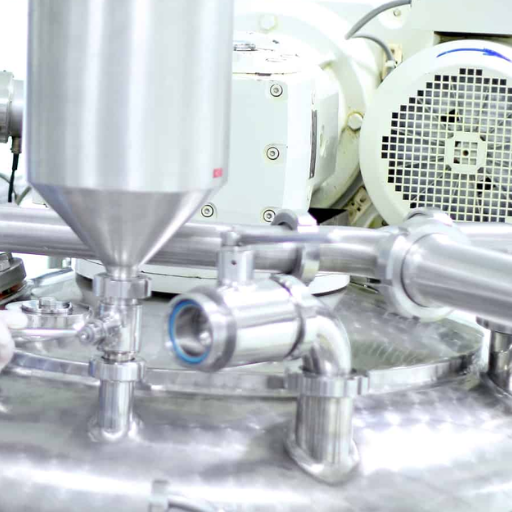

Chemical Processing

Food and Beverage Production

Pharmaceutical Manufacturing

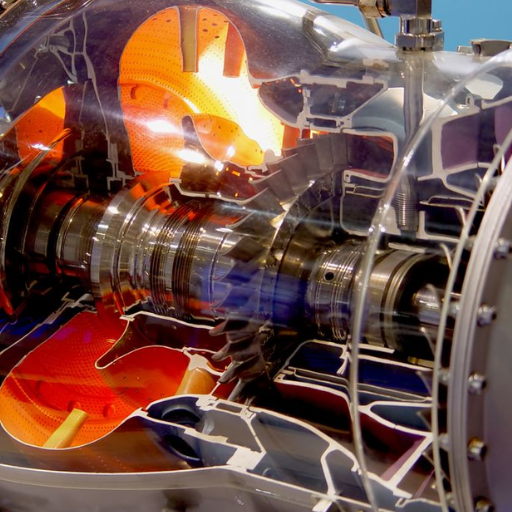

Aerospace Engineering

Power Generation

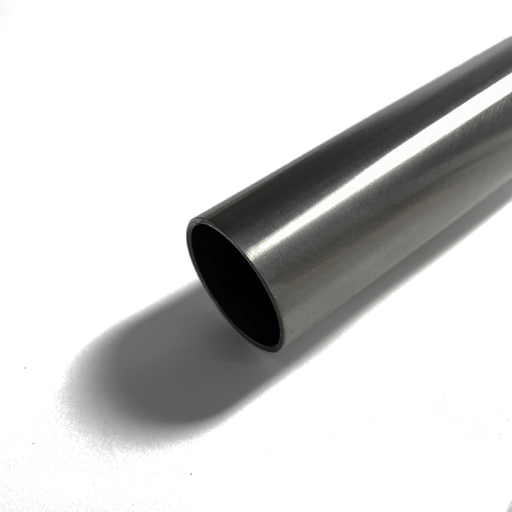

Stainless Steel Seamless Pipe For Sale

Explore examples of stainless steel seamless pipes showcasing durability and quality. For detailed stainless steel seamless pipe dimensions or custom options, contact us today!

Material: Stainless steel grades 304/316L

Industry Standards: ASTM A312

Sizes: 4 inches in diameter

Radius: Available in short radius

Wall Thickness: Schedule 5S, 10S, 40S

Temperature Resistance: Suitable for high temperatures

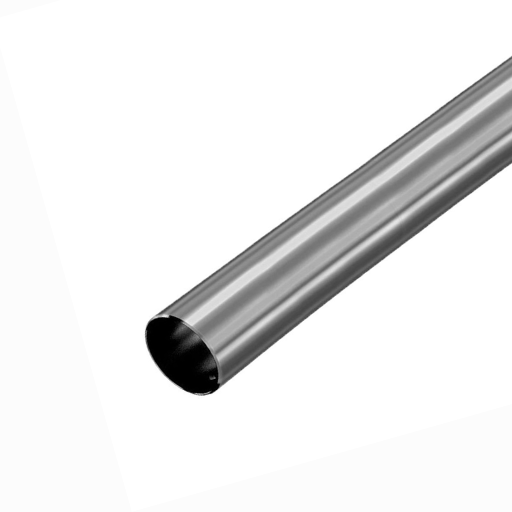

Material: Stainless steel grades 304/316L

Industry Standards: ASTM A312

Sizes: 20 ft length, ½ inch to 24 inches

Radius: Available in short radius

Wall Thickness: Schedule 5S, 10S, 40S

Temperature Resistance: Suitable for high temperatures

Material: Stainless steel grades 304/316L

Industry Standards: ASTM A312

Sizes: ½ inch to 24 inches

Radius: Available in short radius

Wall Thickness: Schedule 160

Temperature Resistance: Suitable for high temperatures

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.