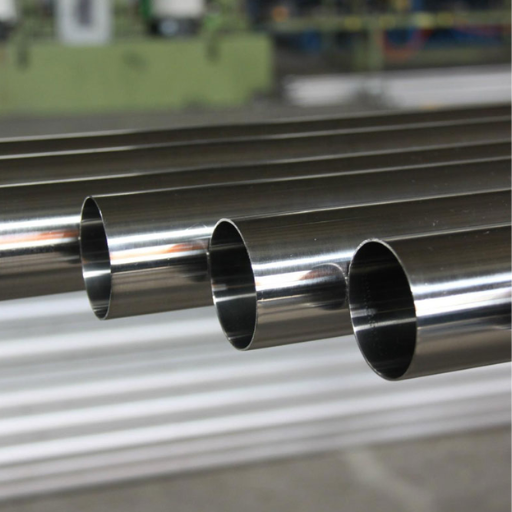

Top 304 Stainless Steel Seamless Pipe Manufacturer in China

Like other seamless pipes, a 304 Stainless Steel Seamless Pipe is an austenitic stainless steel made from grade 304 stainless steel which has 18% chromium and 8 % nickel. A seamless construction means the pipe is produced through an extrusion process, where a solid steel billet is heated and pierced to create a hollow tube, subsequently drawn to the desired size. A uniform structure is thus ensured, making 304 seamless pipes preferable for high temperature and high pressure applications where structural integrity is crucial.

Specification for 304 Stainless Steel Seamless Pipe

| Category | Details |

|---|---|

| Characteristics | 304 Stainless Steel Seamless Pipes are austenitic stainless steel pipes with 18% chromium and 8% nickel (18-8 composition). They are produced without a welded seam via extrusion or piercing, offering a uniform structure. Known for excellent corrosion resistance, non-magnetic properties (in annealed condition), and suitability for high-pressure and sanitary applications. |

| Surface Treatment | - Mill Finish: As-produced, slightly rough surface with a dull appearance. - Pickled and Passivated: Acid-treated to remove impurities and form a protective oxide layer, enhancing corrosion resistance. - Polished: Mechanically polished to a satin, bright, or mirror finish (e.g., 180, 320, or 600 grit) for sanitary or decorative applications. - Bright Annealed: Heat-treated in a controlled atmosphere for a clean, reflective surface. |

| Dimensions and Specifications | - Sizes: Available from 1/8" NB to 24" NB (Nominal Bore), with outer diameters ranging from 10.3 mm to 609.6 mm. - Wall Thickness: Schedules include Sch 5, Sch 10, Sch 40, Sch 80, up to Double Extra Heavy (DXH); thickness ranges from 1.24 mm to 12.7 mm. - Length: Standard lengths of 6 meters (20 feet), with custom lengths up to 12 meters available. - Tolerances: OD ¡À0.125 inches, wall thickness ¡À10%, per ASTM A312. |

| Corrosion Resistance | - General Corrosion: Excellent resistance to a wide range of corrosive environments due to 18% chromium content, forming a passive oxide layer. - Intergranular Corrosion: Susceptible at 425¡ãC¨C860¡ãC due to carbide precipitation; 304L variant (low carbon) mitigates this risk. - Pitting/Crevice Corrosion: Good in mild environments but less resistant to chlorides (e.g., marine settings) compared to 316 stainless steel. |

| Mechanical Properties | - Tensile Strength: 515¨C720 MPa (depending on processing). - Yield Strength: Minimum 205 MPa. - Elongation: Approximately 45%, indicating good ductility. - Hardness: Brinell hardness around 123 HB (annealed condition); can increase with cold working. - Impact Resistance: Good toughness, even at low temperatures. |

| Processability | - Weldability: Excellent; can be welded using TIG, MIG, or other methods; 304L is preferred for welding to avoid carbide precipitation. - Formability: Easily bent, drawn, and formed due to its austenitic structure; suitable for complex piping systems. - Machinability: Moderate; work-hardens during machining, requiring sharp tools and proper cutting speeds. |

| Applications | - Sanitary: Food processing (e.g., dairy, beverage systems), pharmaceuticals (e.g., drug manufacturing), and biotechnology (e.g., bioreactors) due to hygiene compliance. - High-Pressure: Heat exchangers, boilers, condensers, and hydraulic systems. - Chemical/Petrochemical: Pipelines for chemicals, oils, and gases. - Aerospace/Automotive: Fuel lines, exhaust systems. - Architectural: Handrails, structural supports, and decorative elements. |

| Standards | - ASTM A312: Standard for seamless and welded austenitic stainless steel pipes for high-temperature and corrosive service. - ASTM A213: Seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. - ASME SA312: ASME specification for pressure applications. - EN 10216-5: Seamless stainless steel pipes for pressure purposes. - DIN 1.4301: European designation for 304 stainless steel. |

our latest news

Reliable 304 Stainless Steel Seamless Pipe for Your Needs

Connect with China’s leading manufacturers to source premium-grade stainless steel pipes designed for durability, corrosion resistance, and strict hygiene compliance. Ideal for food processing, pharmaceuticals, biotechnology, and more—reach out today to discover our high-quality, seamless solutions tailored to your needs!