Premium Stainless Steel Seamless Tube Manufacturer

Crafted with advanced technology for superior strength, corrosion resistance, and precision in high-pressure industrial applications.

Stainless Steel Seamless Tube

- Premium Quality

- Customizable Sizes

- Industrial Grade

Overview :

Description :

Stainless Steel Seamless Tube is a premium piping solution engineered to meet the rigorous demands of industrial, chemical, and energy applications. Manufactured using advanced cold-drawn and seamless fabrication techniques, these tubes offer exceptional strength, durability, and resistance to corrosion, making them ideal for high-pressure systems and fluid transportation. Available in a wide range of diameters, wall thicknesses, and lengths, as well as stainless steel square tube sizes, they provide versatility for custom projects while adhering to international standards such as ASTM, ASME, and ISO.

The polished or satin surface finish ensures a smooth and hygienic flow, essential for industries like oil and gas, petrochemicals, and power generation. Trusted stainless steel tube manufacturers utilize precise engineering and stringent quality control processes to ensure that Stainless Steel Seamless Tubes deliver reliable performance, even in extreme temperatures and harsh environments. Whether for structural frameworks, high-stakes industrial systems, or specialized square tube applications, these tubes are a trusted choice for long-term durability and functionality.

Get a Quote

Seamless stainless steel tubing for sale

304 Stainless Steel Seamless Tube

Versatile and corrosion-resistant, this ASTM A312 certified tube offers durability for structural and fluid transport applications. Its seamless construction ensures strength and reliability in high-stress environments, suitable for diverse industrial uses.

316 Stainless Steel Seamless Tube

Specifically designed for resistance to extreme environments, this molybdenum-enriched seamless tube excels in chemical, marine, and high-temperature applications. Available in various schedules, it guarantees longevity and performance under intense operational conditions.

Thin Wall Steel Tubing

Ideal for lightweight structural designs, this precision-engineered tubing balances strength and flexibility. Its thin walls allow for easy handling without compromising load-bearing capacity, perfect for automotive and aerospace industries.

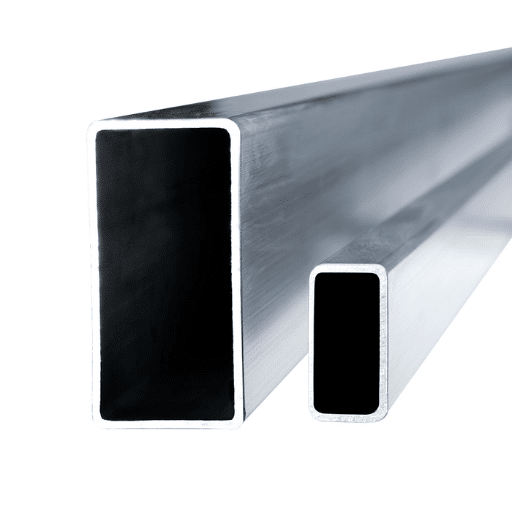

Seamless Square Tubing

Manufactured for precision, this seamless square tubing ensures uniform strength along all edges. Known for its clean aesthetics and high structural integrity, it’s excellent for modern architecture and industrial frameworks.

Large Diameter Stainless Steel Tube

Engineered for large-scale industrial systems, this tube offers unmatched strength and immense flow capacity. With seamless construction, it handles extreme pressures in oil, gas, and water distribution networks.

Get More Information

Feel free to reach out to us for stainless steel tube price per foot, availability, or any additional information. Let us help you find the perfect Stainless Steel Seamless Tube solution for your industry needs.

Why Choose Us

- Expert Craftsmanship: Precision-engineered seamless tubes ensure superior strength and corrosion resistance for demanding applications.

- Customizable Solutions: Tailored diameters, wall thicknesses, and lengths to meet your specific industrial needs.

- Certified Quality: Compliant with ASTM, ASME, and ISO standards for global reliability and performance.

- Dedicated Support: Expert guidance from inquiry to post-purchase, ensuring seamless project execution.

Tailored Solutions for Diverse Industries

Unlock the potential of Stainless Steel Seamless Tube with customized solutions for your unique applications

Custom Fabrication Services

Our advanced manufacturing capabilities allow us to produce seamless tubes in custom diameters, wall thicknesses, and finishes. Whether you need specialized lengths or surface treatments, we ensure precision engineering that meets your exact project specifications.

Global Supply Chain Support

With an efficient global logistics network, we ensure timely delivery of stainless steel seamless tubes to your location. From small-scale orders to bulk shipments, our supply chain solutions are designed to keep your projects on schedule.

Sustainability Initiatives

Our seamless tubes are manufactured using eco-friendly processes and recyclable materials, supporting sustainability goals. We prioritize reducing waste and energy consumption while delivering high-quality, environmentally responsible products.

High-Pressure System Compatibility

Designed to withstand extreme pressures, our seamless tubes are ideal for critical applications in industries like oil and gas, petrochemical, and power generation. Their robust construction ensures reliable performance under demanding conditions.

On-Site Technical Consultation

Our team of experts provides on-site or remote technical guidance to help you select the right seamless tubes for your application. From material selection to installation support, we’re here to assist you every step of the way.

Multi-Industry Applications

Whether for industrial fluid transport, chemical processing, or structural frameworks, our seamless tubes are versatile enough to meet the unique challenges of your industry. We deliver solutions aligned with your specific operational needs.

Advantages of Stainless Steel Seamless Tube

- Stainless steel seamless tubes offer exceptional durability, as they are manufactured without welds, ensuring superior strength and resistance to pressure. Their production process guarantees consistent quality and precise dimensions.

- Compared to welded tubes, seamless tubes are ideal for high-pressure applications due to their uniform structure. They are a preferred choice for critical systems where reliability and safety are paramount.

- The seamless design ensures excellent corrosion resistance, making these tubes suitable for harsh environments. This reliability makes them a top choice for industries requiring long-term performance.

- Seamless tubes are easier to install and maintain, reducing labor and handling costs. This improves overall project efficiency while ensuring consistent performance.

- With superior integrity and resistance to extreme temperatures, stainless steel seamless tubes deliver long-lasting performance in challenging conditions. They are particularly effective in industries requiring high durability and precision.

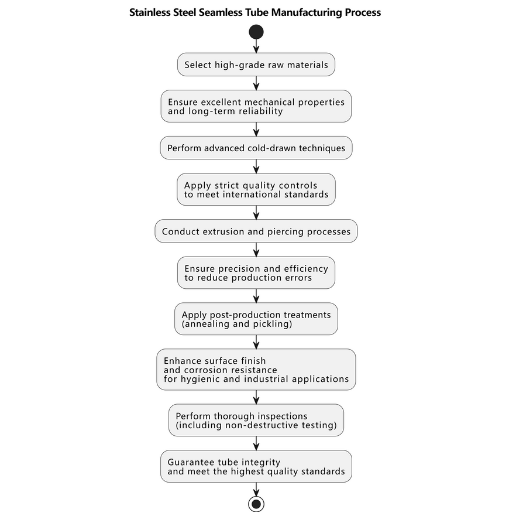

Manufacturing Process

- Stainless steel seamless tubes are produced using advanced cold-drawn techniques, ensuring a smooth finish and strong structure. The process involves strict quality controls to meet international standards.

- The raw materials used in manufacturing are carefully selected to ensure high-grade stainless steel. This guarantees the tubes have excellent mechanical properties and long-term reliability.

- Advanced extrusion and piercing processes ensure precision and efficiency, reducing production errors. This ensures each tube meets exact specifications for consistent performance across all applications.

- Post-production treatments, such as annealing and pickling, enhance the surface finish and corrosion resistance of the tubes. These processes also improve their suitability for hygienic and industrial applications.

- Thorough inspections, including non-destructive testing, are conducted during and after production. This guarantees the integrity of the tubes and ensures they meet the highest quality standards.

Seamless Stainless Steel Tubing Pressure Rating and Size Chart

| Grade/Standard | Corrosion Resistance | Temperature Resistance | Strength | Nominal Composition | Applications |

|---|---|---|---|---|---|

| 304 Stainless Steel Seamless Tube | Good (general environments) | Up to 870°C | Moderate | ~18% Cr, 8% Ni | Food processing, chemical equipment, structural applications |

| 316 Stainless Steel Seamless Tube | Excellent (chloride resistance) | Up to 870°C | Moderate | ~17% Cr, 12% Ni, 2.5% Mo | Marine environments, medical equipment, chemical storage tanks |

| N08825 / 2.4858 Stainless Steel Seamless Tube | Excellent in reducing/oxidizing acids, SCC resistance | Up to 540°C | Moderate | ~42% Ni, 22% Cr, 3% Mo, 2% Cu | Chemical processing, pollution control, oil & gas recovery |

| N06625 Stainless Steel Seamless Tube | Excellent (pitting, crevice, high-temp) | Up to 980°C | High | ~61% Ni, 22% Cr, 9% Mo, 3.6% Nb | Aerospace, marine, chemical processing, nuclear reactors |

| N06690 / 2.4642 Stainless Steel Seamless Tube | Excellent in high-temp aqueous media, SCC resistance | Up to 980°C | High | ~60% Ni, 29% Cr, 9% Fe | Nuclear steam generators, nitric/hydrofluoric acid processing |

| SB-575, B 575 Stainless Steel Seamless Tube | Exceptional in a wide range of aggressive media | Up to 1095°C | High | ~57% Ni, 16% Mo, 16% Cr, 4% W | Pollution control, chemical processing, pulp & paper, waste treatment |

| N10276 / 2.4819 Stainless Steel Seamless Tube | Exceptional in a wide range of aggressive media | Up to 1095°C | High | ~57% Ni, 16% Mo, 16% Cr, 4% W | Pollution control, chemical processing, pulp & paper, waste treatment |

| SB-168, B 168, 5540 Stainless Steel Seamless Tube | Good (oxidation, chloride SCC) | Up to 1095°C | Moderate | ~72% Ni, 16% Cr, 8% Fe | Furnace components, chemical & food processing, nuclear engineering |

| SB-168, B 168, 5870 Stainless Steel Seamless Tube | Outstanding high-temp oxidation resistance | Up to 1200°C | High | ~61% Ni, 23% Cr, 1.4% Al | Industrial furnaces, heat treatment equipment, gas turbine parts |

| SA-240, A 240, 5861 Stainless Steel Seamless Tube | Excellent strength up to 700°C, good corrosion resistance | Up to 700°C | Very High | ~52% Ni, 19% Cr, 18% Fe, 5% Nb, 3% Mo | Aerospace, gas turbines, rocket motors, nuclear components |

| SA-240/SB463, A240/B 463 Stainless Steel Seamless Tube | Excellent resistance to sulfuric acid | Up to 538°C | Moderate | ~35% Ni, 20% Cr, 3.5% Cu, 2.5% Mo | Sulfuric acid handling, chemical, pharma & food processing |

| N08926 / 1.4529 Stainless Steel Seamless Tube | Excellent (pitting & crevice in chloride environments) | Up to 400°C | High | ~25% Ni, 20% Cr, 6.5% Mo, 0.2% N | Desalination, flue-gas desulfurization, chemical processing |

| SB625, B 625 Stainless Steel Seamless Tube | Excellent (pitting, crevice, high-temp) | Up to 980°C | High | ~61% Ni, 22% Cr, 9% Mo, 3.6% Nb | Aerospace, marine, chemical processing, nuclear reactors |

| N08354 Stainless Steel Seamless Tube | Excellent in deep sour gas wells, sulfuric & phosphoric acid | Up to 450°C | High | ~31% Ni, 27% Cr, 3.5% Mo, 1% Cu | Oil & gas production, chemical processing, heat exchangers |

| N06022 / 2.4602 Stainless Steel Seamless Tube | Superior versatility in oxidizing & reducing environments | Up to 1200°C | High | ~56% Ni, 22% Cr, 13% Mo, 3% W | Pharmaceutical reactors, flue-gas systems, waste incinerators |

| SB-127, B 127, 4544 Stainless Steel Seamless Tube | Excellent in seawater, hydrofluoric acid, and alkalis | Up to 538°C | Moderate | ~67% Ni, 23% Cu | Marine engineering, chemical processing, valves, pumps |

| SB-162, B 162, 5553 Stainless Steel Seamless Tube | Outstanding resistance to caustic alkalis | Up to 315°C | Low-Moderate | 99.6% Ni | Caustic evaporators, food processing, electronics, battery connections |

| N06002 / 2.4665 Stainless Steel Seamless Tube | Excellent high-temp strength & oxidation resistance | Up to 1200°C | High | ~47% Ni, 22% Cr, 18% Fe, 9% Mo | Gas turbine afterburners & combustion cans, furnace parts |

Enhance Efficiency with Premium Stainless Steel Seamless Tubing Solutions

How to Choose the Right Stainless Steel Seamless Tube for Your Needs?

Consider application needs, pressure, temperature, and exposure to corrosive elements. Grade 304 is versatile, while 316 suits chloride-rich conditions due to its molybdenum content.

The Role of Alloy and Material Selection in Tube Fabrication

Alloy and material choice impacts tube strength, corrosion resistance, and temperature tolerance. For marine or chemical environments, stainless steel with added molybdenum, like 316, enhances corrosion protection.

What is the advantage of using seamless tubes over welded tubes?

Seamless tubes have no weld, reducing risks of weak spots or leaks under high stress, making them ideal for high-pressure or critical applications.

What is a seamless steel tube used for?

Seamless steel tubes serve in oil rigs, boilers, chemical processing, and automotive parts where high pressure, structural integrity, and corrosion resistance are essential.

Is seamless pipe stronger than welded?

Yes, seamless pipes are generally stronger due to their homogeneous structure, making them suitable for extreme pressure and temperature applications.

Is seamless pipe more expensive?

Yes, seamless pipes usually cost more than welded ones due to complex manufacturing processes and superior performance traits.

What are the grades of seamless steel tube?

Common grades include ASTM A106 (carbon steel), ASTM A334 (low-temp service), and ASTM A179 (heat exchangers). Specific requirements depend on the application.

What are the grades of stainless steel seamless pipes?

Grades include 304/304L, 316/316L for general applications, and specialized grades like 321 for high-temperatures or 904L for high-corrosion resistance.

What is the HS code for SS seamless pipe?

The Harmonized System (HS) Code for stainless steel seamless pipes is often listed as 73044110, applicable for different sizes and grades.

Resources on Stainless Steel Seamless Tube

✷ Applications of Stainless Steel Seamless Tube✷

Stainless steel seamless tubes provide reliable solutions across industries, combining durability, corrosion resistance, and precision for a wide range of applications.

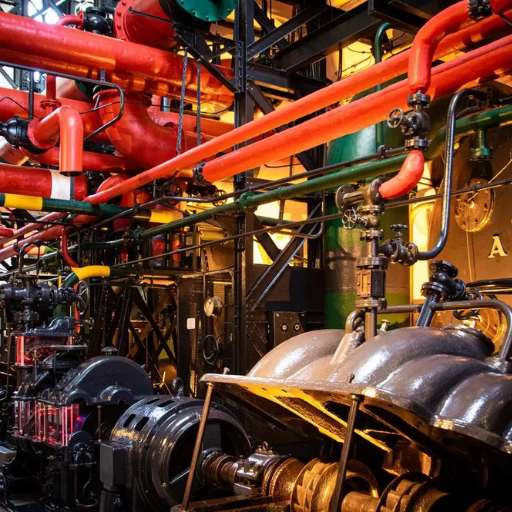

Oil and Gas Industry

Chemical Processing

Power Generation

Aerospace Engineering

Automotive and Exhaust Systems

Marine Applications

Related Products for Stainless Steel Seamless Tubes

Discover robust stainless steel solutions crafted for strength, precision, and versatility across a range of industrial applications.

Size: 24-inch nominal diameter

Material: 304/316L stainless steel

Wall Thickness: 0.25-inch (Schedule 10)

Weight: 63.41 lbs/ft

Standards: ASTM A312, ASME SA312 certified

Length Options: Custom cuts or up to 20 ft minimum

Material: Type 304 stainless steel

Outer Diameter: 1/4 inch (6.35 mm)

Wall Thickness: 0.020 inch

Length Options: Available in 25 ft, 50 ft, or 100 ft coils

Standards: ASTM A269; ISO 9001 certified

Temperature Range: -325°F to 1500°F

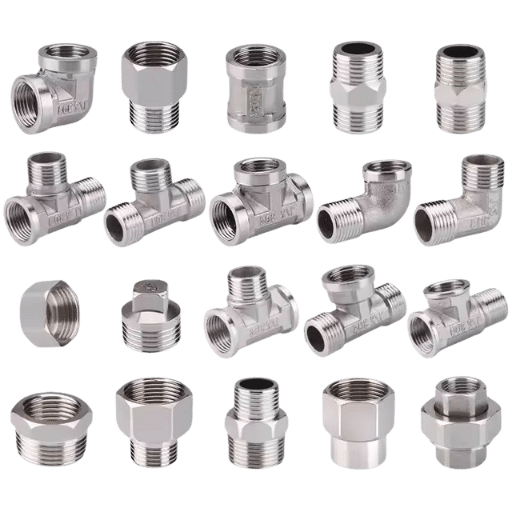

Material: 316 stainless steel

Connection Size: 1/4 inch tube OD

Connection Type: Tube-to-tube or threaded options available

Temperature Range: Up to 800°F (426°C)

Pressure Rating: Up to 6,000 psi (where applicable)

Standards: ASTM and ISO certifications

Latest Blog Posts

Explore our comprehensive resources, including industry insights, application guides, and technical expertise to support your projects.